Professional Documents

Culture Documents

Design of Liquid Retaining Concrete Structures PDF

Uploaded by

zikzak2011Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Liquid Retaining Concrete Structures PDF

Uploaded by

zikzak2011Copyright:

Available Formats

Chapter 2

Basis of design and materials

2.1 Structural action

It is necessary to start a design by deciding on the type and layout of structure to be

used. Tentative sizes must be allocated to each structural element, so that an analysis

may be made and the sizes confirmed.

All liquid-retaining structures are required to resist horizontal forces due to the

liquid pressures. Fundamentally there are two ways in which the pressures can be

contained:

(i) by forces of direct tension or compression (Figure 2.1);

(ii) by flexural resistance (Figure 2.2).

Structures designed by using tensile or compressive forces are normally circular and

may be prestressed (see Chapter 4). Rectangular tanks or reservoirs rely on flexural

action using cantilever walls, propped cantilever walls or walls spanning in two direc-

tions. A structural element acting in flexure to resist liquid pressure reacts on the sup-

porting elements and causes direct forces to occur. The simplest illustration (Figure

2.3) is a small tank. Additional reinforcement is necessary to resist such forces unless

they can be resisted by friction on the soil.

2.2 Exposure classification

Structural concrete elements are exposed to varying types of environmental condi-

tions. The roof of a pumphouse is waterproofed with asphalt or roofing felt and, apart

from a short period during construction, is never externally exposed to wet or damp

conditions. The exposed legs of a water tower are subjected to alternate wetting and

drying from rainfall but do not have to contain liquid. The lower sections of the walls

of a reservoir are always wet (except for brief periods during maintenance), but the

upper sections may be alternately wet and dry as the water level varies. The underside

of the roof of a closed reservoir is damp from condensation–because of the water-

proofing on the external surface of the roof, the roof may remain saturated over its

complete depth. These various conditions are illustrated in Figure 2.4.

Experience has shown that, as the exposure conditions become more severe, pre-

cautions should be taken to ensure that moisture and air do not cause carbonation in the

concrete cover to the reinforcement thus removing the protection to the steel and caus-

ing corrosion, which in turn will cause the concrete surface to spall (Newman, 2003).

Adequate durability can normally be ensured by providing a dense well-compacted

concrete mix (see Section 2.5.2) with a concrete cover (cast against formwork) in the

10

Chapter_2.indd 10 5/9/2014 12:15:23 PM

BASIS OF DESIGN AND MATERIALS

section

section

tension compression

plan plan

a) b)

Figure 2.1 Direct forces in circular tanks. (a) Tensile forces (b) Compressive forces.

2 way span

reaction from

next panel

plan section elevation of one

panel

Figure 2.2 Direct forces of tension in wall panels of rectangular tanks.

friction friction

Figure 2.3 Tension in floor of a long tank with cantilever walls.

11

Chapter_2.indd 11 5/9/2014 12:15:23 PM

DESIGN OF LIQUID RETAINING CONCRETE STRUCTURES

waterproof membrane rain

a) b)

condensation

walls wet or dry

water level varies

walls wet

c)

Figure 2.4 Exposure to environmental conditions: (a) pumphouse roof, (b) water tower and

(c) reservoir.

Wide surface cracks

allowing moisture and

air penetration and

leakage or percolation

of liquid

Figure 2.5 Effect of cracks.

region of at least 40 mm (BS 8500-1), but it is also necessary to control cracking in

the concrete, and prevent percolation of liquid through the member (see Figure 2.5).

Previously, for design purposes, BS 8110 conveniently classified exposure in

terms of relative severity (i.e. mild, moderate, severe). However, exposure classifi-

cation in Eurocode 2 is now related to the deterioration processes, i.e. carbonation,

ingress of chlorides, chemical attack from aggressive ground and freeze/thaw. Act-

ing alongside Eurocode 2 is a more comprehensive guide, BS 8500 (Parts 1 and 2),

to assist in determining cover. For less severe exposure conditions, BS 8500 is per-

haps less onerous than BS 8110. However, for more severe conditions the require-

ments of BS 8500 are different. This is important, as BS EN 1992-3 requires that

all liquid-retaining structures should be designed for at least ‘severe’ conditions of

12

Chapter_2.indd 12 5/9/2014 12:15:24 PM

BASIS OF DESIGN AND MATERIALS

exposure. Where appropriate the ‘very severe’ and ‘extreme’ categories should be

used. As an example, a water tower near to the sea coast and exposed to salt water

spray would be designed for ‘very severe’ exposure.

