Professional Documents

Culture Documents

Spec Sheet Bulk03

Uploaded by

Fabricio AquijeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spec Sheet Bulk03

Uploaded by

Fabricio AquijeCopyright:

Available Formats

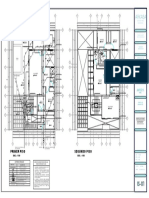

[847]

21 3/4"

[552]

2.00°

848 552

33 3/8" 552 21 3/4"

21 3/4"

BULK 3 Series TECHNICAL SPECIFICATIONS BULK 3 Series TECHNICAL SPECIFICATIONS 33 3/8"

[847] 21 3/4"

[552]

BODY DESIGN BODY SPECIFICATIONS 17 1/2"

24"

[608]

[445]

30 1/2"

Cover Weight 26 lbs [12 kg]

[776] TECHNICAL SPECIFICATIONS FEATURES

Pit Weight 63 lbs [29 kg]

17 1/2"

[445]

30 1/2"

17 1/2"

[445]

17 1/2"

[445]

17 1/2"

[445]

30 1/2"

• Upgradeable

Straight wall design improves lid 776

30 1/2" 30 1/2"

• Lightweight/Strong (TIER 22)

[776] [776] [776]

[776]

30 1/2" Assembled Weight 89 lbs [41 kg]

load strength. 17 1/2" 2" 17 1/2" 17 1/2"

• Patented Anti-Slip Technology

17 1/2" 33 3/8"

[445] [445]

Grade Level Box BULK

[49] 30 1/2" [445] [445] 30 1/2"

30 1/2" 30 1/2" [847]

442 445 442 442 442 [776] [776] [776]

17 3/8" 17 3/8" [776]

17 1/2" 17 3/8"

• Anti-Seize Bolt Technology

772 17 3/8" 772 772

772 2" 2" 17 1/2"

Flush mounted racks enhance sidewall 49

30 3/8" 30 3/8" 30 3/8" 2" 2"

30 3/8" [49]

2" Drawing shown with [49] [49] [49] [445]

30 1/2"

and vertical strength

63 of pit while • Industry Leader

[776] in Anti-Trip

2 1/2"

increasing usable space. 50

2"

[49]

2"

[49]

2"

[49]

2"

[49] Hazard Prevention

50 50 50

608

24"

2" 2" 2" 2" 34"

[865]

34"

[865]

34"

[865]

34"

[865]

• Superior Fatigue Resistance (EST)™

34"

457 457 457 457

• Vertical and Horizontal Rib Design

(3 HOLE DRILL) INSIDE FOLD PANEL 8” Trim off 1/2”

18" 18" 18" 18" Composite Cover [865] 19" 31" 19" 19" 19"

34" [483] [788]

34" [483]

24”/608 mm depth

34" 34"

• Embedded Vertical Racking

[483] [483]

[865] [865] 492 [865] [865] 4921/2" 492

552 847 19 3/8"

492 13 1/2" 13 13 1/2"

19 3/8"

13 1/2"

19 3/8"[343] 19 3/8" [343]

21 3/4" 33 3/8" [343] [343]

• Reduced Installation Cost

24"

• Highest Load Rating to Weight

419

Ribbed sidewall design secures

848

33 3/8" 552

848

33 3/8" 16 1/2" 552

848

33 3/8" 552

848

33 3/8"

BULK 3 Vault Body

34” [865 mm] Depth 552 33 3/8" 33 3/8" 33 3/8" 33 3/8" [476] Ratio in the Industry2"

21 3/4" 21 3/4" 21 3/4" 21 3/4" [847]

552 [847]

552

[847]

552

[847]

552 [49]

Shown

body into backfill soil and 21 3/4" 21 3/4" 21 3/4" 21 3/4"

33 3/8"

eliminates sidewall deflection.

[847]

TESTING CRITERIA

33 3/8" 33 3/8" 33 3/8" 33 3/8" 21 3/4"

[847] [847] [847]

21 3/4" [847] 21 3/4" 21 3/4" 21[552]

3/4"

749 33 3/8" [552] [552] [552] [552]

29 1/2" [847] 24"

21 3/4" 24" 24" 24"

[552]

[608] [608] [608]

Covers meet or exceed:

[608]

ADDITIONAL BODY DEPTHS • EST™ 3 Million Cycles

33 3/8"

[847]

• Telecordia GR-902-CORE

776 776 776 776 21 3/4"

30 1/2" 30 1/2" 30 1/2" 30 1/2"

33 3/8"

28 3/4"

[731] 33 3/8"

28 3/4"

[731] 33 3/8"

• Western Underground

[552] Committee

28 3/4"

[731] 33 3/8"

28 3/4"

[731]

445 445 445 445

[847] [847] [847]

Guide 3.6 [847]

49 49 49 49

14"

• ANSI/SCTE 77 2013-TIER 22

17 1/2" 17 1/2" 2" 17 1/2" 2" 17 1/2" 2" 2"

[357] 18" 17 1/2" 17 1/2" 17 1/2" 17 1/2"

63 63 63 63

2 1/2" 2 1/2" 2 1/2" [457] [445] [445] [445] [445]

2 1/2" 30 1/2" 30 1/2" 30 1/2" 30 1/2"

• EN124 Class B125

24"

[608] [776] [776] [776] [776]

608 608 608 608

24" 24" 24" 24" 31"

HDPE bodies provide easy field 25 lbs [11 kg] [788]

alteration while eliminating water 30 lbs [14 kg] 484 342 Bodies meet or exceed:

552 847 552 847 552 847 552 847 13 1/2"

19 1/8"

• Telecordia GR-902-CORE

2" 2" 2" 2"

absorption and material degradation

21 3/4" 33 3/8"21 3/4" 33 3/8"

21 3/4" 33 3/8"

21 3/4" 33 3/8"

[49] [49] [49] [49]

45 lbs [20 kg] 18”/457 mm depth

419

while maintaining structural integrity,

419 419 419 24" 24" 24" 24"

• Western Underground Committee

16 1/2"

and eliminating toxic fiberglass dust.

