Professional Documents

Culture Documents

m3 Sonar Phs

Uploaded by

Boris GasevicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m3 Sonar Phs

Uploaded by

Boris GasevicCopyright:

Available Formats

APPLICATION NOTE

STRUCTURE INSPECTION

M3 SONAR® PHS

SHALLOW-WATER PORTABLE HYDROGRAPHIC SYSTEM (PHS)

Applications Fast, Easy Plug-and-Play Set-Up and Take-Down

• Engineering inspection of marine structures in ports and harbours The M3 Sonar PHS is a complete plug-and-play system that includes

Plan View (North Up) Isometric View • Dams and water intake inspections all required sensors for deployment.

• Bridge pier and dock inspections

• Shallow water surveys Preconfigured Survey Acquisition and Processing Software

• Outfalls and pipe inspections The M3 Sonar PHS provides excellent survey data at very low cost.

• Pipeline surveys All sensors are input to a laptop computer that is preconfigured with

• Dredge monitoring the user’s specified survey acquisition and processing software and

the M3 Software. The M3 Sonar PHS operates seamlessly with

High Performance at Low Cost HYPACK HYSWEEP and QINSy.

The M3 Sonar® PHS is a powerful, affordable, entry level turn-key

survey system. M3 Sonar PHS features an incredibly small multi- Proven M3 Series MultiMode Multibeam Sonar

beam sonar head and convenient top-side interface unit including a The core of the M3 Sonar PHS is Kongsberg Mesotech’s proven M3

commercial laptop. Special rack mounts are not required. M3 Sonar Series MultiMode Multibeam Sonar. The M3 Sonar is the only instru-

PHS delivers excellent quality data at very low cost of ownership. It is ment in its price point that produces high-quality imaging records and

designed for rapid installation, operation and removal using vessels of 3D bathymetric datasets using the same sonar head.

opportunity.

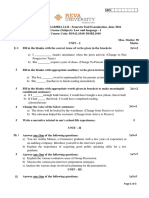

Structure Inspection: Side View Compact and Integrated INS/GNSS System

IHO Compliance to Special Order & 1A Attitude and Positioning Sensor with antennas and receivers. No

The M3 Sonar is capable of achieving bathymetric survey data that accuracy degradation in roll, pitch and heave measurements during

SHEET PILE WALL meets two orders of IHO standards. Specifically: turns; 120 channel dual frequency GPS/GLONASS receiver, RTK,

• Vertical Accuracy compliance can be met over the full +/-60° sector SBAS correction; can support Omnistar and Marinestar

for Order 1 surveys and to at least +/-55° for Special Order.

• Special Order target detection (1 m cube) is met to 20 m and Order Seapath 130-3 (with MRU-3) to 0.08° roll & pitch accuracy

1A target detection (2 m cube) is maintained to 40 m. Seapath 130-H (with MRU-H) to 0.03° roll & pitch accuracy

Exposed sheet wall due to scour

A collapsed portion of the sheet wall

Specifications subject to change without any further notice.

www.kongsbergmesotech.com E-mail: km.sales.vancouver@km.kongsberg.com

Telephone: +1 604 464 8144 Mactaquac Headpond Survey

Toll-free: +1 888 464 1598

Image courtesy of UNB Ocean Mapping Group

M3 SONAR® PHS SYSTEM CONFIGURATION DESIGN

The Seapath 130 series is developed specifically for hydrographic

surveying where high precision heading, position, roll, pitch, heave and

timing are critical measurements. The product combines state-of-the-

art dual frequency GNSS receivers, inertial technology and processing

algorithms in a compact and portable package.

The advanced Seapath navigation algorithms integrates RTK GNSS

data with the inertial sensor data from the MRU. This gives the Seapath

130 unique advantages compared to stand- alone RTK products. The

Seapath product’s accurate roll, pitch and heading measurements allow

the RTK antenna position to be referenced to any point on the vessel

where accurate position and velocity are required. All data from

Seapath have the same time stamp and the output is in real-time.

Subdecimetre position accuracy can be achieved through download

of satellite orbit and clock data from internet and by post processing of

satellite and MRU data.

