Professional Documents

Culture Documents

Oil Purification

Uploaded by

ratheeshkumardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Purification

Uploaded by

ratheeshkumardCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/309404071

PURIFICATION OF TRANSFORMER OIL in PT. PJB UP PAITON

Article · January 2016

DOI: 10.5281/zenodo.56908

CITATIONS READS

0 1,207

1 author:

Totok R. Biyanto

Institut Teknologi Sepuluh Nopember

131 PUBLICATIONS 122 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Development of Killer Whale Algorithms View project

HAZOP for New Pertamina Refinery Unit in Balikpapan Kalimantan Timur View project

All content following this page was uploaded by Totok R. Biyanto on 20 February 2017.

The user has requested enhancement of the downloaded file.

[Wahdaniyah* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

IJESRT

INTERNATIONAL JOURNAL OF ENGINEERING SCIENCES & RESEARCH

TECHNOLOGY

PURIFICATION OF TRANSFORMER OIL in PT. PJB UP PAITON

Gusti Wahdaniyah*, Purnomo Tri Prasetyo, Arif Setiabudi, Totok R. Biyanto

PT. PJB UP Paiton, Probolinggo, Indonesia

Department of Engineering Physics, Institut Teknologi Sepuluh Nopember (ITS) Surabaya, Indonesia

DOI:

ABSTRACT

The purpose of this paper is to describe the filtration or purification of transformer oil. One of the main equipment in

coal-fired power generation unit is transformer. When the transformer fail to operate properly, the continuity of

distribution system become interrupted. As a part of transformer, transformer oil contribute the failure of transformer

due to the aging. To solve this problem, several methods is applied starting from dehydration process, degasification

process, oxidation removal and filtration or purification. After the purification process is performed, the transformer

oil then analyzed. The result shows that the purified transformer oil is better than before purified.

KEYWORDS: Transformer oil, purification, failure.

INTRODUCTION

Transformer is the main equipment in coal-fired power generation unit (PLTU) aside from the turbine equipment, cold

handling and boiler. In the condition of normal load plant capacity, age of the transformer depends on the used

insulation where the insulation has a mechanical, electrical resistance and protected oil isolation that will make the

transformer has the ability to work accepting load or high electrical pressure (electric stress) [1]. Transformer oil as

liquid insulation operates to separate the parts that have difference voltage between parts so that do not occur leap

electrical (flash-over) or spark (spark-over). The failure of the insulation on the high-voltage equipment that occurs

when equipment is operating, it could cause damage to the tool so that the continuity of distribution system becomes

interrupted. From the few cases show that isolation failure related to the existence of a partial discharge. Partial

discharges can occur in solid insulating materials, liquid insulating materials and gas insulating materials. The failure

mechanism on solid insulating material covers intrinsic failures, electro mechanical, thermal and erosion. On gas

material is mainly caused by the mechanism of town send and the mechanism of steamer. While in the liquid material

is caused by bubbles (cavitation), and mixed liquid insulation material (contamination). Liquid insulation is used

because it has 1000 times more density than gas insulation and has high dielectric strength, liquid insulation will fill

a gap or space that will be isolated, and it can absorb the heating that arises and insulates the liquid that tend to be able

to repair itself if there is a release of charge (discharge). But the main drawback of liquid insulation is easily

contaminated [2]. The Damage of the oil insulation in transformer is more caused by age, where naturally insulating

paper that used will damage continuously and naturally transformer oil also oxidize continuously, because there is

oxygen in the oil or there is air in the transformer. Reclamation, inhibitor giving and its product bond such as acid or

sludge and return the oil to the new conditions. The speed of this oxidizing product strongly affected the conditions

of temperature, moisture, electric stress, quality of paper insulation transformer. Nowadays, advanced measurement

and forecasting of these variables [3-4]. There are also several research already available in assessing the health of

transformer oil [5-7]. Meanwhile, in this paper purification process is conducted to assess and restore the transformer

oil health.

REVIEW

Water in Tranformer Oil

Water in transformer oil is obtained from the atmosphere or the product of a chemical reaction. In oil insulation, water

can occur in some of the following conditions:

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[91]

[Wahdaniyah* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

In dissolved condition

In emulsion condition

In the bottom container transformer

Even very little amount of water can have significant effects to transformer characteristics. In this case, the presence

of water emulsion is more dangerous than dissolved condition. Figure 1 shows the curve relationship between the

dielectric strength and quantity of water emulsion in mineral insulator oil.

