Professional Documents

Culture Documents

AFC 528 Revised Design ManualCut & Cover Stru

Uploaded by

mahak100%(1)100% found this document useful (1 vote)

162 views51 pagesAFC

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAFC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

162 views51 pagesAFC 528 Revised Design ManualCut & Cover Stru

Uploaded by

mahakAFC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 51

PROJECT OFFICE ADDRESS: _

AFCONS INFRASTRUCTURE LTD. AFCONS

9, Shiv Park, Ishwar Nagar Society,

Maninagar, Ahmedabad ~ 380008, Gujarat AECONS wrRastRucTURe unareo | SHOPOOYs Pallongi

Email: afcons2291@afcons.com

Ref : AFC/AMD-UG1/2291/GEC-MEGA/0528 Date : 19-08-2017

To,

The Engineer,

General Engineering Consultant (MEGA)

‘SYSTRA-RITES-OCG-AECOM (Consortium)

Block No.1, Third Floor, Karmayogi Bhavan,

Behind Nirman Bhavan, Sector - 108

Gandhinagar ~ 382010, Gujarat, India.

Project: “Design and Construction Underground Stations and Tunnel including Finishes

and excluding PHE, Electrical and HVAC from Chainage 14328.88m to Chainage

11882.88m for Ahmedabad Metro Rail Project Phase-1”.

ubmission of Revised Design Manual for Cut & Cover Structures for UG1

Ref:

1. Contract Agreement No. MEGA/EW/UGSAT/PKG1/Civil dated 09.03.2017

2. Your letter GEC-102-UG1-1713097-A dated 05.06.2017.

3. Our letter AFC/AMD-UG1/2291/GEC-MEGA/0400 dated 07.07.2017

4. Several discussions held with GEC-MEGA,

Dear Sir,

Please find enclosed herewith Subr

Structures for your review & approval.

n of Revised Design Manual for Cut & Cover

S.No. Document no. Description Revision | Status

1 | USEDETORS- CEN ian Manual na >

Thanking you and assuring our best services at all times.

AFCONS INFRASTRUCTURES LIMITED,

jard copies/2 CDs (soft copies)

Copy to: Additional GM (UG), MEGA {1 Hard copy/ 1 CD (soft copy)}

ns

Regd, Office: cons House. 16, Shah Indust Estate. Veera Desai Road, Azad Nagar PO, Box No, 11978, Andheri (Wh Mumbai - 400 053

Tek 191-67191000 /2673 Fax: +91-22-2673 0047/2673 0026 wow-afeons. com

(CIN Nor U4S200ME1976PL.COI9335

NER MEGA-GEC

Ahmedabad Metro Phase-1 Contract: UG1

Transmittal Form

CONTRACTOR GENERAL CONSULTANT

Nan: [Tranemitl Ref No; AFCIANOUGH INANE:

IMR. Suresh Seetaram Hegde 28 e.STEFAN W HOFSAESS

[CONTRACT Ne: IDATE OF SUBMISSION

IMEcwewucsaripKcucivuuzo16 {19.08.17

[SIGNATURE:

We submit: ; Stage of submission:

FPlans Ti specications Sdperatey a on

TiWork plan & methodology [8.0.0 F itemattespecity

Tvesign citric, studies ‘7 Report © Breation

Ticaleutation Ti Prints F other speci: Otess

TP Drewings F Samples

cag [Submission of Revised Design Manual for Cut & Cover Structures for UG1

Date of document | No. of Copies Document reference Revision

6 UG1-D-ET043-GEN-003 Bt

T Foryourinformation

REMARKS

First Submission for Notice of No Objection

‘These are transmitted as checked below :

Fy Resubmission with corrections fr Notice of No Objection

TF onerto speci)

ISSUING ENTITY :

[Ths document (6 hereby aubrited have Boon prope reviewed

cording to ou" QA yetemo cov the complotaness sceuecy

nd valty

Sionature

Pate 15 8] 19

copy To:

AFC-MEGA UGL

f TCPL-GCJV SS

17, LINK ROAD, JANGPURA EXTN. NEW DELHI- 110014,

Phone: 24317684, 24310508, 24319288 FAX: 24316057

This

Dated: 18.08.2017

DESIGN CERTIFICATE

ign Certificate refers to Submission No. ET-043/DC/069 which comprises of

Definitive Design Note in respect of:

DESIGN MANUAL

LEAD DESIGNER'S STATEMENT

We certify that:

(a) The outline designs, design briefs and performance specifications of those elements of

the Permanent Works, as illustrated and described in the documents scheduled in

attached transmittal, complies with the design basis criteria and other contract provisions.

(b) An in-house check has been undertaken and completed to confirm the completeness.

‘Adequacy and validity of the design of the Permanent Works as illustrated and described

in the documents scheduled in attached transmittal.

(ce) Allnecessary and required approvals relating to the design of the Permanent Works, as

illustrated and described in the documents scheduled in attached transmittal, have been

obtained.

(@)_Alll effects of the design comprising the submission on the design of adjacent or other

parts of the Works have been fully taken into account in the design of those parts:

Signed by “Authorized Representative”

(For Designer)

Reamerel

Name Praveen Kumar Sharma

Position/Designation Design Team Leader

Date 18.08.2017

TANDON CONSULTANTS PVT LTD GEOCONSULT India Pvt.Ltd

i STRUCTURAL ENGHEERNG SrECMLSTS Gi Sonera my,

Bk imamgestSonwesane asta 180 908-2015 Certified

180 9001-2015 Certified

LEAD DESIGN CHECKER’S CERTIFICATION

We certify the work described in section A of this certificate has been checked by us, and meets

the requirement of the contract.

Name Position Date ‘Signature

Reviewed By | TARUN GOEL _| Lead Design Checker —

Structure gieln Ky

Verified By |DKSHARMA | Lead Design Checker |i, hey ‘Dit he fyhasr-

Date:

This certifies that all design has been performed utilizing the skill and care to be expected of a

professionally qualified and competent designer, experienced in work of similar nature and scope.

‘This further certifies that all relating to the preparation, review, checking and certification of design

has been verified by us and the design proposed by the designer has been accepted by us vide

sub clause 4.1 of GCC.

‘Signed by “Authorized Representative”

Name

Position/Designation Project Mi horized Signatory

Date

Section | SY

& | Design note No. Description Revision | Status

A ee eee Design Manual RI D

Section Il_

§ | Drawing. | Description Rev Status

METRO LINK EXPRESS FOR GANDHINAGAR

(a

|" AND nana) cone LIMITED

L = GEC CONTRACT: UG |

Contract :

Package UGOI - Design and Construction of Underground Stations and Tunnel including Finishes and Excluding

PHE, Electrical And HVAC from East End of East Ramp to East End of Launching Shaft Near Kalupur Metro

Station from Chainage 14328.88m to Chainage 11882.88m, Which Comprises of East Ramp, Twin Bored

Underground Tunnel Between East Ramp and Kalupur Metro Station all Cut and Cover Portion including Two

‘Underground Station Kankaria East and Kalupur Metro Station including a Portion of NATM and Launching and

Receiving chambers of TBM for Ahmedabad Metro Rail Project, Phase-1

EMPLOYER : METRO LINK EXPRESS FOR GANDHINAGAR AND

AHMEDABAD COMPANY LIMITED (MEGA).

