Professional Documents

Culture Documents

Tips Pressure Gauge

Uploaded by

AleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tips Pressure Gauge

Uploaded by

AleCopyright:

Available Formats

Technical Bulletin #078

Transmission: General

Subject: Pressure gauge

Application: Misc.

Issue Date: November, 1991

General

Pressure Gauge

A significant number of calls we receive involve improper pressures, so we need to use a pressure gauge

when diagnosing problems.

Using a pressure gauge can seem like a formidable task. The reason most people do not use a pressure gauge is

because they do not see the value in using one. Technicians do not see the value because the gauge readings do

not tell them how to fix the problem. This article will attempt to show the technician how to interpret pressure

gauge readings so the technician can find the fix to the problem.

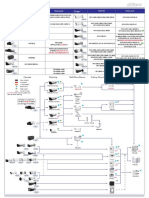

It is best to start pressure tests with mainline pressure. Mainline pressure should be checked in each range: P, R,

N, D, 3, 2, 1. Each range, except Park and Neutral, should be checked under three conditions: Slow idle, fast

idle, and wide open throttle. A form, as in figure 1 should be made to record the readings.

If all pressures are within specification at slow idle then the pump and pressure regulator are functioning proper-

ly.

If all pressures are low at slow idle, it indicates a potential problem in the pump, pressure regulator, filter, low

fluid, or internal leakage. To help verify where the problem is, check pressures at fast idle. If all the pressure

now read normally, it usually indicates a worn pump but the problem could still be internal leaks.

Copyright © 2003 ATRA. All Rights Reserved. ! Page 1 of 2

Technical Bulletin #078

Internal leaks will usually show up in a particular range. For example a forward clutch leak would have normal

pressure in Park, Reverse and Neutral but have low pressure in all forward ranges. A direct clutch leak will show

a pressure drop when the transmission shifts to third and low pressure in reverse because in most cases, the

direct clutch is on in third and reverse.

A restricted filter will usually show up as a gradual pressure drop at higher engine RPM because the filter cannot

pass as much fluid as the pump is trying to draw.

A stuck pressure regulator valve will show up as fixed line pressure which means the same pressure all the time.

The pressure may vary with engine RPM with means low pressure at slow RPM and higher pressure at higher

RPM. There will be no boost in pressure from the TV or modulator system and no reverse boost.

If pressures are high at slow idle it indicates a pressure regulator or throttle pressure problem. On most cars, the

modulator controls throttle pressure. If the transmission has a throttle pressure tap, it will tell you if the throttle

pressure circuit is the problem. On GM units without a throttle pressure tap, remove the TV plunger. If line pres-

sure is now normal then it's a TV problem, if not it's a pressure regulator problem.

Pressures also need to be checked at stall or wide open throttle (WOT). When doing a stall test, always observe

safety precautions such as checking for broken mounts or bad brakes. Testing should always be done under oper-

ating conditions. To do a stall test, put the selector in the range to be tested an with one foot firmly on the brake,

press the accelerator to the floor then note your pressure reading, Some technicians will pull the vacuum line off

or pull the TV cable with the engine at fast idle. That is not operating conditions and will not detect a problem of

trapped vacuum or a cable problem.

If all pressure at stall are low, then you should pull the TV cable to maximum or disconnect the vacuum line. If

the pressures are now ok, the problem is in the cable or vacuum system. If the pressures are still low, then the

problem is in the pump or control system.

If all pressures at stall are high, then look at the idle pressures. If the idle pressures are also high then this could

be a pressure regulator or throttle system problem. If idle pressures are normal then the problem is in just the

throttle system.

The reverse stall test is also a maximum pump output test. If you suspect a weak pump then this test will help

find it. Often this will show up as low pressure at reverse stall but all other pressures including idle will be nor-

mal. If a person wanted to become really proficient with a pressure gauge they should first put a pressure gauge

on their own vehicle and leave it there for exactly one week. Every time they drive the car they should watch the

gauge. After one week, they should then put the pressure gauge on every single car in the shop that DOES NOT

have a problem. Don't use the gauge on cars WITH problems yet. After 30 days of using a gauge on units that

work properly, they can then start using the gauge on units with problems. The technician is accustomed to nor-

mal readings, abnormal readings will stand out like a sore thumb.

To fix todays transmissions, every professional technician must be proficient in the use of a pressure gauge. The

only way to gain this proficiency is to use the pressure gauge daily. Practice makes perfect.

! Page 2 of 2 Copyright © 2003 ATRA. All Rights Reserved.

