Professional Documents

Culture Documents

Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete Blockwork

Uploaded by

Oladunni AfolabiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete Blockwork

Uploaded by

Oladunni AfolabiCopyright:

Available Formats

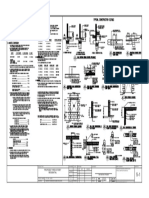

STRUCTURAL STEELWORK STRUCTURAL STEELWORK

BLOCKWORK

GENERAL NOTES CONCRETE FOR REINFORCED CONCRETE FOR STEEL TRUSSES

1.0 GENERAL

1. WORK TO FIGURED 30 N/MM^2 1. SANDCRETE BLOCKWALLS BELOW GROUND

1. (a) CONCRETE TO BE GRADE --------- 1. ALL STRUCTURAL STEELWORK UNLESS OTHERWISE

1.1 ALL LINEAR DIMENSIONS ARE IN MILLIMETERS.

DIMENSIONS ONLY IN FOUNDATIONS. NOTED SHALL BE MILD STEEL TO BS 4360 SLAB LEVEL ARE TO BE FILLED WITH

GRADE 43A EXCEPT HOLLOW SECTIONS WHICH MASS CONCRETE. BACK FILLING IS TO 1.2 THESE NOTES ARE TO BE READ IN CONJUNCTION WITH STRUCTURAL DESIGN BASIS AS

30 N/MM^2

(b) CONCRETE TO BE GRADE -------- SHALL COMPLY WITH GRADE 43c BE CARRIED OUT SIMULTANEOUSLY ON

2. ALL DRAWINGS ARE TO BE APPLICABLE.

IN SUPERSTRUCTURE BOTH SIDES

READ IN CONJUCTION WITH

2. WELDING FABRICATION AND ERECTION OF 1.3 WHERE CONFLICT OCCURS, THIS DOCUMENT SHALL OVERRULE.

ARCHITECTS DRGS, OTHER

2 (a) R = DENOTES MILD STEEL STRUCTURAL STEELWORK SHALL CONFORM

STRUCTURAL DRGS AND TO BS 5950 2. THE WALL THICKNESS OF THE BLOCKS 1.4 STRUCTURAL DRAWINGS MUST BE READ IN CONJUNCTION WITH ARCHITECTURAL

SPECIALISTS DRGS. WHERE REINFORCEMENT ACCORDING TO SHOULD NOT BE MORE THAN 25mm

DRAWINGS, MEP DRAWINGS AND OTHER RELEVANT DOCUMENTS. ANY DISCREPANCIES MUST

HOLES, FIXING ETC. ARE BS 4449 AND IN MILLIMETRE SIZE 3. UNLESS WHERE OTHERWISE NOTED ALL BOLTS

BE IMMEDIATELY BROUGHT TO THE ATTENTION OF THE ENGINEER.

REQUIRED, BARS MAY BE SHALL BE BLACK BOLTS TO BS 4190 AND 3. THE MINIMUM CRUSHING STRENGTH OF THE

(b) T = DENOTES HIGH YIELD, HIGH BOND WASHERS TO BS 4320 SHALL BE PROVIDED 2

DISPLACED SLIGHTLY TO SANDCRETE BLOCKS IS TO BE 2.O N/mm. OF

FOR ALL BOLTS

ACCOMMODATE THESE BUT ROUND REINFORCEMENT TO GROSS AREA OF BLOCK AT 28 DAYS 2.0 CODES & STANDARDS

THEY MUST NOT BE CUT OR 4. ALL WELDS ARE TO BE 6mm. FILLET WELDS 2.1 BS 5950 - Part 1: (2000): STRUCTURAL USE OF STEELWORK IN BUILDING

BS 4449 AND 4466 CONTINUOUS UNLESS WHERE OTHERWISE

REMOVED INDICATED 4. BLOCKWORK TIES BETWEEN BLOCKWORK 2.2 BS 6399 - Part 1: (1996): CODE OF PRACTICE FOR DEAD AND IMPOSED LOADS.

