Professional Documents

Culture Documents

Design Req Gas Service Installation PDF

Uploaded by

Shijo PodiyanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Req Gas Service Installation PDF

Uploaded by

Shijo PodiyanCopyright:

Available Formats

Design Requirements for

Gas Service Installation

Please review entire document before submitting

design drawings and gas service application to

Terasen Gas.

Revision Date: September 30, 2004

Table of Contents

Table of Contents

1. Service Design Overview.............................................................................. 1-1

1.1 Why is this Manual Required? .......................................................................1-1

1.2 Designing and Applying for a Gas Service ...................................................1-1

1.3 Lead Time Requirements................................................................................1-2

1.4 Terasen Gas Design and Install Team...........................................................1-3

Sales Representative ........................................................................................1-3

Installation Coordinator (IC)...............................................................................1-3

Crew Leader......................................................................................................1-3

1.5 Terasen Gas Definitions .................................................................................1-4

Customers .........................................................................................................1-4

1.6 Terasen Gas Structure Classifications..........................................................1-4

Single Family Dwellings (SFD) ..........................................................................1-4

Multi-Family Dwellings (MFD)............................................................................1-5

Townhouses ......................................................................................................1-5

Institutional Structures .......................................................................................1-5

Strip Malls..........................................................................................................1-5

Commercial Low/Mid/High Rises.......................................................................1-5

Industrial Structures And Complexes ................................................................1-5

1.7 Gas Service Design Categories .....................................................................1-5

Service Header Orders (SHO)...........................................................................1-6

Vertical Subdivisions .........................................................................................1-6

Main Construction Orders (MCO)......................................................................1-6

2. Gas Availability ............................................................................................. 2-1

2.1 Main Extensions ..............................................................................................2-1

2.2 The Main Extension (MX) TEST......................................................................2-1

2.3 Refunds of Main Extension Contributory Costs...........................................2-2

3. Determine Load and Delivery Pressure Requirements.............................. 3-1

3.1 Delivery Pressure ............................................................................................3-1

Design Requirements for Gas Service Installation

9/30/2004 Page i

Table of Contents

4. Plan Meter Location and Service Line......................................................... 4-1

4.1 Meter Location .................................................................................................4-1

4.2 Service Line .....................................................................................................4-1

5. Design Meter Enclosure ............................................................................... 5-1

5.1 Overview ..........................................................................................................5-1

5.2 Types of Enclosures .......................................................................................5-2

Meter Recess Enclosures .................................................................................5-2

Cage Enclosures ...............................................................................................5-2

Slab and Fence Meter Enclosures ....................................................................5-2

5.3 Space Requirements .......................................................................................5-2

5.4 Meter Set Protection Posts.............................................................................5-8

Protection Posts ................................................................................................5-8

6. Ensure Drawings Meet Drafting Guidelines................................................ 6-1

6.1 Terasen Gas Drawing Type Definitions.........................................................6-1

6.2 Request and Review Process.........................................................................6-1

6.3 Return Process ................................................................................................6-1

6.4 Cad Formats ....................................................................................................6-2

Acceptable Software Formats ...........................................................................6-2

Units ..................................................................................................................6-2

Projection: .........................................................................................................6-2

6.5 Drawing Package.............................................................................................6-2

Content..............................................................................................................6-2

Mechanical Drawings ........................................................................................6-2

Civil Drawings....................................................................................................6-3

Drawing Attributes .............................................................................................6-3

7. Submit Gas Application and Drawings ....................................................... 7-1

7.1 How to Fill Out a Gas Application..................................................................7-1

Utility Mains .......................................................................................................7-1

Townhomes .......................................................................................................7-1

Design Requirements for Gas Service Installation

9/30/2004 Page ii

Table of Contents

Commercial Buildings........................................................................................7-1

Application by Third Parties on Behalf of the Developer ...................................7-2

After You’ve Submitted Your Application...........................................................7-2

8. Estimating Costs for Gas Service Installation............................................ 8-1

8.1 Standard Pricing..............................................................................................8-1

General..............................................................................................................8-1

Charges on Meter Sets .....................................................................................8-2

8.2 Operating Costs ..............................................................................................8-2

8.3 Main Extensions ..............................................................................................8-2

8.4 Additional Length Charges.............................................................................8-2

Design Requirements for Gas Service Installation

9/30/2004 Page iii

Section 1

Service Design Overview

1. Service Design Overview

This manual is intended for Architects, Mechanical Engineers, and 3rd party contractors

involved in design and construction of residential and commercial structures. The

purpose is to aid them in planning and designing the installation and commissioning of a

gas service.

1.1 Why is this Manual Required?

This manual is designed to assist you in submitting your application and drawing

set to our design professionals. Adherence to these guidelines will help us meet

your scheduling needs and avoid unnecessary complications with your gas

installation project.

1.2 Designing and Applying for a Gas Service

The steps involved in designing and applying for a gas service are:

1. Determine gas availability and the location of the nearest gas main(s)

If there is more than one option the Terasen Gas sales representative can

determine the most cost effective solution

2. Determine the structure gas load requirements

3. Based on main location, select a meter location on the nearest corner of the

structure to the main

4. Plan the service running line to minimize trench obstacles and obstructions

5. Select a meter enclosure (if necessary)

Enclosures are required for:

¾ Any location with any vandalism potential

¾ Most commercial structures

¾ Public edifices such as churches, schools, community centers etc.

6. Ensure all design drawings adhere to Terasen Gas drafting standards and all

information has been included in drawing package

7. Submit drawing package with completed gas service application.

Design Requirements for Gas Service Installation

9/30/2004 Page 1-1

Section 1

Service Design Overview

1.3 Lead Time Requirements

Terasen Gas requests that drawings be submitted at minimum 90 days before

install date. This will ensure adequate time to complete the service and meter-set

design work, obtain municipal approvals and schedule a work crew.

Upon submittal of drawings, Terasen Gas will respond with a letter confirming

receipt of your drawings and provide you with a job reference number.

Design Flowchart

1. Determine

Location of

Nearest Gas

Main

Minimum Contact Install

Delivery Centre to obtain

Pressure? Main Pressure

2.Determine Load

Requirements

Refer to Appliance

Required

specifications or

Meter Outlet

Contact your Gas

Pressure?

Fitter

Is there a

Cage / Enclosure

Potential for

Required

Vandalism?

3. Select Meter

Location

Could Vehicles Protection Posts

Damage the Required (supplied

Meter? by Terasen Gas)

4. Plan Service

Running Line

5. Select

Enclosure Type

(As Required)

9. Ensure all

Drawings adhere

to Terasen

Drafting Standards

Design Requirements for Gas Service Installation

9/30/2004 Page 1-2

Section 1

Service Design Overview

1.4 Terasen Gas Design and Install Team

Sales Representative

A Terasen Gas sales Representative is responsible for our initial customer

interactions and is available to:

• Introduce gas utilization options

• Determine nearest gas main location for your design assessment

• Complete an initial cost estimate

Installation Coordinator (IC)

An IC is responsible for designing and planning your gas service. Their duties

include:

• Receiving gas applications

• Obtaining all project information

• Reviewing submitted drawings

• Communicating required design changes

• Calculating the price

• Scheduling Terasen Gas installation crews based on project status

A builder or developer may be assigned an IC directly dependent upon the

number of respective developments and associated infrastructure requirements.

Crew Leader

A Terasen Gas crew leader is responsible for coordinating the construction of

your gas service: Their duties include:

• Confirming the installation date & job site readiness with the customer

• Ordering required materials

• Confirming resources are available (servicemen, flagging, paving etc.)

