Professional Documents

Culture Documents

Arc Welding Safe Work Procedure

Uploaded by

Yoga Pradipta0 ratings0% found this document useful (0 votes)

90 views2 pagesThis document provides a safe work procedure for arc welding. It lists required personal protective equipment including safety eyewear, footwear, gloves, hearing protection, apron, welding bib, and welding helmet. It describes 7 steps of the welding process and identifies hazards at each step such as electric shock, burns, injuries from falling or dropping equipment. Controls are provided to mitigate each hazard, such as using insulation, protective clothing, ventilation, and ensuring equipment is grounded and in good condition.

Original Description:

Original Title

Arc Welding.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a safe work procedure for arc welding. It lists required personal protective equipment including safety eyewear, footwear, gloves, hearing protection, apron, welding bib, and welding helmet. It describes 7 steps of the welding process and identifies hazards at each step such as electric shock, burns, injuries from falling or dropping equipment. Controls are provided to mitigate each hazard, such as using insulation, protective clothing, ventilation, and ensuring equipment is grounded and in good condition.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

90 views2 pagesArc Welding Safe Work Procedure

Uploaded by

Yoga PradiptaThis document provides a safe work procedure for arc welding. It lists required personal protective equipment including safety eyewear, footwear, gloves, hearing protection, apron, welding bib, and welding helmet. It describes 7 steps of the welding process and identifies hazards at each step such as electric shock, burns, injuries from falling or dropping equipment. Controls are provided to mitigate each hazard, such as using insulation, protective clothing, ventilation, and ensuring equipment is grounded and in good condition.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

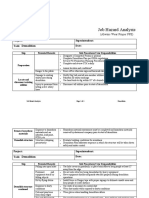

MAST

Safe Work Procedure

Division: Analysis By: Date:

Department: Supervisor: Frequency:

Job Title: Approved By: JSA Number:

Job Title: 71 Arc Welding (RRC) Job Performed By:

REQUIRED PERSONAL PROTECTIVE EQUIPMENT: Safety Eyewear, Safety Footwear, Leather Gloves, Hearing Protection, Apron, Welding Bib, Full-

face Welding Helmet

GENERAL NOTES:

JOB SAFETY ANALYSIS:

Step Description Hazard Controls

1 Set up workpiece on fixture a) Strain/sprain from heavy and/or a) Use mechanical hoist or get assistance from co-worker to set-up/

awkward workpiece--b) Foot injury from adjust workpiece--b) Wear recommended footwear. Ensure

dropping workpiece--c) Trip/fall in area workpiece is securely clamped to fixture--c) Clean/clear work

around Arc Welding workstation--d) area/surfaces of unused tools/materials. Remove dust/debris.--d)

Damage to workpiece from incorrect set- Workpiece should be clean and secure to fixture--e) Wear

up--e) Hand/finger laceration from edge recommended gloves when handling workpieces with sharp edges--f)

of workpiece--f) Hand/finger contusion Use correct tool and wear recommended gloves

from tool slippage while tightening fixture

2 Install electrode rod into torch Electric shock/burn from electrode rod Ensure Arc Welding machine power to arc is electrically de-energized

when changing electrical rod

3 Energize and set Arc Welding a) Electrical shock/burn from contact with a) Ensure welding machine is properly grounded. Welder should be

Machine amperage/ current electrode rod holder--b) Damage to insulated from live electrical parts and dry. Inspect and replace

workpiece from incorrect cables, plugs and leads that show any signs of defects. Wear

amperage/current recommended gloves and clothing.--b) Refer to Op Sheet and/or

Shop Order for correct amperage/current--

Page 1 of 2 Print Date: Jan/25/2008

4 Turn on gas and set flow a) Damage to workpiece from incorrect a) Consult Op Sheet and/or Shop Order for correct flow rate--b)

gas flow rate--b) Bodily injury from Practice caution around compressed gas cylinders. Protect gas

explosion of compressed gas cylinder-- cylinders from excessive heat, mechanical shocks and arcs. Ensure

cylinder is insulated and fastened so it will not fall. Do not use a

compressed gas cylinder that appears to be damaged and/or

defective.--

5 Weld workpiece a) Eye injury from welding flash and/or a) Wear welding helmet with proper grade of filter plate. Ensure

spatter--b) Burns from welding spatter, flash curtains/barriers are used to protect bystanders/observers--b)

