Professional Documents

Culture Documents

CapScrewtapbolts PDF

Uploaded by

anon_404204060Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CapScrewtapbolts PDF

Uploaded by

anon_404204060Copyright:

Available Formats

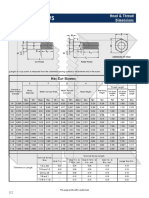

CAP SCREWS & BOLTS

HEX TAP BOLTS A307, Grades 5 & 8

L F

H

Washer face is optional on Tap Bolts.

UNDERSIDE OF HEAD

†Length of a tap bolt is measured from the underhead bearing surface to the extreme end of the bolt.

Fully Threaded Hex Tap Bolts IFI-199 (2014)

Nominal F G H

or Basic

Product Width Across Flats Width Across Corners Head Height

Diameter

Basic Max. Min. Max. Min. Basic Max. Min.

1/4 7/16 0.438 0.425 0.505 0.484 11/64 0.188 0.150

5/16 1/2 0.500 0.484 0.577 0.552 7/32 0.235 0.195

3/8 9/16 0.562 0.544 0.650 0.620 1/4 0.268 0.226

7/16 5/8 0.625 0.603 0.722 0.687 19/64 0.316 0.272

1/2 3/4 0.750 0.725 0.866 0.826 11/32 0.364 0.302

* 9/16 13/16 0.812 0.798 0.938 0.910 23/64 0.371 0.348

5/8 15/16 0.938 0.906 1.083 1.033 27/64 0.444 0.378

3/4 1 1/8 1.125 1.088 1.299 1.240 1/2 0.524 0.455

7/8 1 5/16 1.312 1.269 1.516 1.447 37/64 0.604 0.531

1 1 1/2 1.500 1.450 1.732 1.653 43/64 0.700 0.591

1 1/4 1 7/8 1.875 1.812 2.165 2.066 27/32 0.876 0.749

Nominal Size

Nominal Screw Size Over 1 in. to Over 2-1/2 in. Over 4 in. to

Up to 1 in., incl. Over 6 in.

2-1/2 in., incl. to 4 in., incl. 6 in., incl.

+0.02 +0.02 +0.04 +0.06 +0.10

1/4 to 3/8

-0.03 -0.04 -0.06 -0.10 -0.18

Tolerance on Length +0.02 +0.04 +0.06 +0.08 +0.12

7/16 and 1/2

-0.03 -0.06 -0.08 -0.10 -0.18

+0.02 +0.06 +0.08 +0.10 +0.14

9/16 to 3/4

-0.03 -0.08 -0.10 -0.10 -0.18

+0.08 +0.10 +0.12 +0.16

7/8 and 1 ...

-0.10 -0.14 -0.16 -0.20

+0.12 +0.16 +0.18 +0.22

1 1/4 ...

-0.12 -0.16 -0.18 -0.22

* Dimensions for 9/16” nominal diameter are independent of the IFI-199 standard.

This page prints with a watermark

138

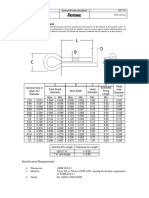

CAP SCREWS & BOLTS

A307, Grades 5, 8 & 18-8 SS HEX TAP BOLTS

A307 Grade-5 Grade-8

Headmark Headmark Headmark

ASTM A307 Tap Bolt: A low carbon, hex head bolt with a machined point which is threaded to the head.

Grade-5 Tap Bolt: A tap bolt made from medium carbon steel.

Description Grade-8 Tap Bolt: A tap bolt made from medium carbon alloy steel and heat-treated.

Stainless Tap Bolt: A tap bolt made from 18-8 stainless steel.

ASTM A307 Tap Bolt: To be used in drilled and tapped holes which are threaded full length. Used instead of a stud and a nut.

Applications/ Grade-5 Tap Bolt: Used to mount motors to machinery; also popular in automotive and truck repair.

Advantages Grade-8 Tap Bolt: Used in automotive and fleet industries where greater tensile strength is required than can be met by a grade-5.

