Professional Documents

Culture Documents

Report On Loss of Compressor Oil From Primary Oil Seperator: Problem

Uploaded by

MugeshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report On Loss of Compressor Oil From Primary Oil Seperator: Problem

Uploaded by

MugeshCopyright:

Available Formats

REPORT ON LOSS OF COMPRESSOR OIL FROM PRIMARY OIL SEPERATOR

PROBLEM:

Reduction of oil level in primary oil separator of C 104 A3 found.

PROBLEM FACED:

The problems faced due to loss of oil from primary oil separator are as follows.

1. Oil manifold temperature high.

2. Discharge temperature high.

3. Discharge pressure high.

4. Motor amps increasing due to improper lubrication.

PROBLEM DESCRIPTION:

Initially during the oil change of C 104 A3 compressor on ,

Level of oil in % :

Level of oil as indicated by level troll :

The amount of oil added in litres :

The oil level was high, in turn caused rise in oil temperature, so in order to optimize the oil level

it was reduced.

Level of oil in % :

Level of oil as indicated by level troll :

The amount of oil removed in litres :

There was persistent reduction of oil level in primary oil separator.

A sudden decrease in level was observed after the draining of economizer.

PROBLEM ANALYSIS:

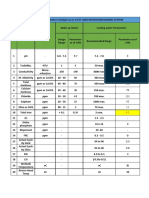

S.NO ACTION OBSERVATION FINDING

1 The drain line was Initially small quantity of oil was Some valve in the drain of

depressurized and opened to found , after which a continuous HT oil circulation system is

check availability of oil. flow was observed passing

2 The suction line and the No trace of oil found

strainer in the suction were

checked

3 The secondary oil separator 80 litres of oil found Too much oil carry over to

was drained secondary oil separator (10

ppm by design)

4 Economizer outlet was No trace of oil found

checked

5 Buffer tank T 402 drain was Nearly 3.25 drums (700 litres Oil was carried over from

checked approx ) of Oil were collected. primary oil separator to

buffer tank through the oil

reclaimer.

POSSIBLE REASONS:

1. The HT compressor package drain valve is not holding well.

2. The valve passing causes the oil to drain form primary oil separator.

3. The drain line is pressurized up to 15 Kg/cm2 (i.e the compressor discharge).

4. The pressurized oil in the drain line moves in to the economizer, which has lower pressure.

5. Whenever the economizer is opened to oil reclaimer in order to reduce its level, the oil is

carried over from the oil reclaimer to the buffer tank through the common line connecting

tank T101B.

6. This is also the reason for increase in economizer level, when it is opened to drain.

RECOMMENDATIONS:

1. Valve passing to be found and attended immediately.

2. Level gauge in T 402 to be made functional.

3. Method to note down the secondary oil separator oil pressure to be found.

4. An SOP to be made for regular draining of T-402 water and possible contamination

5. Secondary oil separator to compressor suction tubing to be checked and % of opening to be

fixed, so that the oil is circulated within the compressor.

You might also like

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- Group 12 LubricationDocument32 pagesGroup 12 LubricationLuisTocoraNo ratings yet

- Engines 19 Gas Turbine Lubrication PDFDocument31 pagesEngines 19 Gas Turbine Lubrication PDFCemalettin öztoprakNo ratings yet

- Seal Oil SysDocument32 pagesSeal Oil SysASHIT KUMAR100% (1)

- Turbine Lube Oil Operation GuideDocument34 pagesTurbine Lube Oil Operation GuideNIHAR BEHERANo ratings yet

- Power Plant Lube Oil Systems and BearingsDocument54 pagesPower Plant Lube Oil Systems and BearingsHelal RahmanNo ratings yet

- Flooded Eva PsDocument3 pagesFlooded Eva PszhyhhNo ratings yet

- Fuel OIL PurufierDocument43 pagesFuel OIL PurufierPatrickNo ratings yet

- 12 SM PDFDocument23 pages12 SM PDFPANHA MENNo ratings yet

- Crude Oil FiscalizationDocument33 pagesCrude Oil FiscalizationMax Singh100% (1)

- Fail Free Commissioning-Steam Turbine Lube Oil SystemDocument24 pagesFail Free Commissioning-Steam Turbine Lube Oil SystemPrabhudhasanNo ratings yet

- 623-12 - Oil SystemDocument60 pages623-12 - Oil SystemA ENGENHARIA DAS COISASNo ratings yet

- Turbine Lubrication System: A Chemical ApproachDocument33 pagesTurbine Lubrication System: A Chemical ApproachSanjit SahooNo ratings yet

