Professional Documents

Culture Documents

Ford We 910 - 2001

Uploaded by

Jason-chungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ford We 910 - 2001

Uploaded by

Jason-chungCopyright:

Available Formats

WORLDWIDE FASTENER STANDARD Date: 2001-01-10

WE 910 DIMENSIONAL REQUIREMENTS FOR HEXAGON AND FLANGED HEXAGON NUTS

1. SCOPE

This standard gives the general and dimensional requirements for hexagon (M4 - M24), flanged

hexagon (M5 - M20), and hexagon thin nuts (M4 - M24).

NOTE: The dimensions specified in Table 1 are not suitable for property classes 9 and 12. The

requirements for Nut and Washer Assemblies are specified in WE 901.

2. REFERENCES

ISO 261 - General purpose metric screw threads - General plan.

ISO 965 - General purpose metric screw threads - Tolerances.

ISO 1502 - General purpose metric screw threads - Gauging.

ISO 1302 - Technical drawings - method of indicating surface roughness.

ISO 4288 - Rules and procedures for the measurement of surface roughness parameters using

stylus instruments.

WE 901 - General requirements for nut and washer assemblies.

WX 100 - Finish Specification

3. GENERAL REQUIREMENTS

3.1 DIMENSIONS AND TOLERANCES

The dimensions and tolerances of hexagon, flanged hexagon, and hexagon thin nuts must

be in accordance with Clauses 1 - 6, Tables 1 - 4, and Figures 1 - 3.

3.2 GAUGING (REFEREE METHOD)

For referee purposes, dimensions e, Ta, m' and c are satisfied if flanged hexagon nuts meet

the requirements for gauging specified in the Appendix.

4. SCREW THREADS

4.1 DIMENSIONS AND TOLERANCES

Screw threads must conform to the dimensions and tolerances specified in ISO 261 and

ISO 965 thread tolerance class 6H.

4.2 GAUGING

Nuts shall assemble on a GO thread plug gauge. The gauge must conform to the

dimensions and tolerances defined in ISO 1502 appropriate to the specified thread size and

class of fit.

When coated with organic type coatings tightness to inspection gauges may be

experienced, see WX 100.

5. FORM AND POSITION TOLERANCES

5.1 CONCENTRICITY OF HEXAGON TO THREAD

The concentricity of the outside diameter of the flanged portion to the thread shall be within

the values specified in Table 4.

5.2 CONCENTRICITY OF FLANGED PORTION TO THREAD

The concentricity of the outside diameter of the flanged portion to the thread shall be within

the values specified in Table 4.

Printed copies are uncontrolled. Page 1 of 6

Copyright © 2001, Ford Global Technologies, Inc.

WORLDWIDE FASTENER STANDARD Date: 2001-01-10

WE 910 DIMENSIONAL REQUIREMENTS FOR HEXAGON AND FLANGED HEXAGON NUTS

5.3 SQUARENESS OF THE BEARING SURFACE TO THE THREAD

5.3.1 HEXAGON NUTS

Both bearing surfaces shall be flat and perpendicular to the axis of the thread

o

within 1 .

5.3.2 HEXAGON FLANGED NUTS

o

The bearing surface shall be flat to concave to a maximum of 1.5 from the plane

formed by the bearing circle diameter (dw). The plane formed by the bearing

o

circle diameter shall be perpendicular to the thread within 1 .

5.4 PARALLELISM OF HEXAGON FLATS TO THREAD

The hexagon flats (measured over the minimum wrenching height m' for hexagon nuts or Ta

for hexagon flanged nuts) must be parallel to the thread within 0.17 x m' for hexagon nuts or

0.17 x Ta for hexagon flanged nuts.

NOTE: All form and position tolerances may be evaluated by use of a GO screw plug

gauge to ISO 1502 thread tolerance class 6g.

5.5 SURFACE ROUGHNESS

The surface roughness of the bearing face should be evaluated in accordance with ISO

4288.