(c) T = TOP WALLS AND COLUMNS/STANCHIONS ARE TO

5. UNLESS NOTED OTHERWISE THE COMPOSITION

3. REMOVE ALL TOPSOIL UNDER TT = TOP TOP OF THE PROTECTIVE SYSTEM SHALL BE: BE PROVIDED AT EVERY COURSE. TIES

3.0 DESIGN LOADS

SLABS. PROVIDE 150mm WELL (a) SURFACE TREATEMENT - D TO BE 6mm BAR STRAPS 700mm LONG

TB = TOP BOTTOM 3.1 ROOF DEAD LOAD - Refer to Calc. sheets

RAMMED AND CONSOLIDATED (b) METAL COATING - NONE INTO THE BLOCKWORK

(d) B = BOTTOM (c) PRE - TREATMENT - NONE 3.2 ROOF LIVE LOAD - Refer to Calc. sheets

NATURALLY OCCURRING

BT = BOTTOM TOP (d) PRIMING PAINT - 1H

HARDCORE MATERIAL OR ROCK (e) FINISHING PAINT - 2T 3.3 WIND LOAD ON ROOF - Refer to Calc. sheets

BB = BOTTOM BOTTOM 5. MAXIMUM POUR HEIGHT FOR ALL FILLED

LATERITE UNDER ALL GROUND AS CLASSIFIED IN TABLE 4 KEY TO TREATMENT BLOCK WORK TO BE 2 COURSES AT A TIME

(e) AS = ALTERNATELY STAGGERED

BEARING SLABS WELL CP 2008 1966 4.0 MATERIALS

(f) AP = ALTERNATELY PLACED

CONSOLIDATED SELECTED FILL 4.1 ALL ROLLED ANGLE MATERIALS SHALL BE CARBON STEEL TO EN10025 S235 (MIN.)

(g) NF = NEAR FACE 6. THE FIRST BAY OF ERECTED STEELWORK IS

OR MASS CONCRETE TO BE 4.2 ALL PLATE & ROD MATERIALS SHALL BE CARBON STEEL TO EN10025 S235 (MIN.)

(h) FF = FAR FACE TO BE LINED AND LEVELLED BY MEANS OF

USED TO MAKE UP LEVELS

(i) EF = EACH FACE TEMPORARY BRACING, BEFORE FURTHER 4.3 BOLT MATERIALS SHALL BE OF GRADE 8.8 WHILE NUT SHALL BE GRADE 8.

WHERE NECESSARY AS

ERECTION SHALL CONTINUE

AGREED WITH THE ENGINEER. 4.4 PROCURED STEEL MATERIALS SHALL BE INSPECTED & APPROVED BEFORE

3. ALL BLINDING AND MASS CONCRETE TO

FOR FILL, LAYERS NOT TO COMMENCEMENT OF FABRICATION.

BE GRADE 15

EXCEED 225mm

7. ANTI - SAG RODS ARE TO BE PROVIDED

AS SHOWN ON DRAWINGS WHERE ANTI - SAG 5.0 WELDING & FABRICATION

4. WHERE BAD GROUND IS

RODS ARE NOT SHOWN ON THE DRAWINGS 5.1 ALL WELDS SHALL BE BOTH SHOP AND FIELD WELDS.

4.ALL CONSTRUCTION JOINT POSITIONS ARE TO

ENCOUNTERED. BELOW THEY ARE TO BE PLACED AT MID-SPAN OF

BE APPROVED BY THE ENGINEER PRIOR TO 5.2 ALL WELDS SHALL BE FILLET WELDS U.N.O.

FOUNDATION LEVEL. THE CASTING BUT THESE SHOULD NOT BE PURLINS OR TO PURLIN MANUFACTURERS

DIFFERENCE IN LEVEL SPACED MORE THAN 10 METRES APART SPECIFICATION 5.3 WELDING PROCEDURE AND SYMBOLS SHALL BE IN ACCORDANCE WITH AWS. D1. MAXIMUM

BETWEEN APPROVED BEARING

WELD LEG IS GIVEN AS 0.7a, WHERE 'A' IS THE THICKNESS OF THE LESSER METAL BEING

STRATUM AND ORIGINAL LEVEL 5. MAXIMUM SIZE OF AGGREGATE TO BE 20mm 8. ALL STEEL SURFACES IN CONTACT WITH

UNLESS OTHERWISE SPECIFIED JOINED.

