Professional Documents

Culture Documents

R3215-005041 Appendix A 2.0 - Datasheet For Corrosion Coupon

Uploaded by

saiful anwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R3215-005041 Appendix A 2.0 - Datasheet For Corrosion Coupon

Uploaded by

saiful anwarCopyright:

Available Formats

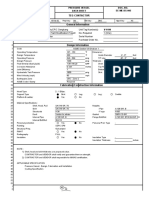

DATASHEET FOR CORROSION COUPONS

SHEET 2 OF 3

1 MANUFACTURER: KOROSI SPECINDO FACILITY: GENERAL

2 QUANTITY: Refer Table 2 LOCATION: JAVA SEA, OFFSHORE, WHT-C TOPSIDE

3 DESIGN REQUIREMENTS

4 Tag No. SP13-CC01

5 P&ID No. KPD13-02-P-PID-2003_R.02A

6 Line No. 150-PF-15023-63410

7 Pipe Class 63410

8

9 DESIGN DATA

10 ANSI Class Rating 600#

11 Design Temperature (max/min) °C -20/120

12 Design Pressure Bar 99.2

13

14 CONNECTION DATA

15 Run Pipe Size DN DN 150

16 Pipe Material ASTM A312 TP316L

17 Wall Thickness mm SCH 80S

18 Corrosion Allowance mm 0

19

20 PARTS AND MATERIALS

21 Access Fitting : Body Type Non Tee

22 Connection Flanged Type, DN 50, 600# RF, 6.25" High

23 Material ASTM A182 F316

24 Part No. KS6000-SBA-NT-F42-SA03-C1-RF

25 Installed Location Top of Pipe

26 Cover : Type Heavy Duty Protective Cover without hole

27 Material ASTM A182 F316

28 Part No. Refer Access fittings Part Number

29 Plug: Type Solid Plug

30 Material SS316L

31 Part No. Refer Access fittings Part Number

32 Coupon Holder : Type Fixed Disc Coupon Holder, Non Weld Type c/w mounting Kit, Length 8.75 Inches (Note 2, 4)

33 Material ASTM A182 F316

34 Part No. KS202-8.75

35 Coupon : Type Flush Disc Coupon, Dia.:1.25", Thickness 0.125" c/w insualtor, serial number and pre-weight

36 Material ASTM A312 TP316L

37 Part No. FDC-SA04-S-1

38 Packing PTFE

39 O-ring Viton

40 Seal PTFE

41 Mounting Top of Pipe, Retrieval able On-Line

42 Internal SS 316

43 Manufacturer KOROSI SPECINO

44 Certification EN 10204 type 3.1

45 Painting and Coating AS PER PROTECTIVE COATING SPECIFICATION, PTS 15.20.03 AND KPD99-01-M-SPE-2001

46 INSPECTION AND TESTING REQUIREMENTS

47 TYPE OF INSPECTION REQUIRED INSPECTION AND TESTING NOTES

48 Visual Examination 100% A) Where visual examination indicates areas of potential concern, LPI shall be applied in

49 Magnetic Particle Examination (Note A) - accordance with ASME V ARTICLE 6 ( LPI ) or ARTICLE 7 (MPI).

50 Liquid Particle Examination (Note A) 100% B) 100 % PMI on raw materials of SS, Duplex SS, Low Alloy, Exotics and 10 % PMI during

51 Radiographic Examination Not Req'd fabrication.

52 Positive Material Identification (Note B) Required C) Hydrotest 1.5 times the maximum flange rating at ambient temperature and as per

53 Pressure Test (Note C) Required ASME B31.3

54

55 NOTES

56 1 Corrosion coupon Tag no., size (in inches) and flange rating to be clearly die stamped on the body and SS 316 tag stamped fixed with braided & crimped

57 316SS wire.

58 2 VENDOR to provide sufficient length for coupon holder to hold corrosion coupon at the bottom/top of pipe.

59 3 Coupon holder length to be finalized by Vendor. Selected length shall be checked by using the resonance frequency / stress calculation.

60 4 System based on 2" flange system, access fitting shall be mounted on 2" Nippoflange having 150mm height.

61 5 Flange face finish shall have a roughness between 125 µ in and 250 µ in.

62 6 Coupon holder shall be retrievable on line without depressurizing the main process line.

63 7 Vendor shall supply Retrieval tool kit and service valve.

64 8 All stainless steel material shall be supplied in a solution annealed condition.