16 1/2" 16 1/2" 16 1/2" [476]

57 lbs [26 kg]

[476] [476] [476]

Guide 3.6

34"

14"

[357]

• ANSI/SCTE 77 2013-TIER 22

749 [865]

749 749 749

29 1/2" 29 1/2" 29 1/2" 29 1/2" • EN 124 Class B125/C250

™

457

Now with Covers • ASTM-457

18"

33 3/8"

[847]

21 3/4"

33 3/8"

[847]

21 3/4"

33 3/8"

[847]

21 3/4"

33 3/8"

[847] • AASHTO M-306 (H-20/25)

21 3/4"

MADE IN USA [552]

• AS3996-Class B/C

[552] [552] [552]

UNITED STATES CANADA EUROPE, MIDDLE EAST, AFRICA 552AUSTRALIA, ASIA, PACIFIC RIM

21 3/4"

21 3/4" 800.423.1863 905.565.1700 44.1322.312590 61.2.8884.4111

channell.com [552]

www.channell.com 484 342 342 342

channell.com

484 342 484 484

13 1/2" 19 1/8" 13 1/2" 19 1/8" 13 1/2" 13 1/2"

19 1/8" 19 1/8"

34" 34" 34"

34"

[865] [865] [865]

[865]

BLK3_Spe6pgFIN.indd 1 7/28/16 1:26 PM

BULK 3 Series TECHNICAL SPECIFICATIONS BULK 3 Series TECHNICAL SPECIFICATIONS

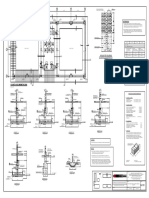

PRODUCT SUMMARY STANDARD FEATURES THE NEW SOLUTION

With over 90 years experience in global (OSP) Consumers also benefit from SHIELD’s Split and Pedestal

Mount Available HDPE Plastic Cover

infrastructure, Channell has developed the patented anti-slip design and anti-trip features. Light Duty 3,000 lbf (13.5 kN)

most advanced pit and chamber technology SHIELD’s cover tread design raises global

in the world! Channell’s BULK and SHIELD industry standards by offering 20% greater 3 covers

patented designs with the complement of slip resistance when compared to concrete,

SUPER BULK for roadway applications offer polymer concrete, steel or cast iron covers.

Composite Ring

global users, consumer, and craft installers SHIELD meets and exceeds Australia AS4586 Optional Composite Cover

safety benefits never before contemplated, but skid specification, the highest global standard in 33,750 lbf (150 kN)

critical when considering new global health and the world! Anti-Slip Tread Design Anti-Trip Cover Recessed Lifting Pin Non-Seizing Bolt System Flush Mounted Sidewall Racks

Allows Field Replacement Increase Usable Space

safety standards. with Cover

SUPER

Overall, BULK’s strength in combination with

BULK’s lightweight design increases installation Channell’s SHIELD covers offers a universal

Ductile Iron Cover

efficiencies while improving overall body weight solution to meet and exceed every company’s with Steel Ring

carrying load capacities versus concrete, needs. Safety always comes first, and that’s why 56,200 lbf (250 kN)

polymer concrete, and many other body BULK and SHIELD are tested to the highest

materials. Reduction of BULK’s body weight standards available in the global market and

protects the safety of installers while shortening Channell is proud to have pioneered Endurance

installation times. Additionally, with BULK Stress Testing (EST™) which analyzes cover 1 body BULK Vault Body

60,000 lbf (267 kN)

bodies, cutting ducts in the field produces no fatigue in the field. EST™ provides essential data Mounting Studs Logo Puck

(Custom Options Available)

Winterized Cable

Drop Slide

harmful dust contaminants which could lead to on the life expectancy of a SHIELD lid in the

installer respiratory issues. field and confirms its potential life expectancy.

Product design, product innovation, safety

All SHIELD covers meet or exceed 33,750 attributes, and new manufacturing technology is

pound-force or 150 kilonewtons in strength. why global customers are specifying Channell’s OPTIONAL FEATURES SPECIFICATION PROOF LOAD PRODUCTS

They never break and offer a lid weight BULK and SHIELD products for their new OSP AMERICAS STANDARDS

reduction over concrete and polymer concrete infrastructure requirements. Pedestrian/Light Duty 3,000 lbf (13.5 kN)

of 50%, and over 70% when compared to cast ANSI/SCTE 77 TIER 15 22,500 lbf (100 kN)

iron. SHIELD’s lighter weight design cover

ANSI/SCTE 77 TIER 22 33,750 lbf (150 kN)

reduces craft injuries while improving health SUPER

AASHTO M-306-10 H 20 40,000 lbf (178 kN)

and safety specifications. SUPER

AASHTO M-306-10 H 25 50,000 lbf (222.4 kN)

SUPER

ASTM-457 46,000 lbf (205 kN)

EMEA STANDARDS

L-Bolt Security System Marker Locator Device Swing-Arm with Butterfly Cable Hook Step Bracket

(SHIELD Cover Shown) Mounting Plate Bracket with Wedge Pedestrian/Light Duty 2,250 lbf (10 kN)

EN 124 Class B125 28,100 lbf (125 kN)

SUPER

EN 125 Class C125 56,200 lbf (250 kN)

APAC STANDARDS

Design and specifications may vary.

Pedestrian/Light Duty 3,370 lbf (15 kN)

AS3996-Class B 18,000 lbf (80 kN)

channell.com AS3996-Class C 33,750 lbf (150 kN)

BLK3_Spe6pgFIN.indd 2 7/28/16 1:27 PM

BULK 3 Series TECHNICAL SPECIFICATIONS BULK 3 Series TECHNICAL SPECIFICATIONS

PRODUCT SUMMARY STANDARD FEATURES THE NEW SOLUTION

With over 90 years experience in global (OSP) Consumers also benefit from SHIELD’s Split and Pedestal

Mount Available HDPE Plastic Cover

infrastructure, Channell has developed the patented anti-slip design and anti-trip features. Light Duty 3,000 lbf (13.5 kN)

most advanced pit and chamber technology SHIELD’s cover tread design raises global

in the world! Channell’s BULK and SHIELD industry standards by offering 20% greater 3 covers

patented designs with the complement of slip resistance when compared to concrete,

SUPER BULK for roadway applications offer polymer concrete, steel or cast iron covers.