UV/infrared radiation and/or electrical Wear recommended protective clothing. Ensure any exposed skin is

contact--c) Inhalation of welding fumes or covered during the welding process. Do not wear metal jewelry and

asphyxiation from displaced oxygen--d) clothing with cuffs and/or pockets. Stay a safe distance away from

Bodily injury from condition or type of arc--c) Use local exhaust ventilation and a fan to maintain good air

workpiece being welded--e) Electrical circulation--d) Do not weld workpiece unless it is properly cleaned--e)

shock hazard--f) Hearing loss from Ensure welding machine is properly grounded. Welder should be

chronic exposure to noisy machinery--g) insulated from live electrical parts and dry. Do not weld when wet.

Fire due to combustible material in Inspect and replace cables, plugs and leads that show any signs of

welding area--h) Hand/finger contact defect.--f) Wear hearing protection--g) Remove any combustible

burn from hot electrode rod material from the immediate welding site. Keep a fire extinguisher

readily available.--h) When electrode rod gets too short, stop welding

and restart with a new electrode rod. Wear recommended gloves.--

6 Complete welding a) Electrical shock/burn or electrical Ensure Arc Welding machine power to arc is electrically de-energized.

contact with conducting objects, When not in use electrode rod should be removed from holder and

flammable liquids and/or compressed gas holder should be placed so it cannot make electrical contact with

cylinders due to energized electrode rod conducting objects, flammable liquids and/or compressed gas

holder cylinders.

7 Remove workpiece from fixture a) Strain/sprain from heavy and/or a) Use mechanical hoist or get assistance from co-workers to

and transport to inspection awkward workpiece--b) Foot injury from transport workpiece--b) Wear recommended footwear. Ensure

dropping workpiece--c) Trip/fall in area workpiece is securely clamped to fixture--c) Clean/clear work

around Arc Welding workstation--d) area/surfaces of unused tools/materials. Remove dust/debris

Hand/finger laceration from edge of regularly--d) Wear recommended gloves when handling workpieces

workpiece--e) Hand/finger contusion from with sharp edges--e) Use correct tool and wear recommended gloves

tool slippage

AUTHORIZED EMPLOYEE INFORMATION:

ID NUMBER: LAST NAME: FIRST NAME: REMARKS:

JOB HISTORY INFORMATION:

DATE: REMARKS:

Approval Signature: Date:

Page 2 of 2 Print Date: Jan/25/2008

You might also like

- Arc Welding - JSADocument6 pagesArc Welding - JSAdroffilcz27No ratings yet

- MachineGuardingSopTech 31Document1 pageMachineGuardingSopTech 31muthuswamy77No ratings yet

- Rocky Mountain Safety ProceduresDocument5 pagesRocky Mountain Safety ProceduresSAMUEL POBRENo ratings yet

- ExcavationDocument3 pagesExcavationprasanna ok100% (1)

- AttachmentDocument12 pagesAttachmentChung TrịnhNo ratings yet

- Safe Work ProcedureDocument5 pagesSafe Work ProcedureSurya Narayan MahapatraNo ratings yet

- WELDING AND CUTTING SAFETYDocument14 pagesWELDING AND CUTTING SAFETYinfos2magi856No ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Maintain Safe Piling RigsDocument12 pagesMaintain Safe Piling RigsashutoshNo ratings yet

- Cable Laying Safety MeasuresDocument5 pagesCable Laying Safety MeasuresDwitikrushna RoutNo ratings yet