- Sop For BFP PumpDocument1 pageSop For BFP PumpHardik ThumarNo ratings yet

- Engineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentDocument26 pagesEngineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentMuhammad aliNo ratings yet

- High ViscosityDocument4 pagesHigh ViscosityAnonymous XtvvG80zuNo ratings yet

- 840 Sample PDFDocument5 pages840 Sample PDFSyed BashaNo ratings yet

- Transformer Oil FiltrationDocument21 pagesTransformer Oil Filtrationnicholaslee100% (5)

- LubricationsDocument9 pagesLubricationsSamarth SNo ratings yet

- Purifier Manual Starting StoppingDocument3 pagesPurifier Manual Starting Stoppingavm4343No ratings yet

- Turbine Lube Oil System AND GENERATOR SealingDocument32 pagesTurbine Lube Oil System AND GENERATOR SealingNishant ChaudharyNo ratings yet

- Oil Circulation Tank 674 GB Register 7Document6 pagesOil Circulation Tank 674 GB Register 7hendraNo ratings yet

- Starting of Cent. PurifierDocument5 pagesStarting of Cent. PurifiermichaelNo ratings yet

- Starting of Cent. PurifierDocument5 pagesStarting of Cent. PurifiermichaelNo ratings yet

- H2 & Seal Oil SysDocument33 pagesH2 & Seal Oil Syssanmukha100% (1)

- Engine Systems SpecificationDocument10 pagesEngine Systems SpecificationAroonBhagwandinNo ratings yet

- Fuel Oil SysDocument58 pagesFuel Oil SysMAMADO2015No ratings yet

- Engine Lubrication System GuideDocument43 pagesEngine Lubrication System Guidekebaman1986No ratings yet

- Seal Oil SystemDocument40 pagesSeal Oil Systemsameer betalNo ratings yet

- Lec 4-Sounding SystemDocument38 pagesLec 4-Sounding SystemArwa Hussein100% (3)

- 2. الدائره الرئيسيةDocument3 pages2. الدائره الرئيسيةالمهندسوليدالطويلNo ratings yet

- APH Lube Oil Flushing - RajeevDocument4 pagesAPH Lube Oil Flushing - Rajeevvishal_vajatNo ratings yet

- Parallel Compressor Oil ManagementDocument4 pagesParallel Compressor Oil ManagementMohammad AmerNo ratings yet

- CMM10 0enDocument8 pagesCMM10 0enLê Viết TrungNo ratings yet

- Hot Oil Heater Manual R1Document14 pagesHot Oil Heater Manual R1Mahmoud Abd-Elhamid Abu EyadNo ratings yet

- Commander III Chapter Viii TroubleshootingDocument78 pagesCommander III Chapter Viii TroubleshootingFilippos100% (4)

- Derrickman Reports PDFDocument1 pageDerrickman Reports PDFjinyuan74No ratings yet

- 6.4L Lubrication SystemDocument7 pages6.4L Lubrication SystemHarsha Prakash GowdaNo ratings yet

- Carly - Oil ManagementDocument7 pagesCarly - Oil ManagementNor Firdaus YunusNo ratings yet

- Oil Flushing Procedures For Steam Turbine & Generator Sets 1Document8 pagesOil Flushing Procedures For Steam Turbine & Generator Sets 1atul singhNo ratings yet

- Group 12 Lubrication System GuideDocument29 pagesGroup 12 Lubrication System GuideMarco CalderonNo ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- PT6 T ENGINES OIL SYSTEMS OVERVIEWDocument45 pagesPT6 T ENGINES OIL SYSTEMS OVERVIEWmotores4297100% (1)

- Generator Seal Oil SystemDocument40 pagesGenerator Seal Oil Systembanukiran samboju100% (4)

- Understanding Oil Return in Refrigeration SystemsDocument6 pagesUnderstanding Oil Return in Refrigeration SystemsSvetoslav VlashkiNo ratings yet

- NNNDocument127 pagesNNNNeeraj maurya100% (2)

- Commissioning Seal Oil SystemDocument42 pagesCommissioning Seal Oil Systempushpa latha100% (1)

- Oil Mist LubricationDocument22 pagesOil Mist LubricationPitipong SunkhongNo ratings yet

- Module g11Document60 pagesModule g11Roderick M. DomioNo ratings yet

- Group 2 Main CircuitDocument3 pagesGroup 2 Main CircuitAlonso PachecoNo ratings yet