Printed copies are uncontrolled. Page 2 of 6

Copyright © 2001, Ford Global Technologies, Inc.

WORLDWIDE FASTENER STANDARD Date: 2001-01-10

WE 910 DIMENSIONAL REQUIREMENTS FOR HEXAGON AND FLANGED HEXAGON NUTS

Figure 1. Hexagon nuts

Table 1. Dimensions of hexagon nuts

Dimensions in mm

Thread Size d M4 M5 M6 M8 M10 M12 M14 M16 M20 M24

Pitch 0.7 0.8 1 1.25 1.5 1.75 2 2 2.5 3

da max. 4.6 5.75 6.75 8.75 10.8 13 15.1 17.3 21.6 25.9

min. 4 5 6 8 10 12 14 16 20 24

dw min. 5.9 6.9 8.9 11.6 13.6 16.6 19.6 22.5 27.7 33.3

e min. 7.66 8.79 11.05 14.38 16.64 20.03 23.35 26.75 32.95 39.55

m max. 3.2 4.7 5.2 6.8 8.4 10.8 12.8 14.8 18 21.5

min. 2.9 4.4 4.9 6.44 8.04 10.37 12.1 14.1 16.9 20.2

1)

m' min. 2.32 3.52 3.92 5.15 6.43 8.3 9.68 11.28 13.52 16.16

s max. 7 8 10 13 15 18 21 24 30 36

min. 6.78 7.78 9.78 12.73 14.73 17.73 20.67 23.67 29.16 35

1) Minimum wrenching height.

2) Surface roughness symbols in accordance with ISO 1302.

Printed copies are uncontrolled. Page 3 of 6

Copyright © 2001, Ford Global Technologies, Inc.

WORLDWIDE FASTENER STANDARD Date: 2001-01-10

WE 910 DIMENSIONAL REQUIREMENTS FOR HEXAGON AND FLANGED HEXAGON NUTS

Figure 2. Flanged hexagon nuts

Table 2. Dimensions of flanged hexagon nuts

Dimensions in mm

Thread Size M4 M5 M6 M8 M10 M12 M14 M16 M20

Pitch 0.7 0.8 1 1.25 1.5 1.75 2 2 2.5

c min. 0.9 1 1.1 1.2 1.5 1.8 2.1 2.4 3

da max. 4.6 5.75 6.75 8.75 10.8 13 15.1 17.3 21.6

min. 4 5 6 8 10 12 14 16 20

dc max. 10 11.8 14.2 17.9 21.8 26 29.9 34.5 42.8

dw min. 5.9 9.8 12.2 15.8 19.6 23.8 27.6 31.9 39.9

e min. 7.66 8.79 11.05 14.38 16.64 20.03 23.36 26.75 32.95

m max. 4 5 6 8 10 12 14 16 20

min. 3.7 4.7 5.7 7.6 9.6 11.6 13.3 15.3 18.9

s max. 7 8 10 13 15 18 21 24 30

min. 6.78 7.78 9.78 12.73 14.73 17.73 20.67 23.67 29.16

1)

m' min 2 2.2 3.1 4.5 5.5 6.7 7.8 9 11.1

2)

r max. 0.24 0.3 0.36 0.48 0.6 0.72 0.88 0.96 1.2

1) Minimum wrenching height.

2) Radius r applies both at the corners and at the flats of the hexagon.

3) Surface roughness symbols in accordance with ISO 1302.

Printed copies are uncontrolled. Page 4 of 6

Copyright © 2001, Ford Global Technologies, Inc.