• Communicating any cost changes that may be required to the customer

• Collecting all field data for records & billing purposes

Design Requirements for Gas Service Installation

9/30/2004 Page 1-3

Section 1

Service Design Overview

1.5 Terasen Gas Definitions

Customers

There are three primary types of end-user customers, each determined by their

volume of gas load and the type of delivery service required. Services are defined

by British Columbia Utilities Commission (BCUC) approved rate schedules. The

customer types are:

1. Residential Customer

2. Commercial Customer

3. Industrial Customer

An indirect or 3rd party may act as an agent in the design and installation of a

residential and commercial structure. These parties are responsible for the

commission of a construction project but may not be the final end-user of the

structure. The indirect customer types are:

1. Developers

2. Architects

3. Builders

4. Trades and Gas Fitters

1.6 Terasen Gas Structure Classifications

Gas can be supplied to any type of residential, commercial or industrial structure.

The primary structure types as defined by Terasen Gas are:

• Single Family Dwellings

• Multi-family Dwellings including low-rises and high-rises

• Townhouses and Row houses

• Institutional Structure including schools, churches and community centres

• Commercial Strip malls

• Commercial Multi-unit buildings including commercial low and high rises

• Industrial structures and complexes

Single Family Dwellings (SFD)

SFD is any residential structure that houses a ‘single’ family unit via a single

entrance. This classification includes in-fills, and bungalows.

Design Requirements for Gas Service Installation

9/30/2004 Page 1-4

Section 1

Service Design Overview

Multi-Family Dwellings (MFD)

MFD is a cluster or more homes accessed by a single common entrance. This

classification includes 4-plexes, condominiums, low-rises and high-rises.

Townhouses

A Townhouse can be classified as a multi-family unit with the exception that each

unit is accessed by its own individual entrance. A townhouse will more than likely

have individual furnaces for each unit while a MFD could potentially have a

centralized boiler system.

Institutional Structures

Institutional structures include: churches, schools, universities, community centers

or any other structure where large groups of people may congregate.

Strip Malls

A strip mall is a commercial structure where all the gas heating may be

centralized so the mall as a whole may gain a preferential rate schedule.

Commercial Low/Mid/High Rises

Commercial rises account for any office tower that is not utilized for residential

purposes.

Industrial Structures And Complexes

Any agriculture, manufacturing or heavy industrial activity can be classified as an

Industrial structure. These structures can be broken down into a steady-state gas

load and a process load based on the type of industrial activity. The division of the

constant and the variable load determines the preferential gas service rate (Rate

Schedule).

1.7 Gas Service Design Categories

All orders for a gas service are handled through the Terasen Gas Installation

Coordination Centre and are termed a “Gas Application”. However, in the design

phase they will be categorized as follows:

Design Requirements for Gas Service Installation

9/30/2004 Page 1-5

Section 1

Service Design Overview

Service Header Orders (SHO)

Service Header Orders are job types where a new customer is being connected to

the gas distribution system, including service for the following types of structures:

• SFD

• MFD

• Most residential and commercial structures

Vertical Subdivisions

Vertical Subdivisions utilize ultrasonic metering to allow individual unit metering

without a large dedication of floor space for individual traditional diaphragm or

rotary meter sets. Vertical Subdivisions typically include the following types of

structures:

• Condominiums

• Mid-rises

• High Rises

Main Construction Orders (MCO)

MCOs are any extension or alteration of the natural gas distribution main in order

to bring the gas distribution system to the new customer. MCO jobs support

connecting:

• SFD

• MFD

• Commercial Customers

• Industrial Customers

• Vertical Subdivisions

Design Requirements for Gas Service Installation

9/30/2004 Page 1-6

Section 2

Gas Availability

2. Gas Availability

Please contact one of the following telephone numbers to identify the location, size and

operating pressure of the nearest natural gas distribution main to your development

property:

• General Main Location Inquires: 1 (888) 224-2710, Press ‘3’ then ‘1’ for

Construction Related Inquiries

• Coastal Sales Representative for main location and gas utilization options for your

development: 604-803-1117 (Stu MacGillivray)

• Interior Sales Representative for main location and gas utilization options for your

development: 250-212-9297 (Brent Hunt)

If more than one main is accessible (as in a corner lot); consult your Terasen Gas Sales

Representative or Install Coordinator to help you select the more economic main tie-in

location.

If your connecting main is located adjacent to the property, additional contributory costs

may not be required.

2.1 Main Extensions

If your connecting main requires an extension in order to expand the distribution

system to meet your needs, a Main Extension Test (MX test) will be performed by

Terasen Gas to determine if you will need to contribute to the cost of the main

extension.

2.2 The Main Extension (MX) TEST

The MX test is a discounted flow analysis of the projected revenue and costs

associated with the main extension. The construction costs to install the main

extension are weighed against the five year net revenue cash flow based on the

load associated with the customers projected and their estimated annual

consumption. If the main extension is deemed to be economic it will be

constructed without contributions from the gas applicant.

The MX Test will be applied to new applications for service requiring new gas

mains, as well as for service header and vertical subdivision applications.

If a MX Test indicates a revenue deficiency, the customers will need to pay a

contribution equal to the revenue deficiency in order for the project to proceed.

If a main extension is required to serve the property, consult your Terasen Gas

Sales Representative or Install Coordinator to determine if your main is

contributory and if additional monies are required.

Design Requirements for Gas Service Installation

9/30/2004 Page 2-1

Section 2

Gas Availability

2.3 Refunds of Main Extension Contributory Costs

If a main is classified as contributory and gas revenues over a 5 year period from

date of construction yield an amount greater than anticipated, main extension

refunds may be allocated to customers.

Refunds occur as additional customers are added to the system or gas

consumption is greater than anticipated resulting in expected revenue deficiency

being eliminated over a 5 year period.

Design Requirements for Gas Service Installation

9/30/2004 Page 2-2

Section 3

Determine Load and Delivery Pressure Requirements

3. Determine Load and Delivery Pressure Requirements

In order to design your gas service, we require the type of gas appliances to be

installed, the number of each type and the total number of BTU’s of the

appliances. This includes any appliances you plan to add in the future. This will

determine the total connected load of your building which determines the size of

your meter.

3.1 Delivery Pressure

The delivery pressures available within the gas distribution grid will vary based

on the age and configuration of the local system infrastructure and local

consumption. In some parts of the grid the highest inlet pressure available can be

as little as 1.75 kPa.

To ensure adequate inlet pressure availability, first determine your load

requirements. Confirm with your mechanical contractor the delivery pressure

necessary. Then, contact the Terasen Gas Install Centre at 604-576-7200 in

Greater Vancouver or toll free: 1-877-576-7200. We can confirm if you will have

adequate inlet pressure for your appliances.

Do not install your house piping until Terasen Gas has approved your meter

location and delivery pressure.

Design Requirements for Gas Service Installation

9/30/2004 Page 3-1

Section 4

Plan Meter Location and Service Line

4. Plan Meter Location and Service Line

4.1 Meter Location

Referencing the gas main location as provided by Terasen Gas, select a meter

location on the nearest corner of the structure to the main via the property line.

