Professional Documents

Culture Documents

ATEX HMI Fault and Explanation PDF

Uploaded by

Jessie GoranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATEX HMI Fault and Explanation PDF

Uploaded by

Jessie GoranCopyright:

Available Formats

M M

a i

j n

o o

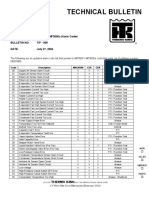

Fault Description

r r ACOM CO DETECTION

F F Troubleshoot

a a

u u

l l

t t

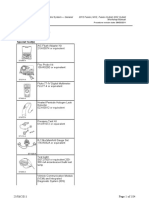

Fault: HORIBA Power down or Horiba Main switch off x - Check Switch / Check Power Supply / Check Fuse

Fault: HORIBA Sample flow rate and pressure is out of specified range x - Open Analyzer / Check Tubing against leaks or blockages / Check Gas Pump

Fault: Exhaust air 1 flow performance too low x - Check Gas Pump inside cabinet /Check Butterfly valve / Check tubing against blockages / check cabinet for leak

Fault: Inlet air 1 flow performance too low x - Check Gas Pump inside cabinet / Check tubing against blockages / check cabinet for leak

Fault: Inlet air 2 flow performance too low x - Check Gas Pump inside cabinet / Check tubing against blockages / check cabinet for leak

Fault: Inlet air 3 flow performance too low x - Check Gas Pump inside cabinet / Check tubing against blockages / check cabinet for leak

Fault: Gas Cooler 1 temperature out of range (low / high alrm) x - Check Gas Cooler / Check Cooler Filter math / Check if cabinet fan is working

Fault: Gas Cooler 2 temperature out of range (low / high alrm) x - Check Gas Cooler / Check Cooler Filter math / Check if cabinet fan is working

Fault: Condenstate guard detecting water penetration x - Check Perestaltic pumps / Check Cooler for functioning

Check if setpoint of the thermostate is 35 degrees( Top right side of the Cabinet - open door on back) Check cabinet

Fault: Cabinet temperature too high for more then 24 hours

x - fan for functioning / Clean filter math of cabinet fan / check air condition of the MCC room

Fault: Analogue signal straight for more than 12 hours x - Check in calibration mode if analogue signal is moving by injecting test gas to the Analyzer / Exchange Analyzer

Fault: Analogue input signal range over flow for more then 24 hours x - Check in calibration mode if analogue signal is moving by injecting test gas to the Analyzer / Exchange Analyzer

Fault: Analogue input signal wire break x - Check in calibration mode if analogue signal is moving by injecting test gas to the Analyzer / Exchange Analyzer

Fault: Exhaust air 1 leakage test failure x - Check for Butterfly Valve is actuating ( 24 Volts ) Check Pressured air supply on butterfly valve / Check Tubing

Fault: Pressure switch detecting low pressure x - Check The Ratio Gas Pump / Check inside Cabinet Tubing / Check the Ratio Underpressure switch

Fault: CO value less than -0,5 ppm for more than 24 hours x - Check in calibration mode if analogue signal is moving by injecting test gas to the Analyzer / Exchange Analyzer

Warning: HORIBA Catalyzer temperature is too low - x Normally this accours when Analyzer is Powered up / Wait for Analyzer reaching his Catalyzer temperature

Warning: HORIBA General fault (Battery low, Temperature sensor fault) - x Open Analyzer / Check Tubing against leaks or blockages / Check for loosen connectors / Exchange Analyzer

Warning: PLC Battery low power - x Exchange PLC Battery

Check if setpoint of the thermostate is 35 degrees( Top right side of the Cabinet - open door on back) Check cabi

Warning: Cabinet temperature too high

- x for functioning / Clean filter math of cabinet fan / check air condition of the MCC room

Warning: Analogue signal straight - x Check for electrical connection of the Analog signal from Analyzer to cabinet terminal / Exchange Analyzer

Warning: Analogue input signal range over flow - x Check in calibration mode if analogue signal is moving by injecting test gas to the Analyzer / Exchange Analyzer

Warning: CO value exceed disarm alarm limit - x Check the Process ambience / Is there any CIP going on near by the probes? / Check if CIP mode is activated

Check if dryer is running / Check the Process ambience / Is there any CIP going on near by the probes?