Stainless Tap Bolt: Used in in environments corrosive to carbon steel, in tapped holes that are threaded full length.

ASTM A307 Tap Bolt: Bolts shall be made from a carbon steel which conforms to the following chemical composition requirements--

Carbon: 0.33 maximum; Manganese: 0.93; Phosphorous: 0.041

Grade-5 Tap Bolt: AISI 1030 - 1541 or equivalent medium carbon steel. Use of an alloy such as 4037 modified steel is also

Material acceptable.

Grade-8 Tap Bolt: Medium carbon alloy steel. Note: For diameters 1/4 thru 7/16 inch, it is permissible to use AISI 1541 steel.

Stainless Tap Bolt: 18-8 Stainless steel

Grade-5 Tap Bolt: Bolts shall be heat treated, oil or water quenched, at the option of the manufacturer, and tempered at

Heat Treatment a minimum tempering temperature of 800°F.

Grade-8 Tap Bolt: Bolts shall be heat treated, oil quenched and tempered at a minimum tempering temperature of 800°F.

ASTM A307 Tap Bolt: Rockwell B69 - B100

Grade-5 Tap Bolt: Rockwell C25 - C34

Core Hardness Grade-8 Tap Bolt: Rockwell C33 - C39

Stainless Tap Bolt: 1/4 thru 5/8”” diam: Rockwell B95 - C32

Grade-5 Tap Bolt: Rockwell 30N54 maximum

Surface Hardness Grade-8 Tap Bolt: Rockwell 30N58.6 maximum

Grade-5 Tap Bolt: 85,000 psi.

Proof Load Grade-8 Tap Bolt: 120,000 psi.

Grade-5 Tap Bolt: 92,000 psi. minimum

Yield Strength* Grade-8 Tap Bolt: 130,000 psi. minimum

Stainless Tap Bolt: 1/4 thru 5/8”” diam: 60,000 psi. minimum

ASTM A307 Tap Bolt: 60,000 psi. minimum

Grade-5 Tap Bolt: 120,000 psi. minimum

Tensile Strength Grade-8 Tap Bolt: 150,000 psi. minimum

Stainless Tap Bolt: 1/4 thru 5/8”” diam: 95,000 psi. minimum

ASTM A307 Tap Bolt: 18% minimum

Elongation* Grade-5 Tap Bolt: 14% minimum

Grade-8 Tap Bolt: 12% minimum

Reduction of Area* Grades 5 & 8 Tap Bolts: 35% minimum (all sizes)

Plating See Appendix-A for plating information.

* These properties are tested only on machined specimens when the testing machine cannot provide for full testing of the parts.

**Product standards require the manufacturer’s head marking to appear on the top of all bolts 1/4” diameter and larger. “X” represents one location such a

marking may appear.

This page prints with a watermark

139

You might also like

- HEX CAP SCREWS & BOLTS SPECIFICATIONSDocument2 pagesHEX CAP SCREWS & BOLTS SPECIFICATIONSHazimNo ratings yet

- Tapbolt SpecsDocument2 pagesTapbolt SpecsJava JavaNo ratings yet

- Flat Socket Head Cap ScrewsDocument8 pagesFlat Socket Head Cap Screwsvietross100% (1)

- Heavy Hex Bolts Spec SheetDocument3 pagesHeavy Hex Bolts Spec SheetLukman Nul HakimNo ratings yet

- Carriage Bolt Square Neck Round Head ScrewsDocument1 pageCarriage Bolt Square Neck Round Head ScrewsBalaji Kanduri100% (1)

- Everything You Need to Know About Cap Screws and BoltsDocument2 pagesEverything You Need to Know About Cap Screws and Boltscucho31No ratings yet

- Socket Head Cap Screws 1960 Series PDFDocument16 pagesSocket Head Cap Screws 1960 Series PDFAlexandre Caciano dos SantosNo ratings yet

- Countersunk Head Cap ScrewsDocument2 pagesCountersunk Head Cap ScrewsmuathNo ratings yet