• Meter location must adhere to vent and ignition clearances

• Consider vandalism and vehicle damage potential when selecting a location

4.2 Service Line

Plan the service running line for minimum obstruction and trench considerations

• Adhere to service line restrictions for both on and off property sections of the

service line

• Adhere to clearances to all other utility service lines

• Provide sleeves for any retaining walls or embankments along the service

running line

Design Requirements for Gas Service Installation

9/30/2004 Page 4-1

Section 4

Plan Meter Location and Service Line

Standard Terasen Gas Service Running Line Configuration

Customer Type Drawing

SFD

SFD –

attached

garage

SFD –

attached

carport

(options A or

B)

Design Requirements for Gas Service Installation

9/30/2004 Page 4-2

Section 4

Plan Meter Location and Service Line

SFD – Duplex

with Strata

Designation

(Option 1)

SFD – Duplex

with Strata

Designation

(Option 2)

SFD – Duplex

without Strata

Designation

(Option 2)

Design Requirements for Gas Service Installation

9/30/2004 Page 4-3

Section 4

Plan Meter Location and Service Line

SFD – with

Main

Extension

Design Requirements for Gas Service Installation

9/30/2004 Page 4-4

Section 4

Plan Meter Location and Service Line

SFD – Service

Extension to 2

risers

MFD

Design Requirements for Gas Service Installation

9/30/2004 Page 4-5

Section 4

Plan Meter Location and Service Line

Rate 3 or

larger MFD

Design Requirements for Gas Service Installation

9/30/2004 Page 4-6

Section 4

Plan Meter Location and Service Line

MFD – 3++

Meters at 2+

Locations

MFD – 3++

Meters at 2+

Locations

MFD – 3++

Meters at 2+

Locations

Design Requirements for Gas Service Installation

9/30/2004 Page 4-7

Section 4

Plan Meter Location and Service Line

MFD – 3++

Locations

Non-Generic

Scenario CONSULT A TERASEN GAS INSTALLATION COORDINATOR 1

Design Requirements for Gas Service Installation

9/30/2004 Page 4-8

Section 4

Plan Meter Location and Service Line

ON PROPERTY SITE SPECIFICATIONS

ON PROPERTY SERVICE LINE SPECIFICATIONS

The following service line requirements must be met when the service line falls within the property:

Configuration Description Drawing

Ground must be ‘well’ compacted for

Compaction o

length of soil surrounding the

service running line

Compacted soil must be within

Rough Grade o

150mm of final grade for complete

length of running line

Design Requirements for Gas Service Installation

9/30/2004 Page 4-9

Section 4

Plan Meter Location and Service Line

Final grade should leave a minimum

Final Grade o

of 457 to 610mm of burial depth for

the service line

o Should run adjacent to property line

o Must be clear of any above or below

Service ground obstructions and building

Running line materials by at least 1 meter

o Running line must be clearly marked

along the property (by stakes) to

final meter position on the structure

o Service line must be in a separate

trench unless a Joint Trench

agreement has been signed

N/A

All underground utilities within the

Foreign Utility o

property must be marked by stakes

Clearances

o A minimum 1.0m horizontal offset

from foreign utilities is preferred.

o A minimum 0.3m vertical offset is

required

See site readiness requirements in

Building o

this Section

Construction

Requirements o All other utilities should be installed N/A

for Gas

Obstructions should be scheduled to

Service o

follow installation of gas lines i.e.

retaining walls, landscaping

Design Requirements for Gas Service Installation

9/30/2004 Page 4-10

Section 4

Plan Meter Location and Service Line

o For Municipal Roads (meters):

A = 0.6, B = 0.6, C = 0.5, D = 0.5,

Distribution E = 0.5

Service Pipe

Cover For Ministry of Transport Corridors

(meters):

A = 1.2, B = 1.2, C = 0.8, D = 0.6,

E = 0.5

o All retaining walls must have a

sleeve installed that allows the

service line to pass through

Retaining

Walls o Minimum sleeve size is 101.6mm

o Rule of thumb: Sleeve should be 2

nominal pipe sizes larger than the

planned service line diameter

Design Requirements for Gas Service Installation

9/30/2004 Page 4-11

Section 4

Plan Meter Location and Service Line

ON PROPERTY TRENCHING SPECIFICATIONS

The following trenching requirements must be met on the customer’s property:

Configuration Description Drawing

o Trenching route should be free of

obstructions. Allow 1 meter

Trench, General clearance between property and

outbuildings, sidewalks, driveways,

ramps, walls, and other

o Excavate 457 to 610mm deep with

a flat trench bottom free of water

Excavation

o If trench conditions are sub-

standard with large aggregates,

than a layer of sand 30mm deep

must bed the trench

Pipe Bedding

o If sand is not available, 20mm

minus road mulch is an acceptable

alternative

Design Requirements for Gas Service Installation

9/30/2004 Page 4-12

Section 4

Plan Meter Location and Service Line

o Surround the pipe with a minimum

of 75mm of rock-free soil or sand

o Backfill in trench must be ‘well’

compacted for length of service

Backfill running line

o Backfill should be compacted by

compaction equipment or wheel

tamping

Design Requirements for Gas Service Installation

9/30/2004 Page 4-13

Section 4

Plan Meter Location and Service Line

OFF PROPERTY SITE SPECIFICATIONS

OFF PROPERTY SERVICE LINE SPECIFICATIONS

The following service line requirements must be met for any section of the service line that falls off the

property into a roadway or on municipal lands:

Configuration Description Drawing

Compacted soil must be within 6” of

Rough Grade o

final grade for complete length of

running line

Final Grade o Final grade should leave 910mm of

burial depth for the service line

Design Requirements for Gas Service Installation

9/30/2004 Page 4-14

Section 4

Plan Meter Location and Service Line

o Should approach the property line

perpendicularly

Service o Must be clear of any above or below

ground obstructions and building

Running line materials by at least 1 meter

o Running line must be clearly marked

to the property line (by stakes or

paint)

o Service line must be in a separate

trench unless a Joint Trench

agreement has been signed

Foreign Utility N/A

o All underground utilities within the

Clearances property must be marked by stakes

o Service line must be clear of any

above or below ground utilities by at

least 1 meter

See site readiness requirements in

Building o

this Section

Construction

Requirements o All other utilities should be installed N/A

for Gas

Obstructions should be scheduled to

Service o

follow installation of gas lines i.e.

retaining walls, landscaping

o For Municipal Roads (meters):

A = 0.6, B = 0.6, C = 0.5, D = 0.5,

Distribution E = 0.5

Service Pipe

Cover For Ministry of Transport Corridors

(meters):

A = 1.2, B = 1.2, C = 0.8, D = 0.6,

E = 0.5

Design Requirements for Gas Service Installation

9/30/2004 Page 4-15

Section 4

Plan Meter Location and Service Line

OFF PROPERTY TRENCHING SPECIFICATIONS

The following trenching requirements must be met for any section of the service line that falls off the property

into a roadway or municipal lands:

Configuration Description Drawing

o Trenching route should be free of

obstructions.

Trench, General N/A

o Trench should cross sidewalks

perpendicularly

Excavation

o Excavate 920mm deep with a flat

Depth trench bottom free of water

o If trench conditions are sub-

standard with large aggregates,

than a layer of sand 30mm deep

Pipe Bedding must bed the trench

o If sand is not available, 20mm

minus road mulch is an acceptable

alternative

o Trench must be backfilled to

Backfill 50mm below top of pavement and

compacted to municipal standards

(Standard Proctor)

Design Requirements for Gas Service Installation

9/30/2004 Page 4-16

Section 4

Plan Meter Location and Service Line

o Pavement must be cold-patched to

regional / local municipal

standards

Pavement N/A

o Brush edge clear of foreign

Repair material to allow for a good bond

o Tamp cold-patch once in place and

finish cold patch with a light

dressing

Design Requirements for Gas Service Installation

9/30/2004 Page 4-17

Section 4

Plan Meter Location and Service Line

METER LOCATION REQUIREMENTS

ENSURING A SAFE METER LOCATION

The following clearances and design requirements must be met in order to ensure safe placement of the

meter set:

Metric Drawing Comments

Building Minimum clearance

requirements from the

Opening & Air service regulator vent

Inlet (measured in any

Clearances direction)

Minimum clearance

requirements between

Vent the service regulator

Clearances vent and any gas

appliance vents

Design Requirements for Gas Service Installation

9/30/2004 Page 4-18

Section 4

Plan Meter Location and Service Line

Space Space Requirements

Requirements for residential meter

sets

Design Requirements for Gas Service Installation

9/30/2004 Page 4-19

Section 4

Plan Meter Location and Service Line

To avoid damage due to

ice the meter set should

Overhang not fall under any drip

line

Clearances

No potential source of

ignition shall exist within

1 meter radius of the

meter set. Potential

Ignition sources of ignition

Source include outdoor pool

heaters, switches,

Clearances electrical meters, plugs,

fuse boxes, motors.