Warning: CO value less than -0,5 ppm for more than 1 hour

- x Check if CIP mode is activated

Warning: Connection to HMI was discountected - x Check electrical connectors of the HMI display

Alarm 1: CO Value exceed alarm level 1 limit (Warning) - x Check Process for temperatures / Is there Anything abnormal from process / Any changes made in process / Are process airflows as usual

Alarm 2: CO Value exceed alarm level 2 limit (Controlled shut-down) - x Check Process for temperatures / Is there Anything abnormal from process / Any changes made in process / Are process airflows as usual

Alarm 3: CO Value exceed alarm level 3 limit (Emergency shut-down and deluge) - x Check Process for temperatures / Is there Anything abnormal from process / Any changes made in process / Are process airflows as usual

Check if dryer is running / Check the Process ambience / Is there any CIP going on near by the probes?

Alarm Passiv: CO Value exceed passiv alarm level

- x Check if CIP mode is activated / Check process for smoldering smells

Warning CF-Card : File Create Error - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File Open Error - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File Write Error - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File Close Error - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File Delete Error - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : Not present - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File could not be created - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File could not be opened - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning CF-Card : File could not be written - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

Warning : Data Log is stopped - x Check Rockwell Card / Switch Key of Rockwell to Stop Mode / Take out card of Rockwell PLC / Read out data sets with the PC / Erase Data sets

You might also like

- 16.heating, Ventilation, Air ConditioningDocument112 pages16.heating, Ventilation, Air Conditioningrobin machadoNo ratings yet

- Maintenance and TroubleshootingDocument3 pagesMaintenance and TroubleshootingOkta AdityaNo ratings yet

- Melag Vacu 23-31 - Fault DiagnosisDocument25 pagesMelag Vacu 23-31 - Fault DiagnosisFrepa_AL100% (3)

- Week 4 - Control Valve PDFDocument13 pagesWeek 4 - Control Valve PDFNur AinNo ratings yet

- ODME Operation InstrDocument5 pagesODME Operation InstrCelal BozdoganNo ratings yet

- Fractionation Tower Controls-Part 1Document38 pagesFractionation Tower Controls-Part 1Rebekah Schmidt100% (1)

- UPDATED6NOV2014-ClassNotes-CONTROL VALVESDocument40 pagesUPDATED6NOV2014-ClassNotes-CONTROL VALVESharrisNo ratings yet

- CO2 System For Engine Room AssignmentDocument7 pagesCO2 System For Engine Room AssignmentVyas SrinivasanNo ratings yet

- Ammonia Detection - Codes & Design Calibration TechDocument7 pagesAmmonia Detection - Codes & Design Calibration TechChrise5502No ratings yet

- Quick Guide On RSP and Kiln Gas Analyzer TroubleshootingDocument5 pagesQuick Guide On RSP and Kiln Gas Analyzer Troubleshootingjun101phNo ratings yet

- Ammonia Detection System Codes and Design Specifications PDFDocument7 pagesAmmonia Detection System Codes and Design Specifications PDFGilberto SanchezNo ratings yet

- TIP005 - MP3000 - MP3000a Alarm CodesDocument2 pagesTIP005 - MP3000 - MP3000a Alarm CodesSerhii75% (4)

- Installation GuideDocument42 pagesInstallation GuideMubashir RajpootNo ratings yet

- General Engine Data Groups 001-009Document14 pagesGeneral Engine Data Groups 001-009Sebastian PoliticNo ratings yet

- Open University' Project Automatic Controls 1 TR-GCM-08 1Document66 pagesOpen University' Project Automatic Controls 1 TR-GCM-08 1hamid vahedil larijaniNo ratings yet

- 0801 B2 BSolutionDocument3 pages0801 B2 BSolutionsajuhereNo ratings yet

- A320 Normal Procedures PDFDocument40 pagesA320 Normal Procedures PDFBright PathNo ratings yet

- Mastercool Air Conditioner Service ManualDocument2 pagesMastercool Air Conditioner Service ManualJubril Akinwande100% (1)

- 13 Alarm ListDocument16 pages13 Alarm Listedisonbobis15No ratings yet

- Ammonia Detection System: Codes and Design SpecificationsDocument8 pagesAmmonia Detection System: Codes and Design SpecificationsnaseerpashaNo ratings yet

- Código de Erro Statim G4Document5 pagesCódigo de Erro Statim G4Rafael OliveiraNo ratings yet

- Checking Charge WO GaugesDocument4 pagesChecking Charge WO GaugesNew UserNo ratings yet