The water quantity that can dissolve in the oil is directly proportional to the increase in the oil temperature as described

in the curve of Figure 2. Then the oil temperature should be considered for separation of water from oil, because the

purification oil in high temperature can decrease the dielectric strength, when water transformation is dissolved to be

emulsion.

Paper isolation on transformer is very porous and it can absorb water in great abundance. The increasing amount of

dissolved water and emulsion in oil insulating, then the amount of absorbed water on the paper insulation is getting

bigger as well. As a result is greatly able to decrease the dielectric strength. After being absorbed, the water is very

difficult to be eliminated. Therefore, to prevent the absorption, it is necessary to keep the water content in oil insulation

at certain level as low as possible [2].

Basic Test for Determining of Tranformer Oil State

Sub-subheading should be 10pt Times new roman, Italic, Justified.

The degradation process of the oil insulation can be monitored and measured by a series of tests, the most important

and widely applied is as following:

1. Water content – test ASTM D 1533

Water is one of the factors that affect the oil quality and transformer characteristic in the transformer. Water content

should be at a level that is as low as possible (no more than 30 ppm) [2].

2. Dielectric strength – test ASTM D 877, D 1816

Characteristic from dielectric strength on transformer oil is very important and usually it will be investigated

first. Physically, dielectric strength is the voltage at which the transformer oil that starts to work. The value should be

at the highest level. The decrease of this value indicates the increase of water content in transformer oil [2].

3. Neutral number - acidity number – test ASTM D 974

The unit of acidity number is mgKOH/mg that represents caustic potassium milligram that added to the gram of oil to

neutralize the acidity. The oil transformer in new condition almost no acid level if the storage procedure and

transformer charging is done correctly. The value of new oil acidity is below 0.05. Acidity level increases in line with

the oxidation process in the oil and proportional to the amount of oxygen content in the oil. Acidity limit in the

transformer oil is 0,2, because in the value of acidity to reach 0,4 resinoid layer will form drastically that affects

characteristic transformer [2].

4. Inter surface stress – IFT test – test ASTM D 971

Inter surface stress is a characteristic that allows the formation of resinoid layer, although it does not mean that this

layer is formed. Physically, inter surface stress is the force that required to break down the oil layer, which is on the

boundary between oil and water. Unit is N/m (or mN/m). The value for the new oil is around 40 mN/m. The value of

inter surface good stress is more than 22 mN/m. Transformer Oil which has inter surface stress with a value of between

15 and 22 mN/m should be purified, while under 15 mN/m it almost certainly shows a resinoid layer [2].

In addition to the fourth above tests also contain several tests for oil isolator such as specific gravity, colour, total

dissolved combustable gas, visual/sediment, total furan, liquid power factor, inhibitor content, and corrosive sulfur

METHOD

Because of the importance of the use of the transformer on a regular basis, reviewing the complexity degradation and

the aging to the problem of the isolation transformer, at this point some methods have been developed, especially

concerning the improvement of condition of isolation transformer passes through some of the following procedures:

1. Dehydration (Removing water content )

2. Degasification (Removing oxygen content and another gases)

3. Removing several oxidation process.

4. Filtration.

Filtration that the most commonly used is in the following:

Natural sedimentation

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[92]

[Wahdaniyah* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

Natural sediment is based separation of water at the bottom of the transformer container naturally, while the

transformer does not operate for at least 24 hours. After that, the oil is pumped out while the water content removed

from the bottom, cleaning is performed repeatedly until the natural sediment is removed. This method is rather slow

and requires more energy, and the efficiency is less satisfactory to meet the standard set [2]

Filter presses

Filter presses can consist of several types of construction but the most used type is based on the principle of circulation

of oil through a series of filtering and absorbing (e.g. filter paper). This method cannot be used to oil degasification. To

remove water content, filtering element must be replaced and dried periodically [2].

Portable devices with filter elements

Portable devices for filtering elements are frequently used because of their small size, easy handling and several

advantages that are compared to use another larger filter. In these devices, there are several ready-used elements such

as cartridge that is used to filter the oil from 1 µm to 25 µm. This device can separate the water and the oil very well[2].

Coalescer filtration

Filtration coalescer is a comparatively new developed method, based on filtering methods for aircraft fuel. The

filtering element is made of fiberglass where water can be separated because of the increase of differential pressure

on its operational. This method has the advantage over the other methods, but the main drawback is the sensitivity of

the filtering elements to the solid particles in the oil.