WORLDWIDE FASTENER STANDARD Date: 2001-01-10

WE 910 DIMENSIONAL REQUIREMENTS FOR HEXAGON AND FLANGED HEXAGON NUTS

Figure 3. Hexagon thin nuts

Table 3. Dimensions of hexagon thin nuts

Dimensions in mm

Thread Size M4 M5 M6 M8 M10 M12 M14 M16 M20 M24

Pitch 0.7 0.8 1 1.25 1.5 1.75 2 2 2.5 3

da max. 4.6 5.75 6.75 8.75 10.8 13 15.1 17.3 21.6 25.9

min. 4 5 6 8 10 12 14 16 20 24

dw min. 5.9 6.9 8.9 11.6 13.6 16.6 19.6 22.5 27.7 33.2

e min. 7.66 8.79 11.05 14.38 16.64 20.03 23.35 26.75 32.95 39.55

m max. 2.2 2.7 3.2 4 5 6 7 8 10 12

min. 1.95 2.45 2.9 3.7 4.7 5.7 6.42 7.42 9.1 10.9

1)

m' min. 1.56 1.96 2.32 2.96 3.78 4.56 5.14 5.94 7.38 8.72

s max. 7 8 10 13 15 18 21 24 30 36

min. 6.78 7.78 9.78 12.73 14.73 17.73 20.67 23.67 29.16 35

1) Minimum wrenching height.

2) Surface roughness symbols in accordance with ISO 1302.

Printed copies are uncontrolled. Page 5 of 6

Copyright © 2001, Ford Global Technologies, Inc.

WORLDWIDE FASTENER STANDARD Date: 2001-01-10

WE 910 DIMENSIONAL REQUIREMENTS FOR HEXAGON AND FLANGED HEXAGON NUTS

Table 4. Form and position tolerances

Dimensions in mm

Nominal M4 M5 M6 M8 M10 M12 M14 M16 M20 M24

Thread

Diameter d

Concentricity - 0.44 0.54 0.66 0.78

Hexagon Flats

to Thread

Concentricity - - 0.86 1.04 1.24 -

Flanged

Portion to

Thread

NOTE: The above dimensions represent Total Indicator Movement.

Printed copies are uncontrolled. Page 6 of 6

Copyright © 2001, Ford Global Technologies, Inc.

You might also like

- WSET Systematic Approach to Tasting (IntermediateDocument63 pagesWSET Systematic Approach to Tasting (IntermediateJason-chung33% (3)

- External GDiMPS Training 1804c and New Portal - V18.5 (Effective 14OCT2019)Document91 pagesExternal GDiMPS Training 1804c and New Portal - V18.5 (Effective 14OCT2019)Karina Valenzuela100% (1)

- Harmonized Document: Fluids Resistance To VariousDocument8 pagesHarmonized Document: Fluids Resistance To VariousJuliano Depetris100% (1)

- Gravimetric Determination of Condensable Components: Group StandardDocument6 pagesGravimetric Determination of Condensable Components: Group Standardthiagomcasimiro100% (1)

- TL 52065 EnglishDocument8 pagesTL 52065 EnglishMiguel FelipeNo ratings yet

- Toyota interior flammability testDocument10 pagesToyota interior flammability testrinusNo ratings yet

- Fiat Group Automobiles Normazione: Various Metallic Part PaintingDocument26 pagesFiat Group Automobiles Normazione: Various Metallic Part Paintingclaudio5475100% (3)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- En 10263-2 2001Document7 pagesEn 10263-2 2001Luca TurraNo ratings yet

- Astm E11Document9 pagesAstm E11Ivan AlanizNo ratings yet

- Shop Manual Sany SY 750HDocument525 pagesShop Manual Sany SY 750HDesta 77100% (2)

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocument5 pagesCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- Technical Cleanliness - Gasket SealingDocument8 pagesTechnical Cleanliness - Gasket SealingLOGANATHAN V0% (1)

- D27 1327 - Ind.F - en - Resist. Imersão em ÁguaDocument9 pagesD27 1327 - Ind.F - en - Resist. Imersão em Águaclaudio5475No ratings yet