Composite Ring

global users, consumer, and craft installers SHIELD meets and exceeds Australia AS4586 Optional Composite Cover

safety benefits never before contemplated, but skid specification, the highest global standard in 33,750 lbf (150 kN)

critical when considering new global health and the world! Anti-Slip Tread Design Anti-Trip Cover Recessed Lifting Pin Non-Seizing Bolt System Flush Mounted Sidewall Racks

Allows Field Replacement Increase Usable Space

safety standards. with Cover

SUPER

Overall, BULK’s strength in combination with

BULK’s lightweight design increases installation Channell’s SHIELD covers offers a universal

Ductile Iron Cover

efficiencies while improving overall body weight solution to meet and exceed every company’s with Steel Ring

carrying load capacities versus concrete, needs. Safety always comes first, and that’s why 56,200 lbf (250 kN)

polymer concrete, and many other body BULK and SHIELD are tested to the highest

materials. Reduction of BULK’s body weight standards available in the global market and

protects the safety of installers while shortening Channell is proud to have pioneered Endurance

installation times. Additionally, with BULK Stress Testing (EST™) which analyzes cover 1 body BULK Vault Body

60,000 lbf (267 kN)

bodies, cutting ducts in the field produces no fatigue in the field. EST™ provides essential data Mounting Studs Logo Puck

(Custom Options Available)

Winterized Cable

Drop Slide

harmful dust contaminants which could lead to on the life expectancy of a SHIELD lid in the

installer respiratory issues. field and confirms its potential life expectancy.

Product design, product innovation, safety

All SHIELD covers meet or exceed 33,750 attributes, and new manufacturing technology is

pound-force or 150 kilonewtons in strength. why global customers are specifying Channell’s OPTIONAL FEATURES SPECIFICATION PROOF LOAD PRODUCTS

They never break and offer a lid weight BULK and SHIELD products for their new OSP AMERICAS STANDARDS

reduction over concrete and polymer concrete infrastructure requirements. Pedestrian/Light Duty 3,000 lbf (13.5 kN)

of 50%, and over 70% when compared to cast ANSI/SCTE 77 TIER 15 22,500 lbf (100 kN)

iron. SHIELD’s lighter weight design cover

ANSI/SCTE 77 TIER 22 33,750 lbf (150 kN)

reduces craft injuries while improving health SUPER

AASHTO M-306-10 H 20 40,000 lbf (178 kN)

and safety specifications. SUPER

AASHTO M-306-10 H 25 50,000 lbf (222.4 kN)

SUPER

ASTM-457 46,000 lbf (205 kN)

EMEA STANDARDS

L-Bolt Security System Marker Locator Device Swing-Arm with Butterfly Cable Hook Step Bracket

(SHIELD Cover Shown) Mounting Plate Bracket with Wedge Pedestrian/Light Duty 2,250 lbf (10 kN)

EN 124 Class B125 28,100 lbf (125 kN)

SUPER

EN 125 Class C125 56,200 lbf (250 kN)

APAC STANDARDS

Design and specifications may vary.

Pedestrian/Light Duty 3,370 lbf (15 kN)

AS3996-Class B 18,000 lbf (80 kN)

channell.com AS3996-Class C 33,750 lbf (150 kN)

BLK3_Spe6pgFIN.indd 2 7/28/16 1:27 PM

BULK 3 Series TECHNICAL SPECIFICATIONS BULK 3 Series TECHNICAL SPECIFICATIONS

PRODUCT SUMMARY STANDARD FEATURES THE NEW SOLUTION

With over 90 years experience in global (OSP) Consumers also benefit from SHIELD’s Split and Pedestal

Mount Available HDPE Plastic Cover

infrastructure, Channell has developed the patented anti-slip design and anti-trip features. Light Duty 3,000 lbf (13.5 kN)

most advanced pit and chamber technology SHIELD’s cover tread design raises global

in the world! Channell’s BULK and SHIELD industry standards by offering 20% greater 3 covers

patented designs with the complement of slip resistance when compared to concrete,

SUPER BULK for roadway applications offer polymer concrete, steel or cast iron covers.

Composite Ring

global users, consumer, and craft installers SHIELD meets and exceeds Australia AS4586 Optional Composite Cover

safety benefits never before contemplated, but skid specification, the highest global standard in 33,750 lbf (150 kN)

critical when considering new global health and the world! Anti-Slip Tread Design Anti-Trip Cover Recessed Lifting Pin Non-Seizing Bolt System Flush Mounted Sidewall Racks

Allows Field Replacement Increase Usable Space

safety standards. with Cover

SUPER

Overall, BULK’s strength in combination with

BULK’s lightweight design increases installation Channell’s SHIELD covers offers a universal

Ductile Iron Cover

efficiencies while improving overall body weight solution to meet and exceed every company’s with Steel Ring

carrying load capacities versus concrete, needs. Safety always comes first, and that’s why 56,200 lbf (250 kN)

polymer concrete, and many other body BULK and SHIELD are tested to the highest

materials. Reduction of BULK’s body weight standards available in the global market and

protects the safety of installers while shortening Channell is proud to have pioneered Endurance

installation times. Additionally, with BULK Stress Testing (EST™) which analyzes cover 1 body BULK Vault Body

60,000 lbf (267 kN)

bodies, cutting ducts in the field produces no fatigue in the field. EST™ provides essential data Mounting Studs Logo Puck

(Custom Options Available)

Winterized Cable

Drop Slide

harmful dust contaminants which could lead to on the life expectancy of a SHIELD lid in the

installer respiratory issues. field and confirms its potential life expectancy.