GENERAL CONSULTANT : CONSORTIUM OF SYSTRA-RITES-OCG-AECOM

(MEGA-GEQ)

DETAILED DESIGN CONSULTANT : TCPL-&C JV

LEAD DESIGN CHECKER : ILF-SCPL JV

CONTRACTOR + AFCONS INFRASTRUCTURE LIMITED.

DOCUMENT STATUS DESIGN MANUAL

Preliminary Design a

Definitive Design uw

Construction Reference Design — | C) UGI-D-ET043-GEN-003-R1

‘This certifies that the report has been checked and approved in accordance with the approved Preliminary

‘Quality Assurance Plan Document No UGI-P-E7043-GEN-001.

Office of

Origin | * Tandon Consultants Pvt. Lid

Designer || vk fh

i rant Chaudhary (VC) Vijcont=

Checker _|:| Ashish Srivastava (AS) FL

Approver | :) Praveen Kumar (PK) Ramanand.

ir] TANDON CONSULTANTS PVT LTD GEOCONSULT India Pvt.Ltd

Einaaa memes es AUSTS saan te Rawhide tee

ate eee Saar

‘GhLnengiesem WEBSITE wwe 180 9004-2018: Certified

| NE METRO LINK EXPRESS FOR GANDHINAGAR |

AND AHMEDABAD COMPANY LIMITED

(MEGA)

MEGH-GEC ——coutmnet vcs

Stee

Praveen Kumar

Consultant Representative Contractor Représeihative

ISSUE CONTROL SHEET

J TCPL-GCaV | Approved By

| Rev | Date Reason For Issue "Prepared | Checked | Approved | pyc

| | by by By

| RO First Submission

| Ri 11.08.17 | Comments incorporated. kw] &

| |

| Signed / Initials - ve AS PK) DKS.

Note:

This page is a record of all issues of this document. All previous issues are hereby superseded

and are to be destroyed.

TANDON CONSULTANTS PVT TLID Gwe GEOCONSULT India Pvt.Ltd |

STRUCTURAL ENGINEERING SPECIALISTS fae term cereimee ARTE Mae

harmon eee

len 180 9004-2015 : Certified

180 8001-208 :Cortied

Phase |AFCONS|

comme 6) cons EAST UTD

tea nto oy

DESIGN MANUAL

CUT & COVER AND STATION STRUCTURES,

TABLE OF CONTENTS

1. INTRODUCTION........

2. CUT & COVER STRUCTURES.

2.1 General Principles

2.2 Design Principles

23 Excavation support

24 Design Life and Serviceability

24.1 General e

2.42 Civil Engineering Structures.

2.43 Road Pavements. c

2.44 Serviceability of Civil and Building Works..

2.5 Material Parameters.

QSA Cement ornare

2.52 Conerete..

2.53. Reinforcement.

2.54 Structural Steel

2.6 Durability Crier

2.6.1 Concrete Grade.

2.62. Fire Design Requirements :

2.6.3 Flexure Cracking.

2.64 Barly Age Thermal and Shrinkage Cracking.

2.7 LOADS & REQUIREMENTS.

A

272

273

2.7.4 Railway Loads...

2.1.5. Coefficient of Dynamic Augment

2.1.6 Derailment & Collision Loads

2.7.7 Fatigue

UGI-D-BT043-GEN-003-RI.docx 1

y) Phase-

TED fo (AFcons)

278 Winton

2.7.9 Temperature.

2.7.10 Seismic Loads.

2.7.11 Construction/Erection Loads

2.7.12 Shrinkage and Creep..

2.7.13 Movement and Distortion

2.7.14 Earth Pressure.

2.7.15 Surcharge...

2.7.16 Groundwater

2.7.17 Accidental

2.7.18 Differential Movement between In-line Structures .

2.7.19 Loading Combinations.

2.8.1 Vertical Deflection Limits

29.2. Flotation. s nas

2.10 Civil Design Work.

2.10.1 Excavation Base Stability...

2.10.2 Excavation Toe Stability

2.10.3 Waterproofing...

2.10.4 Water Control in Excavations..

2.10.5 Underpinning of Existing Building Structures (EBS)...

2.11 Temporary Works..

2H. General Prineiples...00n

2.11.2 Design of Temporary Excavation Support.

2.11.3 Ground Movements...

2.11.4 Construction Dewatering.

2.11.5 Ground Improvement

2.12 Connection Details.

2.12.1 Comers.

2.12.2 Construction Joins.

2.123 Slab to Wall Connections

2.12.4 Connections between Bored and Cut-and-Cover Structures.

UGI-D-ET043-GEN-003-RI.docx 2

FEN =... ‘AFcons|

AFCO FRATRUCTRE TED

‘Sep al ry omgy

2.13 Instrumentation 2

3. LIST OF DESIGN CODES AND STANDARDS.

Appendix A: 120 years’ Service Life

Appendix B: Racking Analysis

UGI-D-BT043-GEN-003-RI.docx 3

Have: AFCONS|

c ual AECONS INFRASTAUCTURE LINED

Se a ey oy

1. INTRODUCTION

‘The contract UG-1 of the Metro-link Express for Gandhinagar & Ahmedabad (MEGA)

consists of two underground stations and connecting tunnels and ramp viz. Kalupur and

Kankaria East. This Design Manual summarises the proposed design criteria and other

related parameters for the project related to structural aspects. This design Manual shall

bbe read in conjunction with ‘outline design specifications’, (Part 2 — Section VI,

Division G2 of tender document). It may be noted that, the basis for developing design

& construction drawings shall be the tender document. This note intends to highlight

the broad overview of design process for permanent works, temporary works for earth

retaining structures and associated sequence of construction. Please refer construction

‘methods, construction sequence and other dimensional drawings for relevant details of

various stations and asscociated structures included in the package.

In addition to design data and criteria particularly specified in tender documents, key

design data extracted from reference design standards, approach towards design of

various elements, a summary of design methods, assumptions, software used have been

provided in this document.

‘The report gives the basis for calculations including the applicable codes and standards,

the material properties, the design method, the loading to be taken into account and the

considered load combinations.

The present document will be used as reference for the future calculation/design notes

and structural drawings for the project.

This report should be read in conjunction with the Geotechnical Interpretative Report

(GIR) specific for each Underground structure. The GIR document will be submitted

separately based on the factual geotechnical investigation report provided.

| This volume is for structural aspects. Separate volumes should be referred for Architectural

| and Geotechnical aspects.