Vacuum dehydration

Vacuum dehydration method is widely used and highly efficient which oil purification was done by warming the oil

isolator and drying it in a vacuum. In this condition boiling point of water is significantly low and the separation of

the water content of the oil can be applied. This method is very efficient to use degasification. The main drawback of

the method is the energy needs for heating oil during the process of purification. An increase in temperature of the

insulating oil is above 65°C, then drying it in a vacuum has caused the loss of an important oil fraction required for

good insulation quality of oil [2]. While at a lower temperature, drying efficiency will decrease rapidly. Transformer

oil purification in PT PJB Paiton also uses this vacuum dehydration method.

RESULTS AND DISCUSSION

After Purification, transformer oil becomes in good condition again as shown in Table 1.

Table 1. The Results of Laboratory Test of Transformer Oil

Reference The Value

Variable Unit

Standard Standard Before After

Neutralisir Number (ACID) MgKOH/mg ASTM D974 <0.06 0.014 0.014

Interfacial Strenght (IFT) mN/m ASTM D971 >32 34.9 37.2

Dielectric Strenght (DIEL) kV ASTM D877 >=30 90 91

0.84-

Specific Gravity (SP. GR) ASTM D1298 0.8718 0.8784

0.91

Colour ASTM D1524 <=3.5 1.5 1.5

Total Dissolved Combustable Gas ASTM D3612 720 53 1

Visual/Seiment ASTM D1524 Clear Clear Clear

Total Furan ASTM D5837 <100 ND ND

20oC <0.1 0.060 0.010

Liquid Power Factor ASTM D924

100oC <2.99 2.140 2.990

Inhibitor Content ASTM D2688 >0.20 ND 0.34

Water Content (Moisture) ppm ASTM D1533 <30 7 6

Corrosive Sulfur ASTM D1275B 1 1B 1B

From the table above shows that the water content in oil transformer declined from 7 ppm to 6 ppm and acquiesce on

standard range that are used i.e. < 30 ppm. For dielectric strength and interfacial strength increases gradually with the

value of 91 kV and 23.1 mN/m. Then for neutralizer number does not changed significantly after purification i.e.

0.014 MgKOH/mg, but it is still on standard range that is used.

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[93]

[Wahdaniyah* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

CONCLUSION

From the results of testing on the lab showed oil transformer parameters before and after reclaimed according the

standard range that is given. Acid level increased from the standard condition 0.008 mmKOH/mg to 0.014

mmKOH/mg. Interfacial tension, specific gravity, and inhibitor content increase after purification. Interfacial tension

increased from 34.9 mN/m to 37.2 mN/m, specific gravity increased from 0.8781 into 0.8784 and inhibitor content of

ND is 0.34. For the value of moisture and dissolved gases decreases after purification is 7 ppm to 6 ppm for moisture

and 53 ppm to 1 ppm for dissolved gas.

ACKNOWLEDGEMENTS

The authors gratefully thank to PT. PJB UP Paiton Indonesia for providing the facilities in conducting this research.

REFERENCES

[1] J. Filippini, R. Tobazéon, P. Guuinic, and O. Moreau, "The spontaneous ionic purification phenomenon of

transformer oil: Presentation and consequences," Journal of Electrostatics, vol. 67, pp. 737-740, 2009.

[2] I. Mačužić and B. Jeremić, "Modern Approach to Problems of Transformer Oil Purification," Tribology in

industry, Kragujevac, vol. 24, 2002.

[3] Bin, Song, and Li En-Wen. "Study on state of health for power transformer oil with multiple

parameters." Power System Technology (POWERCON), 2014 International Conference on. IEEE, 2014.

[4] Malik, Hasmat, et al. "UV/VIS response based fuzzy logic for health assessment of transformer oil." Procedia

Engineering 30 (2012): 905-912.

[5] NEGARA, Yulistya, et al. Investigation of intrinsic breakdown of transformer oil insulation: An experimental

approach. In: Power Engineering and Renewable Energy (ICPERE), 2014 International Conference on.

IEEE, 2014. p. 66-69.

[6] DU, Y., et al. Measurements of moisture solubility for differently conditioned transformer oils. In: Dielectric

Liquids, 1999.(ICDL'99) Proceedings of the 1999 IEEE 13th International Conference on. IEEE, 1999. p.

357-360.