Product design, product innovation, safety

All SHIELD covers meet or exceed 33,750 attributes, and new manufacturing technology is

pound-force or 150 kilonewtons in strength. why global customers are specifying Channell’s OPTIONAL FEATURES SPECIFICATION PROOF LOAD PRODUCTS

They never break and offer a lid weight BULK and SHIELD products for their new OSP AMERICAS STANDARDS

reduction over concrete and polymer concrete infrastructure requirements. Pedestrian/Light Duty 3,000 lbf (13.5 kN)

of 50%, and over 70% when compared to cast ANSI/SCTE 77 TIER 15 22,500 lbf (100 kN)

iron. SHIELD’s lighter weight design cover

ANSI/SCTE 77 TIER 22 33,750 lbf (150 kN)

reduces craft injuries while improving health SUPER

AASHTO M-306-10 H 20 40,000 lbf (178 kN)

and safety specifications. SUPER

AASHTO M-306-10 H 25 50,000 lbf (222.4 kN)

SUPER

ASTM-457 46,000 lbf (205 kN)

EMEA STANDARDS

L-Bolt Security System Marker Locator Device Swing-Arm with Butterfly Cable Hook Step Bracket

(SHIELD Cover Shown) Mounting Plate Bracket with Wedge Pedestrian/Light Duty 2,250 lbf (10 kN)

EN 124 Class B125 28,100 lbf (125 kN)

SUPER

EN 125 Class C125 56,200 lbf (250 kN)

APAC STANDARDS

Design and specifications may vary.

Pedestrian/Light Duty 3,370 lbf (15 kN)

AS3996-Class B 18,000 lbf (80 kN)

channell.com AS3996-Class C 33,750 lbf (150 kN)

BLK3_Spe6pgFIN.indd 2 7/28/16 1:27 PM

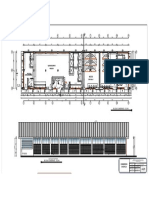

[847]

21 3/4"

[552]

2.00°

848 552

33 3/8" 552 21 3/4"

21 3/4"

BULK 3 Series TECHNICAL SPECIFICATIONS BULK 3 Series TECHNICAL SPECIFICATIONS 33 3/8"

[847] 21 3/4"

[552]

BODY DESIGN BODY SPECIFICATIONS 17 1/2"

24"

[608]

[445]

30 1/2"

Cover Weight 26 lbs [12 kg]

[776] TECHNICAL SPECIFICATIONS FEATURES

Pit Weight 63 lbs [29 kg]

17 1/2"

[445]

30 1/2"

17 1/2"

[445]

17 1/2"

[445]

17 1/2"

[445]

30 1/2"

• Upgradeable

Straight wall design improves lid 776

30 1/2" 30 1/2"

• Lightweight/Strong (TIER 22)

[776] [776] [776]

[776]

30 1/2" Assembled Weight 89 lbs [41 kg]

load strength. 17 1/2" 2" 17 1/2" 17 1/2"

• Patented Anti-Slip Technology

17 1/2" 33 3/8"

[445] [445]

Grade Level Box BULK

[49] 30 1/2" [445] [445] 30 1/2"

30 1/2" 30 1/2" [847]

442 445 442 442 442 [776] [776] [776]

17 3/8" 17 3/8" [776]

17 1/2" 17 3/8"

• Anti-Seize Bolt Technology

772 17 3/8" 772 772

772 2" 2" 17 1/2"

Flush mounted racks enhance sidewall 49

30 3/8" 30 3/8" 30 3/8" 2" 2"

30 3/8" [49]

2" Drawing shown with [49] [49] [49] [445]

30 1/2"

and vertical strength

63 of pit while • Industry Leader

[776] in Anti-Trip

2 1/2"

increasing usable space. 50

2"

[49]

2"

[49]

2"

[49]

2"

[49] Hazard Prevention

50 50 50

608

24"

2" 2" 2" 2" 34"

[865]

34"

[865]

34"

[865]

34"

[865]

• Superior Fatigue Resistance (EST)™

34"

457 457 457 457

• Vertical and Horizontal Rib Design

(3 HOLE DRILL) INSIDE FOLD PANEL 8” Trim off 1/2”

18" 18" 18" 18" Composite Cover [865] 19" 31" 19" 19" 19"

34" [483] [788]

34" [483]

24”/608 mm depth

34" 34"

• Embedded Vertical Racking

[483] [483]

[865] [865] 492 [865] [865] 4921/2" 492

552 847 19 3/8"

492 13 1/2" 13 13 1/2"

19 3/8"

13 1/2"

19 3/8"[343] 19 3/8" [343]

21 3/4" 33 3/8" [343] [343]

• Reduced Installation Cost

24"

• Highest Load Rating to Weight

419

Ribbed sidewall design secures

848

33 3/8" 552

848

33 3/8" 16 1/2" 552

848

33 3/8" 552

848

33 3/8"

BULK 3 Vault Body

34” [865 mm] Depth 552 33 3/8" 33 3/8" 33 3/8" 33 3/8" [476] Ratio in the Industry2"

21 3/4" 21 3/4" 21 3/4" 21 3/4" [847]

552 [847]

552

[847]

552

[847]

552 [49]

Shown

body into backfill soil and 21 3/4" 21 3/4" 21 3/4" 21 3/4"

33 3/8"

eliminates sidewall deflection.

[847]

TESTING CRITERIA

33 3/8" 33 3/8" 33 3/8" 33 3/8" 21 3/4"

[847] [847] [847]

21 3/4" [847] 21 3/4" 21 3/4" 21[552]

3/4"

749 33 3/8" [552] [552] [552] [552]

29 1/2" [847] 24"

21 3/4" 24" 24" 24"

[552]

[608] [608] [608]

Covers meet or exceed:

[608]

ADDITIONAL BODY DEPTHS • EST™ 3 Million Cycles

33 3/8"

[847]

• Telecordia GR-902-CORE

776 776 776 776 21 3/4"

30 1/2" 30 1/2" 30 1/2" 30 1/2"

33 3/8"

28 3/4"

[731] 33 3/8"

28 3/4"

[731] 33 3/8"

• Western Underground

[552] Committee

28 3/4"

[731] 33 3/8"

28 3/4"

[731]

445 445 445 445

[847] [847] [847]

Guide 3.6 [847]

49 49 49 49

14"

• ANSI/SCTE 77 2013-TIER 22

17 1/2" 17 1/2" 2" 17 1/2" 2" 17 1/2" 2" 2"

[357] 18" 17 1/2" 17 1/2" 17 1/2" 17 1/2"

63 63 63 63

2 1/2" 2 1/2" 2 1/2" [457] [445] [445] [445] [445]

2 1/2" 30 1/2" 30 1/2" 30 1/2" 30 1/2"

• EN124 Class B125

24"

[608] [776] [776] [776] [776]

608 608 608 608

24" 24" 24" 24" 31"

HDPE bodies provide easy field 25 lbs [11 kg] [788]

alteration while eliminating water 30 lbs [14 kg] 484 342 Bodies meet or exceed:

552 847 552 847 552 847 552 847 13 1/2"

19 1/8"

• Telecordia GR-902-CORE

2" 2" 2" 2"

absorption and material degradation

21 3/4" 33 3/8"21 3/4" 33 3/8"

21 3/4" 33 3/8"

21 3/4" 33 3/8"

[49] [49] [49] [49]

45 lbs [20 kg] 18”/457 mm depth

419

while maintaining structural integrity,

419 419 419 24" 24" 24" 24"

• Western Underground Committee

16 1/2"

and eliminating toxic fiberglass dust.