UGI-D-ET043-GEN-003-RI docx 4

UGI-D-ET043-GEN-003-RI docx 5

2.

2A

AFCONS)

pea ep cy

CUT & COVER STRUCTURES

General Principles

. Cut-and-Cover structures include all stations, station entrances/exits, vent

shafts, pedestrian subways, utilities, services, ducts, Cut & Cover ramp

structure (where applicable) and the like, other than bored/NATM tunnels, that

are required to be constructed below ground surface including parts of above

ground under this Contract. However, the provisions/stipulations in these

specifications shall also be applied to all other works (including Bored and

NATM tunnels) under the Contract, wherever considered applicable and

relevant,

‘The cut-and-cover structure is proposed to be a rigid box section with permanent

walls as external wall support system and beam-slab & column forming the

internal structural framing. The roof slab shall support the soil and vehicular

surcharge while the passenger and plant/services/structural loads are carried by

the concourse slab/intermediate. The track and platform (including passenger

and plant/services/structural) loads shall be supported by the base slab. The

permanent walls shall resist the lateral earth and hydrostatic pressures in

addition to the surcharge and services/structural loads.

‘The completed stations, station entrances, vent shafts and passenger subways

shall comply with Contract water-tightness criteria (as per clause 2.1(3) of the

Part 2, Sec. VI, ODS, Div. G2 — Cut & Cover structure).

|. Where temporary walls are intended as part of the Permanent Works, the

feasibility and suitability of such structure shall be justified.

The following shall be considered in the design of his cut-and cover structures.

4, Method of construction, including temporary works and construction

sequence.

b, Groundistructure interaction, including the effects of temporary works.

©. Ground pressure, shear force and bending moment distribution during

‘construction and in the long-term.

4, Short-and long-term ground and groundwater response.

Cons-Uot AFCONS

1a el oe nner

. Other static loads changes such as; excavation, surcharge, traffic loadings

and the like.

f. Long-term surface water level changes.

g. Dynamic (such as seismic or vibratory plant) loads and displacements.

6. For the purposes of assessing ground and groundwater pressures during service

stage, the cut-and cover structures shall be considered to be effectively

impermeable rigid box structures subject to "at rest" (Ke) earth pressure and

earth pressure due to seismic force.

7. Structures shall be designed to minimize the effects (such as movement,

distortion of the ground and the like) on all Existing Building Structure (EBS)

that may be affected by the works and shall comply with all the

requirements/provisions of the contract in this respect. Where necessary

additional support for these EBS shall be provided.

8. Temporary ground support shall be designed in accordance with the

requirements of the codes for live load surcharge and all other loads including

seismic loads,

2.2 Design Principles

1, The design of all cut-and-cover structures shall take into account, but not be

limited to the following:

a) The variation in ground conditions along the alignment.

b) The geological/hydro geological features and their variations including

rock joint orientation and spacing etc.

©) The variation in engineering properties of soil or rock within the

influence of the proposed works.

@ All dewatering and groundwater cut-off systems required to maintain

dry and stable’ conditions within all excavations required for these

Works.

©) Any ground treatment before, during or after construction of the Works

(e.g. groundwater recharge) which is required to st

ize the ground and

EBS in order to minimize adjacent ground and EBS movement and

distortion.

can AFCONS

Contract - UGI

1) Methods by which the completed structure shall be secured against

flotation. Any temporary dewatering system shall not be turned off

unless and until provisions have been made to satisfy that the structure

‘will not be subject to leakage or flotation when the ground water returns

to the design levels.

2) Differential groundwater pressures.

1h) Methods of waterproofing the completed structure.

i) The magnitude of ground and EBS movements and distortions, and

changes in loading conditions on these EBS that might be expected as a

result of the works and how these will be mitigated so as to comply with

any imposed constraints or so as to minimize disturbance to these EBS.

i) Any difficulties that the Contractors intended plan might meet with in

respect of access, clearances, working space and obstruction to

excavation.

K) Maintenance of traffic flows along roads including access to adjoining

properties and roads.

1) Noise/vibration levels produced during construction and subsequent

operation of the railway.

m) Control-of heave, swell, piping and instability of the excavations.

n) The effects of earthquake, vibration and vibration induced movements.

2, The following methods of construction shall be used cither individually or in

‘combination depending upon the particular requirements of the location, size and type

of structure.

a) Diaphragm Walls - Particular attention shall be paid to the wall and panel

alignment, the stability of excavation, the mix and condition of the slurry,

placement of the reinforcement cage, methods for forming and locating box-outs,

‘waterproofing of the vertical panel joints, placement of concrete, and the overall

integrity and water-tightness of the formed wall including nominal cover to rebar.

b) Secant Piles/Sheet Piles/Soldier Piles and Horizontal lagging - Particular

attention shall be paid to the construction/installation of the piles and ground

support systems to ensure their integrity and water-tightness and to provide

adequate support to the ground during excavation,

UGLD-ET043-GEN.003-R1 docs 7 SI

Comet -UOt AFCONS|

UGI-D-ET043-GEN-003-RI.docr 8

Diaphragm walling is the preferred support method for the proposed deep stations,

vent shafis/TBM Shafis/ other shafts and other deep excavations close to sensitive

structures, Cut & Cover Box tunnel excavations at large to medium depths close to

existing structures.

Soldier Pile wall/ Bored Pile wall methods of support may be used for other medium

excavations such as Cut & Cover tunnel, entrances/exits, utilities and services ducts

etc., where site conditions/contraints so permit. Soldier pile with wodden lagging is

not permitted.

Only diaphragm wall and secant pile wall can be allowed to form part of the

permanent works.

Where the excavation involves soft ground in upper portion and hard ground (rock)

in lower portion, the diaphragm/secant piles wall may be permitted to be terminated

into hard ground at a level that provides adequate rock socketing and the required

water-tightness, depending upon the geological and hydrological conditions. In such

situations, particular attention shall be paid for design and detailing of the required

shear-pin connection between the diaphragm/secant piles wall and the supporting hard

ground below and also to the ground treatment (e.g. grouting ete.) to seal the junction

between the wall and the ground and its surroundings to ensure their integrity and

water-tightness. In’ the hard ground portion an adequately designed Reinforced

concrete (RCC) permanent lining wall shall be provided. Particular attention shall be

paid for design and detailing of the connection of this RCC lining wall to the various

slabs (including base slab) as applicable and to the diaphragm/secant piles wall,

depending upon the location/shapelsize/available space etc., to ensure integrity and

‘water-tightness of the so formed structural configuration.

2.3. Excavation support

1. General

Detailed Design Report including calculations schedules and drawings for each

proposed excavation support wall construction, prior to the commencement of any

such works shall be prepared and submitted to the Engineer for his notice. This

Design Report shall take into account but not be limited to the following:

a) Earth pressure.

b) Hydrostatic pressure.

