Professional Documents

Culture Documents

K13 High-Flex Waterproofing Slurry

Uploaded by

Amila SampathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K13 High-Flex Waterproofing Slurry

Uploaded by

Amila SampathCopyright:

Available Formats

TECHNICAL DATA SHEET

·Go Further, Mix Better· 1 / 3

TECHNICAL DATA SHEET

K13 HIGH-FLEX WATERPROOFING SLURRY

K13 High-Flex Waterproofing Slurry is a high USES

flexible 2-part acrylic-modified cementitious Apply on interior and exterior surface of wall and slab,

swimming pools, kitchens, toilets, balcony, water tanks.

waterproofing material. The 2-components of

External areas parking deck, planter boxes, sealing

Gomix K13 react chemically after mixing to

precast joints and intersection of two concrete elements.

form a hard and elastic film which bonds Protection to lightweight blocks, hollow blocks, aerated

tenaciously to most concrete or masonry blocks and roof.

substrate to protect against possible ingress of SURFACE PREPARATION

water. Clean the substrate of any protrusion or substances that

may damage the membrane. Ensure all surfaces are

DESCRIPTION free from dirt, dust, grease, oil, wax, curing compounds

K13 is suitable for damp conditions such as and any other loose contaminating materials. Fill all

basement, wet areas and external areas, of most voids, cracks, edges and angles with suitable repair

sites where the surface has to be pre-washed prior material, so that the prepared surface is sound, even

to applying any waterproofing material. and clean.

K13 is not affected by change in weather conditions APPLICATION

in external areas application. Put Gomix K13 Liquid into a clean mixing container.

K13 can receive direct plaster or screed without Add the Gomix K13 Powder gradually while mixing

affecting bond. until a lump free plastic consistency is achieved.

Marbles and tiles can be fixed directly onto K13. Add 1-2 Kg water if necessary.

K13 can accommodate sufficient movement of It is recommended that mechanical mixing

structure up to 2mm width. (400-500 rpm) should be used for 2-3 minutes to

K13 can be used as a repair material for bridging ensure proper dispersion of the components.

cracks in substrate or cracks due to shrinkage. Pre-wet the surface with clean water. Do not allow

pooling or ponding. Very porous surface must be

ADVANTAGES primed with Gomix Primer prior to applying K13.

2 components eliminate risk of incorrect mixing ratio Apply the mixed material onto the prepared surface

Seals lightweight aerated blocks using a block brush, squeegee or roller in a stifling

Seals precast joints action. Apply 2-3 coats finish depending on site

Anti-carbonation protection conditions and film thickness required. If a trowel is

Non-toxic used for application, all undulating or uneven areas

Highly flexible and elastic must be patched to level before applying the Gomix

Will not attack metal K13 to prevent the material from building up too

No protection require prior to fixing other types of thick in one application.

finishes If a 2nd coat is applied, the 1st coat must be left dry

tacky approximately 2-3 hours depending on the

SUITABLE SUBSTRATE thickness, substrate porosity and the temperature.

Concrete, Brickwork Gomix K13 must be protected by rendering or

Precast Surface screeding after 3 days of application.

Lightweight Blocks Note: If applied directly onto lightweight aerated block,

Shotcrete, Roof the block must be primed with Gomix Primer until a

colored tint is visible.

·Go Further, Mix Better· 2 / 3

TECHNICAL DATA SHEET

COVERAGE STORAGE

K13 High-Flex Waterproofing Slurry provides a Shelf life is minimum 1 year when stored in covered

thickness of about 1 -1.5mm. Thickness of dry film and dry environment.

should be maximum 3 mm. Production date is displayed on the packaging.

CLEAN UP

2

For ground moisture waterproof: Approx 1.7kg/m

For hydrostatic pressure waterproof: 2.5kg/m2 (2 All tools and equipment should be cleaned immediately

coats) with clean water after use.

2

For negative side waterproof: Approx 3.0kg/m Hardened material can only be removed mechanically.

HEALTH & SAFETY

PACKAGING Product contains cement, which may cause dermatitis.

25 kg powder craft bags Wear rubber gloves when handling the product.

18 kg latex plastic containers In case of insufficient ventilation, put on suitable

respiratory equipment.

Do not apply the product when the surface

temperature is below 5ºC or greater than 45ºC.

Product is classified as non-hazardous.