16 1/2" 16 1/2" 16 1/2" [476]

57 lbs [26 kg]

[476] [476] [476]

Guide 3.6

34"

14"

[357]

• ANSI/SCTE 77 2013-TIER 22

749 [865]

749 749 749

29 1/2" 29 1/2" 29 1/2" 29 1/2" • EN 124 Class B125/C250

™

457

Now with Covers • ASTM-457

18"

33 3/8"

[847]

21 3/4"

33 3/8"

[847]

21 3/4"

33 3/8"

[847]

21 3/4"

33 3/8"

[847] • AASHTO M-306 (H-20/25)

21 3/4"

MADE IN USA [552]

• AS3996-Class B/C

[552] [552] [552]

UNITED STATES CANADA EUROPE, MIDDLE EAST, AFRICA 552AUSTRALIA, ASIA, PACIFIC RIM

21 3/4"

21 3/4" 800.423.1863 905.565.1700 44.1322.312590 61.2.8884.4111

channell.com [552]

www.channell.com 484 342 342 342

channell.com

484 342 484 484

13 1/2" 19 1/8" 13 1/2" 19 1/8" 13 1/2" 13 1/2"

19 1/8" 19 1/8"

34" 34" 34"

34"

[865] [865] [865]

[865]

BLK3_Spe6pgFIN.indd 1 7/28/16 1:26 PM

[847]

21 3/4"

[552]

2.00°

848 552

33 3/8" 552 21 3/4"

21 3/4"

BULK 3 Series TECHNICAL SPECIFICATIONS BULK 3 Series TECHNICAL SPECIFICATIONS 33 3/8"

[847] 21 3/4"

[552]

BODY DESIGN BODY SPECIFICATIONS 17 1/2"

24"

[608]

[445]

30 1/2"

Cover Weight 26 lbs [12 kg]

[776] TECHNICAL SPECIFICATIONS FEATURES

Pit Weight 63 lbs [29 kg]

17 1/2"

[445]

30 1/2"

17 1/2"

[445]

17 1/2"

[445]

17 1/2"

[445]

30 1/2"

• Upgradeable

Straight wall design improves lid 776

30 1/2" 30 1/2"

• Lightweight/Strong (TIER 22)

[776] [776] [776]

[776]

30 1/2" Assembled Weight 89 lbs [41 kg]

load strength. 17 1/2" 2" 17 1/2" 17 1/2"

• Patented Anti-Slip Technology

17 1/2" 33 3/8"

[445] [445]

Grade Level Box BULK

[49] 30 1/2" [445] [445] 30 1/2"

30 1/2" 30 1/2" [847]

442 445 442 442 442 [776] [776] [776]

17 3/8" 17 3/8" [776]

17 1/2" 17 3/8"

• Anti-Seize Bolt Technology

772 17 3/8" 772 772

772 2" 2" 17 1/2"

Flush mounted racks enhance sidewall 49

30 3/8" 30 3/8" 30 3/8" 2" 2"

30 3/8" [49]

2" Drawing shown with [49] [49] [49] [445]

30 1/2"

and vertical strength

63 of pit while • Industry Leader

[776] in Anti-Trip

2 1/2"

increasing usable space. 50

2"

[49]

2"

[49]

2"

[49]

2"

[49] Hazard Prevention

50 50 50

608

24"

2" 2" 2" 2" 34"

[865]

34"

[865]

34"

[865]

34"

[865]

• Superior Fatigue Resistance (EST)™

34"

457 457 457 457

• Vertical and Horizontal Rib Design

(3 HOLE DRILL) INSIDE FOLD PANEL 8” Trim off 1/2”

18" 18" 18" 18" Composite Cover [865] 19" 31" 19" 19" 19"

34" [483] [788]

34" [483]

24”/608 mm depth

34" 34"

• Embedded Vertical Racking

[483] [483]

[865] [865] 492 [865] [865] 4921/2" 492

552 847 19 3/8"

492 13 1/2" 13 13 1/2"

19 3/8"

13 1/2"

19 3/8"[343] 19 3/8" [343]

21 3/4" 33 3/8" [343] [343]

• Reduced Installation Cost

24"

• Highest Load Rating to Weight

419

Ribbed sidewall design secures

848

33 3/8" 552

848

33 3/8" 16 1/2" 552

848

33 3/8" 552

848

33 3/8"

BULK 3 Vault Body

34” [865 mm] Depth 552 33 3/8" 33 3/8" 33 3/8" 33 3/8" [476] Ratio in the Industry2"

21 3/4" 21 3/4" 21 3/4" 21 3/4" [847]

552 [847]

552

[847]

552

[847]

552 [49]

Shown

body into backfill soil and 21 3/4" 21 3/4" 21 3/4" 21 3/4"

33 3/8"

eliminates sidewall deflection.