65 9 SS 316 / 316L shall be dual certified

R3215-005041 Appendix A 2.0_Datasheet For Corrosion Coupon

You might also like

- Pertamina Matindok Gas Project Master Deliverable ListDocument10 pagesPertamina Matindok Gas Project Master Deliverable Listsaiful anwar0% (1)

- GP 03 19 01Document12 pagesGP 03 19 01Anonymous fvO1W3100% (2)

- Welding Carbon Steel in Sour ServiceDocument8 pagesWelding Carbon Steel in Sour ServiceSarah Shibu ThomasNo ratings yet

- PIP PLSC0021 Pressure Testing of ASME B31.8 Metallic PipingDocument15 pagesPIP PLSC0021 Pressure Testing of ASME B31.8 Metallic Pipingivanov5559100% (1)

- CO-13-100-100-00-PR-L-003 - RevA - Requisition For SP ItemDocument18 pagesCO-13-100-100-00-PR-L-003 - RevA - Requisition For SP Itemsaiful anwarNo ratings yet

- Ac 036630 001Document1 pageAc 036630 001navaronefraNo ratings yet

- Corrosion Coupon Data SheetDocument3 pagesCorrosion Coupon Data SheetKaluoji50% (2)

- Bimetallic CorrosionDocument20 pagesBimetallic CorrosionchristophedepaepeNo ratings yet

- BS 6364-1984 Specification For Valves For Cryogenic ServiceDocument14 pagesBS 6364-1984 Specification For Valves For Cryogenic Service윤규섭100% (1)

- API 17K Production Hoses PDFDocument4 pagesAPI 17K Production Hoses PDFShayan Hasan KhanNo ratings yet

- Daniel Orifice Flanges Provide Accurate Flow MeasurementDocument45 pagesDaniel Orifice Flanges Provide Accurate Flow MeasurementSammyNo ratings yet

- 77313Document9 pages77313manojjuvaliNo ratings yet

- GasketDocument1,120 pagesGasketEntratainmentNo ratings yet

- Imsbc Palm Kernel Shell (PKS)Document6 pagesImsbc Palm Kernel Shell (PKS)majiex77100% (2)

- DNV-RP-F102 - Pipeline Field Joint Coating and Field Repair of Linepipe Coating, October 2003Document38 pagesDNV-RP-F102 - Pipeline Field Joint Coating and Field Repair of Linepipe Coating, October 2003bjlozadaNo ratings yet

- SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS FOR HOT TAP PIPINGDocument3 pagesSAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS FOR HOT TAP PIPINGarockiyathass100% (10)

- PTS 30.48.00.31-P (Feb 08) PDFDocument77 pagesPTS 30.48.00.31-P (Feb 08) PDFsaiful anwarNo ratings yet

- LOCK-O-RING Flanges and PlugsDocument6 pagesLOCK-O-RING Flanges and Plugsrafael_camacho_15No ratings yet

- 15801E09 - Manual ValveDocument390 pages15801E09 - Manual ValveFAUSTO SAMPIETRO33% (3)

- 6.6 Onshore and Offshore Pipeline Design Philosophy PDFDocument28 pages6.6 Onshore and Offshore Pipeline Design Philosophy PDFDonald.K100% (1)

- Sizing and Selection of Actuators For Valves: Nidhin ManoharDocument62 pagesSizing and Selection of Actuators For Valves: Nidhin Manoharsaiful anwarNo ratings yet

- ABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesDocument69 pagesABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesBhaiJan59100% (4)

- Pig ValvesDocument3 pagesPig ValvesteacgNo ratings yet

- Manhours Piping SrilangkaDocument53 pagesManhours Piping Srilangkasaiful anwar0% (1)

- Thermowell Wake Frequency and Stress CalculationDocument2 pagesThermowell Wake Frequency and Stress CalculationJawahar Bhattacharya100% (1)

- GC - GCMSD Consumable and MaintenanceDocument121 pagesGC - GCMSD Consumable and MaintenanceMehidin TahsinNo ratings yet

- Pipeline Pigging and CleaninDocument11 pagesPipeline Pigging and CleaninVidyasen67% (3)

- Pneumatic Actuators Spec for On-Off ValvesDocument12 pagesPneumatic Actuators Spec for On-Off ValvesGOSP3 QC Mechanical100% (1)

- Pressure Vessel Data Sheet for TEG ContactorDocument2 pagesPressure Vessel Data Sheet for TEG ContactorElias EliasNo ratings yet