General

Layout

Design Requirements for Gas Service Installation

9/30/2004 Page 4-20

Section 5

Design Meter Enclosure

5. Design Meter Enclosure

5.1 Overview

Enclosures are required for:

• Institutional structures

• Churches and community centres

• Schools and universities

• Shopping and strip malls

• Mid-rises and condominiums (MFDs)

• Open industrial areas

• Meter sets with control lines

• Any location with vandalism potential

A gas meter enclosure can be accomplished using one of the following methods:

• Enclosure with a concrete slab and fence/cover

• Enclosure with a meter recess

• Enclosure in a cage

• Enclosure within a meter closet

No enclosure is required for:

• Single Family Dwelling; the meter is wall mounted

• Multi-family dwelling if the meter set is located on the property and not

accessible by the general public. The meter is wall-mounted.

The customer is required to supply the enclosure type and/or concrete slab as

confirmed by the Terasen Gas Install Coordinator (IC). Following submission of

your drawings, the IC will review your design and metering requirements before

confirming actual meter and concrete slab dimensions.

Design Requirements for Gas Service Installation

9/30/2004 Page 5-1

Section 5

Design Meter Enclosure

5.2 Types of Enclosures

Meter Recess Enclosures

A meter recess is a meter enclosure installed within the building shell with one

side open to the atmosphere. Meter sets may be installed in a steel, concrete, or

masonry recess to provide both protection from vehicles and an aesthetic facade.

Terasen Gas will provide guidance for the specification of meter set recesses.

Steel recesses are to be supplied and installed by the developer. These guidelines

and enclosed standards do not supercede the judgment or approval of a Terasen

Gas Install Coordinator.

Cage Enclosures

A cage is a meter set enclosure, constructed of mesh panels that enclose all sides

and the top of the meter set. The front and top panels are removable for service

access. If the cage is abutted against a wall, a back panel is not required.

Slab and Fence Meter Enclosures

Certain locations may require that the meter set be enclosed by fencing with a

lockable gate, and be mounted on a concrete slab. The slab and fence size is

determined by meter selection.

5.3 Space Requirements

Enclosure, cage and slab dimensions are dependant on many variables including:

location, meter size, inlet pressure, main location and load. If limited space is an

issue, our Install Centre can draw on our experience and suggest innovative

design solutions and remote placement options.

Contact the Terasen Gas Installation Centre at 604-576-7200 in Greater

Vancouver or toll free: 1-877-576-7200 to discuss the space requirements for your

gas installation project.

Design Requirements for Gas Service Installation

9/30/2004 Page 5-2

Section 5

Design Meter Enclosure

ENCLOSURES – METER RECESSES

Option Installation Type Drawing Comments

No. Description ISO

Standard supports are pipe hangers

1 Pipe Hangers From Recess Roof N/A

suspended from the recess roof

Used for large meter sets but

2 Meter Stand on concrete Slab in Recess

requires a concrete slab for support

Single 1.75 kPa domestic meters do

3 Support Not required N/A

not require support

DESIGN REQUIREMENTS

o Proper clearances must be maintained in a recess so no meter set extremities are obstructed or in contact

with the recess itself

o Steel recesses shall be constructed of mild steel with minimum thickness of 1.52 mm (16 gauge wire)

o Concrete or masonry recesses shall be fully continuous except for the outer opening which shall be fully

open (allowing free and plentiful ventilation)

o Structures other then the gas meter set and the house piping are not permitted within a recess

HOUSELINE CONNECTION REQUIREMENTS

o Houseline connection is located at the front corner of the recess and may not run to the back of the

enclosure unless sufficient clearances are provided

o Inlet connections with a welded steel piping on a steel riser, or a combination meter cock on a PE riser

o Gas House piping shall be sleeved gas-tight where it passes though the recess wall. Sleeves shall be

mortared or welded in place and flexible material shall be used to seal the houseline

Design Requirements for Gas Service Installation

9/30/2004 Page 5-3

Section 5

Design Meter Enclosure

INSTALLATION REQUIREMENTS

o Recesses shall be made watertight to the wall by sealing

o The base of the recess shall be sloped to provide adequate drainage of water

o Meter set must be supported in the recess by an approved method

VENTING REQUIREMENTS

o For industrial and commercial meter recesses, the recess box shall have a suitably vented metal door if the

bottom of the recess is less than 1.2 meters above ground or if there is any danger of vandalism

o Regulators do not need to be vented outside the recess for any standard installation

o All internal meter sets require venting to the outdoors

ENCLOSURES - CAGES

Option Installation Type Drawing Comments

5.3.1 Dimensions

• Slab shall be reinforced

1 Reinforced Slab Refer to Slab Requirements • Refer to concrete slab

requirements for cut-out

location for gas riser

Shall rest on a reinforced slab

Consult Terasen Gas Installation

2 Foot Mounting or set in concrete footings

Coordinator

based on soil conditions

3 Support Not Required N/A N/A

Design Requirements for Gas Service Installation

9/30/2004 Page 5-4

Section 5

Design Meter Enclosure

CAGE USES

o Meter is installed in a location where children congregate

o Meter is installed in a location that may be subject to vandalism

o For any meter that has external pressure sensing line (i.e. 35 and 70 kPa instrument drive meter sets)

SUPPORT REQUIREMENTS

o A reinforced concrete slab with side panels anchored to the slab

o Cage must have fence posts set in footing formed by the concrete slab and designed by the contractor

to suit local soil conditions

o See Fence data sheet for chain link requirements

DESIGN REQUIREMENTS

o There are no designed cages for multi-meter manifolds; these manifolds must be fenced

o Cages must have a single removable front/top panel to allow for servicing

o Cages set against a building do not require a back panel

SLAB DESIGN REQUIREMENTS

o Slab must be 100 mm thick

o Be reinforced concrete

o Allow 150 mm for fence post lateral support and fencing width

SLAB AND FENCE INSTALLATION NOTES

o Fenced slab required where the meter is installed in a location where children congregate

o Fenced slab required where the meter is installed in a location that may be subject to vandalism

o Fenced slab required for any meter that has external pressure sensing line (i.e. 35 and 70 kPa

instrument drive meter sets)

Design Requirements for Gas Service Installation

9/30/2004 Page 5-5

Section 5

Design Meter Enclosure

GENERAL SLAB INFORMATION

o Developer and mechanical contractor should determine the best location for the meter area

o The customer is encouraged to use an aesthetically pleasing fencing medium, compatible with

the surroundings

o The enclosure must have a lockable gate, be secure from vandalism, and have a good life

expectancy

o Chain link fence is not mandatory

o When the fenced enclosure is in a highly visible location, redwood or cedar slats inserted into

the chain link fence are advised

o Interruptible customers must provide a roof over the meter set to protect telemetry equipment

and recording instruments

o Example locations are:

Mid-rises and condominiums

Schools

Churches

Meter sets with control lines

Open industrial areas

Shopping malls

Design Requirements for Gas Service Installation

9/30/2004 Page 5-6

Section 5

Design Meter Enclosure

Figure 1: Chain Link Fence Requirements

Design Requirements for Gas Service Installation

9/30/2004 Page 5-7

Section 5

Design Meter Enclosure

5.4 Meter Set Protection Posts

Protection Posts

When a meter set is exposed to hazards due to vehicular traffic or subject to any

other potential risk of damage, meter protection posts are required.