[7] FEI, Sheng-wei, et al. Particle swarm optimization-based support vector machine for forecasting dissolved

gases content in power transformer oil.Energy Conversion and Management, 2009, 50.6: 1604-1609.

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[94]

View publication stats

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- University of Turkish Aeronautical Association Faculty of Engineering EEE DepartmentDocument57 pagesUniversity of Turkish Aeronautical Association Faculty of Engineering EEE DepartmentratheeshkumardNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AGA Purging.2001 PDFDocument157 pagesAGA Purging.2001 PDFLeDzung100% (1)

- Minipurge Type X / Et Size 1 Manual ML 442: ML 442 V15 26-Nov-14 Page 1 of 23Document36 pagesMinipurge Type X / Et Size 1 Manual ML 442: ML 442 V15 26-Nov-14 Page 1 of 23ratheeshkumardNo ratings yet

- Aramco Coe10602Document73 pagesAramco Coe10602Mahesh Kumar100% (1)

- Gas Insulated Substation Testing and ApplicationsDocument20 pagesGas Insulated Substation Testing and ApplicationsDaniel YustriandiNo ratings yet

- Organization of Genes and Chromosomes CompleteDocument13 pagesOrganization of Genes and Chromosomes Completebiotecnika_testNo ratings yet

- Organic II Reactions (Complete) BETADocument21 pagesOrganic II Reactions (Complete) BETATheoNo ratings yet

- Transformer Oil PurificationDocument7 pagesTransformer Oil PurificationAther AliNo ratings yet

- Presentation Frag101 2017 03 13Document124 pagesPresentation Frag101 2017 03 13Erik Nguyen100% (2)

- Pipe Coat & LiningDocument22 pagesPipe Coat & Liningjadav parixeet100% (3)

- Membrane Technology in Water Treatment ApplicationsDocument11 pagesMembrane Technology in Water Treatment ApplicationsleechulmiuNo ratings yet

- Hospital Housekeeping ManualDocument14 pagesHospital Housekeeping ManualphilipNo ratings yet

- Cable NomenclatureDocument5 pagesCable NomenclatureSushantGore100% (1)

- Where Does The Air GoDocument21 pagesWhere Does The Air GoratheeshkumardNo ratings yet

- Managed Switch Quick Start Guide: FirstDocument6 pagesManaged Switch Quick Start Guide: FirstRicardo FuentesNo ratings yet

- Minipurge Type X / Et Size 1 Manual ML 442Document40 pagesMinipurge Type X / Et Size 1 Manual ML 442ratheeshkumardNo ratings yet

- UtpDocument11 pagesUtpratheeshkumardNo ratings yet

- Little Known Facts About InsulationDocument2 pagesLittle Known Facts About InsulationratheeshkumardNo ratings yet

- Digsi 5Document48 pagesDigsi 5ratheeshkumardNo ratings yet

- PD WithFluorescent FiberDocument13 pagesPD WithFluorescent FiberSukant Bhattacharya100% (1)

- 03 16 Final PoleAttachmentCracking MooreDocument5 pages03 16 Final PoleAttachmentCracking MooreSirish ShresthaNo ratings yet

- Transformer Question AnswerDocument14 pagesTransformer Question AnswerPrashant PuriNo ratings yet

- D758 Minipurge ManualDocument34 pagesD758 Minipurge ManualratheeshkumardNo ratings yet

- Correlation Between Partial Discharges and Gas FormationDocument17 pagesCorrelation Between Partial Discharges and Gas FormationTedy MTNo ratings yet

- File - 46979 (1) CDocument31 pagesFile - 46979 (1) Cmmsaleem1967No ratings yet

- Transformer Question AnswerDocument14 pagesTransformer Question AnswerPrashant PuriNo ratings yet

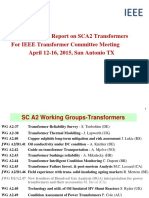

- IEEE CIGRE Liaison Report on SCA2 TransformersDocument7 pagesIEEE CIGRE Liaison Report on SCA2 TransformersratheeshkumardNo ratings yet

- Transformer Question AnswerDocument14 pagesTransformer Question AnswerPrashant PuriNo ratings yet

- Case Study Ethylene Pilot PlantDocument11 pagesCase Study Ethylene Pilot PlantDayo IdowuNo ratings yet

- Purge and Pressurization White Paper WEBDocument16 pagesPurge and Pressurization White Paper WEBratheeshkumardNo ratings yet