As well as defining cover, durability requirements are also achieved by control-

ling cracking. For the serviceability limit state, the maximum (limiting) crack width

is between 0.05 mm and 0.2 mm, depending on the ratio of the hydrostatic pressure to

wall thickness. It should be noted that these limiting crack widths are actually equiva-

lent to total crack width, i.e. in theory, early age, long term and loading (see comments

in Chapter 1). The range of crack widths provided above is provided in BS EN 1992-3.

General guidance on crack control is provided in Section 7.3 of BS EN 1992-1-1. Addi-

tional guidance is given in BS EN 1992-3 because of the nature of the structure. Early

age thermal cracking may result in through cracks, which can lead to seepage or leak-

age. In water-retaining structures this could be deemed a failure. BS EN 1992-3 there-

fore provides a ‘Classification of Tightness’, shown below in Table 2.1. This tightness

represents the degree of protection against leakage: 0 (zero) represents general provi-

sion for crack control in-line with BS EN 1992-1-1; 3 represents no leakage permitted.

Tightness class 1 is normally acceptable for water-retaining structures.

The requirement for ‘No leakage permitted’ does not mean that the structure will

not crack but simply that the section is designed so that there are no through cracks.

There is no crack width recommendation of 0.1 mm for critical aesthetic appearance

in the new Eurocodes as there was in BS 8110. No rational basis for defining the aes-

thetic appearance of cracking exists. BS EN 1992-3 claims that for Tightness class 1

structures, limiting the crack widths to the appropriate value within the range stated

above should result in the effective sealing of the cracks within a relatively short time.

The ratios actually represent pressure gradients across the structural section. As such,

the claim that cracks of 0.2 mm will ‘heal’ provided that the pressure gradient does not

exceed 5 has not changed much to the claim in BS 8007. For crack widths of less than

0.05 mm, healing will occur even when the pressure gradient is greater than 35. The fact

that these cracks do seal is not strictly only due to autogenous healing (i.e. self-healing

due to formation of hydration products) as was claimed in BS 8007, but also possibly

due to the fact that the crack becomes blocked with fine particles. As mentioned above,

sealing under hydrostatic pressure is discussed in Clause 7.3.1 of BS EN 1992-3 and for

serviceability conditions, the limit state appropriate for water retaining structures, crack

widths are limited to between 0.05 and 0.2 mm. When considering appearance and dura-

bility, further guidance with respect to crack widths and their relationship with exposure

conditions can be found in Clause 7.3.1 of BS EN 1992-1-1 and its NA (Table NA.4).

Table 2.1 Tightness classification.

Tightness class Requirements for leakage

0 Some degree of leakage acceptable, or leakage of liquids irrelevant.

1 Leakage to be limited to a small amount. Some surface staining or damp

patches acceptable.

2 Leakage to be minimal. Appearance not to be impaired by staining.

3 No leakage permitted

13

Chapter_2.indd 13 5/9/2014 12:15:24 PM

DESIGN OF LIQUID RETAINING CONCRETE STRUCTURES

2.3 Structural layout

The layout of the proposed structure and the estimation of member sizes must precede

any detailed analysis. Structural schemes should be considered from the viewpoints

of strength, serviceability, ease of construction, and cost. These factors are to some

extent mutually contradictory, and a satisfactory scheme is a compromise, simple in

concept and detail. In liquid-retaining structures, it is particularly necessary to avoid

sudden changes in section, because they cause concentration of stress and hence

increase the possibility of cracking.

It is a good principle to carry the structural loads as directly as possible to the

foundations, using the fewest structural members. It is preferable to design cantilever

walls as tapering slabs rather than as counterfort walls with slabs and beams. The

floor of a water tower or the roof of a reservoir can be designed as a flat slab. Under-

ground tanks and swimming-pool tanks are generally simple structures with constant-

thickness walls and floors.