- 304/316 Stainless Steel Pipe Walls, Weights & Sizes GuideDocument7 pages304/316 Stainless Steel Pipe Walls, Weights & Sizes GuidealiNo ratings yet

- Bolt Size: Diam. 1" 1" To 2-1/2" 2-1/2" To 4" 4" To 6" 6"Document1 pageBolt Size: Diam. 1" 1" To 2-1/2" 2-1/2" To 4" 4" To 6" 6"richiii77No ratings yet

- Taper Dowel Pin ANSIDocument4 pagesTaper Dowel Pin ANSIadzrinNo ratings yet

- Asme b18.2.1 Hvy Hex BDocument1 pageAsme b18.2.1 Hvy Hex BPhú PhạmNo ratings yet

- AS568sizechartgroove DesignDocument2 pagesAS568sizechartgroove DesignKal Al-SaleemNo ratings yet

- QMS 0003Document10 pagesQMS 0003cucho31No ratings yet

- Cotter pin specificationsDocument1 pageCotter pin specificationsD_D_76No ratings yet

- Keyway DimensionsDocument3 pagesKeyway Dimensionstinkku donNo ratings yet

- Button Head Cap ScrewsDocument4 pagesButton Head Cap ScrewsRajesh AlagamNo ratings yet

- Cotter Pin, Stainless Steel: Page 1 of 1 REV-04 Date: July 17, 2017 Pin - Cot.SsDocument1 pageCotter Pin, Stainless Steel: Page 1 of 1 REV-04 Date: July 17, 2017 Pin - Cot.SsRolandoNo ratings yet

- 12 Point Flange Bolt Dimensions & SpecsDocument1 page12 Point Flange Bolt Dimensions & SpecskannivelNo ratings yet

- Dimensions and specifications for finished hex nuts, hex jam nuts, and two way reversible lock nutsDocument2 pagesDimensions and specifications for finished hex nuts, hex jam nuts, and two way reversible lock nutshendrobamaNo ratings yet

- BS 46 :1958 Parallel Keys and Keyway Dimensions StandardDocument3 pagesBS 46 :1958 Parallel Keys and Keyway Dimensions StandardAnatta RahardjoNo ratings yet

- BoltsDocument16 pagesBoltsJJGM120100% (1)

- Butt Weld Tuerca UnionDocument1 pageButt Weld Tuerca UnionRodrigo Galdo MartínezNo ratings yet

- ROSCA AMERICANA GROSSA (UNC) – SPECS FOR UNC THREAD SIZESDocument1 pageROSCA AMERICANA GROSSA (UNC) – SPECS FOR UNC THREAD SIZESromuloacNo ratings yet

- MU06 Rosca Americana Grossa Unc TecemDocument1 pageMU06 Rosca Americana Grossa Unc TecemnevesgoNo ratings yet

- MU06 Rosca Americana Grossa Unc Tecem PDFDocument1 pageMU06 Rosca Americana Grossa Unc Tecem PDFJnr SktNo ratings yet

- Understanding Screw Sizes and ConversionsDocument1 pageUnderstanding Screw Sizes and ConversionsEngineering005No ratings yet

- Washer PDFDocument24 pagesWasher PDFRaul GutierrezNo ratings yet

- Cap (Acorn) Nuts: O P H C N, L CDocument1 pageCap (Acorn) Nuts: O P H C N, L CMAI_QualityNo ratings yet

- Acorn Cap Nut Specs & DimensionsDocument1 pageAcorn Cap Nut Specs & DimensionsMAI_QualityNo ratings yet

- Pre-Calculating Wire-Feed Speed, Travel Speed, and Voltage: Deposition Rate CalculationDocument5 pagesPre-Calculating Wire-Feed Speed, Travel Speed, and Voltage: Deposition Rate CalculationnavasNo ratings yet

- Cotter PinsDocument1 pageCotter Pinsdiyanto AntoNo ratings yet

- Howell Copper Pipe Tube DimensionsDocument1 pageHowell Copper Pipe Tube Dimensionsदिपक शेळकेNo ratings yet