IS TO BE MADE UP USING MASS ALUMINIUM SHEETING ARE TO BE GIVEN

CONCRETE 5.4 WELDING ACTIVITIES SHALL BE CARRIED OUT BY CERTIFIED WELDERS.

TWO COATS OF AN APPROVED BITUMASTIC

PAINT BEFORE FIXING SHEETING

5. ALL DIMENSIONS ARE TO BE

WASHERS OR LOCK NUTS 6.0 SURFACE PREPARATION & PAINTING

CHECKED ON SITE

6.1 AFTER WELDING, STEEL SURFACE SHALL BE CLEANED OF DIRT AND GREASE. HEAVIER

LAYERS OF RUST SHALL REMOVED BY CHIPPING.

6. EXTERNAL WALL FOOTING TO

9. ALL BOLTS IN TENSION SHOULD BE PROVIDED 6.2 ALL LOOSE MILL SCALE, RUST AND FOREIGN MATTER SHALL BBE REMOVED BY THOROUGH

BE 1 METRE MINIMUM DEPTH WITH EITHER DOUBLE COILED SPRING

SCRAPPING, WIRE RUSHING, GRINDING, ETC,.

BELOW EXISTING GROUND

LEVEL OR FINAL GROUND 6.3 NO PAINTING ON SITE SHALL BE DONE IN INCLEMENT WEATHER OR WHEN HUMIDITY OR

LEVEL WHICHEVER IS LOWER

FROST IS LIABLE TO CAUSE WET OR DAMP CONDITIONS ON THE SURFACE TO BE PAINTED.

6.4 ALL PAINT SHALL BE DELIVERED AT THE WORK SITE IN THE ORIGINAL CONTAINERS WHICH

7. ALL DIMENSIONS ARE IN

METRES AND MILLIMETRES DISPLAY THE NAME OF MANUFACTURER AND TRADE MARK. THE COATING SYSTEM SHALL BE

UNLESS NOTED OTHERWISE

FROM MANUFACTURER. PAINT MANUFACTURER'S INSTRUCTION SHALL BE STRICTLY ADHERED

TO.

6.5 AFTER ERECTION OF THE STEELWORK, THE SPECIFIED PAINT SYSTEM SHALL BE

REINSTATED IN ALL AREAS WHERE IT HAS BEEN DAMAGED. ALL FASTENERS SHALL BE

TREATED IN ACCORDANCE WITH THE SPECIFIED PAINT SYSTEM.

6.6 PRIMER - RED OXIDE OTHER COATS - AS SPECIFIED BY CLIENT.

CHECKED DATE

NO REVISIONS DATE

STATUS CHECKED DATE STATUS

NOTES PRELIMINARY APPROVAL JOB TITLE SHEET TITLE CLIENT

SCHEME CONSTRUCTION

PROPOSED RESIDENTIAL DEVELOPMENT MR ABRAHAM AZIEGBE

REVIEW RECORDS

GENERAL NOTES

FOR

MR ABRAHAM AZIGBE

CONSULTANTS:

AT SHEET NO.

DESIGNED DRAWN CHECKED APPROVED DATE

BLOCK 47, PLOT 15, NORTHERN FORESHORE

OOA OOA OOA 11-Dec-18

OOA GLOBAL ENGINEERING CONSULT

NO

ESTATE, ETI OSA LGA, 20 Niyi Ogunneye Street Ojota,

DRAWING REFERENCES DATE PROJECT NO SCALE REV.

DRAWING NO

OAEC/005/018/012

DATE

NTS

LAGOS STATE 012/ 0 01 / 001 Lagos, Nigeria, West Africa.