It is essential for the designer to consider the method of construction and to spec-

ify on the drawings the position of all construction and movement joints. This is nec-

essary as the detailed design of the structural elements will depend on the degree

of restraint offered by adjacent sections of the structure to the section being placed.

Important considerations are the provision of ‘kickers’ (or short sections of upstand

concrete) against which formwork may be tightened, and the size of wall and floor

panels to be cast in one operation.

2.4 Influence of construction methods

Designers should consider the sequence of construction when arranging the lay-

out and details of a proposed structure. At the excavation stage, and particularly on

water-logged sites, it is desirable that the soil profile to receive the foundation and

floors should be easily cut by machine. Flat surfaces and long strips are easy to form

but individual small excavations are expensive to form. The soil at foundation level

exerts a restraining force (the force develops from the restraint of early thermal contrac-

tion and shrinkage) on the structure, which tends to cause cracking (Figure 2.6). The

restraint restraint

a)

restraint restraint

b)

Figure 2.6 Cracking due to restraint by frictional forces at foundation level (a) Floor slab (b) Wall

(indicative only).

14

Chapter_2.indd 14 5/9/2014 12:15:24 PM

BASIS OF DESIGN AND MATERIALS

frictional forces can be reduced by laying a sheet of 1 000 g polythene or other suitable

material on a 75 mm layer of ‘blinding’ concrete. For the frictional forces to be reduced, it

is necessary for the blinding concrete to have a smooth and level surface finish. This can

only be achieved by a properly screeded finish, and in turn this implies the use of a grade

of concrete that can be so finished (BS 8500-1, 2006; Teychenne, 1975; Palmer, 1977).

A convenient method is to specify the same grade of concrete for the blinding layer as

is used for the structure. This enables a good finish to be obtained for the blinding layer,

and also provides an opportunity to check the strength and consistency of the concrete at

a non-critical stage of the job. It also reduces the nominal cover, cnom (BS 8500-1, 2006).

The foundations and floor slabs are constructed in sections that are of a convenient

size and volume to enable construction to be finished in the time available. Sections

terminate at a construction or movement joint (Chapter 5). The construction sequence

should be continuous as shown in Figure 2.7(a) and not as shown in Figure 2.7(b).

By adopting the first system, each section that is cast has one free end and is enabled

to shrink on cooling without end restraint (a day or two after casting), although edge

restraint will still exist (see Chapters 1 and 5). With the second method, considerable

tensions are developed between the relatively rigid adjoining slabs.

Previously, BS 8007 provided three design options for the control of thermal con-

traction and restrained shrinkage: continuous (full restraint), semi-continuous (partial

restraint) and total freedom of movement. On the face of it, it appears that BS EN 1992-3

does not allow semi-continuous design and therefore partial contraction joints have been

excluded. Therefore, Part 3 only offers two options: full restraint (no movement joints)

and free movement (minimum restraint). For the condition of free movement, Part 3 rec-

ommends that complete joints (free contraction joints) are spaced at the greater of 5 m

or 1.5 times the wall height. (This is similar to the maximum crack spacing of a wall,

given in BS EN 1992-1-1 Section 7, with no or less than As, min bonded reinforcement

within the tension zone, i.e. 1.3 times the height of the wall.) However, BS EN 1992-3

also states ‘a moderate amount of reinforcement is provided sufficient to transmit any

movements to the adjacent joint’. This appears contradictory. Hence continuity steel,

less than As, min is still permitted and semi-continuous joints are therefore still allowed.

1 2 3

a)

1 3 2

b)

restraint cracking restraint

c)

Figure 2.7 Construction sequence (a) Preferred sequence (b) Not recommended (c) Effect of

method (b) on third slab panel (cracks shown are illustrative only).