• Install NPS 3 diameter steel posts for residential applications; NPS 4 steel

posts for commercial and industrial locations.

• The number of posts required will vary with meter size

Design Requirements for Gas Service Installation

9/30/2004 Page 5-8

Section 6

Ensure Drawings Meet Drafting Guidelines

6. Ensure Drawings Meet Drafting Guidelines

The purpose of the enclosed Drafting Standards is to provide guidelines on the format

and content of engineered drawings submitted to Terasen Gas for new gas services.

The intention is to minimize design variance and provide an efficient method of design

and reference.

6.1 Terasen Gas Drawing Type Definitions

Sketch: An outline illustration used to convey an idea for a drawing. These types

of drawings do not become part of a record set.

Plan: A drawing prepared for a gas service application by a third party contractor

or developer.

Construction: A drawing, usually altered by Terasen Gas for the Plan Drawing,

prepared for fabrication, construction, modification or extension of a new gas

service / existing gas service for a gas distribution main.

As-Built: A drawing prepared post-construction that represents actual installation

parameters and communicates any deviations from the Construction Drawing.

Record: Final approved drawing that is included in official gas records.

6.2 Request and Review Process

Upon application for a gas service, the applicant is asked to submit a mechanical

plan drawing or “Plan Drawing” with the meter locations included. Terasen Gas

requests both hard copy and digital drawings. The easiest method of submitting

electronic files to us is by emailing gasservice@terasengas.com, this eliminates the

risk of damaged or unreadable disks causing delays in processing your

application.

Once in hand, Terasen Gas can begin to review your mechanical drawing plan.

6.3 Return Process

Terasen Gas will review your drawing set to ensure all specifications and industry

codes are met. You will be contacted if any clarifications are required. Every

effort will be made to approve the meter locations and dimensions as submitted,

however, changes may be necessary due to metering design restrictions.

Confirmation and approval of submitted drawings will be done by phone. Terasen

Gas will not return a copy of the drawing to you.

Design Requirements for Gas Service Installation

9/30/2004 Page 6-1

Section 6

Ensure Drawings Meet Drafting Guidelines

6.4 Cad Formats

Acceptable Software Formats

The following Computer Aided Drawing programs are acceptable formats to

submit drawing to Terasen Gas:

• MicroStation Version 7 or earlier

• AutoCAD 2000 or earlier versions

Units

All drawings must be stored in metres only.

Projection:

UTM NAD 83 coordinates or BCALBERS Equal Area coordinates are preferred.

6.5 Drawing Package

Content

The preferred supplied package is an A4 sized drawing set of:

• Project Scope

• Detailed Site Plan Drawings (site service plan)

• Mechanical Drawing Set

• Architectural Elevation Plan

• Landscape

• Registered Legal Plan Drawings

• Key Plan including other utilities

Mechanical Drawings

Scope Drawing: A concise graphic overview of all mechanical work involved in

the project. The drawing is intended as a reference drawing for listing specific

drawings.

Piping Plan Drawing: Intended to show the physical orientation of all

mechanical piping for construction.

Design Requirements for Gas Service Installation

9/30/2004 Page 6-2

Section 6

Ensure Drawings Meet Drafting Guidelines

Piping Section and Details Drawing: If required to elaborate on the Piping Plan

Drawing, section drawings are an orthographic view to show clearances and

clarify pipe connectivity.

Detailed Plan Drawings: Intended to show the physical orientation and location

of all utilities and structures.

Civil Drawings

Must show:

• A minimum of one dimension reference to the grade

• Must show top of concrete (TOC) on top of all pipe piers

• Must be in orthographic style

Drawing Attributes

The following attributes should be included in the drawing set:

Landbase Content:

• Existing and proposed legal base

• Legend and vicinity map

• Lot lines

• Lot numbers

• Lot addresses (if available)

• Property boundary (including bearings and distances)

• Public property lines and private street limits

• Street names and widths

• Easement ROW’s

• Building footprints (unit numbers and names if available)

• Curbs and gutters

• Driveways

• Public sidewalks

Design Requirements for Gas Service Installation

9/30/2004 Page 6-3

Section 6

Ensure Drawings Meet Drafting Guidelines

Foreign Utility Content:

(Existing and Proposed including all fittings, offsets & dimensioning from lot line

and road ROWs)

• Electric

• Telephone

• Street lighting

• Storm

• Sanitary

• Water lines

Design Requirements for Gas Service Installation

9/30/2004 Page 6-4

Section 7

Submit Gas Applications and Drawings

7. Submit Gas Application and Drawings

7.1 How to Fill Out a Gas Application

Applications for gas service cannot begin without key information from you.

Please ensure that the following information is submitted and correct:

• Owner’s name with billing contact information

• Developer / Engineering Company contact information

• Site address/location

• Registered legal information

• Approximate time frame or site ready date for proposed gas installation

Utility Mains

• Key plan or site plan that also shows other utilities

• Roadworks showing cross sections

Townhomes

• Site servicing plan

• Architectural drawings (including elevation views of buildings)

• Landscaping

Commercial Buildings

• Mechanical drawings

• Architectural drawings (including elevation views of buildings)

• Landscape

• Registered legal

• Site servicing plan

• Gas load information and gas fitter information with contact phone number

Design Requirements for Gas Service Installation

9/30/2004 Page 7-1

Section 7

Submit Gas Applications and Drawings

Application by Third Parties on Behalf of the Developer

An indirect or 3rd party may act as an agent in the design and installation of a

residential and commercial structure. These parties are responsible for the

commission of a construction project but may not be the final end-user of the

structure. The indirect customer types are:

1. Developers

2. Architects

3. Builders

4. Trades and Gas Fitters.

In many cases an agent or 3rd party such as an engineering firm will submit the

construction order but will not be the billable party. In order to ensure accurate

billing Terasen Gas requests that one of the following be completed:

1. The agent provides Terasen Gas with a letter of authorization to initiate the

order for gas service on the developer’s behalf. The letter should clearly

specify which projects the agent is authorized to represent.

2. If the developer has made arrangements with Terasen Gas to begin processing

the order and have been given a notification number, the agent can reference

the notification number to continue with the order processing.

3. If the agent initiates the order without written authorization to act on the

developer’s behalf, Terasen Gas will complete the order with the agent as the

billable party. During order processing if we are informed that this is not

acceptable we will hold the order and instruct the agent to have a

representative from the billable party contact us. The representative will then

be asked to update the billing information before we release the order.

After You’ve Submitted Your Application

1. Paper work and approvals are executed by Terasen Gas. The availability of

service, meter location, and delivery pressure for intended load will be

confirmed, reviewed and approved.

2. All special circumstances will be communicated to you, such as meter

location out of preferred meter location, additional installation charges or

delivery pressure charges, or gas main extensions.

3. In order for installation to proceed, the building and running line must meet all

agreed conditions. The meter enclosure and location should adhere to the

specifications described herein. Once these conditions are met, call the

Terasen Install Coordination Center to inform them the site is ready.

Installation will begin within 3 to 4 weeks if no additional problems arise.

Design Requirements for Gas Service Installation

9/30/2004 Page 7-2

Section 7

Submit Gas Applications and Drawings

4. Natural gas service and meters are installed by Terasen Gas. If a second field

trip is required by Terasen Gas due to the site not being ready, or the site

varies from the Declaration form, additional charges may be levied.