- TL 256 en 2022Document8 pagesTL 256 en 2022Michal BílekNo ratings yet

- CG4460 Supplier Quality SOR for Body Exterior StructuresDocument17 pagesCG4460 Supplier Quality SOR for Body Exterior StructuresPatricioNo ratings yet

- VW50180 en 2000-07-01Document3 pagesVW50180 en 2000-07-01Bruno BrasseurNo ratings yet

- SAEJ1344 V 001Document25 pagesSAEJ1344 V 001Juan VegaNo ratings yet

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- STJLR.50.5041 2009Document9 pagesSTJLR.50.5041 2009Jason-chungNo ratings yet

- Ford We 910 - 2001Document6 pagesFord We 910 - 2001Jason-chungNo ratings yet

- Eight Dimensions of Product Quality ManagementDocument6 pagesEight Dimensions of Product Quality Managementusamaca1No ratings yet

- Requester Change OrderDocument30 pagesRequester Change Ordermousabm75% (4)

- D271389 F' PDFDocument13 pagesD271389 F' PDFReza AbdolahiNo ratings yet

- VW2.8.1 en 2009-12-01Document17 pagesVW2.8.1 en 2009-12-01mehmet ustunNo ratings yet

- TL 212 en 2021 06Document9 pagesTL 212 en 2021 06David DomokosNo ratings yet

- VW 50136 en 2018-03Document10 pagesVW 50136 en 2018-03xu zhangNo ratings yet

- PPAP 4th EdDocument11 pagesPPAP 4th EdEd Ri0% (1)

- PV 6702 EnglischDocument13 pagesPV 6702 Englischjopster84No ratings yet

- VW 011 03Document22 pagesVW 011 03Alexandre UrquizaNo ratings yet

- VW 50019 PDFDocument4 pagesVW 50019 PDFSujay Nahalde100% (1)

- Zn-Ni coating passivation steel corrosion protectionDocument5 pagesZn-Ni coating passivation steel corrosion protectionPaulo Henrique NascimentoNo ratings yet

- ATE N 553 81.09 (En)Document11 pagesATE N 553 81.09 (En)Miguel QueirosNo ratings yet

- TSH7702GDocument8 pagesTSH7702GEmir AkçayNo ratings yet

- 013 Determination of Degree of Rusting of Coatings: C/CTNDocument5 pages013 Determination of Degree of Rusting of Coatings: C/CTNjoaopedrosousa50% (2)

- GMW14672 ProfileID - 000070128Document15 pagesGMW14672 ProfileID - 000070128Muthu Ganesh100% (1)

- VW 50125 enDocument12 pagesVW 50125 enDan IlcaNo ratings yet

- Shot Peening Coverage Requirements: Academic StudyDocument6 pagesShot Peening Coverage Requirements: Academic StudyUmit AytarNo ratings yet

- Worldwide Engineering Standards: Neutral Salt Spray (NSS) TestDocument4 pagesWorldwide Engineering Standards: Neutral Salt Spray (NSS) TestAkmal NizametdinovNo ratings yet

- GMW PQ140-250 PF144x72Document4 pagesGMW PQ140-250 PF144x72seriousguy2No ratings yet

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926No ratings yet

- Organic Coat GMW 14670 PDFDocument4 pagesOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoNo ratings yet

- BMS 0000147Document15 pagesBMS 0000147方綵樺No ratings yet

- TL 52682 enDocument8 pagesTL 52682 enRenato AlbinoNo ratings yet

- PV 1303Document10 pagesPV 1303tufantasma100% (2)

- Scope TestsDocument4 pagesScope TestsGonzalo TelleríaNo ratings yet

- Class. No.: 01151 Descriptors: Vehicle Part, Logo, Marking, LogoDocument12 pagesClass. No.: 01151 Descriptors: Vehicle Part, Logo, Marking, Logoaperezpi26606No ratings yet

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocument7 pagesAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzNo ratings yet