15

Chapter_2.indd 15 5/9/2014 12:15:24 PM

You might also like

- Pile Cap Design at AbutmentDocument4 pagesPile Cap Design at AbutmentAzwani Abdullah100% (1)

- RC Retaining Wall NoteDocument17 pagesRC Retaining Wall NoteMat Zoul100% (2)

- Cracks in Immature Concrete PDFDocument2 pagesCracks in Immature Concrete PDForode franklynNo ratings yet

- Concrete BundsDocument12 pagesConcrete BundsPaul JamesonNo ratings yet

- Analysis and Design of Circular Prestressed Concrete Storage TanksDocument22 pagesAnalysis and Design of Circular Prestressed Concrete Storage TanksLau Kim HwaNo ratings yet

- Bearing CapacityDocument54 pagesBearing CapacityMasood AhmedNo ratings yet

- Pit Side Wall and Base Slab CalculationDocument2 pagesPit Side Wall and Base Slab CalculationJahid HasnainNo ratings yet

- BS 5328-1 - 1997Document28 pagesBS 5328-1 - 1997ماقوريNo ratings yet

- 6 Plate Girder BridgesDocument13 pages6 Plate Girder BridgesEshan GuptaNo ratings yet

- Bs12 PDFDocument15 pagesBs12 PDFraed waheebNo ratings yet

- Eurocode 4: Design of Composite Steel and Concrete StructuresDocument19 pagesEurocode 4: Design of Composite Steel and Concrete StructuresGautam BudhNo ratings yet

- Digest 365 - Soakaway Design (2007)Document8 pagesDigest 365 - Soakaway Design (2007)maanurayaNo ratings yet

- Tank Ring Wall Foundation+&+Annular+RaftDocument12 pagesTank Ring Wall Foundation+&+Annular+Raftasghar750% (2)

- Design of Reinforced Concrete FoundationsDocument16 pagesDesign of Reinforced Concrete Foundationsanirbanpwd76No ratings yet

- Control Thermal Cracking Concrete StructuresDocument5 pagesControl Thermal Cracking Concrete StructuresAnuraNo ratings yet

- Design For 11early Thermal CrackingDocument9 pagesDesign For 11early Thermal CrackingdhruvgokuNo ratings yet

- Water Tank Design (Aci 318-05)Document8 pagesWater Tank Design (Aci 318-05)arnoldNo ratings yet

- PDFDocument3 pagesPDF6BisnagaNo ratings yet

- Overhead Crane Runway Design ConsiderationsDocument2 pagesOverhead Crane Runway Design ConsiderationsapirakqNo ratings yet

- Is 9103 2004Document17 pagesIs 9103 2004Nafeez Ahmed100% (2)

- Why Structural Designs Vary: Common Issues and Best PracticesDocument2 pagesWhy Structural Designs Vary: Common Issues and Best Practicesraj_anu130% (1)

- Indian Codes - Concrete Design PerDocument7 pagesIndian Codes - Concrete Design Peribrahim100% (1)

- Early Thermal Cracking ConcreteDocument13 pagesEarly Thermal Cracking ConcreteOttawa Canada100% (2)

- KDS 41 17 00 건축물 내진설계기준Document131 pagesKDS 41 17 00 건축물 내진설계기준colt0No ratings yet

- Rock Anchor DesignDocument2 pagesRock Anchor Designraj.karanNo ratings yet

- BS 8500 Cement Concrete RequirementsDocument2 pagesBS 8500 Cement Concrete RequirementsLava Sat100% (2)

- RCC Chimney - CICIND CommentaryDocument65 pagesRCC Chimney - CICIND CommentaryVasanth KumarNo ratings yet

- Residential Masonry Structures on Problem SoilsDocument14 pagesResidential Masonry Structures on Problem SoilsrealchicNo ratings yet

- RETAINING WALL DESIGNDocument27 pagesRETAINING WALL DESIGNAjay Kumar GuptaNo ratings yet

- Plate Girder DesignDocument109 pagesPlate Girder Designhasib100% (3)

- 1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandDocument79 pages1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandRianto FelissimoNo ratings yet

- Aci Design PDFDocument91 pagesAci Design PDFSufyan SafiNo ratings yet

- Checks For CompactnessDocument15 pagesChecks For CompactnessjologscresenciaNo ratings yet

- Use of BS 5950Document3 pagesUse of BS 5950Smr Only100% (1)

- 2911 (Part 4) 2013Document16 pages2911 (Part 4) 2013Sangram keshari bejaNo ratings yet

- DIPRA Truck Loads On Pipe Buried at Shallow DepthsDocument5 pagesDIPRA Truck Loads On Pipe Buried at Shallow Depthshussien_azahariNo ratings yet