- AAPTDocument16 pagesAAPTratheeshkumardNo ratings yet

- Summary of Transformer Partial Discharge Detection Methods: Li YandaDocument4 pagesSummary of Transformer Partial Discharge Detection Methods: Li YandaratheeshkumardNo ratings yet

- PD On TrafoDocument5 pagesPD On TraforatheeshkumardNo ratings yet

- Chapter No. Title Page NoDocument13 pagesChapter No. Title Page NoratheeshkumardNo ratings yet

- PD D27 09L 02e - 609 - PDMDocument8 pagesPD D27 09L 02e - 609 - PDMratheeshkumardNo ratings yet

- Acknowledgments List of Figures List of Tables Synopsis Chapter I Introduction 1 II VI VIIDocument2 pagesAcknowledgments List of Figures List of Tables Synopsis Chapter I Introduction 1 II VI VIIratheeshkumardNo ratings yet

- 591 0 PDFDocument6 pages591 0 PDFMohammed Jaffar AdnanNo ratings yet

- HBR Catalogue Eng KKPCDocument2 pagesHBR Catalogue Eng KKPCIulian Victor MafteiNo ratings yet

- Biological Safety CabinetsDocument5 pagesBiological Safety CabinetsAhmed Ali AssafNo ratings yet

- Econo SprayDocument1 pageEcono SprayEliasNo ratings yet

- Qualitative Analysis NotesDocument2 pagesQualitative Analysis NotesFaiaz AhmedNo ratings yet

- Assessment of Drought Tolerance in Mung Bean Cultivarslines As Depicted by The Activities of Germination Enzymes, Seedling's Antioxidative Potential and Nutrient AcquisitionDocument33 pagesAssessment of Drought Tolerance in Mung Bean Cultivarslines As Depicted by The Activities of Germination Enzymes, Seedling's Antioxidative Potential and Nutrient AcquisitionFaisal ShehzadNo ratings yet

- ) :i :: G L : :i:: ! T"'" : 4. Which of The Following Elements Have ElectronDocument10 pages) :i :: G L : :i:: ! T"'" : 4. Which of The Following Elements Have ElectronPadam MantryNo ratings yet

- 05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPDocument17 pages05.09.21 OSR - CO-SC Jee Adv 2020 P1 GTA-28 (P-I) QPRahul RanjanNo ratings yet

- Astm D178Document9 pagesAstm D178Rodrigo Escárate BernalNo ratings yet

- 2022 Puc I Chem Imp QuestionsDocument13 pages2022 Puc I Chem Imp QuestionsCHAKRI BABLUNo ratings yet

- Assignment On CGMPDocument19 pagesAssignment On CGMPRajesh Nayak50% (2)

- Density Tower-Sphsummer 2Document3 pagesDensity Tower-Sphsummer 2api-322723623No ratings yet

- Is 2830 2012 PDFDocument13 pagesIs 2830 2012 PDFK.s. Raghavendra KumarNo ratings yet

- Comparing Fermentation Rates of Wheat, Gram, Rice and PotatoDocument10 pagesComparing Fermentation Rates of Wheat, Gram, Rice and PotatovipulNo ratings yet

- Loctite 515™: Technical Data SheetDocument3 pagesLoctite 515™: Technical Data SheetVincent EsperanzaNo ratings yet

- DiaSys Reagents Price ListDocument5 pagesDiaSys Reagents Price ListchochoroyNo ratings yet

- Experimental and Modeling of A Non-Isothermal CSTRDocument10 pagesExperimental and Modeling of A Non-Isothermal CSTRAlejandra SantosNo ratings yet

- Wide-Lite F Series Floodlight Bulletin 1988Document4 pagesWide-Lite F Series Floodlight Bulletin 1988Alan MastersNo ratings yet

- ...Document44 pages...Mercy'deth MangaoilNo ratings yet

- IMA MCQsDocument18 pagesIMA MCQsPCOP Pharmacy100% (1)

- Hematology Services GuideDocument34 pagesHematology Services GuideLorelie CarlosNo ratings yet

- TANNERIESDocument7 pagesTANNERIESzalabiNo ratings yet

- Calculation Tool For Waste Disposal in Municipal Solid Waste Incinerators MSWI For Ecoinvent v2.1 (2008)Document129 pagesCalculation Tool For Waste Disposal in Municipal Solid Waste Incinerators MSWI For Ecoinvent v2.1 (2008)JKKNo ratings yet