You might also like

- Pressure Pulse Sensor OsciloscopioDocument9 pagesPressure Pulse Sensor OsciloscopioJoao Silva Lopes100% (2)

- Al4 DpoDocument4 pagesAl4 DpoMaría Martz De GarcíaNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Anti Surge ControllersDocument6 pagesAnti Surge Controllersalimohebbi1361100% (1)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- AL4 Pressure Regulation FaultDocument3 pagesAL4 Pressure Regulation Faultsirajmy100% (1)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Rt500 1 Service AdjustmentsDocument29 pagesRt500 1 Service AdjustmentsjulianmataNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- ch46Document15 pagesch46jose perezNo ratings yet

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Pressure Measuring Instruments ReportDocument3 pagesPressure Measuring Instruments ReportSHAHZAIBNo ratings yet

- Plastech Manual LTU6000 enDocument34 pagesPlastech Manual LTU6000 enCesar PomposoNo ratings yet

- What Are Major Fault in Pressure Transmitter 1706271351Document24 pagesWhat Are Major Fault in Pressure Transmitter 1706271351Gangsar DwikaNo ratings yet

- Field Surge Test ProcedureDocument10 pagesField Surge Test ProcedureShyam Adhikary0% (1)

- Al 4 Pressure Regulation FaultDocument4 pagesAl 4 Pressure Regulation Faultcampollano14No ratings yet

- MWD Troubleshooting GuideDocument13 pagesMWD Troubleshooting GuidefedericoNo ratings yet

- SquareD 9013F G TroubleshootingDocument8 pagesSquareD 9013F G TroubleshootingMelissa DorseyNo ratings yet

- AL4 Pressure Regulation Fault 2Document8 pagesAL4 Pressure Regulation Fault 2Ahmed Fotoh100% (11)

- AL4 Pressure Regulation Fault Diagnosis and RepairDocument3 pagesAL4 Pressure Regulation Fault Diagnosis and RepairJesús PonceNo ratings yet

- 4f27e Pruebas EspecialesDocument3 pages4f27e Pruebas EspecialeslibertyplusNo ratings yet

- Diagnosing 6T70/6T75 Transmission Solenoid and Output IssuesDocument6 pagesDiagnosing 6T70/6T75 Transmission Solenoid and Output Issuesfulltransmission100% (1)

- Pressure MeasurementDocument34 pagesPressure Measurementgiskardrev93% (14)

- TechOne - Automatic Transmissions Chapter 23,28Document21 pagesTechOne - Automatic Transmissions Chapter 23,28don krtek100% (1)

- Dodge Ram 42re Throttle Valve ReplacementDocument2 pagesDodge Ram 42re Throttle Valve ReplacementHuuf ArtedNo ratings yet

- DTC P1101Document6 pagesDTC P1101Angel Valenzuela AquinoNo ratings yet

- Vacuum System Testing & Commissioning GuideDocument5 pagesVacuum System Testing & Commissioning GuideDong VanraNo ratings yet

- Ali Endris - 230502 - 204733Document22 pagesAli Endris - 230502 - 204733Ali EndrisNo ratings yet

- MYHT Hydraulic Flow MeterDocument12 pagesMYHT Hydraulic Flow MeterW Morales100% (1)

- I - Systemcomponent TestsDocument34 pagesI - Systemcomponent TestsJose PichinteNo ratings yet

- All ATS TroubleshootingDocument3 pagesAll ATS Troubleshootingandri pristaNo ratings yet

- Xplorer 3500 Operating ManualDocument70 pagesXplorer 3500 Operating ManualMo YNo ratings yet

- Calibration of Pressure GaugeDocument16 pagesCalibration of Pressure GaugeRITIKA SHUKLANo ratings yet

- Safety Safety Safety Safety Guide Guide Guide GuideDocument12 pagesSafety Safety Safety Safety Guide Guide Guide GuideMecanica SeguraNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- High Pressure Pump Supplement DiagnosticsDocument8 pagesHigh Pressure Pump Supplement DiagnosticsMarioMonroy100% (1)

- 1991 Ford Festiva ManualDocument548 pages1991 Ford Festiva ManualMarivic Diaz0% (1)

- Air Cooled Diagnostic Repair Manual 0H9172 Rev JDocument350 pagesAir Cooled Diagnostic Repair Manual 0H9172 Rev Jcw100% (6)

- Dokumen - Tips Using The 1u5470 Engine Pressure GroupDocument11 pagesDokumen - Tips Using The 1u5470 Engine Pressure Grouppedro sosaNo ratings yet

- Inside This Issue: Faq'S TechtipsDocument6 pagesInside This Issue: Faq'S TechtipscarmaNo ratings yet

- 2006.02 Motor Toyota EVAP-Non-Intrusive SystemDocument3 pages2006.02 Motor Toyota EVAP-Non-Intrusive SystemMNo ratings yet

- Module I-3 Pressure InstrumentsDocument41 pagesModule I-3 Pressure Instrumentssuresh6265100% (1)

- Pico Pressure TransDocument16 pagesPico Pressure TransAlan GorelleNo ratings yet