[847]

TESTING CRITERIA

33 3/8" 33 3/8" 33 3/8" 33 3/8" 21 3/4"

[847] [847] [847]

21 3/4" [847] 21 3/4" 21 3/4" 21[552]

3/4"

749 33 3/8" [552] [552] [552] [552]

29 1/2" [847] 24"

21 3/4" 24" 24" 24"

[552]

[608] [608] [608]

Covers meet or exceed:

[608]

ADDITIONAL BODY DEPTHS • EST™ 3 Million Cycles

33 3/8"

[847]

• Telecordia GR-902-CORE

776 776 776 776 21 3/4"

30 1/2" 30 1/2" 30 1/2" 30 1/2"

33 3/8"

28 3/4"

[731] 33 3/8"

28 3/4"

[731] 33 3/8"

• Western Underground

[552] Committee

28 3/4"

[731] 33 3/8"

28 3/4"

[731]

445 445 445 445

[847] [847] [847]

Guide 3.6 [847]

49 49 49 49

14"

• ANSI/SCTE 77 2013-TIER 22

17 1/2" 17 1/2" 2" 17 1/2" 2" 17 1/2" 2" 2"

[357] 18" 17 1/2" 17 1/2" 17 1/2" 17 1/2"

63 63 63 63

2 1/2" 2 1/2" 2 1/2" [457] [445] [445] [445] [445]

2 1/2" 30 1/2" 30 1/2" 30 1/2" 30 1/2"

• EN124 Class B125

24"

[608] [776] [776] [776] [776]

608 608 608 608

24" 24" 24" 24" 31"

HDPE bodies provide easy field 25 lbs [11 kg] [788]

alteration while eliminating water 30 lbs [14 kg] 484 342 Bodies meet or exceed:

552 847 552 847 552 847 552 847 13 1/2"

19 1/8"

• Telecordia GR-902-CORE

2" 2" 2" 2"

absorption and material degradation

21 3/4" 33 3/8"21 3/4" 33 3/8"

21 3/4" 33 3/8"

21 3/4" 33 3/8"

[49] [49] [49] [49]

45 lbs [20 kg] 18”/457 mm depth

419

while maintaining structural integrity,

419 419 419 24" 24" 24" 24"

• Western Underground Committee

16 1/2"

and eliminating toxic fiberglass dust.

16 1/2" 16 1/2" 16 1/2" [476]

57 lbs [26 kg]

[476] [476] [476]

Guide 3.6

34"

14"

[357]

• ANSI/SCTE 77 2013-TIER 22

749 [865]

749 749 749

29 1/2" 29 1/2" 29 1/2" 29 1/2" • EN 124 Class B125/C250

™

457

Now with Covers • ASTM-457

18"

33 3/8"

[847]

21 3/4"

33 3/8"

[847]

21 3/4"

33 3/8"

[847]

21 3/4"

33 3/8"

[847] • AASHTO M-306 (H-20/25)

21 3/4"

MADE IN USA [552]

• AS3996-Class B/C

[552] [552] [552]

UNITED STATES CANADA EUROPE, MIDDLE EAST, AFRICA 552AUSTRALIA, ASIA, PACIFIC RIM

21 3/4"

21 3/4" 800.423.1863 905.565.1700 44.1322.312590 61.2.8884.4111

channell.com [552]

www.channell.com 484 342 342 342

channell.com

484 342 484 484

13 1/2" 19 1/8" 13 1/2" 19 1/8" 13 1/2" 13 1/2"

19 1/8" 19 1/8"

34" 34" 34"

34"

[865] [865] [865]

[865]

BLK3_Spe6pgFIN.indd 1 7/28/16 1:26 PM

You might also like

- Channell - Memoria Descriptiva de Las Cámaras Prefabricadas4 PDFDocument10 pagesChannell - Memoria Descriptiva de Las Cámaras Prefabricadas4 PDFFrancis Richard Lopez RamosNo ratings yet

- Helmer Cerco Perimetrico 02Document1 pageHelmer Cerco Perimetrico 02Harold SimichNo ratings yet

- IE 40055 Est.6Document1 pageIE 40055 Est.6Luis Alejandro Abarca AquinoNo ratings yet

- Cerco perimétrico con especificacionesDocument1 pageCerco perimétrico con especificacionesElvis Jhoel Sosa LozanoNo ratings yet

- Características interruptor potencia tipo tanque muertoDocument2 pagesCaracterísticas interruptor potencia tipo tanque muertojuaco gonzalezNo ratings yet

- Detalles de aligerado y secciones de vigasDocument1 pageDetalles de aligerado y secciones de vigasZoraida Tarazona MontalvoNo ratings yet

- Vivienda Las Palmeras-INST SANIT 1Document1 pageVivienda Las Palmeras-INST SANIT 1Edwin Carmen LazoNo ratings yet

- Vivienda Las Palmeras-InST SANIT 1Document1 pageVivienda Las Palmeras-InST SANIT 1Edwin Carmen LazoNo ratings yet

- Cua-Pa-Pr-Arq-2501-A-1-Planta Ubic - Tip. Tabiques 1° - 2 ° NivelDocument1 pageCua-Pa-Pr-Arq-2501-A-1-Planta Ubic - Tip. Tabiques 1° - 2 ° NivelJhonatanNo ratings yet

- MD - Carabayllo - Ubicacion de Edificaciones - SectorCritico15 - 2016Document1 pageMD - Carabayllo - Ubicacion de Edificaciones - SectorCritico15 - 2016Frank Jonatan Ramos CabreraNo ratings yet

- Pm.01 - Tablero de Distribucion 400a GFGCDocument1 pagePm.01 - Tablero de Distribucion 400a GFGCEnrique Renzo Ascencio PachecoNo ratings yet

- Iaat 7820 PB 2Document1 pageIaat 7820 PB 2Ismael GarciaNo ratings yet

- Proyecto Oficinas Estaban CastilloDocument1 pageProyecto Oficinas Estaban CastilloAlberto VillanuevaNo ratings yet

- Plano Rev.bDocument1 pagePlano Rev.bLizbeth AtamariNo ratings yet

- Ie Al 02Document1 pageIe Al 02VICTOR MARTINEZNo ratings yet

- Municipalidad Provincial de Abancay: Especificaciones TécnicasDocument1 pageMunicipalidad Provincial de Abancay: Especificaciones TécnicasChristian VivancoNo ratings yet

- Plano CimentaciónDocument1 pagePlano CimentaciónJeremy JayoNo ratings yet

- TECHOSDocument1 pageTECHOSCynthia Kareli Culquipoma HurtadoNo ratings yet

- Pasatubos Vigas - H10Document1 pagePasatubos Vigas - H10Jeremias VenturaNo ratings yet

- Reja perfilería metalica cierre perimetralDocument1 pageReja perfilería metalica cierre perimetralDamary Constanza Huaitro VargasNo ratings yet