- A320 Normal ProceduresDocument40 pagesA320 Normal ProceduresRajesh KumarNo ratings yet

- Calibration and Leak-By Test ProceduresDocument2 pagesCalibration and Leak-By Test Proceduresromi_hamdaniNo ratings yet

- Instrumentation Engineer InterviewDocument24 pagesInstrumentation Engineer InterviewNGASSAKI ATONGUI Christ HubertNo ratings yet

- Oral QuestionsDocument145 pagesOral QuestionsVinothen Raj100% (2)

- PinpointsDocument104 pagesPinpointscarloschcarNo ratings yet

- A320 Normal Procedures: Last UpdatedDocument41 pagesA320 Normal Procedures: Last UpdatedabhiNo ratings yet

- A320 Normal Procedures: Last UpdatedDocument41 pagesA320 Normal Procedures: Last UpdatedMax HayesNo ratings yet

- Cleaning at Kiln Take Up Pulley SOPDocument147 pagesCleaning at Kiln Take Up Pulley SOPu10ch019No ratings yet

- Devicenet Network Card: Valve Monitoring SystemsDocument2 pagesDevicenet Network Card: Valve Monitoring SystemsWiliam Robert CarvalhoNo ratings yet

- Mitsubishi Fault Codes PDFDocument38 pagesMitsubishi Fault Codes PDFMislav Perin100% (2)

- 1YR PM ChecklistDocument2 pages1YR PM ChecklistAlexandra JanicNo ratings yet

- Every Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipDocument5 pagesEvery Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipjoyceNo ratings yet

- PRESTART UP CHECKS FOR BOILER DRUM FILLINGDocument3 pagesPRESTART UP CHECKS FOR BOILER DRUM FILLINGPrudhvi RajNo ratings yet

- A320 Ame Self ExaminationDocument6 pagesA320 Ame Self ExaminationKarwane MuntazireenNo ratings yet

- DesignDocument23 pagesDesignChukwuma OnukuNo ratings yet

- HAZOP ReportDocument4 pagesHAZOP ReportHtoo Akari KhinNo ratings yet

- Alaris 7100-7200 Infusion Pump - Service GuidelineDocument4 pagesAlaris 7100-7200 Infusion Pump - Service Guidelinethe7king the7kingNo ratings yet

- Prosedur Pencegah KebakaranDocument2 pagesProsedur Pencegah KebakaranNeguib FarahNo ratings yet

- Scanner Calibration and Operation GuideDocument4 pagesScanner Calibration and Operation GuideCrystal KingNo ratings yet

- Operation: Service PortsDocument17 pagesOperation: Service PortsJulietina PerezNo ratings yet

- WJL 6000Document8 pagesWJL 6000totoNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Operating Instructions Manifold Charging and TestingDocument20 pagesOperating Instructions Manifold Charging and TestingLUIS FERNANDO PINONo ratings yet

- ERT 321 Process Control & DynamicsDocument49 pagesERT 321 Process Control & Dynamicshakita86No ratings yet

- ENM-10 Level SensorsDocument6 pagesENM-10 Level SensorsAnteUkićNo ratings yet

- Dynamic Pass BoxDocument3 pagesDynamic Pass BoxMd.Tareque AbdullahNo ratings yet

- Ventilator TroubleshootingDocument4 pagesVentilator TroubleshootingerwanNo ratings yet

- Habor Precise Alarm Codes AB Type 2B Controller: Error ExplanationDocument6 pagesHabor Precise Alarm Codes AB Type 2B Controller: Error ExplanationBeroaldo AmorimNo ratings yet

- BPI BA Field Test Checklist: Discussion With HomeownerDocument5 pagesBPI BA Field Test Checklist: Discussion With HomeownerbullfrogkillerNo ratings yet

- Instrumentation Interview QuestionsDocument72 pagesInstrumentation Interview QuestionsGowtham An94% (18)

- A320 Normal ProceduresDocument41 pagesA320 Normal ProceduresIlker BakkalNo ratings yet

- Tank Relief PhilosophyDocument8 pagesTank Relief Philosophyking4lifeNo ratings yet

- Instructions For Changing A Complete Burnout CompressorDocument25 pagesInstructions For Changing A Complete Burnout Compressorapi-242281017No ratings yet

- Ammonia Detection System Codes and Design SpecificationsDocument10 pagesAmmonia Detection System Codes and Design Specificationsluv muvNo ratings yet