T: +234 808 401 6324 - F: +234 808 401 6324

OAEC/005/018/012/STR/001 DECEMBER, 2018 E: ooaglobalengineering@yahoo.co.uk - W: www.--

You might also like

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- 1532 Base PlanDocument1 page1532 Base PlanAnonymous qEPNPwA0% (1)

- Critical Review of Is 1893-1 and - 2 Draft 2023 Ver 2Document14 pagesCritical Review of Is 1893-1 and - 2 Draft 2023 Ver 2SzcNo ratings yet

- cb12 07-15-05 V8Document1 pagecb12 07-15-05 V8Katracho2No ratings yet

- Jobs For NICMAR Alumni (Responses)Document6 pagesJobs For NICMAR Alumni (Responses)Tushar DoshiNo ratings yet

- Notes: Castings: V501Document2 pagesNotes: Castings: V501Katracho2100% (1)

- SOURCE-CODE-LISTDocument175 pagesSOURCE-CODE-LISTsan_lookNo ratings yet

- Prof Ashok Jain - A Critical Review of Is 13920Document11 pagesProf Ashok Jain - A Critical Review of Is 13920kukadiya127_48673372No ratings yet

- Drawings - Kappa 400kV Tubular Busbar Layout SignedDocument1 pageDrawings - Kappa 400kV Tubular Busbar Layout SignednunoandreNo ratings yet

- Residential Proposed Three-Storey: Engr. Mayson R. FesalbonDocument1 pageResidential Proposed Three-Storey: Engr. Mayson R. FesalbonMarc Arjo MontelibanoNo ratings yet

- BS 5400 Part 6 1999 PDFDocument36 pagesBS 5400 Part 6 1999 PDFDang Thanh TuanNo ratings yet

- Stainless Steel Bolts ManufacturerDocument3 pagesStainless Steel Bolts ManufacturerRajtilak MetalNo ratings yet

- Price List DT 10.09.20 PDFDocument48 pagesPrice List DT 10.09.20 PDFIshan Goel100% (1)

- RCDC V6 Release NotesDocument13 pagesRCDC V6 Release NotesManju BirjeNo ratings yet

- Andhra Pradesh Candidate Details List with Registrations, Names, States and ContactDocument566 pagesAndhra Pradesh Candidate Details List with Registrations, Names, States and Contactamoosh masseyNo ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationCristian WalkerNo ratings yet

- Static and Dynamic Performance of Tall Bridge Abutments With Counterfort ConfigurationDocument11 pagesStatic and Dynamic Performance of Tall Bridge Abutments With Counterfort ConfigurationSm ConsultantsNo ratings yet

- Steel Girder Comparison and Sensitivity AnalysisDocument6 pagesSteel Girder Comparison and Sensitivity AnalysisvinoraamNo ratings yet

- Empanelled Architects PDFDocument4 pagesEmpanelled Architects PDFnandkishorNo ratings yet

- Peb Me Class Work 2Document39 pagesPeb Me Class Work 2tmaniiNo ratings yet

- Compet DDocument63 pagesCompet Dvasudeva yasasNo ratings yet

- CFSD - Paper - 2013 AISI CFS Design Manual - 11-05-2014 PDFDocument13 pagesCFSD - Paper - 2013 AISI CFS Design Manual - 11-05-2014 PDFBONDHON-2 APARTMENTNo ratings yet

- Best Solar Mounting Structure ManufacturersDocument6 pagesBest Solar Mounting Structure Manufacturerssolar mountNo ratings yet

- Cgna14427enc 001Document280 pagesCgna14427enc 001GicuNo ratings yet

- Aisc 01Document5 pagesAisc 01amokhtaNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationjanidevangNo ratings yet

- Everything about Pennar Purlins for Steel BuildingsDocument4 pagesEverything about Pennar Purlins for Steel BuildingsmaheswarreddyNo ratings yet

- Weld GroupDocument4 pagesWeld GroupJay PadamaNo ratings yet

- Iron and Steel Railway WagonsDocument35 pagesIron and Steel Railway Wagonsrajbir_singhNo ratings yet

- Lib CivilDocument13 pagesLib CivilPandal RajNo ratings yet

- Etabs Shear Wall Design Manual Ubc 97 PDFDocument2 pagesEtabs Shear Wall Design Manual Ubc 97 PDFMichelle0% (1)

- Approach Methodology-Sharavati Bridge-CSBDocument10 pagesApproach Methodology-Sharavati Bridge-CSBSK SwainNo ratings yet

- Curved BeamsDocument7 pagesCurved BeamsStructural SpreadsheetsNo ratings yet

- Steel Structures 2 Project AnalysisDocument36 pagesSteel Structures 2 Project AnalysisAnamaria-Ileana LăzăroiuNo ratings yet

- 02-Duplex Stainless Steel For Indian Construction and Architecture Application-YpsuriDocument10 pages02-Duplex Stainless Steel For Indian Construction and Architecture Application-YpsuriPrashant PatilNo ratings yet

- 37 PDFDocument14 pages37 PDFID SkechtNo ratings yet

- Design of MonorailDocument24 pagesDesign of MonorailSherwin PonsNo ratings yet

- Power Transmission Companies - IndiaDocument2 pagesPower Transmission Companies - IndiaAkash TyagiNo ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- 10A7BDE500FF4295B7ABC9F036FC8968.xlsDocument220 pages10A7BDE500FF4295B7ABC9F036FC8968.xlsJakaNo ratings yet

- ASDIP Steel - Composite Beam Verification ExampleDocument6 pagesASDIP Steel - Composite Beam Verification ExampleEdwin VizueteNo ratings yet

- Modified BOQ - Presidency University 14.01.2015Document34 pagesModified BOQ - Presidency University 14.01.2015yogeshNo ratings yet

- List of Alumni SR No 1146 Website 1Document11 pagesList of Alumni SR No 1146 Website 1Tikoo AdityaNo ratings yet

- Input File For StaadDocument120 pagesInput File For StaadNilay GandhiNo ratings yet

- Circular Section Crack Width Under Pure TensionDocument1 pageCircular Section Crack Width Under Pure TensionAbinash ModakNo ratings yet

- Short Column AnalysisDocument1 pageShort Column Analysisrelu59No ratings yet

- N12192.1a-C-0-000-1-01-0 Civil Design Basis Rev-0Document18 pagesN12192.1a-C-0-000-1-01-0 Civil Design Basis Rev-0Anonymous 3kDy7eNo ratings yet

- Zamil Steel Brochures English 68 PagesDocument35 pagesZamil Steel Brochures English 68 PagesAmr El-ShorbagyNo ratings yet

- Thesis PDFDocument115 pagesThesis PDFstore filesNo ratings yet

- Structural Designer - IDocument6 pagesStructural Designer - Iankit prajapatiNo ratings yet

- Offer Steel Building FormatDocument16 pagesOffer Steel Building FormatShamsul IslamNo ratings yet

- STAAD ParametersDocument47 pagesSTAAD ParametersAnonymous HJ7hmihhNo ratings yet

- Engr Micheal STRDocument12 pagesEngr Micheal STRUmar SaiduNo ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- General notes on reinforced concrete structuresDocument1 pageGeneral notes on reinforced concrete structuresDJNo ratings yet

- Structural Engineering Working Drawings for KC Holding BuildingDocument5 pagesStructural Engineering Working Drawings for KC Holding BuildingAgonyi OzzomataNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Civil / Structural Construction Notes: Nearest Faultline Site Location FromDocument1 pageCivil / Structural Construction Notes: Nearest Faultline Site Location FromVince Bagsit PolicarpioNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- Reinforcing Bars and Construction Joint DetailsDocument1 pageReinforcing Bars and Construction Joint DetailsJack O SalemNo ratings yet

- Retaining Wall DesignDocument106 pagesRetaining Wall Designriz2010No ratings yet

- Building A Change Management OfficeDocument7 pagesBuilding A Change Management OfficeOladunni AfolabiNo ratings yet

- How To Calculate Bearing Capacity of Soil From Plate Load TestDocument14 pagesHow To Calculate Bearing Capacity of Soil From Plate Load TestOladunni AfolabiNo ratings yet

- Proposed Osara Dam Water Treatment WorksDocument1 pageProposed Osara Dam Water Treatment WorksOladunni AfolabiNo ratings yet

- Planning Commision - Model-RFQDocument93 pagesPlanning Commision - Model-RFQPradeep Reddy BoppidiNo ratings yet

- Loop 202 Preliminary Design Public Input Meeting Report Presentation Boards Appendix GDocument6 pagesLoop 202 Preliminary Design Public Input Meeting Report Presentation Boards Appendix GOladunni AfolabiNo ratings yet

- Design-Build ADOT Loop 202 South Mountain Freeway - FluorDocument2 pagesDesign-Build ADOT Loop 202 South Mountain Freeway - FluorOladunni AfolabiNo ratings yet

- The Role of Transaction Advisers in A PPP Project PDFDocument15 pagesThe Role of Transaction Advisers in A PPP Project PDFOladunni AfolabiNo ratings yet

- QMS MANUAL - QMS MNL 51 001 - R0 - ApprovedDocument52 pagesQMS MANUAL - QMS MNL 51 001 - R0 - ApprovedOladunni Afolabi100% (3)

- 29.00 Design Procedures For C and C v19Document11 pages29.00 Design Procedures For C and C v19Oladunni AfolabiNo ratings yet

- The Role of Transaction Advisers in A PPP Project PDFDocument15 pagesThe Role of Transaction Advisers in A PPP Project PDFOladunni AfolabiNo ratings yet

- 06-GB Moment ConnectionsDocument16 pages06-GB Moment ConnectionscblerNo ratings yet

- Attachment IV - Nigeria Content Execution PlanDocument4 pagesAttachment IV - Nigeria Content Execution PlanOladunni AfolabiNo ratings yet

- Traffic Parameter DefinitionsDocument1 pageTraffic Parameter DefinitionsOladunni AfolabiNo ratings yet

- Financial Proposal TemplateDocument6 pagesFinancial Proposal TemplateAndile Ntuli100% (1)

- Admin Block-Floors PlansDocument1 pageAdmin Block-Floors PlansOladunni AfolabiNo ratings yet

- Wire Size and Amp Ratings PDFDocument3 pagesWire Size and Amp Ratings PDFOladunni AfolabiNo ratings yet

- Audit Report 2013-11 - Public Works - Construction Contracts Review (AUD14003) (City Wide)Document7 pagesAudit Report 2013-11 - Public Works - Construction Contracts Review (AUD14003) (City Wide)Oladunni AfolabiNo ratings yet

- Church Sound BookDocument43 pagesChurch Sound BookKevin BroussardNo ratings yet

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Document3 pagesDesign Parameters For Longitudinal Bars (Beams - BS 8110)Oladunni AfolabiNo ratings yet

- 3.3kw Solar Array Support StructureDocument6 pages3.3kw Solar Array Support StructureOladunni AfolabiNo ratings yet

- Attachment Iv - Nigeria Content Execution Plan PDFDocument4 pagesAttachment Iv - Nigeria Content Execution Plan PDFOladunni Afolabi100% (3)

- Sector Insights: Skills and Performance Challenges in The Energy SectorDocument13 pagesSector Insights: Skills and Performance Challenges in The Energy SectorOladunni AfolabiNo ratings yet

- Admin Block ElevationDocument1 pageAdmin Block ElevationOladunni AfolabiNo ratings yet

- VarshaB SessionVII 29dec2006 PDFDocument20 pagesVarshaB SessionVII 29dec2006 PDFOladunni AfolabiNo ratings yet

- What Are Exegesis, Eisegesis, and Hermeneutics - PDFDocument5 pagesWhat Are Exegesis, Eisegesis, and Hermeneutics - PDFOladunni Afolabi100% (1)

- Fighting Sexual TemptationsDocument27 pagesFighting Sexual TemptationsOladunni AfolabiNo ratings yet

- Beme For DamDocument5 pagesBeme For DamOladunni Afolabi50% (2)

- Automated Computerized GarageDocument1 pageAutomated Computerized GarageOladunni AfolabiNo ratings yet

- 2013-Pump Sizing With Exercises r1Document25 pages2013-Pump Sizing With Exercises r1edhy_03No ratings yet

- AWC DES310 Connections 1hr 141128Document74 pagesAWC DES310 Connections 1hr 141128frakedjakeNo ratings yet

- BBR CMI Tendon Brochure - Optimize PDFDocument32 pagesBBR CMI Tendon Brochure - Optimize PDFWenix008 OniNo ratings yet

- LATICRETE Medical, Educational and Hospitality Facilities Technical Design ManualDocument290 pagesLATICRETE Medical, Educational and Hospitality Facilities Technical Design ManualLATICRETE® InternationalNo ratings yet

- 18 LockoutDocument5 pages18 LockoutheniNo ratings yet

- NAS1834Document2 pagesNAS1834Ray DutchmanNo ratings yet

- NFPA13 - Pt1 - Handout Cambios Nfpa 13Document33 pagesNFPA13 - Pt1 - Handout Cambios Nfpa 13Eden FriasNo ratings yet

- 006 DEW Kaltarbeitsstahl GBDocument96 pages006 DEW Kaltarbeitsstahl GBhelderfsnNo ratings yet

- International Standard: Second Edition 2018-07Document20 pagesInternational Standard: Second Edition 2018-07HafiziAhmadNo ratings yet

- Joe BLDG Tech PreboardDocument13 pagesJoe BLDG Tech Preboardcorazon philNo ratings yet

- Buhl MannDocument2 pagesBuhl ManndsiucNo ratings yet

- PIPE AND FLANGE PART DETAILSDocument1 pagePIPE AND FLANGE PART DETAILSfaviikaujaNo ratings yet

- Aipi - 03 02 018Document57 pagesAipi - 03 02 018Kenan Sofu100% (3)

- CEMS A 10 Part II APPXDocument3 pagesCEMS A 10 Part II APPXaldairlopesNo ratings yet

- Course Outline For Reinforced Concrete IDocument2 pagesCourse Outline For Reinforced Concrete ITefera TemesgenNo ratings yet

- Bindal Group's vision of sustainability and growthDocument8 pagesBindal Group's vision of sustainability and growthhr bindalNo ratings yet

- Major Bridge Drawing SetDocument51 pagesMajor Bridge Drawing SetNilay Gandhi100% (1)

- Hyd-Stc-Phe - Boq - 13.10.2023Document2 pagesHyd-Stc-Phe - Boq - 13.10.2023AMOLNo ratings yet

- DVS Technical Codes On Plastics Joining TechnologiesDocument11 pagesDVS Technical Codes On Plastics Joining TechnologiesEmanuel NovoaNo ratings yet

- BT Silfos 15 ENDocument1 pageBT Silfos 15 ENIonutCiobanuNo ratings yet

- Design No. J718: BXUV.J718 Fire Resistance Ratings ANSI/UL 263Document3 pagesDesign No. J718: BXUV.J718 Fire Resistance Ratings ANSI/UL 263mmmmmNo ratings yet

- Ceramic InstallationDocument49 pagesCeramic InstallationKevin Tate100% (1)

- FAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...Document16 pagesFAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...César Díaz LiberonaNo ratings yet

- Fundamentals of Structural Engineering gnv64 PDFDocument6 pagesFundamentals of Structural Engineering gnv64 PDFAbhishekNo ratings yet

- Top Hat & Cladding SectionsDocument8 pagesTop Hat & Cladding SectionsDavid ShutteNo ratings yet

- Pera, Amrouz - 1998 - Development of Highly Reactive Metakaolin From Paper Sludge PDFDocument8 pagesPera, Amrouz - 1998 - Development of Highly Reactive Metakaolin From Paper Sludge PDFJuan EstebanNo ratings yet

- Identifier Suppliers List-GavinDocument5 pagesIdentifier Suppliers List-GavingavinNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServicemarykongNo ratings yet

- Manual On Pavement Design PDFDocument31 pagesManual On Pavement Design PDFAnil Kumsr T B100% (3)

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- Ductile Iron (DI) Pipes - Quality StandardsDocument3 pagesDuctile Iron (DI) Pipes - Quality StandardsKalpana KrishnaNo ratings yet