- BS 3148 1980 PDFDocument11 pagesBS 3148 1980 PDFAnoyNo ratings yet

- Block Pavement Design v5 PDFDocument5 pagesBlock Pavement Design v5 PDFsyaifullah88No ratings yet

- Design of Liquid Retaining Concrete StructuresDocument6 pagesDesign of Liquid Retaining Concrete StructuresmoorhouseNo ratings yet

- CVS 416 Notes - 2016-17Document70 pagesCVS 416 Notes - 2016-17Victor KemeiNo ratings yet

- Reinforced Concrete Beam DeflectionsDocument25 pagesReinforced Concrete Beam DeflectionsashenafiNo ratings yet

- Chapter Two Materials and PropertiesDocument15 pagesChapter Two Materials and PropertiesAdel KhalilNo ratings yet

- Thermal Concrete CrackingDocument7 pagesThermal Concrete Crackingignacio_vazquez_18No ratings yet

- Art Sol-FondationDocument7 pagesArt Sol-FondationMouhammed AbdallahNo ratings yet

- Khodaie Et Al-ACI Spring 2016Document13 pagesKhodaie Et Al-ACI Spring 2016erosNo ratings yet

- 62 Determination Load Sharing Effects Sprayed Concrete Tunnel LiningsDocument8 pages62 Determination Load Sharing Effects Sprayed Concrete Tunnel Liningsp_ignatiusNo ratings yet

- 62 Determination Load Sharing Effects Sprayed Concrete Tunnel LiningsDocument8 pages62 Determination Load Sharing Effects Sprayed Concrete Tunnel LiningsMAPV1945No ratings yet

- Chap. 4Document50 pagesChap. 4gossayeNo ratings yet

- Izni 202Document24 pagesIzni 202shahrilzainul77No ratings yet

- Bridge Deck Construction GuideDocument21 pagesBridge Deck Construction Guide4chi11esNo ratings yet

- Chapter Six First Semester 2020-2021Document22 pagesChapter Six First Semester 2020-2021Khaled AlomariNo ratings yet

- Understanding The Complexities of Designing Diaphragms in Buildings For EarthquakesDocument21 pagesUnderstanding The Complexities of Designing Diaphragms in Buildings For Earthquakesjunhe898No ratings yet

- Water - Retaining StructuresDocument26 pagesWater - Retaining StructuresManuel Alberto PeñarandaNo ratings yet

- Desing Criteria For A Controlled DemolitionDocument12 pagesDesing Criteria For A Controlled Demolitionajmc1No ratings yet

- 46 Dam Constructions 0Document33 pages46 Dam Constructions 0Chaitanya KumbharNo ratings yet

- IMPLICATION OF UNBONDEDNESSDocument13 pagesIMPLICATION OF UNBONDEDNESSFatima KhalidNo ratings yet

- BS 8500 For Building Structures: Concrete Design InformationDocument8 pagesBS 8500 For Building Structures: Concrete Design Informationroyal_eagle04No ratings yet

- Seminar On Causes, Evaluation, and Repair of Cracks in Concrete StructuresDocument31 pagesSeminar On Causes, Evaluation, and Repair of Cracks in Concrete StructuresSyed Mohd MehdiNo ratings yet

- Design Formula For EC2 Version 04 UTMDocument23 pagesDesign Formula For EC2 Version 04 UTMJackieSimNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- ReadmeDocument5 pagesReadmeAnonymous 1nwZ5xiTDNo ratings yet

- Answer Key en 000Document4 pagesAnswer Key en 000Tylin Vong100% (1)

- Deformation According To Dead Load CaseDocument14 pagesDeformation According To Dead Load Casezikzak2011No ratings yet

- TCC33X Flat SlabsDocument52 pagesTCC33X Flat SlabsEnrike GarciaNo ratings yet

- Cum Activezi Autocad 2014Document1 pageCum Activezi Autocad 2014AlexysNo ratings yet

- CPD 2015121Document60 pagesCPD 2015121Benny LinNo ratings yet

- Foundation Profile & Soil ConditionsDocument1 pageFoundation Profile & Soil Conditionszikzak2011No ratings yet

- Bulats Sample Paper - En001Document32 pagesBulats Sample Paper - En001mome85No ratings yet