©) Deck load

Pee AFCONS)

Contract - UGI

Sipe na ae ony

4d) Surcharge loads.

©) Seismic and/or vibratory loads

4) Support types and arrangement.

8) Any other incidental load.

h) Construction / deconstruction sequence.

i) Calculated ground and adjacent EBS movements and distortions.

4) Calculated fluctuations in groundwater levels both within and outside of the

excavation and support walls.

1k) Calculated changes in EBS loading conditions.

1) Construction plant and machinery movement and their maximum loads on

structure

2. Method statement

a) The method statement shall give full details of materials, plant, and operations

involved in the construction of excavation support walls, The method statement

shall be incorporated into the design report submission and shall include but

mot be limited to the following details:

i, Formation of the joints between panels and installation of water stops;

ii, _ Method of producing the durable concrete;

ii, Methods of handling within the excavations and disposing of

groundwater outside the excavations;

iv. Sequence of excavation and concreting of panels;

¥. Methods of instrumentation, monitoring and reporting of the

performance of all adjacent EBS that may be affected by the works;

vi. Methods of instrumenting, monitoring and reporting on the

performance of the excavation support walls and their lateral support

systems;

vii, Type and construction of permanent lining wall;

viii, Contingency and emergency procedures to be implemented in the event

that monitoring indicates tolerances assosciated with the excavation

support wall may be exceeded;

b) Where temporary ground support is provided using polymer slurry, the

following additional information shall be provided in the method statement 1% reinforcement |180

[Blockwork Wall Thickness 150

[Staircase (waists) 170

UGI-D-ET043-GEN-003-RI.docx 16 te a

ae Cc AFCONS)

Spent ne ei ey

Alll above ground ancillary structural elements shall be designed for a minimum fire resistance

period of 2 hours. The minimum element thicknesses for this fire resistance shall be as follows:

[Element [Minimum Sizes for 2-hour FRP (mm)

|RC Slab Thickness 125

|RC Beam Width 200

IRC Column Sizes 300

IRC Wall Thickness 160

IBlockwork Wall Thickness 100

2.6.3 Flexure Cracking

Formulae for Flexural crack width shall be as mentioned as per IRS CBC.

Permissible crack width criterion for UG Station shall as per Table below:

[Maximum [Nominal Cover]

[Exposure Minimum

[Element [Location ICrack Width] for Crack Width]

\Condition (Cover (mm)

(um) Icheck (mm)

[Soil Face Severe 02 B 50 |

Diaphragm Wall

[Excavated Face | Moderate | 0.25 5 5

Soil Face Severe 02 50 5

[Roof Slab

lExcavated Face |Moderate | 0.25 50 40

[Concourse Slab Moderate| 0.25 50 40

Soil Face severe 02 5 30

Base Slab

[Excavated Face |Moderate| 0.25 50 40

[Retaining Wall |Soil Face severe 02 50 45

[Excavated Face |Moderate | 0.25 50 40

[Columns Moderate | 0.25 50 40

Water Tank Severe [0.2 50 45

(Contact with|

[Beams Top Face] Severe | 0.2 50 45

oi

UGI-D-ET043-GEN-003-RI docx n

Seay ree! AFCONS|

oc OX WERASTRUCTRE UTED

Stet le ony

[No Contact]

Moderate] 0.25 50 40

|with Soil

[Simply 70 40

‘Beams Bottom Moderate] 0.25

|Supported

& Side Face —

(Continuous [Moderate | 0,25 50 40

Notes:

Wrapping Mesh required in cover zone (of a mnimum size of A252 to BS:4483) for 4 hrs

fire resistance protection requirements,

1. Ground slab/beam is protected by waterproof membrane and a minimum of 50-

millimetre-thick blinding, the concrete surface is fully protected from the effects of

Griving rain, and aggressive water. Therefore, the exposure class shall be considered to

bbe moderate.

2. Nominal cover is measured to the outermost main reinforcement.

3. Nominal cover does not include any allowance for construction tolerance.

4, External surfaces are fully protected by Architectural rendering and cladding and hence

shall be considered to be having moderate exposure condition.

5. For underground structures, minimum diameter of main reinforcement bar all be 12mm

and for distribution it shall be 10mm, for underground structures.

6. Minimum reinforcement as per IRS: CBC.

For underground section in contact with NALLAH/Sewer water with or within the

influence zone, minimum required cover must be increased by a minimum if 15mm.

Early Age Thermal and Shrinkage Cracking

1. Suitable reinforcement shall be designed & provided to prevent early age thermal

and shrinkage cracking for walls and slabs more than 250 millimetres thick and

subjected to internal and external restraints during construction. The thermal and

shrinkage strains due to early age temperature differences and shrinkage shall be

accounted for in the design of reinforcement for cracking.

2, Generally, bundling of the bars and more than one layer of bards is not preferred.

‘Smaller diameter bars in any direction are placed at closer intervals to prevent

carly age thermal and shrinkage cracks. The limits specified in table of Cl. 2.4

aes AFcons)

tne Pa ep one

above shall be imposed. Guidance can be sought from CIRIA C660 on Early Age

‘Thermal Control of concrete.

3. Anti-crack reinforcement shall be provided in all wall & slabs more than 250mm

thick to distribute cracking arising from shrinkage, early thermal and temperature

effects. Recommendations given in C1 3.9.4.19 of part 1 of BS 8110 shall be

followed with the modification for Minimum reinforcement as listed below:

* For grade 500 and above — 0.125% of the concrete cross-sectional area.

* For grade 250 — 0.15% of the concrete cross-sectional area.

In addition, C/e distance spacing between the bars should not be greater than 160mm.

2.7 LOADS & REQUIREMENTS

2.7.1 General

Unless specified otherwise, the principles of structural design for concrete and steel elements

shall comply with codes given in tis contract and precedence of codes shall be followed

respectively. For design life and durability considerations, the Sub-Sections 2.4 and 2.6 shall

be referred to.

2.7.2 Nominal Loads

For the purpose of computing stresses and dformations, the following minimum load types and

consequential effects shall be taken into account as applicable.