5. Terasen Gas will gasify the service from the gas main to the meter.

6. In-house piping and hookup to meter are completed by a private gas fitter. The

gas fitter must arrange for inspection by a municipal or provincial authority.

7. Upon approval by the gas inspector, if the house piping is complete and

clearly marked including meter unit ID tags, the gas fitter may energize the

house piping.

8. A Terasen Gas representative may conduct periodic meter inspections, as

required, according to your type of meter.

Design Requirements for Gas Service Installation

9/30/2004 Page 7-3

Section 7

Submit Gas Applications and Drawings

SITE READINESS REQUIREMENTS

The following requirements must be met for Terasen Gas installation crews to install you gas service line and

meter.

ITEM REQUIREMENT

Please keep the planned installation date on your schedule. Please advise your Terasen Gas

Representative at least two weeks away from the planned installation date of any delays in your

1 project that may impact our crews. Having our crews arrive at your site and not being able to work is

very costly for us and may seriously impact your ability to effectively reschedule the gas main

installation.

The gas main will have an approved offset from the property line or fixed structure depending on the

installation. Typically, this offset is 0.9 metres. This offset must be preserved for Terasen Gas and

must also be wide enough for excavation (about 0.5m). Encroachments into this offset by other

2 utilities may significantly impact our ability to install our gas main. We may be forced to abandon the

installation if we cannot safely and efficiently work. It may take up to a month before our crews will

be able to return. Please ensure that the running line is clear of encroachments prior to our crew’s

arrival.

Utility corridors must be within 0.15m (6”) of final grade. This is imperative especially on hillside

development as future driveway construction may severely reduce the protective cover over the gas

3 main. This may require a costly gas main lowering. Other shallow utilities must also have their lot

servicing ductwork deep enough such that the gas main can remain at sufficient depth throughout its

length. Please ensure that the running line is at the correct grade prior to our crew’s arrival.

Our crews will depend on the drawings of other utilities to excavate safely. If you are aware of any

4 significant changes to the locations of these utilities or have any knowledge of any hazards please

ensure that the Terasen Gas crew leader is aware of these changes and hazards.

Please ensure that the utility corridor is free of construction materials and debris. We will have to re-

5 schedule the work if our ability to work safely and productively is seriously impaired. This will be the

judgement of the crew leader.

The pre-installation of ducts to simplify natural gas installations is encouraged as this prevents our

crews cutting through fresh asphalt or avoids excavating through congested or hazardous areas.

6 However, these ducts must be installed properly for us to effectively utilize. Please contact your

Terasen Gas representative to provide you the guidelines (DES 04-01-02) for installing ducts for

natural gas distribution or service lines.

It is imperative that our crews work safely and install our gas mains to the required standards. Our

crews are required to abide by all WCB requirements and will not be able to tolerate unsafe working

conditions. The crew leader must be able to reach the site supervisor to discuss any unsafe

7 conditions found. If we cannot install our gas mains to the correct standard then the crew leader will

discuss with the site supervisor to determine the best course of action which may include

abandoning the installation until the site is ready for gas mains installation.

Design Requirements for Gas Service Installation

9/30/2004 Page 7-4

Section 8

Estimating Costs for Gas Service Installation

8. Estimating Costs for Gas Service Installation

8.1 Standard Pricing

General

The general application fee accounts for installation of the gas service line to the

Terasen Gas preferred meter location (1.5m past the structure corner closest to the

gas main)

The standard gas installation cost as of July 2004 is:

• $215 gas service installation

• $85 per gas meter installed

Any additional installation costs will be provided at the time of application.

All costs levied are per meter charges for installation of additional length. Terasen

Gas determines per meter cost for all geographic regions within British Columbia

based on historical costs to travel to the location and install a standard gas service

in the local soil conditions.

Additional costs to the customer can include:

• Meter set installation anywhere other than in the Preferred Meter Location:

charges are based on extra pipe length required

• Meter Set Protection Posts: if meter location is near potential vehicular or

pedestrian traffic then protective measures must be taken, as specified by the

National Gas Code. Terasen Gas will install the protection posts.

• Meter Set Enclosures: if the meter set is located in an area where damage

could occur to the meter set due to accidents or vandalism, or near an area

where children play, such as schools, churches or community centers, a meter

enclosure is required. This is typically a cage of fencing material or a

structurally sound fence with locking gate. Meter enclosures are the

responsibility of the customer.

• Additional site visits by Terasen Gas due to the site not being ready for gas

service on the scheduled date.

• Gas Main Extensions: A 5 year net revenue projection is calculated by a MX

Test Based on the net revenue projection, and factors such as size and location

of the development or customer, Terasen Gas may collect a portion or all of

the cost of extending the main. The contribution may be completely or

partially refunded after 1-5 years

Design Requirements for Gas Service Installation

9/30/2004 Page 8-1

Section 8

Estimating Costs for Gas Service Installation

• Frost Charges: in certain geographical areas the customer may be charged

frost fees based on actual frost encountered during installation of gas service.

• Additional engineering, construction or installation costs due to the lay of the

land or a customer’s special requirements.

Charges on Meter Sets

The customer is responsible for all costs over the basic service extension and

meter set installation. Depending upon the connecting load, the customer may

incur the following costs:

• Meter protection posts

• Extra meter sets

• Installation out of the preferred location

These charges will be levied by Terasen Gas following the service installation

Costs and requirements that are the responsibility of the customer to coordinate

and install include:

• Fences

• Concrete slabs

• Meter cages.

8.2 Operating Costs

Unless special circumstances arise, all costs in maintaining a meter set are

included as a basic monthly charge on your Terasen Gas bill.

8.3 Main Extensions

If your connecting main is located adjacent to the property, additional

contributory costs may not be required.

If your connecting main requires an extension in order to expand the distribution

system to meet your needs, a Main Extension Test (MX test) must be completed

and the application may result in contributory costs being assessed. Discuss with

your installation coordinator.

8.4 Additional Length Charges

Please consult an Install Coordinator for more information about pricing in your

region.

Design Requirements for Gas Service Installation

9/30/2004 Page 8-2

You might also like

- Ground Improvement Techniques ExplainedDocument71 pagesGround Improvement Techniques ExplainedlohitsnNo ratings yet

- APP Installation Detroit Diesel S2000 7SA2000 PDFDocument233 pagesAPP Installation Detroit Diesel S2000 7SA2000 PDFthanhhai31No ratings yet

- LWUA Vol2. Reformat PDFDocument274 pagesLWUA Vol2. Reformat PDFKenny Wong100% (6)

- UFC - 3-260 - 01 Airfield Heliport Planning DesignDocument414 pagesUFC - 3-260 - 01 Airfield Heliport Planning DesignPricop CosminNo ratings yet

- Drafting Purchase Price Adjustment Clauses in M&A: Guarantees, retrospective and future oriented Purchase Price Adjustment ToolsFrom EverandDrafting Purchase Price Adjustment Clauses in M&A: Guarantees, retrospective and future oriented Purchase Price Adjustment ToolsNo ratings yet

- Lighting Design ManualDocument99 pagesLighting Design ManualMoustafa Nabil100% (3)

- Verbal Instruction ConfirmationDocument2 pagesVerbal Instruction ConfirmationShijo PodiyanNo ratings yet

- Engineering NotesDocument209 pagesEngineering NotesSrinivasKrishnanNo ratings yet

- LWUA Standard Specification Water System Construction 2009Document274 pagesLWUA Standard Specification Water System Construction 2009Roland Anaum100% (3)

- Cdot Metric Conversion ManualDocument193 pagesCdot Metric Conversion Manualnadher albaghdadiNo ratings yet

- Design Criteria Manual ALL - DraftDocument100 pagesDesign Criteria Manual ALL - Draftjake4itNo ratings yet