- ASME B18.2.1-2010 Hex Bolt Dimensions and SpecsDocument1 pageASME B18.2.1-2010 Hex Bolt Dimensions and SpecsadrbimNo ratings yet

- BSPT and NPT tapered pipe thread characteristicsDocument2 pagesBSPT and NPT tapered pipe thread characteristicsainul yakinNo ratings yet

- Mechanical fastener dimensions and specificationsDocument7 pagesMechanical fastener dimensions and specificationsLorena PessanhaNo ratings yet

- ASTM Fasteners Dimension Tables-15Document1 pageASTM Fasteners Dimension Tables-15tylerstearnsNo ratings yet

- ASTM Standards Dimension ComparisonDocument2 pagesASTM Standards Dimension Comparisonvon18No ratings yet

- NutshvyhexDocument2 pagesNutshvyhexXerxes YuudaiNo ratings yet

- 3660-5 F Drill Bit Sheet UpdateDocument2 pages3660-5 F Drill Bit Sheet Updatecaptainamerica1284No ratings yet

- Racer's Conversion Chart: Gauge To Inches To MillimetersDocument1 pageRacer's Conversion Chart: Gauge To Inches To MillimetersRaditya PurnamahadiNo ratings yet

- NutshvyhexstructDocument1 pageNutshvyhexstructXerxes YuudaiNo ratings yet

- Steel Pipe Pile Unit Weights - Marine - Pile - FoundationsDocument1 pageSteel Pipe Pile Unit Weights - Marine - Pile - FoundationsjuliancajiaoNo ratings yet

- Kelly Pipe Wall Thickness and Weight ChartDocument1 pageKelly Pipe Wall Thickness and Weight ChartjoesamsoNo ratings yet

- F C Width Across Corners Basic Max Width Across FlatsDocument8 pagesF C Width Across Corners Basic Max Width Across FlatsJJGM120No ratings yet

- ANSI B16.5 Slip On Flanges SizesDocument1 pageANSI B16.5 Slip On Flanges SizesJoséFranciscoJfKballeroNo ratings yet

- TFA & TorqueDocument1 pageTFA & TorquePither ZuritaNo ratings yet

- Sandale IPS PE 3408 4710 Pipe ChartDocument2 pagesSandale IPS PE 3408 4710 Pipe ChartMarco Antonio Carrillo FalconNo ratings yet

- ASME B18.9 TabDocument2 pagesASME B18.9 TabmarceloNo ratings yet

- 405.7 - Types of Gaslift ValvesDocument7 pages405.7 - Types of Gaslift ValvesHassan GDOURANo ratings yet

- Machshop ManualDocument14 pagesMachshop ManualAnthony BoydNo ratings yet

- Socket Set Screw SizeDocument2 pagesSocket Set Screw Sizepavan_joshi_5No ratings yet

- Ma Pipe Dimensions and WeightsDocument1 pageMa Pipe Dimensions and WeightsKirkNo ratings yet

- FormulasDocument4 pagesFormulascristiamhiguita6No ratings yet

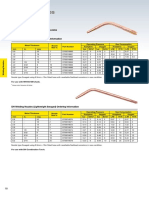

- Swaged and Lightweight Welding NozzlesDocument2 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Hex Allign Keys Size and TolerenceDocument7 pagesHex Allign Keys Size and TolerenceLesle GpNo ratings yet

- Hex Allign Keys Size and TolerenceDocument7 pagesHex Allign Keys Size and TolerenceLesle GpNo ratings yet

- Tire-Fond ReliableDocument1 pageTire-Fond ReliablelavignenoeNo ratings yet

- Pocket Guide to Stabilizers: Carry-Along Reference GuideFrom EverandPocket Guide to Stabilizers: Carry-Along Reference GuideRating: 5 out of 5 stars5/5 (1)

- TLE9 Q2 Wk.-1-3 Mod1 DrafRoofPlan V2docxDocument38 pagesTLE9 Q2 Wk.-1-3 Mod1 DrafRoofPlan V2docxJayson Cajate100% (1)

- Contractors List CurrentDocument8 pagesContractors List CurrentzefanyaNo ratings yet