- ESTRUCTURASDocument1 pageESTRUCTURASlucasNo ratings yet

- 10.im-Osi2100446-Ge013 - RLDocument1 page10.im-Osi2100446-Ge013 - RLINVERTOP GEODESIATOPOGRAFIANo ratings yet

- P-4 Fin:0+010,00Document1 pageP-4 Fin:0+010,00Pablo Andres Soto CalderónNo ratings yet

- Arv 1103 A1-01 Planta Arquitectonica de ConjuntoDocument1 pageArv 1103 A1-01 Planta Arquitectonica de ConjuntoOVIEL TORRESNo ratings yet

- 9-12. Manija San Miguel 1Document4 pages9-12. Manija San Miguel 1DR. SALOMON PEREZNo ratings yet

- Leslie Carol Chavez Lescano: Closet Cto de Bomba de Piscina Subterraneo Calentador A Gas de Piscina Escalera de GatoDocument1 pageLeslie Carol Chavez Lescano: Closet Cto de Bomba de Piscina Subterraneo Calentador A Gas de Piscina Escalera de GatoAlberto ArandaNo ratings yet

- 06 Nivel Típico Iluminación-ModelDocument1 page06 Nivel Típico Iluminación-Modelgabosansor90No ratings yet

- Mario Estr. FinalDocument2 pagesMario Estr. FinalMaylin AlvaroNo ratings yet

- Procedimiento para el manejo de zonas arboreadas y puntos de control en proyectos de infraestructuraDocument10 pagesProcedimiento para el manejo de zonas arboreadas y puntos de control en proyectos de infraestructurabladiNo ratings yet

- Bloque B-Eb-04Document1 pageBloque B-Eb-04elmer espinoNo ratings yet

- ACABADOSDocument1 pageACABADOSAKshop SnkrNo ratings yet

- Edificio deportivo de 5,027 m2Document1 pageEdificio deportivo de 5,027 m2OVIEL TORRESNo ratings yet

- Plano Cimentacion InicialDocument1 pagePlano Cimentacion InicialALBERTO LARANo ratings yet

- Estructura E1 01Document1 pageEstructura E1 01Juan Casas TovarNo ratings yet

- A-002 ArquitectonicoDocument1 pageA-002 Arquitectonicocamilo andres cutiva caraballoNo ratings yet

- Aicc CNCH 4 PK100 Eem DRW 05 10002 - 00aDocument1 pageAicc CNCH 4 PK100 Eem DRW 05 10002 - 00aALEJANDRO FLORESNo ratings yet

- Seccion Alzado: Municipalidad Provincial de HuariDocument1 pageSeccion Alzado: Municipalidad Provincial de Huarimoreno chinchayNo ratings yet

- Plano AAC - Ruta de Ductos N1Document1 pagePlano AAC - Ruta de Ductos N1Raul H CastroNo ratings yet

- Sección A3-A3 1:25: Especificaciones TécnicasDocument1 pageSección A3-A3 1:25: Especificaciones TécnicasDAMJER REY QUISPE CHANCAYAURINo ratings yet

- Plano Barandas para Buzones Rev. ADocument1 pagePlano Barandas para Buzones Rev. ARichard L Condori ChNo ratings yet

- Especificaciones técnicas para estructura metálica de menos deDocument1 pageEspecificaciones técnicas para estructura metálica de menos deRichard L Condori ChNo ratings yet

- Tapa Sanitaria: CisternaDocument1 pageTapa Sanitaria: Cisternausuario666No ratings yet

- Plano Topografico-CajabambaDocument1 pagePlano Topografico-Cajabambakeyvin acuña saucedoNo ratings yet

- LOSA DE APROXIMACION-Layout1Document1 pageLOSA DE APROXIMACION-Layout1ING.KRISS AGRAMONTENo ratings yet

- Jaula para Gases IndustrialesDocument1 pageJaula para Gases IndustrialesBELTRANNo ratings yet

- Arq 1Document1 pageArq 1Roberth RuilovaNo ratings yet

- Vivienda Residencial: Planta Aligerado 3er NivelDocument1 pageVivienda Residencial: Planta Aligerado 3er NivelErick GuttierrezNo ratings yet

- Brh-Esquemas - Peb - Sullana-Flujograma de Entregables de DiseñoDocument1 pageBrh-Esquemas - Peb - Sullana-Flujograma de Entregables de DiseñoEdgr CastilloNo ratings yet

- P.A Propuesta 3Document1 pageP.A Propuesta 3Maria De Jesus Franco RiveraNo ratings yet

- Puertas DetalleDocument1 pagePuertas DetalleKathy Alessandra Espinoza GutarraNo ratings yet

- Esquema Constructivo Alarmas y ElectricosDocument1 pageEsquema Constructivo Alarmas y ElectricosLuis Faustino Rodriguez LopezNo ratings yet

- Presupuesto de materiales para reforma de bañoDocument1 pagePresupuesto de materiales para reforma de bañoYulian PolaniaNo ratings yet

- Es0117-Ima-000-Pl-001 - 02 H1Document1 pageEs0117-Ima-000-Pl-001 - 02 H1Jose Carlos OcañaNo ratings yet

- Mapa de Nivel MorretesDocument1 pageMapa de Nivel MorretesEmerson PawoskiNo ratings yet

- P112-Planos Estructura, Intalaciones Electricas y Sanitarias PDFDocument7 pagesP112-Planos Estructura, Intalaciones Electricas y Sanitarias PDFVladimir Carrazco EnriquezNo ratings yet

- Distribucion de Planta 7Document1 pageDistribucion de Planta 7Jorge es PeredaNo ratings yet

- Planta General Sanit SG 01bDocument1 pagePlanta General Sanit SG 01bvicente arturo bautista gonzalesNo ratings yet

- LAMINA 04 - Domingo FautinoDocument1 pageLAMINA 04 - Domingo FautinosantgoeltonNo ratings yet

- Arquitectura CamerinosDocument1 pageArquitectura CamerinosShirley Leslie Bernaola PomaNo ratings yet

- Disposición General de Cañerías Correa 206 1/2Document1 pageDisposición General de Cañerías Correa 206 1/2Edder Manuel Castillo PerezNo ratings yet