- Chennai Metro Rail DPR for Phase II ProjectDocument638 pagesChennai Metro Rail DPR for Phase II Projectkmmanoj196850% (2)

- Engineering Design SpecificationsDocument95 pagesEngineering Design Specifications1229206304No ratings yet

- RehabilitationDocument147 pagesRehabilitationAbraham MukokandukuNo ratings yet

- Design Standards Manual: Chapter 3 - Civil Design: Facilities Management and Operations CenterDocument31 pagesDesign Standards Manual: Chapter 3 - Civil Design: Facilities Management and Operations CenterTumulak IanNo ratings yet

- Marine Operations RequirementsDocument80 pagesMarine Operations RequirementsNishant GuptaNo ratings yet

- Appendix A - Scope of Work - A4J8F3Document19 pagesAppendix A - Scope of Work - A4J8F3Donald JabagatNo ratings yet

- Qcs 2010 Part 8.02 EarthworksDocument20 pagesQcs 2010 Part 8.02 EarthworksRotsapNayrbNo ratings yet

- IRC Ammonia Sensor OverviewDocument48 pagesIRC Ammonia Sensor OverviewDerekNo ratings yet

- 1 CORE Consulting Engineers PLCDocument137 pages1 CORE Consulting Engineers PLCEngineeri TadiyosNo ratings yet

- Drainage QCSDocument280 pagesDrainage QCSAyman Al HasaarNo ratings yet

- Specifications Fro Sewerage PlantDocument569 pagesSpecifications Fro Sewerage PlantfayasNo ratings yet

- MS GS I1r26 2 PDFDocument93 pagesMS GS I1r26 2 PDFCyrus YikNo ratings yet

- Desain LRT PDFDocument754 pagesDesain LRT PDFWahyu SaputraNo ratings yet

- Doosan Dx140LCRDocument314 pagesDoosan Dx140LCRko Autos100% (1)

- Aashto T 245Document10 pagesAashto T 245Conteconsanchez100% (2)

- NA To BS EN 1997-2 2007.aspx PDFDocument16 pagesNA To BS EN 1997-2 2007.aspx PDFDang Thanh TuanNo ratings yet

- Vdocument - in LRT Design GuidelinesDocument490 pagesVdocument - in LRT Design GuidelinesAlly KhooNo ratings yet

- Pumping Station Design GuidelinesDocument47 pagesPumping Station Design Guidelinesrotciv132709No ratings yet

- RICS - Paula Boast - Oman Arbitration and Dispute Resolution PDFDocument60 pagesRICS - Paula Boast - Oman Arbitration and Dispute Resolution PDFShijo PodiyanNo ratings yet

- Service Compendium 01 - 2013 enDocument162 pagesService Compendium 01 - 2013 enGerman CarbajalNo ratings yet

- Fidic Comparison PDFDocument46 pagesFidic Comparison PDFShijo PodiyanNo ratings yet

- Updated DPR For Chennai Metro Rail Phase-IIDocument645 pagesUpdated DPR For Chennai Metro Rail Phase-IINavinNo ratings yet

- Long Term Control Plan Part 3 of 3Document300 pagesLong Term Control Plan Part 3 of 3Loo Wei SungNo ratings yet

- Itsmanual PDFDocument157 pagesItsmanual PDFtesfayeNo ratings yet

- MORTH ClausesDocument3 pagesMORTH Clausesupeida dox100% (2)

- TR-514 (Road Design Manual) PDFDocument780 pagesTR-514 (Road Design Manual) PDFAbdullah Mansoor67% (3)

- OSN 3500 2500 1500 Hardware Description ManualDocument379 pagesOSN 3500 2500 1500 Hardware Description Manualngtinh100% (19)

- ACI 32510r - 95 PDFDocument32 pagesACI 32510r - 95 PDFFerdinand Yesaya NapitupuluNo ratings yet

- LNG To Power Addendum To EsIA Project EIA PDFDocument538 pagesLNG To Power Addendum To EsIA Project EIA PDFleonelNo ratings yet

- Arema Mre Chapter 6 2019Document3 pagesArema Mre Chapter 6 2019Septrum0% (1)

- Greenville County Stormwater ManualDocument193 pagesGreenville County Stormwater ManualD AuldNo ratings yet

- 5.0 General Technical SpecificationDocument39 pages5.0 General Technical SpecificationBishnu Thapa MagarNo ratings yet

- 03 Part 2 - Annex A - Customer System Requirement v1.0Document29 pages03 Part 2 - Annex A - Customer System Requirement v1.0Valentinas PranskunasNo ratings yet

- TM ACP Install (E)Document112 pagesTM ACP Install (E)enjiniring sbklNo ratings yet

- P WMA 11 - U10 - 00 - 3312 - 3 - 1 - 4-SD4 - Cost Model - FinalDocument133 pagesP WMA 11 - U10 - 00 - 3312 - 3 - 1 - 4-SD4 - Cost Model - FinalSokha RUNNo ratings yet

- Table of Contents Template 3Document2 pagesTable of Contents Template 3kehiv40245No ratings yet

- RFG 000310Document384 pagesRFG 000310Jaime OchoaNo ratings yet

- AES - MountainView - CUP - Waiver - 13may2022 REDACTEDDocument827 pagesAES - MountainView - CUP - Waiver - 13may2022 REDACTEDseyedamir mohammadiNo ratings yet

- DPR Ambala KurukshetraDocument85 pagesDPR Ambala KurukshetraAbdul Wajid AliNo ratings yet

- JG Supplier Quality Manual v00 0311Document21 pagesJG Supplier Quality Manual v00 0311BESNo ratings yet

- Spez LBR Iisy enDocument76 pagesSpez LBR Iisy enMatyas Takacs100% (1)

- Chapter 1: General Requirements: Able of OntentsDocument1 pageChapter 1: General Requirements: Able of OntentsARCH.A. AbualkassNo ratings yet

- Petroleum Regulations 101514Document107 pagesPetroleum Regulations 101514luiasnadradeNo ratings yet

- Duplicator JP730 JP735Document174 pagesDuplicator JP730 JP735Cristian BobaruNo ratings yet

- 6标技术文件Document294 pages6标技术文件Sudip ShresthaNo ratings yet

- Specification of Fast TrackDocument223 pagesSpecification of Fast TrackSudish amatyaNo ratings yet

- Cost Estimates of CSP 1335150Document107 pagesCost Estimates of CSP 1335150Hesham FandyNo ratings yet

- New Features in PLANBAR 2020-0Document100 pagesNew Features in PLANBAR 2020-0Koresh KhalpariNo ratings yet

- Estudo de Caso em TunelDocument126 pagesEstudo de Caso em TunelMSalesNo ratings yet

- Snow Making/Mountain Operations Technology Assessment: Final ReportDocument62 pagesSnow Making/Mountain Operations Technology Assessment: Final ReportJohn Lloyd UgaleNo ratings yet

- Qulliq Energy Corp., General Rate Application 2010Document285 pagesQulliq Energy Corp., General Rate Application 2010NunatsiaqNewsNo ratings yet

- Newfoundland Power Service and Metering Guide: Date Rev. DescriptionDocument53 pagesNewfoundland Power Service and Metering Guide: Date Rev. Descriptionparallax1957No ratings yet

- Structures Design ManualDocument171 pagesStructures Design ManualAshebir AjemaNo ratings yet

- V-10130901-0202-0193 Livre Du Tra 01Document51 pagesV-10130901-0202-0193 Livre Du Tra 0120501 20501No ratings yet