[Dead loads (including notional loads) DL imposed (Live) loads LL

{Superimposed Dead loads SIDL [Earth Pressure EP

[Railway loads RL Surcharge SR

(Centrifugal CF | Hydrostatic we:

find Loads WL |Accidental AC

(Temperature loads TE [Buoyancy force BF

[Seismic Loads EQ [Braking/Traction BR (TR)

[Construction / Erection ER |Collision load cL

(Dynamic DY — |Derailment load DR

Fatigue FG [Shrinkage

UGI-D-ET043-GEN-003-RI docx 19

eile

Phase-1

Contract - UGI

AFCONS!

eee ee any

(Creep

CP [Movement and Distortion ~ MD ‘|

2.7.3 Design Loads

Design shall include all of the following loads:

2.7.3.1 Dead Loads

Self-weight of the materials shall be calculated in accordance with IS 875:1987 Part 1

2.7.3.2 Superimposed Dead Loads and Imposed (Live) Load

‘The minimum distributed and concentrated loads shall be in accordance with Table below and

contract specifications

Superimposed Dead Loads (SIDL) & Imposed (Live) Loads (all loads are unfactored)

‘Superimposed Dead Load Imposed Load

Description | Fimishes | Partitions | Ceiling & UDL. Concentrated

(kN/m*) | (Nim?) | Services (KNim’) Load (KN)

(vim?) (Note2 & 3)

Station

Concourse 24 10 10 60 a

Area (Note 5) | qnote 6) | (Note 6) (Note 1)

Platform 24 10 : 60 isa

Area (Note 5) | (Note 6) (Note 1)

Track (Note 11) Refer Section 3.3.3

Stairs and 1a 1.0 60 ra

Landings (Note 4) . (Note 6) (Note 1) 2

General Plant | 2.4 10 100 a

Rooms, Pump | (Note 5) - (Note 6) (Note 7) °

General 24 10 1.0 FA ag

Office (Note 5) | (Note 6) | (Note 6)

Staff Rooms | 24 : Ee 60 75

E (Note 5) (Note 6)

Toilets, 24 10 10

6.0 15

Change Note 5) | (Notes) | (Note 6)

Store ae) = fd 10.0 150

(Note 5) (Note6)

UGI-D-ET043-GEN-003-RI.docx

20

ree AFCOnS|

Saeet neem omnr

Water Tank, 24 20.0/ (Water Ht

Fire Tank (Notes) ° - +0.3m) :

Chiller 24 . 10 | 100 | 15.0 ote

Rooms (Note 5) (Note 6) (Note 7) D

Transformer, 24 10 20.0 20.0 (Note

Sub station | (Note 5) 7 (Note 6) (Note 7) n

‘Switch Gear 24 a 1.0 15 100

| Plant Room | (Note 5) (Note6) | (Note 7)

Root Shab) 24 . 10 Soil Load + 20 7

(ote 5) (Note 6) Wote 8 & 9)

Notes:

1, Stairs and landings to be designed for the same load as the floors to which they give access

with a minimum of 5 kN/m? and a maximum of 10 kN/m?,

2. Concentrated loads act on a square of 300 mm each side,

3. As specified or wall loads in accordance with layout in architectural plan, whichever is

greater.

4. All loads are unfactored.

5. Minimum of 100 mm thick screed on top, unit weight of 24 KN/m’.

6. As specified above or the imposed load from services fixed to the underside of floor

whichever is greater.

7. The design loads shall be actual plantlequipment loads or the ones specified above,

whichever is maximum. For seismic design plate/machinery loading shall be considered

as Super Imposed Dead Load.

8, Backfill / Barth Load Shall be calculated for the available soil depth for a unit weight of

soil of 20 kN/m?.

9. Live Load surcharge of 20 kN/m’ shall be considered for slabs subjected to traffic

surcharge.

10. The Construction Load on concourse Level shall be minimum 10 KN/m?

11. The Track loads due to:

a) Track work- UIC rails and other fittings and accessories.

b) Track bed - RCC blocks or concrete pour or precast slabs in RCC with inserts and

fittings in case of unballasted track (450 to 600 mm thick) or PSC sleepers over 250/300

mm of ballast for ballasted track.

fay AFCcOns|

iconmact UG! con merce we

©) Other loads - as per Indian Railway Standards (IRS) and Bureau of Indian Standards

GIs).

2.7.4 Railway Loads

Each component of the structure shall be designed/checked for all possible

combonations of these loads and forces. They shall resist the effect of the worst

combinations.

1, Vertical Train Live Load

The Train live Load will have the following axle configuration

Axle loads = 16 tons

‘Maximum number of successive cars: 6

where,

L=22600mm

a= (balance)

b= 2200mm to 2400mm (Length of a rigid wheel base for single bogie)

b + c= 14800mm + 250mm (Distance between bogie centres)

‘Maximum number of axles shall be loaded on the station to arrive at maximum

longitudinal force, max shear and max BM. Since both the tracks shall be supported by

single slab, hence superstructure and substructure shall be checked for one track loaded

condition as well as both tracks loaded condition

Maximum number of axles shall be loaded on the structure to arrive at maximum

Jongitudinal force, maximum shear and maximum bending moments. The structure shall

be checked for one-track load condition as well as (both) 2-tracks load condition,

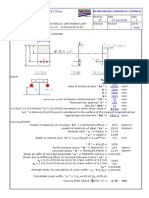

2. Lurching

Lurching forces are caused by the temporary transfer of part of live loading from one

rail to another, In accordance with BS5400: Part 2 — Specification for Loads —

Clause 8.2.7, 56% of track load shall be considered acting on one rail concurrently

eee A ie

Car eat AFCONS|

(See ae Coon ny

with 44% of the track load on the other rail (See Figure below). This redistribution of

load need only be taken into account on one track where members support two

tracks. Lurching may be ignored in the case of elements that support load from more

than two tracks,

+ ¥

3. Nosing

‘An allowance shall be made for lateral loads applied by trains to the track. In

accordance with BS5400 : Part 2 — Specification for Loads — Clause 8.2.8, nosing

force shall be taken as a single nominal load of 100KN, acting horizontally in either

irection at right angles to the track at rail level and at such a point as to produce the

‘maximum effect in the element under consideration.

It shall be applied on both the straight and curved track. For element supporting more

than one track a single load as specified shall be taken.

This force shall always be combined with the vertical train load. However, it shall be

neglected in combination with scismic loading.

4. Horizontal Train Live Load

Braking and Traction

+ Braking load is taken as 18% of the unfactored vertical loads.

* Traction load is taken as 20% of the unfactored vertical loads.

‘+ Where the structure carries two tracks, both tracks shall be considered to

be occupied simultaneously. Traction forces shall be considered as acting

‘on one track and braking forces acting on the other, with both forces acting

in the same direction simultaneously to produce the worst loading condition,

in the rails and supporting elements.

‘* Provision shall be made in supporting elements for the effects of horizontal

and longitudinal forces transferred to rails, especially in ballast less deck.

‘© Additional stresses while considering this contingency may be proposed

by the Contractor for Notice by the Engineer. Forces shall then be

UGI-D-ET043-GEN.003-RI.docx B te cS

Const UG \AFCONS|

itp te ay nme

calculated for the case of interaction between continuous welded rails

and a concrete structural support resulting from temperature differentials of

the rail and concrete base.

‘© Longitudinal forces shall consider the effects on stability and safety of

the applied axle-loading arising from a broken rail on a ballastless track.

‘* As per RDSO guidelines on seismic Design of Railway Bridges-January

2015, in transverse/ longitudinal seismic condition, only 50% of gross

tractive effort/braking force shall be considered

‘* Forces due to temperature variation in long welded stee! rail.