- ASHRAE STANDARD 69 - Summery PDFDocument14 pagesASHRAE STANDARD 69 - Summery PDFyogesh shindeNo ratings yet

- 6M7 - Gr12 JMLDocument26 pages6M7 - Gr12 JMLPyae Win MaungNo ratings yet

- Atlas Copco Xrvs 476 Manual (054 058) PDFDocument5 pagesAtlas Copco Xrvs 476 Manual (054 058) PDFjoseNo ratings yet

- General HydraulicsDocument36 pagesGeneral HydraulicsPeetNo ratings yet

- Switchboard Safety Devices: What Are ?Document8 pagesSwitchboard Safety Devices: What Are ?Chamika Dilshan WickramawardenaNo ratings yet

- LSMtron Operating MaintenanceDocument56 pagesLSMtron Operating MaintenanceCơ DungNo ratings yet

- Oil Mist Training - Maintenance LevelDocument63 pagesOil Mist Training - Maintenance LevelMatthew MontgomeryNo ratings yet

- Chapter 8. NGL Recovery-Lean Oil Absorption-1Document24 pagesChapter 8. NGL Recovery-Lean Oil Absorption-1Vikash Kumar ShuklaNo ratings yet

- Audel HVAC Fundamentals, Volume 2: Heating System Components, Gas and Oil Burners, and Automatic ControlsFrom EverandAudel HVAC Fundamentals, Volume 2: Heating System Components, Gas and Oil Burners, and Automatic ControlsNo ratings yet

- Centrifugal: CompressorsDocument98 pagesCentrifugal: CompressorsMugesh100% (1)

- 14-08 Microchem ReportDocument1 page14-08 Microchem ReportMugeshNo ratings yet

- Standards Followed in Design of Oil JettyDocument12 pagesStandards Followed in Design of Oil JettyMugeshNo ratings yet

- Improve manufacturing performance through loop checkingDocument8 pagesImprove manufacturing performance through loop checkingOhaneje Uzoma67% (3)

- CanteenDocument1 pageCanteenMugeshNo ratings yet

- Unloading HosesDocument8 pagesUnloading HosesMugeshNo ratings yet

- Design standards for cross-country pipelinesDocument14 pagesDesign standards for cross-country pipelinesMugeshNo ratings yet

- For More BPCL Papers - : Click HereDocument4 pagesFor More BPCL Papers - : Click HereMugeshNo ratings yet

- OISD Recommended Practices for Storing and Handling Bulk LPGDocument40 pagesOISD Recommended Practices for Storing and Handling Bulk LPGMugeshNo ratings yet

- OISD Standard for Optimized Oil and Gas Installation LayoutsDocument29 pagesOISD Standard for Optimized Oil and Gas Installation LayoutsMugeshNo ratings yet

- Six Sigma Green Belt: (Weekend-Centred GB - 51 Batch)Document4 pagesSix Sigma Green Belt: (Weekend-Centred GB - 51 Batch)MugeshNo ratings yet

- (II) S.No. Technical Assistant Trainees (TAT) / Lab Analyst Trainees (LAT) Qualification No. of PostsDocument7 pages(II) S.No. Technical Assistant Trainees (TAT) / Lab Analyst Trainees (LAT) Qualification No. of Postssurendar kohliNo ratings yet

- EB Power Consumption & Cost For April'18: LT /HT DG Power Generation & It's CostDocument4 pagesEB Power Consumption & Cost For April'18: LT /HT DG Power Generation & It's CostMugeshNo ratings yet

- On Industrial Hazards and Safe Handling of Hazardous MaterialsDocument34 pagesOn Industrial Hazards and Safe Handling of Hazardous MaterialsMugeshNo ratings yet

- Shift Schedule Intercom NumbersDocument11 pagesShift Schedule Intercom NumbersMugeshNo ratings yet

- CHE 31 Chemical Engineering CalculationsDocument13 pagesCHE 31 Chemical Engineering CalculationsxxkooonxxNo ratings yet

- Shift Incharge ResponsibilitiesDocument1 pageShift Incharge ResponsibilitiesMugeshNo ratings yet

- Tuticorin Terminal Wins Best Terminal Award for 2016Document2 pagesTuticorin Terminal Wins Best Terminal Award for 2016MugeshNo ratings yet

- Risk Assessment Check List - Condensate ProjectDocument6 pagesRisk Assessment Check List - Condensate ProjectMugeshNo ratings yet

- Butane Propane SL No N-Butane Isobutane Propane Butane WT% Propane WT%Document9 pagesButane Propane SL No N-Butane Isobutane Propane Butane WT% Propane WT%MugeshNo ratings yet