- Turma1 G01 RelDocument79 pagesTurma1 G01 RelFilipe MonteiroNo ratings yet

- Nuclear Commerce: Its Control Regime and the Non-Proliferation TreatyFrom EverandNuclear Commerce: Its Control Regime and the Non-Proliferation TreatyNo ratings yet

- 7 Top Recruitment Agencies in Germany For English Speakers - FasthireDocument8 pages7 Top Recruitment Agencies in Germany For English Speakers - FasthireShijo PodiyanNo ratings yet

- Bewerbung als "Position NameDocument3 pagesBewerbung als "Position NameShijo PodiyanNo ratings yet

- German Nominative Accusative Pronouns Cases ArticlesDocument8 pagesGerman Nominative Accusative Pronouns Cases ArticlesShijo PodiyanNo ratings yet

- Try This Malabar Tamarind Chutney To Reduce Belly Fat - Kerala RecipeDocument2 pagesTry This Malabar Tamarind Chutney To Reduce Belly Fat - Kerala RecipeShijo PodiyanNo ratings yet

- Blue Butterfly 'S Quotes From 6 August 2020 - 26 August 2020Document106 pagesBlue Butterfly 'S Quotes From 6 August 2020 - 26 August 2020Shijo PodiyanNo ratings yet

- Ehegattennachzug enDocument8 pagesEhegattennachzug enShijo PodiyanNo ratings yet

- Blue Butterfly 'S Quotes From 6 August 2020 - 26 August 2020Document106 pagesBlue Butterfly 'S Quotes From 6 August 2020 - 26 August 2020Shijo PodiyanNo ratings yet

- Earn Rs 25,000 Per Month Through Papaya TappingDocument4 pagesEarn Rs 25,000 Per Month Through Papaya TappingShijo PodiyanNo ratings yet

- Pavement Dwg.Document1 pagePavement Dwg.Shijo PodiyanNo ratings yet

- Easy Three-Ingredient Mysore Pak - Food - Manorama EnglishDocument1 pageEasy Three-Ingredient Mysore Pak - Food - Manorama EnglishShijo PodiyanNo ratings yet

- 10 Mistakes People Make While Construct..Document5 pages10 Mistakes People Make While Construct..Shijo PodiyanNo ratings yet

- FIDIC Lecture - EOT & Related Costs in ConstructionDocument39 pagesFIDIC Lecture - EOT & Related Costs in Constructionsomapala88No ratings yet

- Easy Way To Grow Roots in Almond Bought From Market PDFDocument1 pageEasy Way To Grow Roots in Almond Bought From Market PDFShijo PodiyanNo ratings yet

- Concrete Pour CardDocument2 pagesConcrete Pour CardShijo PodiyanNo ratings yet

- Detecting Dyslexia in Children - Lifestyle Health - English ManoramaDocument7 pagesDetecting Dyslexia in Children - Lifestyle Health - English ManoramaShijo PodiyanNo ratings yet

- LSW Specs PavingDocument58 pagesLSW Specs PavingShijo PodiyanNo ratings yet

- Design Req Gas Service InstallationDocument1 pageDesign Req Gas Service InstallationShijo PodiyanNo ratings yet

- Legend of Symbols: Drawing NumberDocument1 pageLegend of Symbols: Drawing NumberKHALED MOHAMMADNo ratings yet

- 003 - Piling WorksDocument3 pages003 - Piling WorksShijo PodiyanNo ratings yet

- Pipeline Gas Chapter2Document23 pagesPipeline Gas Chapter2LTE002No ratings yet

- SoCalGas Gas Regulator Location RequirementsDocument1 pageSoCalGas Gas Regulator Location RequirementsShijo PodiyanNo ratings yet

- Pipe SizeDocument1 pagePipe SizeShijo PodiyanNo ratings yet

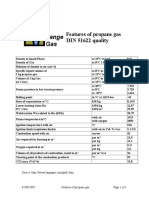

- Features of Propane Gas DIN 51622 QualityDocument1 pageFeatures of Propane Gas DIN 51622 QualityShijo PodiyanNo ratings yet

- Equipment Perfect NormsDocument1 pageEquipment Perfect NormsShijo PodiyanNo ratings yet

- Design Req Gas Service InstallationDocument51 pagesDesign Req Gas Service InstallationShijo PodiyanNo ratings yet

- Compaction Factor TestDocument3 pagesCompaction Factor TestNitisha Rathore100% (5)

- Sub Er Question Paper Sample 1Document11 pagesSub Er Question Paper Sample 1Sakar ShresthaNo ratings yet

- Towards Analytical Mix Design For Large-Stone Asphalt MixesDocument17 pagesTowards Analytical Mix Design For Large-Stone Asphalt MixesShyue Leong LeeNo ratings yet

- Schedule of Rates LGED PDFDocument363 pagesSchedule of Rates LGED PDFসামিউল হাসান শান্ত75% (4)

- Manual Testing ConceptsDocument9 pagesManual Testing ConceptsstinginxsNo ratings yet

- Especificaciones Tecnica Rola de Tiro BW6Document2 pagesEspecificaciones Tecnica Rola de Tiro BW6Walter HerreraNo ratings yet

- Indian Standard CodesDocument4 pagesIndian Standard CodesStar BlitzNo ratings yet

- MT Catalog 2015-2016Document258 pagesMT Catalog 2015-2016rubitovaleNo ratings yet

- 2.3 - Mr. Methsara Lokuge - Material Engineer (Matara) PDFDocument22 pages2.3 - Mr. Methsara Lokuge - Material Engineer (Matara) PDFmpchanakaNo ratings yet

- Experiment No. 2 California Bearing RatioDocument7 pagesExperiment No. 2 California Bearing RatioPatricia TubangNo ratings yet

- Practical No. 9 (CBR)Document5 pagesPractical No. 9 (CBR)slawek780303No ratings yet

- COMPACTION OF SOILS (Loiza)Document2 pagesCOMPACTION OF SOILS (Loiza)Loiza Joi MulanoNo ratings yet

- Questions and Answers For Preparation To UPDA ExamDocument9 pagesQuestions and Answers For Preparation To UPDA ExamSameh AllaouiNo ratings yet

- (Earth Filling) Purchase Order To HeavenDocument2 pages(Earth Filling) Purchase Order To HeavenShuhan Mohammad Ariful HoqueNo ratings yet

- Granular Material To Control Pumping Under Concrete PavementDocument1 pageGranular Material To Control Pumping Under Concrete PavementFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Concrete: CementDocument10 pagesConcrete: CementHumberto MorenoNo ratings yet

- Ball Embedment TestDocument4 pagesBall Embedment TestMansueta StefanusNo ratings yet

- ENCE340 SyllabusDocument4 pagesENCE340 SyllabusDaniel FioreNo ratings yet

- T Specs SRL-005Document226 pagesT Specs SRL-005Umar100% (1)

- Density of Soil and Rock in Place by The Water Replacement Method in A Test PitDocument14 pagesDensity of Soil and Rock in Place by The Water Replacement Method in A Test PitJesus Luis Arce GuillermoNo ratings yet

- Standard Practice For The Design and Construction of High Density Polyethylene Pipe (Hdpe)Document56 pagesStandard Practice For The Design and Construction of High Density Polyethylene Pipe (Hdpe)Cire Lop CastroNo ratings yet

- CS533E, CS533E XT, CP533E: Vibratory Soil CompactorsDocument12 pagesCS533E, CS533E XT, CP533E: Vibratory Soil CompactorsBudi setyantoNo ratings yet

- 7 - How To Make Concrete Pavers PDFDocument4 pages7 - How To Make Concrete Pavers PDFKan BunsamranjitNo ratings yet

- Keramo - Pipes - Vitrified 1Document60 pagesKeramo - Pipes - Vitrified 1sasa.vukoje100% (1)