- FluidDocument10 pagesFluidSHAHZAIBNo ratings yet

- Module 4 Activity No. 5 Experiment No. 4Document15 pagesModule 4 Activity No. 5 Experiment No. 4MARIANNEANGEL DEVILLENANo ratings yet

- DTC P0011Document7 pagesDTC P0011Internal88No ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- Dryer Service ManualDocument35 pagesDryer Service ManualReggie Byrum50% (2)

- DTC P1121 Flowchart Ford Escort ZX2Document23 pagesDTC P1121 Flowchart Ford Escort ZX2JeffNo ratings yet

- Fam CC206 - 1Document254 pagesFam CC206 - 1David YanuarNo ratings yet

- Testing and Adjusting PRESION MARGINAL DE DIRECCIONDocument5 pagesTesting and Adjusting PRESION MARGINAL DE DIRECCIONEver MendozaNo ratings yet

- Beginner's Guide To Differential Pressure TransmittersDocument9 pagesBeginner's Guide To Differential Pressure TransmittersAmmar AltamimyNo ratings yet

- Tccs Toyota Computer Controlled SystemDocument5 pagesTccs Toyota Computer Controlled SystemĐức HòangNo ratings yet

- OVERPRESSURE PROTECTION METHODS REVIEWDocument6 pagesOVERPRESSURE PROTECTION METHODS REVIEWJohn Jairo ValenciaNo ratings yet

- Operator Manual PDFDocument5 pagesOperator Manual PDFkeith lemonsNo ratings yet

- Operation Manual of Semi Automatic Hydraulic Power Pack Dated 21.03.2017 1Document28 pagesOperation Manual of Semi Automatic Hydraulic Power Pack Dated 21.03.2017 1Fiker Er MarkNo ratings yet

- Pressure Regulators vs. Backpressure RegulatorsDocument5 pagesPressure Regulators vs. Backpressure Regulatorskpmalik6364No ratings yet

- RTAA 100 Ton Compressor Lip Seal FailuresDocument4 pagesRTAA 100 Ton Compressor Lip Seal FailuresWidya Putra100% (1)

- 02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCDocument16 pages02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCAleNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- Atb1758 U341E TOYOTA NO FORWARD AFTER VALVE BODY WORKDocument2 pagesAtb1758 U341E TOYOTA NO FORWARD AFTER VALVE BODY WORKAleNo ratings yet

- 12-2010 09a, Jf506eDocument17 pages12-2010 09a, Jf506eAleNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- 02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCDocument16 pages02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCAleNo ratings yet

- Atra 12-2009Document19 pagesAtra 12-2009ossoskiNo ratings yet

- Technical Bulletin #867: A/T Harsh 3-2 Downshift - New TCMDocument3 pagesTechnical Bulletin #867: A/T Harsh 3-2 Downshift - New TCMAleNo ratings yet

- 2006-02 4R70W No ReverseDocument13 pages2006-02 4R70W No ReverseAleNo ratings yet

- 2006-02 4R70W No ReverseDocument13 pages2006-02 4R70W No ReverseAleNo ratings yet

- 2019 - 041 Tag InformationDocument1 page2019 - 041 Tag InformationAleNo ratings yet

- Mp0A, A0Ya, B0Ya: Technical Bulletin #861Document2 pagesMp0A, A0Ya, B0Ya: Technical Bulletin #861AleNo ratings yet

- Atb747 RL4F03A Harsh Shifts and Lack of Power PDFDocument1 pageAtb747 RL4F03A Harsh Shifts and Lack of Power PDFAleNo ratings yet

- Atb866 RE4F03A-V 2000-2001 G20 Lacks Power Due To Low Battery VoltageDocument1 pageAtb866 RE4F03A-V 2000-2001 G20 Lacks Power Due To Low Battery VoltageAleNo ratings yet

- Atb852 RE4F04B, RE4F04W CHECK BALL LOCATIONSDocument1 pageAtb852 RE4F04B, RE4F04W CHECK BALL LOCATIONSAle100% (3)

- MaxiTPMS Pad 2017-10-12Document1 pageMaxiTPMS Pad 2017-10-12AleNo ratings yet

- Technical Bulletin #868: 2.4L Engine PCM Reprogramming For Harsh 3-2 DownshiftDocument1 pageTechnical Bulletin #868: 2.4L Engine PCM Reprogramming For Harsh 3-2 DownshiftAleNo ratings yet

- Ucd111 SNMP Mib OldDocument13 pagesUcd111 SNMP Mib Oldjovani88888No ratings yet

- Atb209 Isuzu 4l80-E ...... High or Low PressureDocument3 pagesAtb209 Isuzu 4l80-E ...... High or Low PressureAleNo ratings yet