TECHNICAL INFORMATION

PRODUCT INFORMATION

Tensile Strength >1.9N/mm2 ASTM D412-92

Elongation at break > 200% ASTM D412-92

Adhesion to concrete > 1.2 N/mm2 ASTM D4541

Hardness Shore A > 95 ASTM S2240 : 91

Improves water resistance of concrete Passed

DIN 1048

by more than 7 times @ 0.2kgf/cm2

Chemical resistance Passed NaOCI-0.5% NH4OH-1.25% HCI-3.7%

Toxicity Passed BS 6920

Flexible over 25mm diameter mandrel Passed

Bridge cracks up to 2mm –Passed

Water vapour transmission – < 25g/m2 /24 hrs

Chloride Content < 0.01%

Pot Life (@30°C) Approx. 2 hours

Drying Time (30°C) Touch Dry Approx. 1 - 3 hours

Foot Trafficable 4 hours

Ponding Test 24 hours after application

For further information consult our Technical Department

GoMix Co., Limited

Hong Kong Office: Bright Way Tower 33 Mong Kok Rd Mong Kok KL HK

Guangzhou Office: Rm 717-718, Huaerdun Hotel, #557, Xinshi R, Baiyun, Guangzhou, China

Tel.: 0086 20 6106 9818 Email: hkgomix@gmail.com

Fax: 0086 20 6106 9819 Web.: http://www.gomixcoat.com

·Go Further, Mix Better· 3 / 3

You might also like

- V 8 e Bridge Details SetDocument25 pagesV 8 e Bridge Details SetJuan Gutier CcNo ratings yet

- TM34 Tilt Up Technical ManualDocument41 pagesTM34 Tilt Up Technical ManualFelipe CantillanoNo ratings yet

- Concrete and masonry specificationDocument7 pagesConcrete and masonry specificationAicxyNo ratings yet

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDocument13 pagesPrinciples and Practices of Stud Welding: State-Of-The-Art Paperalbert limantonoNo ratings yet

- Method Statement For Cochrane Category-I Fence Installation Work ProcedureDocument14 pagesMethod Statement For Cochrane Category-I Fence Installation Work ProcedureRoger Mallari100% (3)

- Coreslab Load Tables Specs Details 2011Document25 pagesCoreslab Load Tables Specs Details 2011Adriana WaltersNo ratings yet

- Circular Precast Concrete ManholesDocument5 pagesCircular Precast Concrete ManholesAnthony Quintua PatinoNo ratings yet

- DGS 1482-002 REV 2 - Sanitary Storm Sewer and CulvertsDocument13 pagesDGS 1482-002 REV 2 - Sanitary Storm Sewer and CulvertscarloNo ratings yet

- Municipal ArchitectureDocument138 pagesMunicipal ArchitecturestormreaderNo ratings yet

- Hanson ManualDocument410 pagesHanson ManualJohn StanleyNo ratings yet

- Institute of Gaming & Animation ThesisDocument83 pagesInstitute of Gaming & Animation Thesissiraj singh100% (3)

- FSD - Instrumentation Outside Plant Manhole and Conduit SystemDocument24 pagesFSD - Instrumentation Outside Plant Manhole and Conduit Systemjubail13No ratings yet

- Pre Cast ConstructionDocument55 pagesPre Cast ConstructionAmalaNo ratings yet

- Ke 2000 S PDS GB 0218Document4 pagesKe 2000 S PDS GB 0218tri vien nguyen ngocNo ratings yet

- Polyhard: Mineral Based Dry Shake Floor HardenerDocument2 pagesPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNo ratings yet

- Costar 2K: Cementitious Waterproof MembraneDocument2 pagesCostar 2K: Cementitious Waterproof MembranePearl GbolahanNo ratings yet

- BoscoflexDocument2 pagesBoscoflexGeloNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembranenizarazuNo ratings yet

- PDS - E - Igolflex R 2011-10 - 1 PDFDocument3 pagesPDS - E - Igolflex R 2011-10 - 1 PDFSiEn PhaNithNo ratings yet

- Boscoseal RC2Document2 pagesBoscoseal RC2Angelo Carlo MalabananNo ratings yet

- Product Data Sheet: Sikacoat® PlusDocument3 pagesProduct Data Sheet: Sikacoat® PlusReno MaulanaNo ratings yet