- Fabrication and welding works safetyDocument3 pagesFabrication and welding works safetyMohamedSaidNo ratings yet

- NSCI Awards 2018 ApplicationDocument7 pagesNSCI Awards 2018 ApplicationJason Smith100% (1)

- JHA for Potentially Hazardous CratesDocument4 pagesJHA for Potentially Hazardous CratesTnarg RagawNo ratings yet

- Warehouse Job Hazard AssessmentDocument2 pagesWarehouse Job Hazard AssessmentAnonymous cuHV7lTNo ratings yet

- ABC's of Fall Protection: Murray State University Susan MillerDocument24 pagesABC's of Fall Protection: Murray State University Susan MillerSam SalesNo ratings yet

- Jsa of Solvent Filling in VarnishesDocument3 pagesJsa of Solvent Filling in VarnishesMuhammad AliNo ratings yet

- Lifting Fixing of GI SheetDocument1 pageLifting Fixing of GI SheetJack PNo ratings yet

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREmalimsaidi_160040895No ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith sNo ratings yet

- Confined Space SapDocument2 pagesConfined Space SapfairusNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- JOB SAFETY PLAN Replacement of CylinderDocument2 pagesJOB SAFETY PLAN Replacement of CylinderMaxi ProNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- PPE Training PresentationDocument65 pagesPPE Training PresentationIsizwa WorkshopNo ratings yet

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- JsaDocument10 pagesJsaTanzeel LiaqatNo ratings yet

- Risk Assessment: Kitchen - HomeDocument5 pagesRisk Assessment: Kitchen - HomesonofoddinNo ratings yet

- Officeriskassess 260109Document1 pageOfficeriskassess 260109api-330763254No ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument11 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- Safety Alert 49 - Cable Pulling IncidentDocument1 pageSafety Alert 49 - Cable Pulling IncidentTareq Ziad KhalifaNo ratings yet

- Forklift Jha Move Pallets Loads Around YardDocument5 pagesForklift Jha Move Pallets Loads Around YardAhsan IqbalNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- JHA for Hill Cutting Activities at Port of SalalahDocument8 pagesJHA for Hill Cutting Activities at Port of SalalahSreekumarNo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingmuthuswamy77No ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- SWP 01 - Delivery, Unloading, Storage and Transferring of MaterialsDocument3 pagesSWP 01 - Delivery, Unloading, Storage and Transferring of MaterialsGerald Wong Ntt100% (1)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- Sources Risks Workers Health SafetyDocument8 pagesSources Risks Workers Health SafetyRahulNo ratings yet

- Explanatory and Illustrative Purposes Only: Appendix 6 - HSE Hazards & Effects Management ProcessDocument7 pagesExplanatory and Illustrative Purposes Only: Appendix 6 - HSE Hazards & Effects Management ProcessRonald AranhaNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNo ratings yet

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocument3 pagesRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- Nebosh Igc 3 Report-1-1 - 1Document17 pagesNebosh Igc 3 Report-1-1 - 1Muhammad ShahzaibNo ratings yet

- Welding and Cutting SafetyDocument22 pagesWelding and Cutting SafetyyawarhassanNo ratings yet

- Dr. Nirali Patel Pediatric Emergency MedicineDocument31 pagesDr. Nirali Patel Pediatric Emergency Medicinemarsan12No ratings yet

- 71 Arc Welding - Job Procedure - 2Document3 pages71 Arc Welding - Job Procedure - 2Angga EHSKOINNo ratings yet

- Arc Welding Safe Work ProcedureDocument3 pagesArc Welding Safe Work ProcedureAdilMunirNo ratings yet

- Safe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety AnalysisDocument2 pagesSafe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety Analysisrazed86No ratings yet

- Vertical Jaw Relation Recording MethodsDocument17 pagesVertical Jaw Relation Recording MethodsHarish VsNo ratings yet

- Li-ION Battery Charger FeaturesDocument2 pagesLi-ION Battery Charger Featureshariyadi aryoNo ratings yet