5. Centrifugal Force - Centrifugal Force shall be considered as per IRS Bridge

Rules.

2.75 Coefficient of Dynamic Augmentation

Impact factor for longitudinal analysis shall be 1.2 while for transverse analysis the

same shall be 1.67.

2.7.6 Derailment & Collision Loads

A) Derailment Loads shall be in accordance with Clause 8.5.2 of BS 5400, Part 2 with the

exception that condition (¢) shall not apply to underground structures.

B) The Structural elements within 10m of the center line of track, which are at risk from

collision by railway vehicles, shall be designed for the following collision loading.

Collision loads shall be considered at ultimate limit state only:

i. For Station platform edges a nominal load of 1000KN acting horizontally and

normal to the platform slab edge over a length of 2.2m, shall be considered.

ii. For all structural elements other than platform edges a nominal point load of

1250KN acting horizontally in any direction at the top of the element level, or 1.2m.

above the adjacent rail level, whichever is less, shall be considered. Where the soffit

of the structural element occurs between 1.2m and 4.0m above adjacent rail level,

the load shall be applied at soffit level.

The above-mentioned loads are indicative only. In case the relevant Authority

specifies a different loading for Derailment and/or Collision, the Contractor shall

adopt the same.

iv. The adjacent structures are to be protected by direct means (e-g., strengthening) or,

indirect means (¢.g., repositioning rail alignments or providing barriers) to ens

UGL-D-ETOA-GEN-O05-81 docx m4 SG

(7AUE CAN Contec -vc AFCONS)

these structures are still functional after an impact occurs. It is required to mitigate

impact effects on elements that may be adversely affected without enhancements.

2.7.7 Fatigue

2.79

UGI-D-ET043-GEN-003-RI.doct 25

The nominal loading for the design of members in accordance with fatigue

requirements shall comprise trains with six individual cars each having four axles, the

axle loads and vehicle lengths as specified in 2.7.4

Fatigue load histories shall be evaluated to provide valid and representative design

spectra, with stress histories analysed by the rainflow or equivalent method, both in

conjunction with the projected annual tonnages of rail traffic per track. The provisions

‘of BS 5400 Part 10 Clause 9.3.3 or other relevant methods may be used as a rigorous,

‘method of evaluation of compliance with fatigue criteria,

‘Wind load

Wind loading may affect the surface elements of inderground structures such as vent-

shafts, entry structrues, cooling towers and ancillary structures. The effects on the

temporary structures shall also be considered. For ebove ground structures, the wind

loads will be taken as per IS: 875 Part 3, Wind effect from venting in below-ground

areas shall be designed appropriately

Temperature

Forces may arise from a thermal gradient within a structural element; this may be from.

external sources or, in the case of fresh concrete, from the intemal heat of hydration

during curing.

‘These forces shall be considered in combination with those from other types of loads

to determine the worst loading condition. ‘Locked-in’ forces from temperature effects

(exg., from curing of concrete) shall be considered as a permanent load and due

allowance made in the design for such.

‘Temporary works with structural steel bracing elements or similar may also suffer

adverse effects from thermal strains. These thermal strains shall be suitably accounted

for and suitable measures shall be taken to avoid losses in preloading and subsequent

excessive deformations in structural members.

Pee! AFCONS|

Contract - UGI cos uRASTUCTURE UTED

2.7.10 Seismic Loads

General

Seismic effects shall be considered on all structures, including underground structures.

Evaluation of seismic loads shall conform to RDSO guidelines on seismic design of

Railway Bridges, the relevant Indian Standards or to other relevant seismic standards

or references where the Indian Standards are either not applicable or do not provide

sufficient guidance or formulaes. The zonal demarcations for levels of seismicity

shall be evaluated as per IS 1893- 2002. Where two or more zones are deemed to

act on a structure, the more onerous level of compliance shall be used in the design

when a static lateral force analysis approach is used. Alternatively, the structural loads

can be directly evaluated using a dynamic lateral force (response-spectra) approach.

The structure is required to be evaluated as an ‘important service and community

building’ for the purpose of “functional use’ as stated in IS 1893. Seismic design using

a response-spectra approach requires adopting the more onerous loading from strong-

‘motion data from recent seismic events in the region or from earthquake events

‘that have occurred in the similar ground conditions and suitably factored accounting

for intensity in the region. The effects of load changes and deformation as a result of

soil behaviour (eg, liquefaction) shall be allowed for in the assessment and design.

Seismic design for above-ground structures Earthquake design shall follow RDSO

guidelines on seismic Design of Railway Bridges — January 2015 and IS 1893 for

Seismic requirements and the ductile detailing of reinforced concrete structure shall

comply with IS 13920 & IS 4326. The design base shear shall be calculated based on

recommendation given in RDSO guidelines on seismic Design of Railway Bridges —

January 2015 and IS: 1893. The total design lateral force or design seismic base shear

(VB) along any principal direction shall be determined by the following expression:

VB = AW

Where

Ah = Design horizontal acceleration spectrum value, using the fundamental natural

period Ta calculated according to clause 7.6 of IS 1893-2002 (Part 1) in the considered

direction of vibration, and;

W-= Seismic weight of the building calculated according to cl. 7.4.2 of IS1893-

2002 Part 1

UGI-D-ET043-GEN-003-RI.docx 6

Phase {

er AFCONS)|

2.741

2742

The design horizontal seismic coefficient A, for a structure shall be determined by

the following expression :

An= (ZT Sa)/(2 Rg)

Provided that for any structure with T < 0.1 s, the value of Ah will not be taken less

than Z/2 whatever be the value of IR

Where,

Z=Zone factor. The project site falls within Zone Ill. Zone factor (Z) of 0.16 shall

bbe taken as per IS 1893-2002 (Part 1).

1 =Importance factor shall be taken as 1.5.

R=Response reduction factor shall be as per Table 7 of IS 1893,

Sa/g = Average response acceleration coefficient for soft soil or medium soft soil as,

given by RDSO guidelines based on appropriate natural periods (Ta) and damping of

the structure, These curves represent free field ground motion,

Damping for the concrete structure shall be assumed as 5%.

For N>100 soil shall be considered as stiff soil or soft soil. Rock shall be defined by

RQD criteria only.

[PGA for DBE should be 0.12g is considered for design purposes. The

limportance factor of 1.5 is already built in these values.

For UG Station box, sesismic effects will be calculated using Free Field Deformation

ignoring the soil-structure interaction. For details refer Appendix-B.

Construetion/Erection Loads

‘The weight of all permanent and temporary materials together with all other forces and

effects which can operate on any part of structure during construction shall be taken

into account. For construction stage only ‘ULS design checks’ shall be made keeping.

partial safety factors for imposed loads as 1.3 as specified in ‘outline design

specifications’, (Part 2 ~ Section VI, Division G2 of tender document). Allowances

shall be made in the permanent design for “locked-in” stresses caused in any member

during construction.