- RCCe11 Element DesignDocument9 pagesRCCe11 Element Designrelu59No ratings yet

- Compdyn 2011 PaperDocument19 pagesCompdyn 2011 Paperzikzak2011No ratings yet

- Complete RCC Design Very ImportantDocument41 pagesComplete RCC Design Very ImportantAmal PremachandranNo ratings yet

- Design and Cost Comparison Between Frame & Shear Walls Structural Systems For Multi Story BuildingsDocument21 pagesDesign and Cost Comparison Between Frame & Shear Walls Structural Systems For Multi Story Buildingszikzak2011No ratings yet

- Aplimat2017 Musil Sivy Chlebo ProkopDocument13 pagesAplimat2017 Musil Sivy Chlebo Prokopzikzak2011No ratings yet

- Paper Comparativa AISC-EC PDFDocument18 pagesPaper Comparativa AISC-EC PDFJhonny AlvarezNo ratings yet

- Simplified Seismic Analysis Procedures For Elevated TanksDocument19 pagesSimplified Seismic Analysis Procedures For Elevated TanksCesar Yoshio Sanchez HuchiyamaNo ratings yet

- Tanks Lecture 3Document70 pagesTanks Lecture 3zikzak2011No ratings yet

- Bulats Writing Part Two Useful Phrases For ReportsDocument3 pagesBulats Writing Part Two Useful Phrases For ReportsZubair Lone100% (1)

- M8MSESE EWT FRAMEStaging CircularColumns 04december2012Document13 pagesM8MSESE EWT FRAMEStaging CircularColumns 04december2012zikzak2011No ratings yet

- Seismic Performance of Circular Elevated Water Tank: Rupachandra J. Aware, Dr. Vageesha S. MathadaDocument6 pagesSeismic Performance of Circular Elevated Water Tank: Rupachandra J. Aware, Dr. Vageesha S. Mathadazikzak2011No ratings yet

- Parametric Study of RCC Staging (Support Structure) For Overhead Water Tanks As Per 1s-811682-1985 and Is-3370-Ijaerdv04i0159905Document5 pagesParametric Study of RCC Staging (Support Structure) For Overhead Water Tanks As Per 1s-811682-1985 and Is-3370-Ijaerdv04i0159905Editor IJAERDNo ratings yet

- Sgem 2013Document9 pagesSgem 2013Zitheeq UmarNo ratings yet

- Design of Water Retaining Structures To ECDocument44 pagesDesign of Water Retaining Structures To ECVincent Teng100% (4)

- INCAM 2017 Paper 246Document5 pagesINCAM 2017 Paper 246zikzak2011No ratings yet

- Ijems 14 (2) 2007 133-145Document13 pagesIjems 14 (2) 2007 133-145zikzak2011No ratings yet

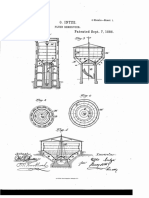

- Intze. Fluid Reservoir. 'NO. 348,912. Patented Sept. 7, 1886Document7 pagesIntze. Fluid Reservoir. 'NO. 348,912. Patented Sept. 7, 1886zikzak2011No ratings yet

- Design of Overhead Circular Water Tank With Flat Base: Presented ByDocument12 pagesDesign of Overhead Circular Water Tank With Flat Base: Presented Byzikzak2011No ratings yet

- Watertank GS PDFDocument24 pagesWatertank GS PDFManoj RautNo ratings yet

- Parametric Study of RCC Staging (Support Structure) For Overhead Water Tanks As Per 1s-811682-1985 and Is-3370-Ijaerdv04i0159905Document5 pagesParametric Study of RCC Staging (Support Structure) For Overhead Water Tanks As Per 1s-811682-1985 and Is-3370-Ijaerdv04i0159905Editor IJAERDNo ratings yet

- Simplified Seismic Analysis Procedures For Elevated TanksDocument19 pagesSimplified Seismic Analysis Procedures For Elevated TanksCesar Yoshio Sanchez HuchiyamaNo ratings yet

- Fresnel Equations and Light GuidingDocument33 pagesFresnel Equations and Light GuidingMehdi RabbaniNo ratings yet

- Worzakowska2016 Article ThermalBehaviorDecompositionMeDocument10 pagesWorzakowska2016 Article ThermalBehaviorDecompositionMeJavier Andres Munoz ChavesNo ratings yet