- HWDocument20 pagesHWAnonymous zpitrB80oNo ratings yet

- DatashKFD2eet 1Document3 pagesDatashKFD2eet 1kfd2No ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Nagpur - Soil Report - Unlocked PDFDocument56 pagesNagpur - Soil Report - Unlocked PDFANKESH SHRIVASTAVANo ratings yet

- Harvia Products For Steam Room: Natural Well-BeingDocument4 pagesHarvia Products For Steam Room: Natural Well-BeingAhmadSalaimehNo ratings yet

- Saep 500Document9 pagesSaep 500Anonymous 4IpmN7OnNo ratings yet

- Thermax 1Document53 pagesThermax 1Miera MoreNo ratings yet

- Bill of Materials Perimeter Fence - PartialDocument2 pagesBill of Materials Perimeter Fence - PartialEljoy C. Agsamosam100% (1)

- 2012 Leatherman Military CatalogDocument28 pages2012 Leatherman Military CatalogMario LopezNo ratings yet

- Crown Battery Service Manual 101110Document42 pagesCrown Battery Service Manual 101110Nelson Canteri100% (1)

- Exposed Linear Encoders HeidenheinDocument76 pagesExposed Linear Encoders HeidenheinKenan HebibovicNo ratings yet

- WagonR CNG ManualDocument20 pagesWagonR CNG ManualbhoiniravNo ratings yet

- 061FDocument1 page061FRoddy GonzalezNo ratings yet

- Datasheet Briosil Primer 6-7360P - Eng - 25-08-11Document3 pagesDatasheet Briosil Primer 6-7360P - Eng - 25-08-11SUBODHNo ratings yet

- Samsung Pd22eo Chassis Lw22a13w LCD TV SMDocument96 pagesSamsung Pd22eo Chassis Lw22a13w LCD TV SMchiru.stefan5869No ratings yet

- IQ/OQ Protocol: Installation Qualification/ Operation QualificationDocument12 pagesIQ/OQ Protocol: Installation Qualification/ Operation QualificationRambabu komati - QANo ratings yet

- F400E Bubble-03445C-06 EN HR MK SL SQ SR PDFDocument288 pagesF400E Bubble-03445C-06 EN HR MK SL SQ SR PDFtmpopescuNo ratings yet

- Muhammad Amiruddin Bin Ahmad: Contact DetailsDocument3 pagesMuhammad Amiruddin Bin Ahmad: Contact DetailsMuhammad Amiruddin Bin AhmadNo ratings yet

- Forensics Activity 6.5Document2 pagesForensics Activity 6.5vivek jangraNo ratings yet

- ASME Class 150-300 Cast Stainless Steel Gate & Globe Valves 1/2-24Document10 pagesASME Class 150-300 Cast Stainless Steel Gate & Globe Valves 1/2-24Andres CortezNo ratings yet

- Have ST DoneDocument2 pagesHave ST DoneBeatriz LGNo ratings yet

- 2009 Coal Clean TechnologyDocument71 pages2009 Coal Clean TechnologyCapoeira SitanggangNo ratings yet

- Kitchen Equipment Boq PDFDocument82 pagesKitchen Equipment Boq PDFAnonymous qOBFvINo ratings yet

- 1YSA160042 en Brochure AutoLink ALTADocument12 pages1YSA160042 en Brochure AutoLink ALTAninjaNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Policy Mandate of R.A. 8559Document15 pagesPolicy Mandate of R.A. 8559jaypeneyra100% (1)

- K-Chief 500 AmcsDocument34 pagesK-Chief 500 AmcsZacharioudakis Iasonas0% (1)

- 02c Bim PXP Template v2.0 PDFDocument18 pages02c Bim PXP Template v2.0 PDFLeonardo ManzioneNo ratings yet

- Byelaws of MohaliDocument42 pagesByelaws of MohaliAkshay GuptaNo ratings yet

- One GPL GBDocument35 pagesOne GPL GBRadu DobreNo ratings yet

- TR 45-02 Literatur RPMDocument8 pagesTR 45-02 Literatur RPMZen MuttNo ratings yet

- Lean Technology and Waste Minimization in Construction Industry Using SPSSDocument11 pagesLean Technology and Waste Minimization in Construction Industry Using SPSSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Witness Test Data ProgramDocument3 pagesWitness Test Data ProgrameduardolsNo ratings yet