- Mesc Spe 74 001 2016Document7 pagesMesc Spe 74 001 2016Salahuddin FarooquiNo ratings yet

- Pipeline Welding SpecificationDocument31 pagesPipeline Welding SpecificationAnonymous hBBam1nNo ratings yet

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabDocument19 pagesMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaNo ratings yet

- Pipe Line DemagtizeDocument2 pagesPipe Line DemagtizeJames Bradford100% (3)

- NORSOK Standard Jacket PipesDocument28 pagesNORSOK Standard Jacket PipesvuongNo ratings yet

- Pipeline Pigging Philosophy for Rumaila ProjectDocument15 pagesPipeline Pigging Philosophy for Rumaila ProjectfadhilNo ratings yet

- Psp-Koti-19 - Hot Tapping Procedure - Rev 0Document14 pagesPsp-Koti-19 - Hot Tapping Procedure - Rev 0cheehoong82No ratings yet

- Flange Management ProcedureDocument21 pagesFlange Management ProcedureDarrel Espino Aranas100% (1)

- Corrosion Coupon Data SheetDocument3 pagesCorrosion Coupon Data SheetĐiệnBiênNhâmNo ratings yet

- Application of Submarine and Floating Hoses in Offshore SPMDocument60 pagesApplication of Submarine and Floating Hoses in Offshore SPMSabila Shani TalsaNo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- Msog-M1402-P-Rp-006 Rev 1Document44 pagesMsog-M1402-P-Rp-006 Rev 1Mohd Nazir NorlanNo ratings yet

- List Shell Dep Amp Mesc Spe PDFDocument9 pagesList Shell Dep Amp Mesc Spe PDFAzhar Ahmad100% (1)

- Yet-Agru-Exe-Meb-000-Cmm-Prc-0001 Comm & Start Up PhilosophyDocument6 pagesYet-Agru-Exe-Meb-000-Cmm-Prc-0001 Comm & Start Up Philosophymohsin moin100% (1)

- Spherical - Tank Erection ProcessDocument30 pagesSpherical - Tank Erection ProcessJavierfox9889% (9)

- Industrial MixersDocument22 pagesIndustrial MixersKaustubh ThawkarNo ratings yet

- Split SleeveDocument3 pagesSplit Sleeveast654No ratings yet

- Piping Design Layout and Stress AnalysisDocument19 pagesPiping Design Layout and Stress AnalysisSolomon EmavwodiaNo ratings yet

- PIP STE05121 Anchor Bolt Design Guide PDFDocument56 pagesPIP STE05121 Anchor Bolt Design Guide PDFVasan Sam100% (1)

- Valve data sheet listing technical detailsDocument9 pagesValve data sheet listing technical detailsashams492No ratings yet

- Bolt Tightening TorqueDocument10 pagesBolt Tightening Torquekb7401100% (1)

- Test API RP 1111Document2 pagesTest API RP 1111Nguyễn QuânNo ratings yet

- Black PowderDocument48 pagesBlack PowderxiaotaoscribdNo ratings yet

- Nace Corrosion 1991 Paper No 577 Predictive Model For Co2 Corrosion Engineering PDFDocument10 pagesNace Corrosion 1991 Paper No 577 Predictive Model For Co2 Corrosion Engineering PDFqwerty1 qwerty9No ratings yet

- Basic Info About Glaze FormulationsDocument3 pagesBasic Info About Glaze FormulationsThongMaVanNo ratings yet

- ASTM Materials Table for Carbon Steel, Stainless Steel & Alloy SteelDocument1 pageASTM Materials Table for Carbon Steel, Stainless Steel & Alloy SteelveerappapanchalNo ratings yet

- Saep 122Document18 pagesSaep 122Handa Bin AdiNo ratings yet

- Api RP 1111 E5Document3 pagesApi RP 1111 E5Oğuzcan Şahin0% (1)

- G LokDocument37 pagesG Lokkkozak99No ratings yet

- SP-1136 Cathodic Protection DrawingsDocument4 pagesSP-1136 Cathodic Protection Drawingshappale2002No ratings yet

- ASME B16.47 Ser. A, Ser. B Industry Standard and AWWA Flanges Robert-James Sales, IncDocument25 pagesASME B16.47 Ser. A, Ser. B Industry Standard and AWWA Flanges Robert-James Sales, IncChairul AnwarNo ratings yet