- Duroflex 1K: Product Data SheetDocument4 pagesDuroflex 1K: Product Data SheetVaittianathan MahavapillaiNo ratings yet

- Sikacoat Pds enDocument3 pagesSikacoat Pds enHendrawan PratamaNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoNo ratings yet

- Sikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor HardenerDocument5 pagesSikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor Hardenermusiomi2005No ratings yet

- Coper Cem Flex 2C: High Technology Cement Based 2 Component Waterproofing MembraneDocument2 pagesCoper Cem Flex 2C: High Technology Cement Based 2 Component Waterproofing MembraneBradley VellaNo ratings yet

- Duromatic BLW: Product Data SheetDocument2 pagesDuromatic BLW: Product Data SheetVaittianathan MahavapillaiNo ratings yet

- SikaCoat PlusDocument3 pagesSikaCoat PlusJKR BuildersNo ratings yet

- Sika Top Seal - 107 ElasticDocument2 pagesSika Top Seal - 107 Elasticislam ashrafNo ratings yet

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocument2 pagesPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNo ratings yet

- PDS - SikaCoat Plus Ver.01Document3 pagesPDS - SikaCoat Plus Ver.01Debby PuspitaNo ratings yet

- Boscolastic TDSDocument2 pagesBoscolastic TDSSasi KumarNo ratings yet

- Data Sheet - APE SEALKOTE - Waterproof - Latex Bitumen EmulsionDocument2 pagesData Sheet - APE SEALKOTE - Waterproof - Latex Bitumen EmulsionMochamad BhadawiNo ratings yet

- Waterproof acrylic cement coating protects concreteDocument2 pagesWaterproof acrylic cement coating protects concreteFourier MakambioNo ratings yet

- LANKEM CEYLON PLC (SPECIAL PROJECTSDocument2 pagesLANKEM CEYLON PLC (SPECIAL PROJECTSniroshniroshNo ratings yet

- Sikalastic-1 KMYDocument3 pagesSikalastic-1 KMYboyzesNo ratings yet

- Olycryl Olycryl: Acrylic Based Waterproofing CoatingDocument2 pagesOlycryl Olycryl: Acrylic Based Waterproofing CoatingVaittianathan MahavapillaiNo ratings yet

- Pds Pentens HKP T 100Document2 pagesPds Pentens HKP T 100As-Syaff ResourcesNo ratings yet

- POLYCELL PU 510WB 22sDocument2 pagesPOLYCELL PU 510WB 22snorlailiNo ratings yet

- Davco K11 Flex - Brochure (Brochure)Document2 pagesDavco K11 Flex - Brochure (Brochure)John Joseph IdanoNo ratings yet

- 81 - Polydek Super P-1Document3 pages81 - Polydek Super P-1Faiz RahmatNo ratings yet

- TDS-EN-Contite Flex - Rev 007-Feb 22Document2 pagesTDS-EN-Contite Flex - Rev 007-Feb 22LONG LASTNo ratings yet

- Renovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationsDocument1 pageRenovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationswassimmahfouzNo ratings yet

- Uzin L 3 Gold: Product Data SheetDocument2 pagesUzin L 3 Gold: Product Data SheetFloorkitNo ratings yet

- Flexible cement waterproof coatingDocument2 pagesFlexible cement waterproof coatingGobinda Nayek100% (1)

- TDS en Contite WS2 Rev 022 Nov 18Document2 pagesTDS en Contite WS2 Rev 022 Nov 18Josip MedvedNo ratings yet

- Hygrosmart Imper C2K FlexDocument3 pagesHygrosmart Imper C2K Flexmeena nachiyarNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Sika Raintite: Liquid Membrane Waterproofing SystemDocument2 pagesSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNo ratings yet

- Sikagard - 62: Solvent Free Epoxy CoatingDocument5 pagesSikagard - 62: Solvent Free Epoxy CoatingLance Zhengling YinNo ratings yet

- TDS Hydroproof Xtra IndiaDocument2 pagesTDS Hydroproof Xtra IndiaJoeNo ratings yet

- Cap Hydroseal2Document2 pagesCap Hydroseal2Medrar TareqNo ratings yet

- Superflex enDocument4 pagesSuperflex enmathaikuttyNo ratings yet

- Thermal insulation and waterproofing liquid membraneDocument4 pagesThermal insulation and waterproofing liquid membranemaga2292No ratings yet

