Professional Documents

Culture Documents

About Welding Process 41

Uploaded by

XerexCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

About Welding Process 41

Uploaded by

XerexCopyright:

Available Formats

Welding Processes 41

and the the billets are rolled. The cladding is done by explosive welding. Dissimilar

metal welds can be easily made by explosive welding method. Such welding process

is commonly used is electrical and cryogenic applications.

Pipes can be welded by explosive welding process with lapped joint through

the simultaneous initiation of external and internal explosive charges as indicated

in Fig. 1.21. The process can be easily applied under pipe line construction

conditions. The charges progressively denote from the apex outwards to the open

end of the angular gap established by the overlapping or bell and spigot

configuration. The intense pressure generated at the point of collision, in

combination with the angular collision geometry, causes severe flow of the surface

layer of the pipes and the formation of a jet. The jet—a mixture of the two surface

layers and their contaminants—is expelled from the collision zone leaving

uncontaminated metal surface in intimate contact for the formation of a metallurgical

or solid phase bond.

Another method of joining two pipes by explosive method is based on an inner

ring welding. A backing outer ring is placed outside the joint to take up the

detonating

Fig. 1.22 Explosive welding of two pipes with inner ring.

force. The inner ring along with the explosive is placed at the junction of the two

pipes as indicated in Fig. 1.22. When the explosive detonates, the inner ring expands

and gets welded on to the inner surfaces of the two pipes. The entire force is taken

care of by the back outer ring. By suitable dimensioning and controlled deformation,

the inner bore diameter can be properly adjusted to suit the pipes. As all the

You might also like

- Excavator Structural Components & Welding FundamentalsDocument37 pagesExcavator Structural Components & Welding Fundamentalssurianto100% (1)

- Blow MoldingDocument46 pagesBlow MoldingShashank ChauhanNo ratings yet

- Welds - Static and Fatigue Strength - IiDocument27 pagesWelds - Static and Fatigue Strength - IiOuseppachan Ambooken100% (1)

- 16 M - MotoniveladoraDocument2 pages16 M - MotoniveladoraCharles HornNo ratings yet

- Ice Plant ProcesDocument3 pagesIce Plant ProcesCedie Refuerzo100% (1)

- RMC Plant Manufacturing Project ReportDocument84 pagesRMC Plant Manufacturing Project ReportHarshada Hikare100% (1)

- Post Installed RebarDocument38 pagesPost Installed RebarSingDollarNo ratings yet

- Diagrama Hidraulico 320d FM HarvesterDocument1 pageDiagrama Hidraulico 320d FM HarvesterMatiasNo ratings yet

- GR 300EX 1 Operation ManualDocument290 pagesGR 300EX 1 Operation Manualleobond760% (5)

- Wire Cable and TerminationsDocument12 pagesWire Cable and Terminationsதுரைராஜ் இலட்சுமணன்No ratings yet

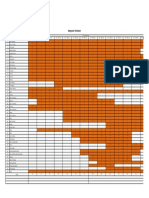

- Manpower Schedule ProjectDocument1 pageManpower Schedule ProjectColitz D. KhenNo ratings yet

- Electric Welding: Some of The Advantages of Welding AreDocument11 pagesElectric Welding: Some of The Advantages of Welding ArePriyadarshi MNo ratings yet

- Cineo 2560servicemanualDocument732 pagesCineo 2560servicemanualjrusalen1100% (1)

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- International Conference on Steel, Space and Composite Structures Parameters Design Optimisation Anchor JointDocument10 pagesInternational Conference on Steel, Space and Composite Structures Parameters Design Optimisation Anchor JointMiguel Rivera100% (1)

- Resistance Seam WeldingDocument16 pagesResistance Seam Weldingkkpkk100% (1)

- Microstructural Changes in The Forge Weld Area During HF-ERWDocument4 pagesMicrostructural Changes in The Forge Weld Area During HF-ERWilze86No ratings yet

- Osd35 0136 067Document208 pagesOsd35 0136 067Samir Mervyn Razvi100% (6)

- PerforatingDocument78 pagesPerforatingامير العذاريNo ratings yet

- Construction MaterialDocument11 pagesConstruction Materialحسين الشريفNo ratings yet

- BEUMER Apron Conveyors 01kjdecxsedDocument12 pagesBEUMER Apron Conveyors 01kjdecxsedGeorge Lapusneanu100% (1)

- Installation With Mortar - Umlauf 2015Document18 pagesInstallation With Mortar - Umlauf 2015Moud SaklyNo ratings yet