- Mounting Systems For Solar TechnologyDocument24 pagesMounting Systems For Solar TechnologyEngineering SESNANo ratings yet

- Time Calculation PDFDocument2 pagesTime Calculation PDFSAE/SO Damudya MahbubNo ratings yet

- HVAC Consolidated Issues ListDocument10 pagesHVAC Consolidated Issues ListSaid Massinissa Elhadj AliNo ratings yet

- Sintap BRITISH STEEL The Significance of Y-T RatioDocument33 pagesSintap BRITISH STEEL The Significance of Y-T RatioAshish TanejaNo ratings yet

- Pool Accessories: Code 00258 Code 34331APC Code 00301 Code 00300Document1 pagePool Accessories: Code 00258 Code 34331APC Code 00301 Code 00300MechanicalLatestNo ratings yet

- Polysure PP RM30CRDocument1 pagePolysure PP RM30CRyansyafNo ratings yet

- Transport Schedule of TopicsDocument4 pagesTransport Schedule of TopicsHarshaNo ratings yet

- Neer Ground Clamps: GC: Bronze Clamps GC: Zinc ClampsDocument2 pagesNeer Ground Clamps: GC: Bronze Clamps GC: Zinc ClampsLuis Guillermo BenitezNo ratings yet

- Code of Bitumean 14374 PDFDocument8 pagesCode of Bitumean 14374 PDFshreelabNo ratings yet

- Majestic Wood Fireplace MatrixDocument11 pagesMajestic Wood Fireplace MatrixmarilynkcarlinNo ratings yet

- ARCA SOUTH DYNAMIC DESIGNDocument26 pagesARCA SOUTH DYNAMIC DESIGNJan LhesterNo ratings yet

- 5.paver Block Subbase DesignDocument4 pages5.paver Block Subbase Designarvind sharmaNo ratings yet

- BXUV.P264 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P264 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Valero Blinding Guideline Provides Safety ProceduresDocument13 pagesValero Blinding Guideline Provides Safety ProcedureskishorsinghNo ratings yet

- Structural Design I (Reinforced Concrete Design) : in CE 422Document24 pagesStructural Design I (Reinforced Concrete Design) : in CE 422jereck loquisoNo ratings yet

- Steel Connections: ResultsDocument6 pagesSteel Connections: ResultsJay SalasNo ratings yet

- Catalogue Cen TC 132 November 2017 PDFDocument32 pagesCatalogue Cen TC 132 November 2017 PDFСтанислав ПодольскийNo ratings yet

- Cast Steel Y-Strainers ANSI 150-600 LB: 0062 API 6D-0444Document1 pageCast Steel Y-Strainers ANSI 150-600 LB: 0062 API 6D-0444Camilo SanchezNo ratings yet

- Magnolia Plan: Cover SheetDocument17 pagesMagnolia Plan: Cover SheetUzair Javed100% (1)

- Paul Shewmon Diffusion in Solids 1989Document252 pagesPaul Shewmon Diffusion in Solids 1989Mustafa Yasin Aslan100% (2)

- AZ LicensesDocument29 pagesAZ LicensessivaNo ratings yet

- Steel Sheet PilesDocument20 pagesSteel Sheet PilesEko PrasetyoNo ratings yet

- Kroma Tower Makati City Condo Preselling Alveo LandDocument30 pagesKroma Tower Makati City Condo Preselling Alveo Landpreselling0% (1)

- Pavement Materials and Construction (PM&C)Document20 pagesPavement Materials and Construction (PM&C)Rakshith SNo ratings yet

- PAC Chillers With Screw CompressorsDocument2 pagesPAC Chillers With Screw CompressorsMahmoud MohamedNo ratings yet

- DRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanyDocument1 pageDRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanybillNo ratings yet

- Assignment 2 Soil MechanicsDocument2 pagesAssignment 2 Soil Mechanicsbashiir warsameNo ratings yet

- Drain 600x600Document7 pagesDrain 600x600Himanshu ChaturvediNo ratings yet