- Informe Final 02Document16 pagesInforme Final 02Fabricio AquijeNo ratings yet

- Plan de Gobierno de Verónika MendozaDocument64 pagesPlan de Gobierno de Verónika Mendozafnmp11100% (1)

- Laboratorio No5 - Diseño Digital - UNMSM (2012-II)Document8 pagesLaboratorio No5 - Diseño Digital - UNMSM (2012-II)Fabricio AquijeNo ratings yet

- Arqui - Compu (Clase 12) Inst. 8086Document20 pagesArqui - Compu (Clase 12) Inst. 8086Fabricio AquijeNo ratings yet

- Ii Conversatorio Clínico PediátricoDocument5 pagesIi Conversatorio Clínico PediátricoFabricio AquijeNo ratings yet

- Round MujeresDocument14 pagesRound MujeresFabricio AquijeNo ratings yet

- Experiencia3 FisicaIIDocument17 pagesExperiencia3 FisicaIIFabricio AquijeNo ratings yet

- 1lab de Fisica IIDocument17 pages1lab de Fisica IIFabricio AquijeNo ratings yet

- Informe Previo 1Document4 pagesInforme Previo 1Fabricio AquijeNo ratings yet

- Informe Previo 1Document4 pagesInforme Previo 1Fabricio AquijeNo ratings yet

- Arbitrio 5 PDFDocument99 pagesArbitrio 5 PDFJOSÉ ALFREDO JIMÉNEZ CORREANo ratings yet

- Unidad 1 EmpresaDocument7 pagesUnidad 1 EmpresaJulia ToledoNo ratings yet

- Enclave BananeroDocument3 pagesEnclave BananeroMonica ArceNo ratings yet

- Calidad Por Valor Agregado Eje 2Document19 pagesCalidad Por Valor Agregado Eje 2alNo ratings yet

- Cerrejon Plan de Administración de Los Controles CríticosDocument19 pagesCerrejon Plan de Administración de Los Controles CríticosLEYDI CONFECCIONESNo ratings yet

- Capitulo 1-Introduccion A La Resistencia de MaterialesDocument41 pagesCapitulo 1-Introduccion A La Resistencia de MaterialesJuandavidPabónNo ratings yet

- Gruas y Operaciones de IzajeDocument32 pagesGruas y Operaciones de IzajeCarlos Diego Capcha GagoNo ratings yet

- Fabricación de geomembranasDocument5 pagesFabricación de geomembranasMisael MedinaNo ratings yet

- 09 Análisis DAFODocument37 pages09 Análisis DAFOPedro Benjamin Venegas QuezadaNo ratings yet

- Manual Transferencia de Tecnologia SostenibleDocument61 pagesManual Transferencia de Tecnologia Sosteniblecova5609100% (3)

- Primeros gobiernos de la isla de Hispaniola y control españolDocument3 pagesPrimeros gobiernos de la isla de Hispaniola y control españolescarlett dNo ratings yet

- Solicitud conformación comisión recepción actividad AIIDocument3 pagesSolicitud conformación comisión recepción actividad AIIHilder Cruz GarciaNo ratings yet

- Caso Real de Innovación EcofloraDocument21 pagesCaso Real de Innovación EcofloraÓSCAR ÁNGEL100% (1)

- Ejercicios Prácticos de Impuesto A La RentaDocument1 pageEjercicios Prácticos de Impuesto A La RentaJenny ARNo ratings yet

- Proyecto Final DocumentaciónDocument72 pagesProyecto Final DocumentaciónThomás SolisNo ratings yet

- Colonialismo en Asia y ÁfricaDocument11 pagesColonialismo en Asia y ÁfricaLuciana MojicaNo ratings yet

- Administración estratégica del mantenimiento en 4 etapasDocument15 pagesAdministración estratégica del mantenimiento en 4 etapasJESUS ALEJANDRO ABURTO MARTÍNEZNo ratings yet

- Taller de Fundamentos Del SGCDocument3 pagesTaller de Fundamentos Del SGCJorgeEspitiaDelValleNo ratings yet

- ¿Cómo Instalar El Software Isuzu G-IDSS E-IDSS - El - Herramientas OBD2 para CocheDocument8 pages¿Cómo Instalar El Software Isuzu G-IDSS E-IDSS - El - Herramientas OBD2 para CocheDenisEcheverriNo ratings yet

- 1 Modelo Expediente de Diagnóstico Técnico Legal 07.01.2022Document22 pages1 Modelo Expediente de Diagnóstico Técnico Legal 07.01.2022JUAN FERNANDO VIVEROS ZARATENo ratings yet

- Derecho A La SaludDocument22 pagesDerecho A La SaludKevin Rueda0% (1)

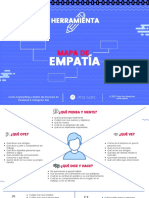

- Cuaderno Mapa de EmpatíaDocument5 pagesCuaderno Mapa de EmpatíaVictor FernandezNo ratings yet

- Trabajo Final Adm. Terminado PDFDocument9 pagesTrabajo Final Adm. Terminado PDFFanny de los SantosNo ratings yet

- APLICADocument9 pagesAPLICAGustavo Salazar TinsecNo ratings yet

- Tabla (Tiendas Departamentales)Document48 pagesTabla (Tiendas Departamentales)García Hernández Diana 4O2No ratings yet

- Parcial 1 Gestion Tranporte y Distribucion GENTILDocument8 pagesParcial 1 Gestion Tranporte y Distribucion GENTILGENTILNo ratings yet

- ITIL vs COBIT: Comparación de marcos de gestión TIDocument1 pageITIL vs COBIT: Comparación de marcos de gestión TIالله ووكر وبالله100% (1)

- Acta de Suspension de Plazo de Ejecucion de Obra FinalDocument1 pageActa de Suspension de Plazo de Ejecucion de Obra FinalFelix Vilcas GarciaNo ratings yet

- Ecologia Semana 1 Parcial 2Document2 pagesEcologia Semana 1 Parcial 2miguel chavezNo ratings yet

- Bases de DatosDocument32 pagesBases de DatosSchumacher PerezNo ratings yet