Shrinkage and Creep

Provisions shall be made for the effects of shrinkage and creep within concrete

structures. This includes interface shear transfer mechanisms as a result of differential

UGI-D-ET093-GEN-003-RI.doct n iF cs

peel AFCONS!|

conan OG cons austere wud

Sept lr ony

2.113

2.714

2.7.15

creep and residual shrinkage effects from staged casting of concrete elements. The

shrinkage and creep strains shall be included in calculation of long term deflection of

all structural elements in accordance with Annexure C of IS 456-2000 and the limits

specified in IS 456 and IS 800 shall be applied.

Movement and Distortion

Consideration of the forces resulting from differential movement (distortion) of

foundation elements shall be checked as appropriate. All movements and distortions

‘must not be greater than the least of the following limits:

= adhered to in the Relevant Codes

= as acceptable to the Relevant Authority

~ as specified in the Contract.

These may be architectural, structural, rail performance or other types of limitations

currently in force.

Earth Pressure

Underground vertical elements that are in direct contact with the ground shall be

designed as permanent retaining walls to resist the lateral ‘At Rest’ earth pressure. The

dynamic increment or seismic force on soil as per RDSO guidelines shall also be be

considered. The earth pressure coefficients shall be deduced based on Geotechnical

Interpretative Report separately.

Surcharge

1) For existing buildings and other existing structure occupying areas around the

excavation, detailed assessments based on building and foundation type, and

loading are to be carried out to determine the applied loads and other impacts of

such building loads on the proposed underground structure. For future buildings or

planned infrastructure, the appropriate Authorities and Employer/Enginecr shall be

consulted for obtaining the details for taking into account the surcharge to be

considered for the design of underground structures.

2) Where provision for a specific fature structure is not made, a minimum uniformly

distributed surcharge of SOkPa at the design finished ground level shall be assumed.

In case, the actual building load surcharge exceeds SOKPa, the actual value shall be

considered.

UGI-D-ET043-GEN-003-RI.docx 2B te cs

SAN Cer AFCONS)

3) Footpath live load shall be adopted as SkPa,

4) A vehicular live load surcharge of 20KPa shall be adopted for the design of all

underground structures,

5) A general loading due to construction plants and equipment (during construction

stage) shall be taken to be a minimum of 10kPa. For heavy plants and equipment,

the actual loading shall be determined individually and considered in the design.

2.7.16 Groundwater

1) Loads due to water pressure shall be calculated using a unit weight of 10 kN/m?

for fresh water and a unit weight of 10.3 KN/m* for sea-water.

2) Should liquefaction of soils be a potential risk then the design water table level for

permanent structures shall include layers affected by liquefaction if this is above

the design groundwater levels

3) The effects of temporary drawdown, seepage and base heave effects shall be

considered in design of the temporary works, and catered for in the permanent

works if there is a ‘locked-in’ effect from carry-over forces. The extent of the

temporary walls shall be sufficient to mitigate the effects of such loads during

construction.

4) The full uplift force due to groundwater shall be considered in the design both in

the temporary and permanent design stages of structures. The effects of flotation

loads shall be allowed for in the design both in the temporary and permanent

design stages.

5) The proposed structures (primarily the stations) may act as obstructions to

groundwater movement. The Contractor shall design and subsequently construct

for unobstructed movement of the groundwater through and around these

structures so that these structures do not result in changes to the phreatic surface

that exceed normal expected diurnal fluctuations.

Accidental

The design shall allow for impact loading of 50 KN acting at any position & any

direction on temporary works or on partially completed permanent works.

UGI-D-ET043.GEN-003-RI.doct 29

ee

2.7.18 Differential Movement between In-line Structures

AFCONS)|

‘Sper rl nip omro

Differential movement between adjacent in-line structures arising from static and/or

dynamic loading shall be evaluated. Due allowance for such shall be incorporated into

the size of the structures and detailing of joints to ensure that the total and differential

movements, including distortion and relative rotation, between in-line structures shall

not exceed the serviceability limits of the structures for the design life of the structures,

2.7.19 Loading Combinations

Each component of the structure shall be designed and checked for all possible

combinations of applied loads and forces. The load factors and load combinations for

ultimate and serviceability limit states are specified in the following table.

‘Ultimate Limit State Load Combinations

Load Dead Load (DL) | Imposed Lond (iL) | Grounsan’ Water | Wind | Seismic

Combination ood a

‘Adverse | Benefecial | Adverse | Benefecial | Adverse | Benefecial | (WL) | (EQ)

1.DL+ |

SIDL+ TL a) ¢ 1s - [3s o ; _

2.DL+ ]

SIDLYEQ ag 09 S - | - - 1s | 1s

3.DLt

SIDL#IL + 12 - 12 S 12 S 12 | 12

EQ |

4.Construction

Stage(**) 1s - 13 - 1s - - :

5.Collision /

Accidental i 1.0 1s - 1s 10 - -

Notes:

1. Load combination 4 will be used in checking temporary works proposals and checking the

structure during temporary construction stages. The imposed load is the construction

imposed load.

2. For checking structures at the Extreme water levels, the partial factors of safety for water

loads shall be reduced as per table ECO7 of the ODS.

3. Structural steel design load combinations and partial factors of safety for the design of

‘structural steelwork are to be in accordance with IS 800 - Code of Practice for the Structural

‘Use of Steel Work.

UGI-D-ET043-GEN-003-RI docx

on

Is)

PAE 23.01 (AFCONS|

‘Sipecg ne mp Conny

4, Earthquake loads are reversible.

5. 50% imposed load is to be used in line with the building mass calculated for seismic loads

in load case 2 & 3.

6. Creep, shrinkage, temperature and differential settlement are not considered in combination

with the lateral loads at ultimate limit state. Creep and shrinkage effects will usually be

‘minor for building type structures, no specific calculation will be necessary for Ultimate

limit state.

7. Wind load combinations are applicable for above-ground structures and shall be considered

in addition to the other combinations.

8. Wind and earthquake load will not be considered to be acting simultaneously.

9. (#*) For those structural members which are load bearing during the construction stage and

subsequently form part of the Permanent Works, the Serviceability Limit State(SLS)

checks shall be carried out both for” Construction” and “Service/Operation” stages.

10, Also for factor SIDL loads reference shall be made to BS5400 Part 4 and BD/37(including,

for ULS and SLS).

State load Combinations

tancominin | Dnt | ym Crm | win ent

1. DL+SIDL+L 10 10 1.0 - -

3. DL+SIDLHL+EQ 1.0 1.0 10 10 10

2.7.20 Design Conditions

‘© Structure shall be designed for the following four main conditions

a) “Construction” - during and immediately after construction of the Works.

b) “Service/Operation” - during general operation of the completed facility.