- Mass SpecDocument42 pagesMass SpecChilotaw MulukenNo ratings yet

- FARHAT - Microondas Livre de Solvente e AssistidaDocument38 pagesFARHAT - Microondas Livre de Solvente e AssistidaAnderson LuizNo ratings yet

- Adhesive RecSecondary TBDocument1 pageAdhesive RecSecondary TBAleksandr TsymbalNo ratings yet

- Flow Chart of Pouch, Cylinder and Coin Cell by MTI's Battery EquipmentDocument6 pagesFlow Chart of Pouch, Cylinder and Coin Cell by MTI's Battery EquipmenthcaNo ratings yet

- Membrane Reactor by Shivani MunishwarDocument32 pagesMembrane Reactor by Shivani MunishwarShivani MunishwarNo ratings yet

- PCC Technova Series CPL Cylindrical ValvesDocument5 pagesPCC Technova Series CPL Cylindrical ValvesAnju VijayanNo ratings yet

- Evs Unit 3 (2020)Document16 pagesEvs Unit 3 (2020)Testing FunNo ratings yet

- CorrosionDocument4 pagesCorrosionTotis TotosNo ratings yet

- Megin M 44WDocument2 pagesMegin M 44WRadoi RaduNo ratings yet

- Prediction of Defects in Antifriction Bearings Using Vibration Signal AnalysisDocument5 pagesPrediction of Defects in Antifriction Bearings Using Vibration Signal AnalysisdossokyNo ratings yet

- Lab 3 Drug Analysis and DNA ExtractionDocument12 pagesLab 3 Drug Analysis and DNA ExtractionBeaNo ratings yet

- Materials 12 02972Document13 pagesMaterials 12 02972ade muchlasNo ratings yet

- Sch3u7 - Stoichiometry Review NotesDocument11 pagesSch3u7 - Stoichiometry Review Noteskartika.pranotoNo ratings yet

- Michael Atiyah - Kelvin Lecture: Solitons - A New Paradigm in Mathematical PhysicsDocument13 pagesMichael Atiyah - Kelvin Lecture: Solitons - A New Paradigm in Mathematical PhysicsVing666789No ratings yet

- Trace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence DetectionDocument5 pagesTrace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence Detectiontribo technicalNo ratings yet

- Handbook of Polymeric Foams and Foam Technology: HanserDocument10 pagesHandbook of Polymeric Foams and Foam Technology: Hanserfreidor0% (2)

- Handwritten IP 1 U 1 NOTESDocument16 pagesHandwritten IP 1 U 1 NOTESapple crazypineappleNo ratings yet

- Yr 8 Textbook Answer Keys (F To G)Document11 pagesYr 8 Textbook Answer Keys (F To G)Faheem BhaimedNo ratings yet

- Drew XP Lube Oil Five Test Kit Manual R0Document22 pagesDrew XP Lube Oil Five Test Kit Manual R0Gaurav100% (1)

- Steady Flow Past a Cylinder SimulationDocument11 pagesSteady Flow Past a Cylinder SimulationSoumya Satyakanta SethiNo ratings yet

- M.M. : 35 DPP # 04 TIME : 30 MINDocument2 pagesM.M. : 35 DPP # 04 TIME : 30 MINArjun SabnisNo ratings yet

- Chapter 8 Materials of ConstructionDocument9 pagesChapter 8 Materials of ConstructionMartin UribeNo ratings yet

- Exp.06 Preparation of P-Bromo AcetanilideDocument3 pagesExp.06 Preparation of P-Bromo AcetanilideAnanda VijayasarathyNo ratings yet

- Food Additives and PreservativesDocument5 pagesFood Additives and PreservativesNur Adibah JalaluddinNo ratings yet

- An Experimental Investigation of An Ejector Operating With R245faDocument6 pagesAn Experimental Investigation of An Ejector Operating With R245famhdmkNo ratings yet

- Chart 2Document1 pageChart 2Phoebe Sedantes100% (1)

- Chem Lab Report Copper and ZincDocument6 pagesChem Lab Report Copper and ZincwendyNo ratings yet

- Astm G115-10Document13 pagesAstm G115-10ABC100% (2)