- Hydrostatic TestingDocument18 pagesHydrostatic TestingRicardoNo ratings yet

- SAES-L-132 PDF Download - Material Selection For Piping Systems - PDFYARDocument6 pagesSAES-L-132 PDF Download - Material Selection For Piping Systems - PDFYARZahidRafique100% (1)

- HT Chart For ASME Material-B31.3Document1 pageHT Chart For ASME Material-B31.3MurugananthamParamasivamNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- Multidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) ADocument4 pagesMultidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) AHOSAM HUSSEINNo ratings yet

- Flanges Awwa c207Document28 pagesFlanges Awwa c207inacioprojNo ratings yet

- API 6D Errata 10 UpdateDocument1 pageAPI 6D Errata 10 UpdateANANDNo ratings yet

- API Standards For Safe Offshore Operations BrochureDocument1 pageAPI Standards For Safe Offshore Operations BrochureVõ Quang Kiệt100% (1)

- API 598 Testing Procedure-20130720-032647Document2 pagesAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- Fail Safe PhilosophyDocument3 pagesFail Safe PhilosophyjojonNo ratings yet

- BV Gate Valve DS 15111Document2 pagesBV Gate Valve DS 15111yulianus_srNo ratings yet

- Ptfe Torque Chart Aps KitsDocument2 pagesPtfe Torque Chart Aps KitsJo KingsNo ratings yet

- Pages 33 To 34 From TREX-000-EXE-KQKS-000-PIP-TDS-0001 - 2Document2 pagesPages 33 To 34 From TREX-000-EXE-KQKS-000-PIP-TDS-0001 - 2Ahmed ShitataNo ratings yet

- Resistance Temperature Detector - RTDDocument1 pageResistance Temperature Detector - RTDSreejesh SundaresanNo ratings yet

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- Data Sheet For Gas FilterDocument1 pageData Sheet For Gas FilterKhánh TrầnNo ratings yet

- A307 Ius Pi DS 1211Document2 pagesA307 Ius Pi DS 1211muddisetty umamaheswarNo ratings yet

- Annex-32 (Compressed Air Station)Document1 pageAnnex-32 (Compressed Air Station)saiful anwarNo ratings yet

- Annex-45 (CW For Red Mud Pressure)Document1 pageAnnex-45 (CW For Red Mud Pressure)saiful anwarNo ratings yet

- Annex-21 (Ash Removing System)Document1 pageAnnex-21 (Ash Removing System)saiful anwarNo ratings yet

- SG1767BFS-2P02!50!021-001 B Plan-Lime Milk PreparationDocument1 pageSG1767BFS-2P02!50!021-001 B Plan-Lime Milk Preparationsaiful anwarNo ratings yet

- Annex-1 - B (General Layout) PDFDocument1 pageAnnex-1 - B (General Layout) PDFsaiful anwarNo ratings yet

- PID - ASPHALT STORAGE TANK & TRANSFER PUMP-Layout1 PDFDocument1 pagePID - ASPHALT STORAGE TANK & TRANSFER PUMP-Layout1 PDFsaiful anwarNo ratings yet

- Pid - Asphalt Storage Tank & Transfer Pump-Layout1Document1 pagePid - Asphalt Storage Tank & Transfer Pump-Layout1saiful anwarNo ratings yet

- Annex-1 - B (General Layout)Document1 pageAnnex-1 - B (General Layout)saiful anwarNo ratings yet

- Annex-1 - B (General Layout)Document1 pageAnnex-1 - B (General Layout)saiful anwarNo ratings yet

- Pid - Asphalt Storage Tank & Transfer Pump-Layout1Document1 pagePid - Asphalt Storage Tank & Transfer Pump-Layout1saiful anwarNo ratings yet

- BOQ Form Retender KANDocument5 pagesBOQ Form Retender KANsaiful anwarNo ratings yet

- Datasheet ComplianceDocument15 pagesDatasheet Compliancesaiful anwarNo ratings yet

- Valve Marking (API 6a - API 6d)Document1 pageValve Marking (API 6a - API 6d)saiful anwarNo ratings yet

- Metal Seals For Valve ApplicationsDocument3 pagesMetal Seals For Valve Applicationssaiful anwarNo ratings yet

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsDocument30 pagesTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarNo ratings yet

- Pneumatic Testing Hazards: Vol. 11 No. 3a, 2011Document1 pagePneumatic Testing Hazards: Vol. 11 No. 3a, 2011saiful anwarNo ratings yet