- VW01155 en 2005-02-01Document8 pagesVW01155 en 2005-02-01koalaboi0% (1)

- TL 233, 11-2010, enDocument8 pagesTL 233, 11-2010, enMiguel QueirosNo ratings yet

- TMS6900Document14 pagesTMS6900Josue Garcia QuiniNo ratings yet

- R 021 R 2 A 1 eDocument24 pagesR 021 R 2 A 1 egsuoag100% (1)

- Din 6930 Octobre 2011Document18 pagesDin 6930 Octobre 2011Franck Savignard100% (1)

- GM 6194M 2004Document7 pagesGM 6194M 2004JOVANY LOPEZNo ratings yet

- Vehicle Parts PV 2005: Klass.-Nr. 50 32 1 September 2000Document3 pagesVehicle Parts PV 2005: Klass.-Nr. 50 32 1 September 2000erik0007No ratings yet

- TL244 en 2004-12-01Document6 pagesTL244 en 2004-12-01koalaboiNo ratings yet

- TL 226 en 2018Document13 pagesTL 226 en 2018Michal BílekNo ratings yet

- VW 13750 - 2014-05 - enDocument21 pagesVW 13750 - 2014-05 - enHarold_katzerNo ratings yet

- 9.55460-2009 - Needle Punched and Nonwoven Fabrics For Interior Vehicle LiningsDocument14 pages9.55460-2009 - Needle Punched and Nonwoven Fabrics For Interior Vehicle Liningsclaudio5475No ratings yet

- Worldwide Engineering Standards: General Specification HVAC & PT Cooling GMW15866Document11 pagesWorldwide Engineering Standards: General Specification HVAC & PT Cooling GMW15866Akmal NizametdinovNo ratings yet

- Test of Ozone Resistance and Plastic Deformation: Group StandardDocument4 pagesTest of Ozone Resistance and Plastic Deformation: Group Standardali soydaşNo ratings yet

- VW 10550 enDocument3 pagesVW 10550 enIsabel SierraNo ratings yet

- 32-00-008 enDocument40 pages32-00-008 enJose ValenciaNo ratings yet

- Quality Evaluation StandardDocument7 pagesQuality Evaluation Standardsatish_trivediNo ratings yet

- Harmonized "Cluster" Document: Fasteners Property Classes of Special ServiceDocument7 pagesHarmonized "Cluster" Document: Fasteners Property Classes of Special ServiceIBRNo ratings yet

- Autoliv Material SpecificationsDocument4 pagesAutoliv Material Specificationskrishnamartial8269No ratings yet

- STPE510 - Dadi Per Saldatura A Filo (SUMITOMO)Document10 pagesSTPE510 - Dadi Per Saldatura A Filo (SUMITOMO)LucaNo ratings yet

- Assembly InstructionsDocument8 pagesAssembly InstructionsEduardo Farrera RedondoNo ratings yet

- Analysis and Optimization of Cooling Channels Performances For Industrial ExtrusDocument12 pagesAnalysis and Optimization of Cooling Channels Performances For Industrial ExtrusJason-chungNo ratings yet

- 03 2017 0041 自攻螺絲垂直引拔抵抗7Document16 pages03 2017 0041 自攻螺絲垂直引拔抵抗7Jason-chungNo ratings yet

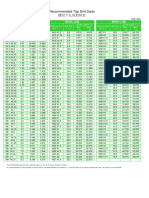

- Recommended Tap Drill SizesDocument4 pagesRecommended Tap Drill SizesJason-chungNo ratings yet

- Saarstahl 11SMn30 steel sheet specsDocument1 pageSaarstahl 11SMn30 steel sheet specsnovkovic1984No ratings yet

- Toleranties Rubberartikelen Algemeen PDFDocument2 pagesToleranties Rubberartikelen Algemeen PDFJason-chungNo ratings yet