- Bostik Boscolastic Rev1Document2 pagesBostik Boscolastic Rev1decenabuilders2016No ratings yet

- Contite WS2 015 Jul10Document2 pagesContite WS2 015 Jul10chriscivil12No ratings yet

- WP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Document2 pagesWP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Ade KurniawanNo ratings yet

- Proofex LM 0519Document2 pagesProofex LM 0519Ger ShorttNo ratings yet

- The Anydron Manual - Working With PU Waterproof CoatingsDocument5 pagesThe Anydron Manual - Working With PU Waterproof Coatingsakis5375No ratings yet

- 113 DR Fixit FastflexDocument3 pages113 DR Fixit FastflexreshmitapallaNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- Epoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Document3 pagesEpoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Rajesh GiriNo ratings yet

- Sika Nigeria - Sika Grout 212 - V2Document3 pagesSika Nigeria - Sika Grout 212 - V2willy iremNo ratings yet

- Product CatalogueDocument11 pagesProduct CatalogueLong An DoNo ratings yet

- Sikalastic 632 R PDFDocument4 pagesSikalastic 632 R PDFDan BermasNo ratings yet

- 112 DR Fixit Pidifin 2kDocument3 pages112 DR Fixit Pidifin 2kreshmitapallaNo ratings yet

- Ex Pan Proof 100Document3 pagesEx Pan Proof 100Amar WadoodNo ratings yet

- Quicseal 119: AquapoxyDocument4 pagesQuicseal 119: AquapoxyRenaldo BunaidiNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Sikacoat®: Product Data SheetDocument3 pagesSikacoat®: Product Data SheetFaichal AbdanNo ratings yet

- TDS Hydroproof Xtra India2Document2 pagesTDS Hydroproof Xtra India2Sameehu TVNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Policy FrameworkDocument19 pagesPolicy FrameworkAmila SampathNo ratings yet

- Carriageofgoodbysea 121110020207 Phpapp02Document29 pagesCarriageofgoodbysea 121110020207 Phpapp02Amila SampathNo ratings yet

- Bit OilDocument42 pagesBit OilAmila SampathNo ratings yet

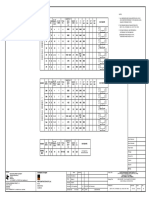

- BAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMDocument1 pageBAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMAmila SampathNo ratings yet

- VIEW - 'X': Key PlanDocument1 pageVIEW - 'X': Key PlanAmila SampathNo ratings yet

- 9negotiableinstruments 120527122657 Phpapp01Document33 pages9negotiableinstruments 120527122657 Phpapp01Amila SampathNo ratings yet

- To Lasaght For Pricing - (01-09-2020)Document2 pagesTo Lasaght For Pricing - (01-09-2020)Amila SampathNo ratings yet

- Structural Design Calculation of Culvert at Ch. 7+804: Construction of Package 1J (Ch. 6+900km - Ch. 8+050km)Document1 pageStructural Design Calculation of Culvert at Ch. 7+804: Construction of Package 1J (Ch. 6+900km - Ch. 8+050km)Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Document1 pageComment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Amila SampathNo ratings yet

- Structural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Document2 pagesStructural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Amila SampathNo ratings yet

- The Engineer:: Central Expressway Project Section - 03Document1 pageThe Engineer:: Central Expressway Project Section - 03Amila SampathNo ratings yet

- Bluescope Lysaght Lanka (PVT) LTD: Colombo OfficeDocument3 pagesBluescope Lysaght Lanka (PVT) LTD: Colombo OfficeAmila SampathNo ratings yet

- 542) Cida-Dev-Ccr-Fo-07 (E)Document4 pages542) Cida-Dev-Ccr-Fo-07 (E)Amila SampathNo ratings yet

- Structural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Document1 pageStructural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Amila SampathNo ratings yet

- Beam Bar ScheduleDocument12 pagesBeam Bar ScheduleAmila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 20181107Document1 pageComment Management Sheet (CMS) P-A Ramp C A1 20181107Amila SampathNo ratings yet