- Vapour PR Vs TemperatureDocument5 pagesVapour PR Vs TemperatureMugeshNo ratings yet

- A1 Side Suction NRVDocument4 pagesA1 Side Suction NRVMugeshNo ratings yet

- LPG Physical PropertiesDocument6 pagesLPG Physical PropertiesMugeshNo ratings yet

- Lect12 Recycle Bypass PurgeDocument1 pageLect12 Recycle Bypass PurgeMugeshNo ratings yet

- Volume Correction Factors-Liquefied Petroleum Gas or PropaneDocument5 pagesVolume Correction Factors-Liquefied Petroleum Gas or PropaneDadang Ibnu SetyawanNo ratings yet

- LPG Storage Terminal,: TuticorinDocument1 pageLPG Storage Terminal,: TuticorinMugeshNo ratings yet

- Hazop Condesate LoadingDocument9 pagesHazop Condesate LoadingMugeshNo ratings yet

- LPG Storage Terminal,: TuticorinDocument1 pageLPG Storage Terminal,: TuticorinMugeshNo ratings yet

- Our Valued Client: Presented ToDocument65 pagesOur Valued Client: Presented ToMugeshNo ratings yet

- Human Resouse Accounting Nature and Its ApplicationsDocument12 pagesHuman Resouse Accounting Nature and Its ApplicationsParas JainNo ratings yet

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDocument12 pages2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalNo ratings yet

- WassiDocument12 pagesWassiwaseem0808No ratings yet

- ME6404 Thermal EngineeringDocument18 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- Piping MaterialDocument45 pagesPiping MaterialLcm TnlNo ratings yet

- 14 15 XII Chem Organic ChaptDocument2 pages14 15 XII Chem Organic ChaptsubiNo ratings yet

- SD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Document6 pagesSD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Lawrence PeNo ratings yet

- Abinisio GDE HelpDocument221 pagesAbinisio GDE HelpvenkatesanmuraliNo ratings yet

- Conceptual FrameworkDocument24 pagesConceptual Frameworkmarons inigoNo ratings yet

- Computer Portfolio (Aashi Singh)Document18 pagesComputer Portfolio (Aashi Singh)aashisingh9315No ratings yet

- 13 Fashion Studies Textbook XIDocument158 pages13 Fashion Studies Textbook XIMeeta GawriNo ratings yet

- (Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingDocument17 pages(Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingKatherine Natalia Pino Arredondo100% (1)

- Microsoft Word 2000 IntroductionDocument72 pagesMicrosoft Word 2000 IntroductionYsmech SalazarNo ratings yet

- Inbound 9092675230374889652Document14 pagesInbound 9092675230374889652Sean Andrew SorianoNo ratings yet

- EnerSys Global Leader in Industrial BatteriesDocument32 pagesEnerSys Global Leader in Industrial BatteriesAshredNo ratings yet

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDocument11 pagesOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanNo ratings yet

- Obligations and Contracts Bar Questions and Answers PhilippinesDocument3 pagesObligations and Contracts Bar Questions and Answers PhilippinesPearl Aude33% (3)

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Amar Sonar BanglaDocument4 pagesAmar Sonar BanglaAliNo ratings yet

- Binomial ExpansionDocument13 pagesBinomial Expansion3616609404eNo ratings yet

- A General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDocument37 pagesA General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDiego JesusNo ratings yet

- HistoryDocument144 pagesHistoryranju.lakkidiNo ratings yet

- Rhodes Motion For Judicial NoticeDocument493 pagesRhodes Motion For Judicial Noticewolf woodNo ratings yet

- IELTS Vocabulary ExpectationDocument3 pagesIELTS Vocabulary ExpectationPham Ba DatNo ratings yet

- The Changing Face of War - Into The Fourth GenerationDocument5 pagesThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozNo ratings yet

- Time Table For Winter 2023 Theory ExaminationDocument1 pageTime Table For Winter 2023 Theory ExaminationSushant kakadeNo ratings yet

- Mythi From AndromedaDocument383 pagesMythi From AndromedaRico MinnerNo ratings yet

- Cells in The Urine SedimentDocument3 pagesCells in The Urine SedimentTaufan LutfiNo ratings yet

- Brain, Behavior, and Immunity: Alok Kumar, David J. LoaneDocument11 pagesBrain, Behavior, and Immunity: Alok Kumar, David J. LoaneRinaldy TejaNo ratings yet

- Capacity PlanningDocument19 pagesCapacity PlanningfarjadarshadNo ratings yet