- Atlas Aluminium Datasheet 5052 Rev Oct 2013Document3 pagesAtlas Aluminium Datasheet 5052 Rev Oct 2013Jason-chungNo ratings yet

- Toleranties Rubberartikelen AlgemeenDocument2 pagesToleranties Rubberartikelen AlgemeenJason-chung100% (1)

- 36smnpb14 1.0765 pr80 11l37 EngDocument1 page36smnpb14 1.0765 pr80 11l37 EngJason-chungNo ratings yet

- Hyster P2.5-3.0Document3 pagesHyster P2.5-3.0alkskgNo ratings yet

- Fundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, IndianDocument35 pagesFundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, Indianyair Enrique Romero OspinoNo ratings yet

- Thompson SteelDocument53 pagesThompson SteelAllan KardekNo ratings yet

- DIMENSIONINGDocument32 pagesDIMENSIONINGnagamalleswarrao50% (2)

- Arcadis Study On Universal Overhead Contact Line Design Phase2 enDocument81 pagesArcadis Study On Universal Overhead Contact Line Design Phase2 enPavanNo ratings yet

- CPCCCA3025 Self Study GuideDocument9 pagesCPCCCA3025 Self Study GuidePranay BansalNo ratings yet

- Fixturlaser Documenter User ManualDocument58 pagesFixturlaser Documenter User ManualMicroficheNo ratings yet

- PORON Polyurethanes Product Availability BrochureDocument10 pagesPORON Polyurethanes Product Availability BrochureArnoldo_lacNo ratings yet

- Engineering MetrologyDocument2 pagesEngineering MetrologyAditi RoyNo ratings yet

- Elevator en PDFDocument11 pagesElevator en PDFMichael FordwuoNo ratings yet

- 561 110 Falk True Hold Low Speed Backstops CatalogDocument23 pages561 110 Falk True Hold Low Speed Backstops Catalognenny_vhNo ratings yet

- Silka Large Format Blocks 0608Document36 pagesSilka Large Format Blocks 0608besartNo ratings yet

- ACI 117-10 Specification For Tolerances For Concrete Construction and Materials (ACI 117-10) and CommentaryDocument80 pagesACI 117-10 Specification For Tolerances For Concrete Construction and Materials (ACI 117-10) and Commentaryfostbarr100% (1)

- HPKM PPKM Eng PDFDocument20 pagesHPKM PPKM Eng PDFNikola MarinkovicNo ratings yet

- Lab Session: 07 Indexing Jig DesignDocument7 pagesLab Session: 07 Indexing Jig DesignSyed Asif BukhariNo ratings yet

- Rolling Bearing Part1 GeneralDocument16 pagesRolling Bearing Part1 GeneralSANLU HTUT100% (1)

- University Question Papers of MQC Control System and WorkstudyDocument38 pagesUniversity Question Papers of MQC Control System and WorkstudyDIPAK VINAYAK SHIRBHATENo ratings yet

- Coupling ZAPEX 5 & RWN 400 - DatasheetDocument2 pagesCoupling ZAPEX 5 & RWN 400 - Datasheetmarco diaz zepedaNo ratings yet

- Sa 7902Document3 pagesSa 7902MaciekNo ratings yet

- Mahr Air Gage CatalogDocument26 pagesMahr Air Gage CatalogAnkur TripathiNo ratings yet

- Tri ConeDocument2 pagesTri ConeANo ratings yet

- 1371893623330-Steel and Aluminium Works PDFDocument68 pages1371893623330-Steel and Aluminium Works PDFDivya AhujaNo ratings yet

- API 5l Spec OngcDocument27 pagesAPI 5l Spec OngcjamilvoraNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- Case Study On Corrosion Assessment of Infield Pipelines byDocument10 pagesCase Study On Corrosion Assessment of Infield Pipelines byHazim NaharNo ratings yet

- 9975 1Document5 pages9975 1Senthil Kumar GanesanNo ratings yet