Seapath® Compact 130 Series

STRUCTURE INSPECTION

You might also like

- 2008 Hummer h2 OwnersDocument504 pages2008 Hummer h2 OwnersBoris GasevicNo ratings yet

- Kongsberg Hydrographic Brochure v1 LRDocument17 pagesKongsberg Hydrographic Brochure v1 LRBoris GasevicNo ratings yet

- EX1R Housing Setup GuideDocument26 pagesEX1R Housing Setup GuideBoris GasevicNo ratings yet

- GoPro HERO3 BlackUM ENG 130-02482-000 RevCDocument66 pagesGoPro HERO3 BlackUM ENG 130-02482-000 RevCBoris GasevicNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- C-Band Block Frequency ConvertersDocument2 pagesC-Band Block Frequency ConvertersThanhNo ratings yet

- Bovee Bct9 Tif 12Document16 pagesBovee Bct9 Tif 12Mussadaq JavedNo ratings yet

- Certificate SampleDocument2 pagesCertificate SampleAljenneth MicallerNo ratings yet

- CRI Profile v1.2 User Guide Text Final Dec.14.2021Document10 pagesCRI Profile v1.2 User Guide Text Final Dec.14.2021pedroponceNo ratings yet

- Formacion Continua OnlineDocument1 pageFormacion Continua OnlineVictor ArevaloNo ratings yet

- Upgrading Cowon A2 HDDDocument11 pagesUpgrading Cowon A2 HDDgaddNo ratings yet

- Math - Can't Understand The Cost Function For Linear Regression - Stack OverflowDocument2 pagesMath - Can't Understand The Cost Function For Linear Regression - Stack OverflowriteshNo ratings yet

- PhotogrammetryDocument45 pagesPhotogrammetryValerie VictoriaNo ratings yet

- Lesson 4 Activity CrashingDocument17 pagesLesson 4 Activity CrashingMuhammad Syahir BadruddinNo ratings yet

- Corel Draw New Product Flyer Tutorial 130528105758 Phpapp01 PDFDocument31 pagesCorel Draw New Product Flyer Tutorial 130528105758 Phpapp01 PDFSima DragosNo ratings yet

- FLEXIBOWL V2.0 - Electrical Panel (EN)Document7 pagesFLEXIBOWL V2.0 - Electrical Panel (EN)Adolfo ReverteNo ratings yet

- Hummer Space Adventure Service ManualDocument73 pagesHummer Space Adventure Service ManualTony KututoNo ratings yet

- EmanuelDocument4 pagesEmanuelbawihpuiapaNo ratings yet

- QP 5Document129 pagesQP 5Kaushal Suresh SanabaNo ratings yet

- SDL in PracticeDocument32 pagesSDL in PracticeJeaze Dias da SilvaNo ratings yet

- Maths Clinic Gr12 ENG SmartPrep v1.0 1 PDFDocument69 pagesMaths Clinic Gr12 ENG SmartPrep v1.0 1 PDFNakeisha Jesse Napallatan50% (6)

- Case Study of Building A Data Warehouse With Analysis ServicesDocument10 pagesCase Study of Building A Data Warehouse With Analysis ServicesbabussnmcaNo ratings yet

- Basics of Computer SystemsDocument37 pagesBasics of Computer SystemsANANDA RAO DEVARAKONDANo ratings yet

- 3D Printing For The Jewellery IndustryDocument4 pages3D Printing For The Jewellery Industryru4angelNo ratings yet

- Sagemcom GSMR WorkshopDocument15 pagesSagemcom GSMR WorkshopstorpiNo ratings yet

- Objective Measurement of Speech Privacy in Open Offices Using Articulation IndexDocument6 pagesObjective Measurement of Speech Privacy in Open Offices Using Articulation IndexNada KhlifNo ratings yet

- Assignment 1 TasksDocument3 pagesAssignment 1 TasksNur SabrinaNo ratings yet

- Conceptual Framework-ThesisDocument3 pagesConceptual Framework-ThesisKristyl PereyeNo ratings yet

- Kaoru IshikawaDocument4 pagesKaoru IshikawapearlsugarfairyNo ratings yet

- inteliLIGHT® LoRa Data Sheet - FRE-220 ControllerDocument2 pagesinteliLIGHT® LoRa Data Sheet - FRE-220 ControllerSanela BeganovicNo ratings yet

- Error CodesDocument10 pagesError CodesSwapnali ShindeNo ratings yet

- Module 2 Creating A Wbs 1Document6 pagesModule 2 Creating A Wbs 1api-639091589No ratings yet

- Positioning Dominoes With Expressions: TwistDocument12 pagesPositioning Dominoes With Expressions: TwistGustavoLadinoNo ratings yet

- Research Paper Two-ColumnDocument22 pagesResearch Paper Two-ColumnJoseph TsoNo ratings yet

- CustomSim VCS WPDocument11 pagesCustomSim VCS WPManda SwamyNo ratings yet