- Operator Manual T2100-ST2 - ST1Document50 pagesOperator Manual T2100-ST2 - ST1Nurul FathiaNo ratings yet

- Instrument To Be CalibratedDocument3 pagesInstrument To Be Calibratedsumit chauhanNo ratings yet

- Analytical Mechanics SolutionsDocument193 pagesAnalytical Mechanics SolutionsQuinton Boltin67% (9)

- Demo DLLDocument2 pagesDemo DLLArlene Diokno100% (1)

- Gas Turbine Performance Enhancement Update: GE Energy ServicesDocument45 pagesGas Turbine Performance Enhancement Update: GE Energy Servicesesteban100% (1)

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocument3 pagesRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNo ratings yet

- Kaustubh Laturkar Fuel Cell ReportDocument3 pagesKaustubh Laturkar Fuel Cell Reportkos19188No ratings yet

- Variants of NormalDocument9 pagesVariants of NormalFaizah HannyNo ratings yet

- ASSEMBLING COMPUTER: HOW TO BUILD A PCDocument48 pagesASSEMBLING COMPUTER: HOW TO BUILD A PCCeejaay PelinaNo ratings yet

- CIVL-365 Tutorial 8 SolutionDocument3 pagesCIVL-365 Tutorial 8 SolutionIvsNo ratings yet

- List of Computer Networking DevicesDocument1 pageList of Computer Networking Deviceskamit17102900100% (1)

- Tramadol Drug StudyDocument1 pageTramadol Drug Studymilkv82% (11)

- Approach To Malabsorption (SANJAY)Document58 pagesApproach To Malabsorption (SANJAY)Sanjay KumarNo ratings yet

- Applied Acoustics: André M.N. Spillere, Augusto A. Medeiros, Julio A. CordioliDocument13 pagesApplied Acoustics: André M.N. Spillere, Augusto A. Medeiros, Julio A. CordioliAbdelali MoumenNo ratings yet

- M. Valerio Assignment 6.1Document1 pageM. Valerio Assignment 6.1Mark Kristian ValerioNo ratings yet

- Arihant 40 Days Crash Course For JEE Main Physics (Crackjee - Xyz)Document464 pagesArihant 40 Days Crash Course For JEE Main Physics (Crackjee - Xyz)Milan Dai50% (4)

- Mycotoxin Test ProcedureDocument3 pagesMycotoxin Test ProcedureKishenthi KerisnanNo ratings yet

- ASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesDocument1 pageASME B31.4-2016 Pipeline Transportation Systems For Liquids and SlurriesJose Rodrigo Salguero DuranNo ratings yet

- Blues, Rock and Americana MixDocument4 pagesBlues, Rock and Americana MixLuis CrownNo ratings yet

- Margot's Cafe MenuDocument1 pageMargot's Cafe Menumichael_burns_24No ratings yet

- Parameters Governing Predicted and Actual RQD Estimation - FINAL - PUBLISHED - VERSIONDocument14 pagesParameters Governing Predicted and Actual RQD Estimation - FINAL - PUBLISHED - VERSIONKristian Murfitt100% (1)

- Akshay 71 Seminar ReportDocument22 pagesAkshay 71 Seminar ReportSanket Yadav25% (4)

- Borneo SporenburgDocument2 pagesBorneo SporenburgDorin TecuceanuNo ratings yet

- Wyoming County Fair (2022)Document20 pagesWyoming County Fair (2022)Watertown Daily TimesNo ratings yet

- Abbey Pain Scale assessment toolDocument2 pagesAbbey Pain Scale assessment toolMuhammad RezgiaNo ratings yet

- Chapter 5 Coordinate GeometryDocument33 pagesChapter 5 Coordinate GeometryKalNo ratings yet

- Dod EngDocument2 pagesDod Engvk4415003No ratings yet

- 10 01 Breather Filters GBDocument8 pages10 01 Breather Filters GBosuengNo ratings yet