- Compression Spring Design (Static Loads) : Music WireDocument2 pagesCompression Spring Design (Static Loads) : Music Wiresaiful anwarNo ratings yet

- Catalog MetalSeals PTD3359-EN PDFDocument108 pagesCatalog MetalSeals PTD3359-EN PDFsaiful anwarNo ratings yet

- Painting Sop Rev 2 Krm0201 A Guf 422 16Document4 pagesPainting Sop Rev 2 Krm0201 A Guf 422 16saiful anwarNo ratings yet

- Activities Carried Out in Quality Control LaboratoryDocument61 pagesActivities Carried Out in Quality Control LaboratorySunil SingireddyNo ratings yet

- Quantitative Analysis of PGM Using XRFDocument6 pagesQuantitative Analysis of PGM Using XRFGrigorescuVeronica100% (1)

- Nitoseal MS600 sealant for immersed conditionsDocument4 pagesNitoseal MS600 sealant for immersed conditionsmilanbrasinaNo ratings yet

- Ficha Tecnica Astm 514Document1 pageFicha Tecnica Astm 514Ruben Dario Mamani ArellanoNo ratings yet

- Nature Koligatif SolutionDocument28 pagesNature Koligatif SolutionDiah SukmawatiNo ratings yet

- Interzinc 22 Application Guidelines UkDocument10 pagesInterzinc 22 Application Guidelines Ukapde06No ratings yet

- Zhou Yi 50Document155 pagesZhou Yi 50emiliofalsoNo ratings yet

- 13 Corrosion Protection Best Practice - EDocument37 pages13 Corrosion Protection Best Practice - ENam TrinhNo ratings yet

- Cryogenic Transfer Line ChilldownDocument10 pagesCryogenic Transfer Line ChilldownIgnacio ChaparroNo ratings yet

- Welding Non-Code Specialty Equipment: NIOEC-SP-90-11Document8 pagesWelding Non-Code Specialty Equipment: NIOEC-SP-90-11aminNo ratings yet

- Materials Today: Proceedings: Jamal Eddine Hamoutami, Oum El Khaiat MoustachiDocument9 pagesMaterials Today: Proceedings: Jamal Eddine Hamoutami, Oum El Khaiat MoustachiAli petekNo ratings yet

- Quantitative Techniques in Textile EngineeringDocument26 pagesQuantitative Techniques in Textile EngineeringRAGHUL MNo ratings yet

- Optimal DC Cable Selection in PV DesignsDocument8 pagesOptimal DC Cable Selection in PV DesignsHelena AraujoNo ratings yet

- Chapter - Ii Principles of PhotocatalysisDocument10 pagesChapter - Ii Principles of PhotocatalysisAbbas aliNo ratings yet

- Beam Design ReportDocument22 pagesBeam Design Reportkwoshaba pidsonNo ratings yet

- Li-Ion pd2019 Mot SolutionsDocument2 pagesLi-Ion pd2019 Mot SolutionsManuel BermudezNo ratings yet

- (Doi 10.1016/B978-0-08-055294-1.00270-1) Efron, N. - Comprehensive Biomaterials - Development of Contact Lenses From A Biomaterial Point of View - Materials, Manufacture, and Cli - Compressed PDFDocument25 pages(Doi 10.1016/B978-0-08-055294-1.00270-1) Efron, N. - Comprehensive Biomaterials - Development of Contact Lenses From A Biomaterial Point of View - Materials, Manufacture, and Cli - Compressed PDFAstrit KiranaNo ratings yet

- CHEM 4 NotesDocument334 pagesCHEM 4 NotesMokayaNo ratings yet

- Vehicle Body Materials PDFDocument5 pagesVehicle Body Materials PDFAghil BuddyNo ratings yet

- Energy MethodsDocument15 pagesEnergy MethodsgalehNo ratings yet

- Tle 6 (Industrial Arts) Week 8 Day 2Document3 pagesTle 6 (Industrial Arts) Week 8 Day 2Krisna HundosNo ratings yet

- Masterseal 909: Re-Injectable Hose For Construction and Cold Joints in ConcreteDocument2 pagesMasterseal 909: Re-Injectable Hose For Construction and Cold Joints in Concretevelmurug_balaNo ratings yet

- Module 8 Welding Metallurgy For The WIDocument39 pagesModule 8 Welding Metallurgy For The WIRamesh R100% (1)