©) “Accidental” - during “Construction and/or “Service/Operation” when

unusual incidents, such as collision/derailment etc. occur, which may alter

loading conditions.

UGE D ETS GENE 4 te Ses

Toy AFCONS|

Contract - UG cons nastmCTUR UTD

4) “Extreme” - during “Construction and/or “Service/Operation” when

‘groundwater may rise to unusually high level.

‘* The assumed partial load factors and overall design factors of safety for the four main

conditions shall be included with the calculations to determine and design for the most

critical cases as provided in his design submissions

‘¢ For ground loads on cut-and-cover structures, the worst combination (minimum and

maximum) of lateral loading shall be considered for the Construction and

Service/Operation condition.

2.8 Deflection Criteria

The deflection limitations imposed in 1S 456 and IS 800 shall be followed for Concrete

and Structural Steel elements used in permanent works respectively.

2.8.1 Vertical Deflection Limits

The deflection of structure or part thereof shall not adversely affect the appearance or

efficiency of the structure or finishes or partitions. The deflection shall be limited to the

following.

2.8.1.1 Diaphragm wall

‘The vertical and horizontal deflections of the D-wall are to be limited only in the cases,

‘where there is an existing building in the close vicinity of D-wall. The traditional methods

shall be used to estimate the settlement at ground level (volume loss) due to deflected

shape of Diaphragm wall. The settlement analysis shall be carried out along the alignment

and the existing buildings shall be checked after review of information available in the

building assessment and risk assessment report.

2.8.1.2 Concrete structures

‘© The final deflection due to all loads including the effects of temperature, creep

and shrinkage and measured from the as-cast level of the, supports of floors, roofs

and all other horizontal members, should not exceed span/250.

© The deflection including the effects of temperature, creep and shrinkage

occurring after erection of partitions and the application of finishes should not

normally exceed span/350 or 20 mm whichever is less.

UGI-D-E1043-GEN-003-RI docx 2

Pay ee ot AFCONS|

ons RAST MED

hme ro ep enna

‘The settlement analysis shall be carried out along the alignment and the existing

buildings shall be checked after review of information available in the building

assessment and risk assessment report,

2.8.1.3 Steel structures

Designs shall comply with the limits defined in IS 800:2007.

a) Plunge-in steel column

Plunge in steel column shall be designed considering stress limit as per IS 800:2007. The

final section for service stage shall be RCC structure only.

2.9. Design Groundwater Levels

291 General

‘The groundwater levels to be assumed in design for various stages or conditions shall be

as follows:

“Construction” — groundwater level at measured maximum elevation + 1.5m.

“Service/Operation” ~ Maximum HFL as per last 50 yrs data + 1.0m,

“Accidental” ~ groundwater level at ground level.

“Extreme” — Maximum HFL as per last 50 yrs data + 2.0m

2.9.2. Flotation

+ A-minimum soil cover over the underground structures shall be 2.0m or depth to

the underside of major utilities which ever is greater.

+ Structure shall be checked against flotation during service stage for groundwater

level at ‘Ground’ as well as actual groundwater level for construction stage.

* For protection against flotation in the fully dry internal condition, the following

shall apply.

a) A load factor of 0.9 shall be applied to the self-weight of the structure,

including the first stage only of the track concrete. The minimum selfweight

of proposed Over Site Development structures (including structural weight

and any backfill proposed on the over site structure) may be included in the

flotation assessment.

b) A load factor of 0.9 shall be applied to the weight of backfill material over JE

fhe structure. Fe(ononn)a)

= ee /

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- fcu fy wc Ec column properties material section loading crackDocument2 pagesfcu fy wc Ec column properties material section loading crackprabhuNo ratings yet

- Corbel DesignDocument107 pagesCorbel DesignMrJanji JohnyNo ratings yet

- Interpreter of MaladiesDocument50 pagesInterpreter of MaladiesmahakNo ratings yet

- Irc 6-2016Document107 pagesIrc 6-2016Manvendra Nigam100% (26)

- RCC Design 3/7Document18 pagesRCC Design 3/7Nandan Anil GaikwadNo ratings yet

- Bridge RuleDocument105 pagesBridge Ruleamawauce78% (9)

- 161620157356791Document5 pages161620157356791mahakNo ratings yet

- Elastic Analysis of Tall Reinforced Concrete Frames On Elastic Sub-Base"Document8 pagesElastic Analysis of Tall Reinforced Concrete Frames On Elastic Sub-Base"mahakNo ratings yet

- CRAck WidthDocument4 pagesCRAck WidthmahakNo ratings yet

- 8Document15 pages8api-3696315No ratings yet

- Beam Design: Beam Data Final ResultDocument2 pagesBeam Design: Beam Data Final ResultmahakNo ratings yet

- Nirma Bus RoutesDocument2 pagesNirma Bus RoutesmahakNo ratings yet

- Design of Shallow FootingDocument28 pagesDesign of Shallow FootingDeepak Singh93% (14)

- Design of Shallow FootingDocument28 pagesDesign of Shallow FootingDeepak Singh93% (14)

- Ahmedabad Station DBR 24.06.2018 R0 - DBR Comments Via Letter 220724-BLR-MEGA - 017Document40 pagesAhmedabad Station DBR 24.06.2018 R0 - DBR Comments Via Letter 220724-BLR-MEGA - 017mahakNo ratings yet

- Determination of Netural Axis and Computing Moment of ResistanceDocument14 pagesDetermination of Netural Axis and Computing Moment of Resistanceshujah1106853No ratings yet

- Tran To Pdgec 01 09 2017Document3 pagesTran To Pdgec 01 09 2017mahakNo ratings yet

- Is 6006 1983Document22 pagesIs 6006 1983kannankrivNo ratings yet

- 13Document18 pages13api-3696315No ratings yet

- Nirma Bus RoutesDocument2 pagesNirma Bus RoutesmahakNo ratings yet

- Comparative Study For Shear Design Using IRC 112 2011 IRC 21 2000 PDFDocument4 pagesComparative Study For Shear Design Using IRC 112 2011 IRC 21 2000 PDFrammirisNo ratings yet

- Bangalore Metro DBRDocument30 pagesBangalore Metro DBRmahakNo ratings yet

- A-IX IRL Comments On Model DBRDocument4 pagesA-IX IRL Comments On Model DBRmahakNo ratings yet

- Wire Drawn Special Rod Wire Testing LaboratoryDocument2 pagesWire Drawn Special Rod Wire Testing Laboratoryarunt_19No ratings yet

- SP16-Design Aid For RC To IS456-1978Document252 pagesSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- 03-Heat Release in CombustionDocument44 pages03-Heat Release in CombustionEvi SiswantoNo ratings yet

- A-IX IRL Comments On Model DBRDocument4 pagesA-IX IRL Comments On Model DBRmahakNo ratings yet