- Atb164 Re4r01a, R4a-El Nissan ...... Planetary FailureDocument4 pagesAtb164 Re4r01a, R4a-El Nissan ...... Planetary FailureAleNo ratings yet

- Mitchell LinksDocument2 pagesMitchell LinksAleNo ratings yet

- Readme SSLDocument1 pageReadme SSLbarsumgmailNo ratings yet

- Ucd Diskio MibDocument2 pagesUcd Diskio MibAleNo ratings yet

- Udp MibDocument3 pagesUdp MibAleNo ratings yet

- CopyrightDocument1 pageCopyrightKane RangerNo ratings yet

- Ucd Ipfilter MibDocument5 pagesUcd Ipfilter MibAleNo ratings yet

- Changes VCDDocument2 pagesChanges VCDAleNo ratings yet

- After Install Overwrite Od5.exe With One Included in Fix Folder. Then Add Data As NormalDocument1 pageAfter Install Overwrite Od5.exe With One Included in Fix Folder. Then Add Data As NormalAleNo ratings yet

- Atb1571 Nissan RE4F04B PDFDocument1 pageAtb1571 Nissan RE4F04B PDFAle100% (1)

- Absence Makes The Heart Grow FonderDocument27 pagesAbsence Makes The Heart Grow FondereljhunNo ratings yet

- Technote Torsional VibrationDocument2 pagesTechnote Torsional Vibrationrob mooijNo ratings yet

- Cutter Wheel - H1140Document4 pagesCutter Wheel - H1140Sebastián Fernando Canul Mendez100% (2)

- SC Earthquake GuideDocument8 pagesSC Earthquake GuideNevin SmithNo ratings yet

- Porta by AmbarrukmoDocument4 pagesPorta by AmbarrukmoRika AyuNo ratings yet

- Fund. of EnterpreneurshipDocument31 pagesFund. of EnterpreneurshipVarun LalwaniNo ratings yet

- Basic Principles of Local GovernmentDocument72 pagesBasic Principles of Local GovernmentAnne Camille SongNo ratings yet

- MPC-006 DDocument14 pagesMPC-006 DRIYA SINGHNo ratings yet

- Ethics Module 2 - NotesDocument1 pageEthics Module 2 - Notesanon_137579236No ratings yet

- 2.gantry Rotation Safety CheckDocument2 pages2.gantry Rotation Safety CheckLê Hồ Nguyên ĐăngNo ratings yet

- TP5 W9 S9 R0Document2 pagesTP5 W9 S9 R0DickiEffendy0% (1)

- LOD Spec 2016 Part I 2016-10-19 PDFDocument207 pagesLOD Spec 2016 Part I 2016-10-19 PDFzakariazulkifli92No ratings yet

- District: Surkhet: PopulationDocument13 pagesDistrict: Surkhet: PopulationkarunNo ratings yet

- Abundance BlocksDocument1 pageAbundance BlockssunnyNo ratings yet

- POLIOMYELITISDocument26 pagesPOLIOMYELITISIzhra Margate100% (1)

- PDLAMMPS - made easy: An introductionDocument8 pagesPDLAMMPS - made easy: An introductionSaeed AbdNo ratings yet

- LOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorDocument1 pageLOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorHorizon 99No ratings yet

- The Relevance of Vivekananda S Thought IDocument16 pagesThe Relevance of Vivekananda S Thought IJaiyansh VatsNo ratings yet

- r32 - Rb26dett Ecu PinoutDocument1 pager32 - Rb26dett Ecu PinouttospotNo ratings yet

- Sanchez 07 Poles and Zeros of Transfer FunctionsDocument20 pagesSanchez 07 Poles and Zeros of Transfer FunctionsYasmin KayeNo ratings yet

- Hot Tub BrochureDocument124 pagesHot Tub BrochureMai Tuan AnhNo ratings yet

- Personality Types and Character TraitsDocument5 pagesPersonality Types and Character TraitspensleepeNo ratings yet

- Tyfo SDocument2 pagesTyfo SAndi AsNo ratings yet

- Deforestation Management System Using Force and SoundDocument4 pagesDeforestation Management System Using Force and SoundManeesh SvsNo ratings yet

- SSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANDocument2 pagesSSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANIvica IndjinNo ratings yet

- Vrio Analysis Slide Template 16x9 1Document8 pagesVrio Analysis Slide Template 16x9 1Alt HrishiNo ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Com Statement (HT APFC22 - 02)Document2 pagesCom Statement (HT APFC22 - 02)SOUMENNo ratings yet

- Buddhism Beyond ReligionDocument7 pagesBuddhism Beyond ReligionCarlos A SanchesNo ratings yet

- Fendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKDocument5 pagesFendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKRizal RachmanNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- Natural Gas Processing: Technology and Engineering DesignFrom EverandNatural Gas Processing: Technology and Engineering DesignRating: 5 out of 5 stars5/5 (8)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet