Professional Documents

Culture Documents

Anchoring Length Rev .02

Uploaded by

KhalidHiluCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchoring Length Rev .02

Uploaded by

KhalidHiluCopyright:

Available Formats

Date 18/11/2018

Jordan

Project Data

Anchored Calculation for

UD2.4-Package 1 LSA

I. Project Data

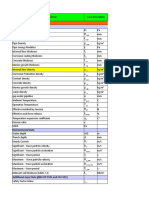

Points Bend Cover Approx Length Thrust at 9 bar in tons

degree m between bend

1 45 1.3 7.8

2 45 1.3 2m 7.8

3 11.25 1.9 374m 2.018

4 Tee 1.5 130 m 10.295

5 Tee 1.5 179 m 10.295

6 Tee 1.4 20 m (Between 10.295

point 7- Point 6)

7 45 1.2 20 m (Between 7.8

point 7- Point 6)

8 45 1.2 2 m (Between 7.8

Point 8- Point 7)

9 Tee 1.65 175 m 10.295

Pipeline Technical-Sales Department 1

Date 18/11/2018

Jordan

ANCHORING LENGTH

CALCULATION

II. ANCHORING LENGTH CALCULATION

Self-anchoring of push-in joints is an alternative to concrete anchor blocks for withstanding the effects

of hydraulic thrusts.

It is used essentially where there are space constraints (urban areas) or in unstable soil.

II.1.1. Principle

his technique consists of anchoring sufficient

joints on either side of a bend to make use of the

pipe/soil friction forces for counteracting the

hydraulic thrust force.

The anchoring system used has no particular

bearing on the calculation of the length to be

anchored.

II.1.2. Calculation of the length to be anchored (ALABAMA method)

PS

Length to be anchored : L tg x c

Fn 2 2 2

L : length to be anchored (m)

P : site pressure test (Pa)

S : cross section (m² )

: bend angle (rad)

Fn : friction force per metre of pipe (N/m)

c : safety coefficient (1.2, generally)

Pipeline Technical-Sales Department 2

Date 18/11/2018

Jordan

ANCHORING LENGTH

CALCULATION

Fn = K.f (2 We + Wp + Ww)

Wp : linear weight of empty pipe (N/m)

Ww : linear weight of water (N/m)

We : linear weight of backfill (N/m)

f : soil/pipe friction coefficient

K : pressure distribution coefficient of backfill around

the pipes (depending on compaction K = 1.1 to 1.5)

We = HD . 1

1 = 1 (test with joints backfilled)

1 = 2/3 (test with joints uncovered)

D : pipe outside diameter (m)

H : depth of cover (m)

f= 2 tg (0,8 )

2 = 1 ; pipe with zinc or zinalium coating + bituminous or epoxy paint

2 = 2/3 ; TT pipe, with polyethylene or polyurethane coating

2 = 2/3, with polyethylene sleeve

Where Kf = min K. 2/3 tg (0,8 ) ; 0,3

tg

2 2 2

Blank flange 1

90° bend 0.7854

45° bend 0.4880

22 ½° bend 0.2734

11 ¼° bend 0.1450

The safety coefficient may be applied to the length to be anchored, depending on:

- the laying conditions,

- the quality and compaction of the earth fill,

- uncertainty regarding the physical characteristics of the earth fill.

Where applicable, allowance should be made for any partial presence of groundwater by correcting

the weight of the full pipe by applying the corresponding Archimedes’value.

Pipeline Technical-Sales Department 3

Date 18/11/2018

Jordan

ANCHORING LENGTH

CALCULATION

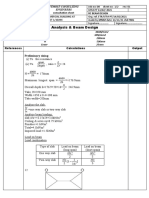

II.2. Equal Angle Vertical Offset

*extract from DIPRA thrust restraint design for ductile iron pipe

II.3. Combined Horizontal Angle Bends

*extract from DIPRA thrust restraint design for ductile iron pipe

Pipeline Technical-Sales Department 4

Date 18/11/2018

Jordan

ANCHORING LENGTH

CALCULATION

II.4. Calculation

1&2 3 4

Ground

Taking into account of the embankment yes yes yes

Depth of cover (m) 1.3 1.5 1.5

Presence of groundwater no m no

Groundwater level (m) -- - --

Density (tun/m3) 1.9 1.9 1.9

Friction angle (°) 35 35 35

Pipe

Type STD VI STD VI STD VI

Small pipe -- -- --

Great pipe -- -- --

Type of coating Standard Standard Standard

Length of section (m) 2 -- --

Pressure (bar) 9,0 9 9

Type : Test Pressure Test Pressure Test Pressure

Fitting

Type of fitting Successive Single bend TEE

bends

Bend Nr.1 45 11.25 --

Bend Nr.2 45 -- --

Nominal size (mm) 350 350 350

Small nominal diameter (mm) -- -- --

Great nominal diameter (mm) -- -- --

Exerced thrusts

Type of thrust Horizontal Horizontal horizontal

Pipe's mass (kg/m) 68.833 68.833 67.9

Ground mass (t/m3) 0.933 1.077 1.077

Water mass (kg/m) 96.2 96.2 96.2

Upthrust buoyancy (Kg/m) -- --

Coef. of friction pipe/soil 0,66 0.66 0,66

Frictional force (t/m) 1.35 1.541 1.541

Results

Hydraulic thrust (tun)

P1 = 7.880 2.018 10.295

P2 = 7.880 --

Safety coefficient 1.5 1.5 1,5

Lengths to anchore (m)

L1 = 7.317 1.453 10.021

L2 = 7.317 1.453 --

Pipeline Technical-Sales Department 5

Date 18/11/2018

Jordan

ANCHORING LENGTH

CALCULATION

5 6 7&8 9

Ground

Taking into account of the embankment yes yes yes yes

Depth of cover (m) 1.5 1.4 1.2 1.65

Presence of groundwater no no no no

Groundwater level (m) -- -- -- --

Density (tun/m3) 1.9 1.9 1.9 1.9

Friction angle (°) 35 35 35 35

Pipe

Type STD VI STD VI STD VI STD VI

Small pipe -- -- -- --

Great pipe -- -- -- --

Type of coating Standard Standard Standard Standard

Length of section (m) -- -- 2 --

Pressure (bar) 9 9 9,0 9

Type : Test Test TP TP

Pressure Pressure

Fitting

Type of fitting TEE TEE Successive TEE

bends

Bend Nr.1 -- -- 45 --

Bend Nr.2 -- -- 45 --

Nominal size (mm) 350 350 350 350

Small nominal diameter (mm) -- -- -- --

Great nominal diameter (mm) -- -- -- --

Exerced thrusts

Type of thrust horizontal horizontal Horizontal horizontal

Pipe's mass (kg/m) 67.9 67.9 68.833 67.9

Ground mass (t/m3) 1.077 1.005 0.862 1.185

Water mass (kg/m) 96.2 96.2 96.2 96.2

Upthrust buoyancy (Kg/m) -- -- -- --

Coef. of friction pipe/soil 0,66 0,66 0,66 0,66

Frictional force (t/m) 1.541 1.446 1.255 1.684

Results

Hydraulic thrust (tun)

P1 = 10.295 10.295 7.880 10.295

P2 = -- -- 7.880 --

Safety coefficient 1,5 1,5 1.5 1,5

Lengths to anchore (m)

L1 = 10.021 10.683 8.001 9.169

L2 = 8.001 --

Pipeline Technical-Sales Department 6

Date 18/11/2018

Jordan

ANCHORING LENGTH

CALCULATION

Single bend - horizontal Single bend - vertical : upwards

P P

L1 L1

L2 L2

Single bend - vertical : downwards Successive bends

L1 P1

Lc

P2

L2 L2

L1 P

Bayonet Tee

L1 P1

L2 L

Lc

P2

P

Capping fittings Reducing fittings

L

L P

Pipeline Technical-Sales Department 7

Date 18/11/2018

Jordan

Conclusion

III. Conclusion

According to the project data and above hypothesis about the soil characteristics, the below length

might be anchored (for one line DN 350):

Points Length to be anchored (m)

Before 1 8

Between 1 & 2 2

After 2 8

Before 3 6

After 3 6

4(Tee Fitting ) 12

5(Tee Fitting ) 12

6 (Tee Fitting ) 12

Before 7 12

Between 7 to 8 2

After 8 12

9 (Tee Fitting ) 12

Total 104

Important: SG PAM Company offer technical knowledge and possibilities of calculations in his capacity

as a manufacturer. The design notes issued by SG PAM does not in any way engage the responsibility

of SG PAM, even partial, because SG PAM does not aim to replace the contractors and / or consultant.

Pipeline Technical-Sales Department 8

You might also like

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- CP1 With Numbers PDFDocument63 pagesCP1 With Numbers PDFAtanu AdhiakryNo ratings yet

- Cantilever Retaining WallDocument5 pagesCantilever Retaining WallAditya Singh ChauhanNo ratings yet

- Falling Film Evaporation An OverviewDocument11 pagesFalling Film Evaporation An OverviewZahraNo ratings yet

- Part 6 Analysis and Design of PurlinsDocument18 pagesPart 6 Analysis and Design of PurlinsPaul P.No ratings yet

- Structural Design Report For High Lift Pump StationDocument195 pagesStructural Design Report For High Lift Pump StationEphrem GalNo ratings yet

- Calculations by Yg Plot 55 & 56 01.02.23Document63 pagesCalculations by Yg Plot 55 & 56 01.02.23Shanil BussooaNo ratings yet

- Thermal Expansion Analysis of SPM and Subsea PipelineDocument10 pagesThermal Expansion Analysis of SPM and Subsea PipelineFandy Sipata100% (2)

- US08013FU1Document10 pagesUS08013FU1Vanco AdziskiNo ratings yet

- 1.1 Subject Information: Statical Calculation For Masonry Abutment DesignDocument10 pages1.1 Subject Information: Statical Calculation For Masonry Abutment DesignabadittadesseNo ratings yet

- Bearing Capacity Calculation (Is 6403:1981) : d c c c c q q q q γ γ γ γDocument1 pageBearing Capacity Calculation (Is 6403:1981) : d c c c c q q q q γ γ γ γAnand RaghuwanshiNo ratings yet

- Weight CalculationDocument13 pagesWeight CalculationPankaj BijweNo ratings yet

- Wind Girder Calculations: Appendix 'M' Is Applicable?Document8 pagesWind Girder Calculations: Appendix 'M' Is Applicable?Anonymous LKi1w1uNo ratings yet

- Tinh Chieu Dai Bau NeoDocument3 pagesTinh Chieu Dai Bau NeoTrần Minh ChiếnNo ratings yet

- 40m 4PC Girder (Thk. 80 In.) (For 2.4m C.G of Girder) Ok.Document32 pages40m 4PC Girder (Thk. 80 In.) (For 2.4m C.G of Girder) Ok.Prodip Mondal100% (1)

- Deck Slab LSD (12.9m) - 14mDocument17 pagesDeck Slab LSD (12.9m) - 14mGaurav SinghNo ratings yet

- CP2 With Numbers PDFDocument62 pagesCP2 With Numbers PDFAtanu AdhiakryNo ratings yet

- IJSRD Comparative Study of Slab Culvert DesignDocument4 pagesIJSRD Comparative Study of Slab Culvert DesignDarshan ShahNo ratings yet

- Derrick-Mast & Block Line - Shell Well Eng. NotebookDocument12 pagesDerrick-Mast & Block Line - Shell Well Eng. NotebookReza BorahNo ratings yet

- 1 Adhesive TapeDocument35 pages1 Adhesive TapeAhmad AlShahrourNo ratings yet

- Anchor Block (Combined)Document210 pagesAnchor Block (Combined)Bishnu Thapa MagarNo ratings yet

- Data Input Flowline Properties: Pipe Pipe Pipe 3Document12 pagesData Input Flowline Properties: Pipe Pipe Pipe 3Septian FirdausNo ratings yet

- HYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemDocument11 pagesHYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemJMVNo ratings yet

- 2 3 5 Practice Paper Bridge Abutment DesignDocument15 pages2 3 5 Practice Paper Bridge Abutment DesignAbhishek PawarNo ratings yet

- Bridge Abutment DesignDocument15 pagesBridge Abutment DesignPRAVEEN NAUTIYALNo ratings yet

- Methods of Vacuum Consolidation and Their Deformation AnalysesDocument14 pagesMethods of Vacuum Consolidation and Their Deformation AnalysesLinh GeotechniqueNo ratings yet

- Session IX HydraulicsDocument72 pagesSession IX Hydraulicsjoe_b_32607No ratings yet

- Analysis & Beam Design: Preliminary SizingDocument20 pagesAnalysis & Beam Design: Preliminary SizingmichaelNo ratings yet

- Design of PIle FoundationDocument15 pagesDesign of PIle FoundationPraveen Kumar KattamuriNo ratings yet

- Test - Pile Report - R2Document4 pagesTest - Pile Report - R2Fahad IqbalNo ratings yet

- SS0-5000-J-005-R1 & S-005-R1 Containerized Substation FoudationDocument15 pagesSS0-5000-J-005-R1 & S-005-R1 Containerized Substation FoudationAllan MwesigwaNo ratings yet

- Review of Field Data from HDD Pilot Hole DrillingDocument17 pagesReview of Field Data from HDD Pilot Hole Drillingali ameliNo ratings yet

- 2Document24 pages2jasekanNo ratings yet

- Steel Truss Bridge 85 MT Bowarch Pedestrian BridgeDocument19 pagesSteel Truss Bridge 85 MT Bowarch Pedestrian Bridgeakshay kothiyalNo ratings yet

- 6.0m Abutment Design (4 P.C Girder-12 Pile) (Final & Ok)Document30 pages6.0m Abutment Design (4 P.C Girder-12 Pile) (Final & Ok)Prodip MondalNo ratings yet

- Group 5Document1 pageGroup 5Yasin Mohamed BulqaazNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument389 pagesRCC31R Rigorous One-Way SlabsCioabla BogdanNo ratings yet

- Tubular Steel Sections Offer Cost Savings Over Angular SectionsDocument3 pagesTubular Steel Sections Offer Cost Savings Over Angular SectionsKripasindhu BordoloiNo ratings yet

- Footing Pile Cap Design: Project: Footing Number: EngineerDocument9 pagesFooting Pile Cap Design: Project: Footing Number: EngineerIshor ThapaNo ratings yet

- CFDLV14 N5 P98 105Document8 pagesCFDLV14 N5 P98 105mabm89No ratings yet

- Ngo Et Al. - 2018 - Prediction of Degree of Impregnation in Thermoplastic Unidirectional Carbon Fiber Prepreg by Multi-Scale ComputationDocument12 pagesNgo Et Al. - 2018 - Prediction of Degree of Impregnation in Thermoplastic Unidirectional Carbon Fiber Prepreg by Multi-Scale ComputationNgô Ích SơnNo ratings yet

- Comparative study of slab culvert design using IRC codesDocument5 pagesComparative study of slab culvert design using IRC codesimamtaNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- 2022analytical Method For Predicting Pile Running During - 2022 - Applied Ocean ReseDocument16 pages2022analytical Method For Predicting Pile Running During - 2022 - Applied Ocean Rese叶晓平No ratings yet

- Design of Main Girder (Compatibility Mode)Document58 pagesDesign of Main Girder (Compatibility Mode)Mohamed Azazy100% (1)

- U-Ditch Drainage Calculation: 1. Design Criteria 1.1. Material PropertiesDocument3 pagesU-Ditch Drainage Calculation: 1. Design Criteria 1.1. Material PropertiesRianto FelissimoNo ratings yet

- STRESSING CALCULATIONS - Malbogon BridgeDocument1 pageSTRESSING CALCULATIONS - Malbogon BridgeRay Vincent Agorita FriasNo ratings yet

- Thermal Control of High Power Applications On Cubesats: October 2018Document16 pagesThermal Control of High Power Applications On Cubesats: October 2018Josue Manuel Pareja ContrerasNo ratings yet

- Civil Engineering Standard DatasDocument14 pagesCivil Engineering Standard DatasP S HARSHITANo ratings yet

- 001-135-12-Design Report-Washout Chamber-R0Document43 pages001-135-12-Design Report-Washout Chamber-R0Anonymous 3kDy7eNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- 2 3 5 Practice Paper Bridge Abutment DesignDocument15 pages2 3 5 Practice Paper Bridge Abutment DesignAchilleas21No ratings yet

- Beam Design: Span Depth L DDocument17 pagesBeam Design: Span Depth L DmichaelNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsMohammad Twaha JaumbocusNo ratings yet

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112Rupendra palNo ratings yet

- Inclined Retaining Wall RCC Design 4mDocument10 pagesInclined Retaining Wall RCC Design 4mRahul GargNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- HR Evalulation PDFDocument1 pageHR Evalulation PDFKhalidHiluNo ratings yet

- Khalid Hilluu CV4Document3 pagesKhalid Hilluu CV4KhalidHiluNo ratings yet

- Final Presentation 10.12.2019Document104 pagesFinal Presentation 10.12.2019KhalidHiluNo ratings yet

- Week 9 HandoutsDocument23 pagesWeek 9 HandoutsKhalidHiluNo ratings yet

- Calculating present, future, and annual values in time value of money problemsDocument3 pagesCalculating present, future, and annual values in time value of money problemsKhalidHiluNo ratings yet

- Week 9 HandoutsDocument23 pagesWeek 9 HandoutsKhalidHiluNo ratings yet

- Multiple Regression Project PDFDocument62 pagesMultiple Regression Project PDFKhalidHiluNo ratings yet

- Khalda Commercial Building OFFERSDocument11 pagesKhalda Commercial Building OFFERSKhalidHiluNo ratings yet

- Wilson Spieles-Prediction of Sulfide EmissionDocument30 pagesWilson Spieles-Prediction of Sulfide EmissionKhalidHiluNo ratings yet

- Thrust Restraint Design For DI PipeDocument24 pagesThrust Restraint Design For DI PipefazyroshanNo ratings yet

- DemandsDocument2 pagesDemandsKhalidHiluNo ratings yet

- Perancangan Struktur Baja 1Document53 pagesPerancangan Struktur Baja 1Saya BimaNo ratings yet

- DinDocument11 pagesDinharshadNo ratings yet

- T-ZED Homes, Whitefield, BengaluruDocument5 pagesT-ZED Homes, Whitefield, BengaluruHello ShraaNo ratings yet

- Fdas - Specs PDFDocument10 pagesFdas - Specs PDFAiron Jay MangabatNo ratings yet

- POWERPACKDocument31 pagesPOWERPACKcristianNo ratings yet

- 17-7ph TechsummaryDocument3 pages17-7ph Techsummarytahera aqeel100% (1)

- Void Slab Shop DrawingDocument4 pagesVoid Slab Shop DrawingWk JoeAnNo ratings yet

- Piping Course هام جداDocument206 pagesPiping Course هام جداMohamed Ibrahim100% (1)

- Ps-x01 Nls InputdataDocument100 pagesPs-x01 Nls InputdatapckolNo ratings yet

- Guidelines For Plan Check and Permit Requirements For Solar Energy SystemsDocument9 pagesGuidelines For Plan Check and Permit Requirements For Solar Energy SystemsRPantelNo ratings yet

- Designation System of Screws and BoltsDocument3 pagesDesignation System of Screws and BoltsGiri DharanNo ratings yet

- Portfolio 2013Document29 pagesPortfolio 2013mucupNo ratings yet

- Solar Project Construction: Nextera Energy Resources (Neer)Document20 pagesSolar Project Construction: Nextera Energy Resources (Neer)absriva00No ratings yet

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- VILLA 430: Hyderabad, TelanganaDocument27 pagesVILLA 430: Hyderabad, TelanganaH A I K U S T U D I ONo ratings yet

- Comparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric LoadDocument10 pagesComparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric Loadmohamed alyozbakiNo ratings yet

- Specs-Stage 2& 3-TrackworksDocument76 pagesSpecs-Stage 2& 3-Trackworksismail tp100% (2)

- Sikafloor - 161 PDFDocument5 pagesSikafloor - 161 PDFShaik FazilNo ratings yet

- TechnipFMC Project MobilizationDocument9 pagesTechnipFMC Project MobilizationJobJob100% (8)

- ABEL SH Solids Handling Pumps GB-web-02 2020Document6 pagesABEL SH Solids Handling Pumps GB-web-02 2020ha liNo ratings yet

- Fire Water Hydrants: Product CatalogueDocument3 pagesFire Water Hydrants: Product Catalogueseeralan balakrishnanNo ratings yet

- JD - Internship at CyondDocument2 pagesJD - Internship at CyondStupidity TalksNo ratings yet

- How To Control The Warping of Parts in Thin SheetDocument6 pagesHow To Control The Warping of Parts in Thin SheetNeil WayneNo ratings yet

- Ts LCRBY FiltersDocument2 pagesTs LCRBY FiltersRazvanNo ratings yet

- Rehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadDocument2 pagesRehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadAljie CañeteNo ratings yet

- Steel Doors and Windows For 2013-14Document59 pagesSteel Doors and Windows For 2013-14Senthil KumarNo ratings yet

- Shaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Document21 pagesShaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Carlos Arturo Casas HuamánNo ratings yet

- PIP PCECV001 Guidelines For Application of Control ValvesDocument39 pagesPIP PCECV001 Guidelines For Application of Control ValvesAndresNo ratings yet

- Piping Design in Detailed EngineeringDocument4 pagesPiping Design in Detailed Engineeringmaneeshmsanjagiri0% (1)

- Useful ECBC Tables and TermsDocument17 pagesUseful ECBC Tables and TermsAnoop SharmaNo ratings yet