- Schedule of Doors & Windows: Detail of Septic TankDocument1 pageSchedule of Doors & Windows: Detail of Septic TankAmila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A 37+710 Cross Head - 20181203Document2 pagesComment Management Sheet (CMS) P-A 37+710 Cross Head - 20181203Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Design Calculations of Expansion Joints For All Expressway Viaducts (30m Girder) - 20181126Document2 pagesComment Management Sheet (CMS) Design Calculations of Expansion Joints For All Expressway Viaducts (30m Girder) - 20181126Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Document1 pageComment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A2 20181029-4893Document3 pagesComment Management Sheet (CMS) P-A Ramp C A2 20181029-4893Amila SampathNo ratings yet

- Bridge drainage and aquaplaning report reviewDocument2 pagesBridge drainage and aquaplaning report reviewAmila SampathNo ratings yet

- Comment Management Sheet (CMS) 20171221 - Structural DesignDocument2 pagesComment Management Sheet (CMS) 20171221 - Structural DesignAmila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Document3 pagesComment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Amila SampathNo ratings yet

- Comment Management Sheet (CMS) OPB 69+902 D 20190507Document1 pageComment Management Sheet (CMS) OPB 69+902 D 20190507Amila SampathNo ratings yet

- Comment Management Sheet (CMS) OPB 69+902 D 20190321Document1 pageComment Management Sheet (CMS) OPB 69+902 D 20190321Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Example 20171213Document3 pagesComment Management Sheet (CMS) Example 20171213Amila SampathNo ratings yet

- Comment Management Sheet (CMS) A2 - 38+620-39+073 - 20181112Document1 pageComment Management Sheet (CMS) A2 - 38+620-39+073 - 20181112Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Bridge 60+850 To 60+875 C 20190316Document1 pageComment Management Sheet (CMS) Bridge 60+850 To 60+875 C 20190316Amila SampathNo ratings yet

- Comment Management Sheet (CMS) 20171221 - Structural DesignDocument2 pagesComment Management Sheet (CMS) 20171221 - Structural DesignAmila SampathNo ratings yet

- Field Trip 2 - Coreslab Structures Inc Essay - FinalDocument11 pagesField Trip 2 - Coreslab Structures Inc Essay - Finalmmg009No ratings yet

- Asamoah Et Al - Cost Analysis of Precast and Cast-in-Place Concrete Construction PDFDocument11 pagesAsamoah Et Al - Cost Analysis of Precast and Cast-in-Place Concrete Construction PDFsatrio luhur wNo ratings yet

- China Construction Eight Engineering Division Corporation LimitedDocument1 pageChina Construction Eight Engineering Division Corporation LimitedChong YsNo ratings yet

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDocument2 pagesSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanNo ratings yet

- Prefab Construction &precastDocument31 pagesPrefab Construction &precastKURUBA SARAN RAJ SamNo ratings yet

- Twin-Wall A4 PDFDocument2 pagesTwin-Wall A4 PDFDanielRendaNo ratings yet

- Designing The Exterior Wall An Architectural Guide To The Vertical Envelope Full ChapterDocument41 pagesDesigning The Exterior Wall An Architectural Guide To The Vertical Envelope Full Chapterrobert.burge405100% (26)

- Journal - Developing Risk Assessment For The Production of Precast Concrete WallDocument7 pagesJournal - Developing Risk Assessment For The Production of Precast Concrete WallDK DMNo ratings yet

- Different Bridge Construction MethodsDocument25 pagesDifferent Bridge Construction MethodsMuhammad FarooqNo ratings yet

- Project TitlesDocument38 pagesProject TitlesKarthik ManiNo ratings yet

- Building Tech 5 NotesDocument7 pagesBuilding Tech 5 NotesUniqueQuiverNo ratings yet

- IRC 6-Amendments - 01-10-19Document42 pagesIRC 6-Amendments - 01-10-19vasuNo ratings yet

- Ultratech Cement Limited: Jetty Extension ProjectDocument43 pagesUltratech Cement Limited: Jetty Extension Projectlaxman kumarNo ratings yet

- CLC Blocks PDFDocument2 pagesCLC Blocks PDFSureshKumar DevulapallyNo ratings yet

- Design of Steel Structures for Multi-Storey BuildingsDocument33 pagesDesign of Steel Structures for Multi-Storey Buildingshari1008108100% (1)

- Precast BrochureDocument12 pagesPrecast BrochureNicholasOmodingNo ratings yet

- HongKong SPC Library 2018 PDFDocument3,866 pagesHongKong SPC Library 2018 PDFAzharudin ZoechnyNo ratings yet