Professional Documents

Culture Documents

02 - 7!15!0002 Rev 2 - STD Types of Non Standard Gaskets (Shell & Tube Exchangers)

Uploaded by

Darshan Panchal0 ratings0% found this document useful (0 votes)

8 views3 pagesTypes of Non Standard Gaskets (Shell & Tube Exchangers)

Original Title

02_7!15!0002 Rev 2_STD Types of Non Standard Gaskets (Shell & Tube Exchangers)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTypes of Non Standard Gaskets (Shell & Tube Exchangers)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pages02 - 7!15!0002 Rev 2 - STD Types of Non Standard Gaskets (Shell & Tube Exchangers)

Uploaded by

Darshan PanchalTypes of Non Standard Gaskets (Shell & Tube Exchangers)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

soit,

s8ar ties © NOAL LANED

‘TYPES OF NON STANDARD

GASKETS

(SHELL & TUBE EXCHANGERS)

STANDARD No.

7-15-0002 Rev. 2

Page tof 3

1D.

Lp

on

TYPE-10 TYPE-12

TOTES UEDA SDB SRS nat

Rev. Prepared ‘Checked ‘Sids. Committee — Stds. Bureau

Rev pate = : “aod ema chara

‘Approved by,

‘Copyright IL = A rah mae

Format No 6 OOOO FA Rove

TYPES OF NON STANDARD STANDARD No.

SUB Gy ENGNERS. ee

ged bees QNIAieD GASKETS 7-48-0002 Rev. 2

SN ae aves tnoma (SHELL & TUBE EXCHANGERS)

Page 20f 3

AA]

TYPE-14 TYPE-15

TYPE-16

2 26,03.04 REVISED AND REISSUED AS STANDARD MKD

Rev. Prepared

No Bate Purpose =o

‘Approved by

Format No, BOO00T FA Rav Copyright IL - A rahe evened

STANDARD No.

SGRfeRRS @B ENGINEERS

eae ON UMITED 7-48-0002 Rev. 2

wt _ (SHELL & TUBE EXCHANGERS) fea

PERMISSIBLE TOLERAN( ane

x’ PASS PARTITION PLATE.

34 THIS. SIDE

ER)

COE OOO ER RY,

FILLER

20.8 | 20.8

TYPICAL SECTION OF METAL

JACKETTED GASKETS

nae CENTRING RING

GASKET 0.D. (0)

4 WIDE NOSE casker wots | CENTRING_RING

|

a Tn —— —."*

a vemos \weran woes wires FILLER

CTYPICAL DETAIL OF

IRAL We

GASKET THK.

NOSE_THK.

GENERAL NOTES~

1. ALL DIMENSIONS ARE IN mm UNLESS STATED OTHERWISE,

2. THE HARDNESS OF THE METAL FOR SOLID OR CLAD GASKETS SHALL BE MINIMUM 15 BHN LOWER THAN

THAT OF THE MATERIAL OF THE FLANGE GASKET SEATING SURFACE AND IN ANY CASE NOT TO EXCEED

THE FOLLOWING.

(0) LOW CARBON STEEL / LS = 110 BHN

(b) § Cr. 1/2 Mo. = 130 BHN

(c) STAINLESS STEEL — 160 BHN

(d) 11 = 13 Cr. - 170 BHN

(e) MONEL — 130 BHN

(f) SOFT IRON - 90 BHN

(@) COPPER, BRASS - 50 BHN

(h) ALUMINIUM - 30 BHN

FILLER IN METAL JACKETTED GASKETS SHALL NOT BE OF COMPRESSED TYPE.

ALL GASKETS SHALL BE MADE IN ONE CONTINUOUS PIECE ALL AROUND INCLUDING THE PASS PARTITION

RIBS AND THEREFORE MUST BE CUT FROM ONE SHEET.

THE CORNER RADII OF ALL GASKETS TO BE 10 mm,

SOLID FLAT METAL GASKET SHALL BE 2 mm. THK.

7. FOR SPIRAL WOUND GASKETS:—

c) THE PASS PARTITION RIB SHALL BE OF SOLID METAL OR METAL JACKETTED WELDED TO CENTRING RING.

b) CENTRING RING THK. SHALL BE SAME AS NOSE THK

©) GASKET THK. SHALL BE AS SPECIFIED IN EQUIPMENT DRAWINGS. IT SHALL BE MIN. 4.5 FOR

SHALL DIA UP TO 1000 & MIN. 6.55 FOR SHALL DIA MORE THEN 1000, IF NOT SPECIFIED.

8. ‘m’ AND ‘y’ VALUES SHALL BE AS PER ASME SEC. Vill DIV. |

9. GASKET PLAN IS VIEWED FROM DIRECTION "x"

10, FILLER SHALL BE ARAMIDE FIBRE UNLESS SPECIFIED OTHERWISE IN DRAWINGS & ASBESTOS NOT TO BE USED.

Fa RE — ws — TA Ech

tl

Rev. Prepared ‘Checked | ‘Std. Bureau

pose Gonwenor airman

No Bate Pup. by i Ch

‘Approved by

Fomat No, COOODOTFE Revd ‘Copyright Ek - Al ihe reseed

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDocument3 pagesPressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Transportation - Bearing LoadDocument3 pagesTransportation - Bearing LoadDarshan PanchalNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Vanillin Crude B Column Mechanical DatasheetDocument3 pagesVanillin Crude B Column Mechanical DatasheetDarshan PanchalNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- IBIC Nozzle Local LoadDocument1 pageIBIC Nozzle Local LoadDarshan PanchalNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

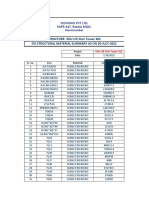

- VDU Lift Stair Tower 302 - Material Summary - ListDocument4 pagesVDU Lift Stair Tower 302 - Material Summary - ListDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalNo ratings yet

- Calculate Hertz Contact Stresses SafelyDocument5 pagesCalculate Hertz Contact Stresses SafelyDarshan PanchalNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)