- Forming metals using explosives and electromagnetic pulsesDocument6 pagesForming metals using explosives and electromagnetic pulsesharicoolestNo ratings yet

- Explosive Forming or HERFDocument6 pagesExplosive Forming or HERFharicoolestNo ratings yet

- 火灾下盾构隧道衬砌拼接接头力学行为试验研究 郭震Document11 pages火灾下盾构隧道衬砌拼接接头力学行为试验研究 郭震hu yuexinNo ratings yet

- High Energy Rate Forming ProcessesDocument9 pagesHigh Energy Rate Forming ProcessesDivya MukhiaNo ratings yet

- Practical 5 Welding and Welding SymbolsDocument5 pagesPractical 5 Welding and Welding Symbolsmechman03No ratings yet

- Pressure Welding Processes of Tubular Parts and PiDocument4 pagesPressure Welding Processes of Tubular Parts and PiPriti GaraiNo ratings yet

- Pro Tech 1 CH 8Document31 pagesPro Tech 1 CH 8weldsvNo ratings yet

- Finite Element Simulation of Explosive WeldingDocument14 pagesFinite Element Simulation of Explosive WeldingWahyu Lailil FaisNo ratings yet

- MIAB Welding of ThickDocument6 pagesMIAB Welding of ThickErickNo ratings yet

- Welding and Welding SymbolsDocument4 pagesWelding and Welding SymbolsOscar ArcesioNo ratings yet

- Measuring Geotechnical InstrumentsDocument5 pagesMeasuring Geotechnical InstrumentsVinayak ChaturvediNo ratings yet

- High Energy Rate FormingDocument24 pagesHigh Energy Rate Formingpetroleum7No ratings yet

- Chapter 7: High Energy Rate Forming: Theory of Metal Forming (MME4045)Document4 pagesChapter 7: High Energy Rate Forming: Theory of Metal Forming (MME4045)PraneethNo ratings yet

- Electric WeldingDocument56 pagesElectric WeldingKilaru Sai KiranNo ratings yet

- Special Forming ProcessDocument11 pagesSpecial Forming Processvelavansu0% (2)

- Chapter-1: 1.1 WeldingDocument27 pagesChapter-1: 1.1 WeldingAbhishek PandeyNo ratings yet

- Design of RC Structure - Day 4Document9 pagesDesign of RC Structure - Day 4Tapabrata2013No ratings yet

- Seam Welding MachineDocument63 pagesSeam Welding MachinemboomiNo ratings yet

- Theory of auto-frettage and residual stresses in thick-walled pressure vesselsDocument14 pagesTheory of auto-frettage and residual stresses in thick-walled pressure vesselsAllswell ElleNo ratings yet

- 1-11 Other Welding Processes - Electro Slag, Rotary FrictionDocument24 pages1-11 Other Welding Processes - Electro Slag, Rotary FrictionSolomonNo ratings yet

- Welding of Girders To Insert Plates of Composite Steel-Concrete StructureDocument8 pagesWelding of Girders To Insert Plates of Composite Steel-Concrete StructureRahulNo ratings yet

- Advance Welding TechnologyDocument52 pagesAdvance Welding Technologypankaj3753No ratings yet

- MPW for Joining Similar and Dissimilar MetalsDocument18 pagesMPW for Joining Similar and Dissimilar MetalsBANOTH SHIVAKUMARNo ratings yet

- Electric Welding Processes GuideDocument32 pagesElectric Welding Processes GuideAMAR CHAND MEENANo ratings yet

- Influence of Mandrel's Surface and Material On The Mechanical Properties of Joints Electromagnetic Compression PDFDocument10 pagesInfluence of Mandrel's Surface and Material On The Mechanical Properties of Joints Electromagnetic Compression PDFmohamad zareNo ratings yet

- Determination of Soil Parameters.: Stress Analysis of Piping SystemsDocument1 pageDetermination of Soil Parameters.: Stress Analysis of Piping Systemsdowload_bearliaNo ratings yet

- Electric Welding: Unit-IiDocument41 pagesElectric Welding: Unit-IiKUMAR SNo ratings yet

- IIW Welding Practitioner Module 1 - Processes & EquipmentDocument35 pagesIIW Welding Practitioner Module 1 - Processes & EquipmentSolomonNo ratings yet

- Deperming Technology in Large Ferromagnetic PipesDocument3 pagesDeperming Technology in Large Ferromagnetic PipesAntonio PerezNo ratings yet

- Effect of Welding Sequence and The Transverse GeomDocument18 pagesEffect of Welding Sequence and The Transverse GeomAris WicaksonoNo ratings yet

- Welding, Soldering and BrazingDocument11 pagesWelding, Soldering and BrazingAyush 100niNo ratings yet

- Effect of Plastic Deformation On The Microstructure and Plasticity of High Frequency Electric Resistance WeldingDocument4 pagesEffect of Plastic Deformation On The Microstructure and Plasticity of High Frequency Electric Resistance WeldingNia KurniaNo ratings yet

- Machine Design 2 Chapter 8 JmrivetsDocument8 pagesMachine Design 2 Chapter 8 Jmrivetstest 2No ratings yet

- CHAPTER 2 Bolts and RivetsDocument14 pagesCHAPTER 2 Bolts and RivetsrhanfrancisabrauNo ratings yet

- Prestensioning & Post-TensioningDocument40 pagesPrestensioning & Post-TensioningKURUBA SARAN RAJ SamNo ratings yet

- Bolted Conn. With Hot-Dip Galv. Steel Memb.Document14 pagesBolted Conn. With Hot-Dip Galv. Steel Memb.PaulNo ratings yet

- Annals 2021 3 19Document5 pagesAnnals 2021 3 19Cioroaga Bogdan DorelNo ratings yet

- Indian Institute of Welding - ANB Refresher Course – Process 06 ADVANCED WELDING PROCESSESDocument28 pagesIndian Institute of Welding - ANB Refresher Course – Process 06 ADVANCED WELDING PROCESSESRaghu vamshiNo ratings yet

- Advance Welding TechnologyDocument90 pagesAdvance Welding TechnologyRajib MandalNo ratings yet

- Moment Connections With Cast-In AnchorsDocument3 pagesMoment Connections With Cast-In AnchorskoreshNo ratings yet

- Proc.-06 Advanced Welding ProcessesDocument28 pagesProc.-06 Advanced Welding ProcessesK JeevanNo ratings yet

- BTI1133 Ch31Document40 pagesBTI1133 Ch31ACC SHNo ratings yet

- Us3467410 PDFDocument4 pagesUs3467410 PDFNaza GavaputriNo ratings yet

- Effect of Welding Current Intensity On Tensile Strength of Pressure Vessel Steel Submerged Welded JointsDocument4 pagesEffect of Welding Current Intensity On Tensile Strength of Pressure Vessel Steel Submerged Welded JointsCioroaga Bogdan DorelNo ratings yet

- Static Metal Sealing Mechanism of A Subsea Pipeline Mechanical ConnectorDocument16 pagesStatic Metal Sealing Mechanism of A Subsea Pipeline Mechanical ConnectorHadi KoraniNo ratings yet

- 1986 KumagaiDocument11 pages1986 KumagaihetpinNo ratings yet

- Welding and Welding SymbolsDocument4 pagesWelding and Welding SymbolsNehaJainNo ratings yet

- Bartłomiej Żyliński, Ryszard BuczkowskiDocument18 pagesBartłomiej Żyliński, Ryszard BuczkowskiAgustin A.No ratings yet

- The Design and Construction of Concrete-Filled Steel Tube Column FramesDocument12 pagesThe Design and Construction of Concrete-Filled Steel Tube Column FramesrohitNo ratings yet

- Causes of Failure of High-Tensile Stud Bolts UsedDocument8 pagesCauses of Failure of High-Tensile Stud Bolts Usedacar1No ratings yet

- An Essential Guide to Electronic Material Surfaces and InterfacesFrom EverandAn Essential Guide to Electronic Material Surfaces and InterfacesNo ratings yet

- Question On Welding 73 PDFDocument1 pageQuestion On Welding 73 PDFXerexNo ratings yet

- Question On Welding 70 PDFDocument1 pageQuestion On Welding 70 PDFXerexNo ratings yet

- Question On Welding 69 PDFDocument1 pageQuestion On Welding 69 PDFXerexNo ratings yet

- Question On Welding 1Document1 pageQuestion On Welding 1XerexNo ratings yet

- Question On Welding 68 PDFDocument1 pageQuestion On Welding 68 PDFXerexNo ratings yet

- Question On Welding 64 PDFDocument1 pageQuestion On Welding 64 PDFXerexNo ratings yet

- Question On Welding 67 PDFDocument1 pageQuestion On Welding 67 PDFXerexNo ratings yet

- Question On Welding 71 PDFDocument1 pageQuestion On Welding 71 PDFXerexNo ratings yet

- Question On Welding 62 PDFDocument1 pageQuestion On Welding 62 PDFXerexNo ratings yet

- Question On Welding 74 PDFDocument1 pageQuestion On Welding 74 PDFXerexNo ratings yet

- Question On Welding 61 PDFDocument1 pageQuestion On Welding 61 PDFXerexNo ratings yet

- MMA welding pipe overhead issuesDocument1 pageMMA welding pipe overhead issuesXerexNo ratings yet

- Question On Welding 56 PDFDocument1 pageQuestion On Welding 56 PDFXerexNo ratings yet

- Question On Welding 57 PDFDocument1 pageQuestion On Welding 57 PDFXerexNo ratings yet

- Question On Welding 65 PDFDocument1 pageQuestion On Welding 65 PDFXerexNo ratings yet

- Question On Welding 63 PDFDocument1 pageQuestion On Welding 63 PDFXerexNo ratings yet

- Question On Welding 47 PDFDocument1 pageQuestion On Welding 47 PDFXerexNo ratings yet

- Question On Welding 66 PDFDocument1 pageQuestion On Welding 66 PDFXerexNo ratings yet

- Question On Welding 55 PDFDocument1 pageQuestion On Welding 55 PDFXerexNo ratings yet

- Question On Welding 1Document1 pageQuestion On Welding 1XerexNo ratings yet

- Question On Welding 60 PDFDocument1 pageQuestion On Welding 60 PDFXerexNo ratings yet

- Question On Welding 51 PDFDocument1 pageQuestion On Welding 51 PDFXerexNo ratings yet

- Question On Welding 52 PDFDocument1 pageQuestion On Welding 52 PDFXerexNo ratings yet

- Question On Welding 59 PDFDocument1 pageQuestion On Welding 59 PDFXerexNo ratings yet

- Question On Welding 58 PDFDocument1 pageQuestion On Welding 58 PDFXerexNo ratings yet

- Question On Welding 53 PDFDocument1 pageQuestion On Welding 53 PDFXerexNo ratings yet

- Question On Welding 48 PDFDocument1 pageQuestion On Welding 48 PDFXerexNo ratings yet

- Question On Welding 50 PDFDocument1 pageQuestion On Welding 50 PDFXerexNo ratings yet

- Question On Welding 49 PDFDocument1 pageQuestion On Welding 49 PDFXerexNo ratings yet

- Question On Welding 44 PDFDocument1 pageQuestion On Welding 44 PDFXerexNo ratings yet

- Bharat Heavy Electrical Limited (Bhel) BhopalDocument29 pagesBharat Heavy Electrical Limited (Bhel) BhopalBha KuNo ratings yet

- MTL Product OverviewDocument56 pagesMTL Product OverviewAries dNo ratings yet

- Aksesouar - Extra XeiristiriaDocument4 pagesAksesouar - Extra Xeiristiriainfo7879No ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyErwin EleserioNo ratings yet

- Samsung AC Manual PDFDocument56 pagesSamsung AC Manual PDFSaravanan VkNo ratings yet

- GervaisDocument3 pagesGervaisJinggle BellNo ratings yet

- What Is Cross Wall Construction - Features and BenefitsDocument4 pagesWhat Is Cross Wall Construction - Features and BenefitswaynectwNo ratings yet

- Application of Materials in Interior DesignDocument2 pagesApplication of Materials in Interior DesignInternational Educational Applied Scientific Research Journal (IEASRJ)No ratings yet

- PagesDocument48 pagesPagesmetasoniko2014No ratings yet

- Ofna/Picco .26 Engine 51214 Pull Start 51213 Non-Pull Start: New Engine Break-InDocument3 pagesOfna/Picco .26 Engine 51214 Pull Start 51213 Non-Pull Start: New Engine Break-InClaude LerouxNo ratings yet

- Ethane Production in Texas EnterpirseDocument35 pagesEthane Production in Texas EnterpirseJaspal Singh SahotaNo ratings yet

- 3ah3 PDFDocument44 pages3ah3 PDFAndi GheorgheNo ratings yet

- Testing of Sand Quality at Construction Site For ConcreteDocument6 pagesTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNo ratings yet

- 2B Green BioEnergy Final Project AugDocument100 pages2B Green BioEnergy Final Project AugAnthony MNo ratings yet

- Victor Aviation BrochureDocument19 pagesVictor Aviation BrochureLucas CoelloNo ratings yet

- ABS Summary TextDocument12 pagesABS Summary TextjesusmemNo ratings yet

- Profile - Viet Phat Industry Technology JSCDocument15 pagesProfile - Viet Phat Industry Technology JSCLuong AnhNo ratings yet