Professional Documents

Culture Documents

Lincoln CentroMatic 85535 Controller

Uploaded by

veereshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lincoln CentroMatic 85535 Controller

Uploaded by

veereshCopyright:

Available Formats

UNCOLN CENTRO.

MATIC@

Model 85535 Controller

Series rrC"@

@ Indicates change

JAN .06 Form 404005 Section - C8 pase - 278F3

CENTRO.MATIC@

The memory feature will work as follows:

Dioswitch set to "Memory Off'- Will result in a lube cycle each

time power is turned on. Lube cycle will start at the beglnning

of the on time setting.

Dipswitch set to "Memory On"

1 . Power is turned off during the off time (time between lube

cycles). When turning power back on will cause the lube

cycle to continue from the point of interruption.

2. Power is turned ofi during the on time or pumplng time.

Turning power back on will cause the lube cycle to start at

Safety the beginning of the on tlme setting.

Read and carefully observe these operating instructions before

unpacking and operating the controller! The Timer Mode

controller must be operated, maintained and repaired exclu- When the dipswitch is set to the timer mode, amount of time

sively by persons familiar with the operating that the pump is on will be determined by the setting of the

instructions. Local safety regulations regarding installation, dipswitch. Time will be either 30 seconds or 2 minutes.

operation and maintenance must be followed.

Operate this controller only after safety instructions and this

Controller Mode

When the dipswitch is set to the controller mode, a

service manual are fully understood.

pressure switch must be installed in the lube supply line. This

will provide pressure-monitoring capabilities. The

pressure switch will reset the controller when the Bet pr6s-

$, wnnNrNG sure is detected. The controller will initiate an alarm whsn

the pump fails to develop sufficient pressure to actuate the

This symbol identifies

pressure switch within the dipswitch setting of 30 seconds or

the potential for a

2 minutes.

hazardous srtua'tion.

lf this warning is not

followed, a serious Description

could occur.

General Description

Model 85535 controller is used to program the cycle

Controller Operation frequency of a lubrication pump. Lube cycles are

The time between lube events is determined by the setting of determined by the setting of internal switches. The cycles

the rotary switch, which selects the numeral setting, and the times are selected to meet system requirements. During the

dipswitch, which selects the units in either minutes or hours. "ON" time, the air to the pump solenoid will be

energized.

When used in the timer mode, the pump will remain on for the

amount of time that was selected by the dipswitch. Time will Appropriate Use

be either 30 seconds or 2 minutes (see Timer Mode). . Model 85535 is exclusively designed for use in a

Centralized Lubrication System.

When used in the controller mode, the amount of time that the . The maximum ratings given should not be exceeded.

pump is on is determined by the closing of a pressure switch in . Any other use not in accordance with the instructions will

the lube supply line (see Controller Mode). Failure of the pres- result in loss of claim for warranty and liability.

sure switch to close within the time setting of the dipswitch,

either 30 seconds or 2 minutes, will result in an alarm condi- Product Specification :

tion. The alarm LED will turn on and the alarm contact will Input Voltage: 21VDC to 30 VDC

close. The controller will continue to initiate lube cycles while Current Consumption: 100 MA (less external load)

in alarm. Load Relay Contact: 2 amps inductive load at 30 VDC

Alarm Relay Contact: 2 amps inductive load at 30 VDC

When the low-level switch closes, the alarm LED will turn on Enclosure: NEMA 12

and the alarm contact will close. The controller will continue to Temperature Range: -40' F to 'l 50' F (-40' C to 65' C)

initate lube cycles while in alarm- Alarm condition will remain Net Weight: 4 lbs.

until low-level switch opens. Off Time (adjustable): 30 seconds minimum

30 hours maximum

Pressing the manual lube button on the enclosure cover will On Time: 30 seconds minimum

always initiate a lube event. 2 minutes maximum

Lubrication System: Centro Matic

Page Number - 2 Form 404005

CENTRO.MATIC@

Field Gonnections

Terminal Strio 1 throuqh 8 Terminal Strio 1 through 4

Terminal 1 Bat + Terminal 1 Low level switch

Terminal 2 Bat - Terminal 2 (closes to indicate an alarm)

Terminal 3 24 VDC source for Terminal 3 System pressure switch (closes to end lube

Terminal 4 external air to pump solenoid. Terminal 4 cycle). Only used in the Controller Mode.

Terminal 5 Dry alarm contact Terminal Strip AB

Terminal 6 (contact closes on fault) Terminal A Remote Normally Open

Terminal B Manual Lube Switch

Observe correct polarity for Terminals 1,2,3

and 4.

24 VDC

6

..- +J \Ure - - .o\, o-1 PRESSURE

I

SW I TCH

2 I

-I

I

MANUAL LUBE

L-

-o o- SWI TCH

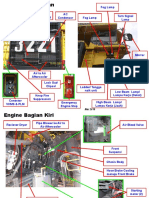

SYSTEM COMPONENTS

Part No. Qtv. Descriotion

otlJJO 1 Fu se Holder

,l

68552 7.5 Am p Fuse

L

350283 1 24 VDC Solenoid

lllustration 1@

Wiring Diagram

1. Incoming Power: 24VDC.

2.24VDC Air Solenoid Valve.

3. Optional Alarm wired by customer.

4. Keypad with indicator lights and manual lube push button.

5. Optional Low Level Switch wired by customer.

6. Pressure Switch wired by customer- Not needed if used in the timer mode.

@ 7. Remote Manual Lube Switch.

@ Indicates change

Form 404005 Page Number - 3

CENTRO.MATIC@

Gontroller Gomponents and Setting the Off Time Switch - See lllustration 2

Using the Rotary Switch you can select .5, 1,2, 4,8, 15,24 or

Controller 30. The units are either minutes or hours as determined by the

mode switch setting.

Mode Swltch ldentlflcation - See lllustratlon 2

30 seconds or 2 mlnutes - Select the maximum amount

Enclosure Cover - See lllustration 2

of "On'l'ime". Green LED - Indicates that power is applied to the

Timer or Gontroller - Select llmer Mode or

controller.

Green LED -

Controller Mode.

Indicates that the pump is on.

Hours or Minutes . Select units for the "Off Time"

Red LED - Indicates an alarm condition,

Memory Off or Memory On -

used with the Rotary Switch.

Select memory feature.

Manual Lube - Pressing will initiate a lube cycle.

Repair Parts List

Item Quan. Descriotion Part Number

1 1 Timer Board 250599

, 1 Kcvnad Acs'rr 249695

O POWER

O PUMP ON

O ALARM

CONTROL

SWTCH OFF SWTCH ON

.0.=". lE tro.=".

TIMER IEEICONTROLLE

HOURS

MEI\4ORY

IEIMINUTES

13

MEMoRY oN fr4vpc I uorr.l--1".^r, lTlu^

MODE SWITCH

| ^ l:m:ruu ,,',1-J6-l ,^*FlMgL:;

One Lin@ln Way, g Louis. MO 63120-1576

WA R N I N G

ELECTRICAL SHOCK HAZARD

TURN OFF AND LOCK OUT POWER

BEFORE OPENING ENCLOSURE

lllustration 2

@ Indicates change

Page Number - 4 Form 404005

IJDTCOLN CENTRO.MATIC@

, 'll2" (8e mm)

l--

5/16'(8 mm Dia. Mtg. Holes)

(4 places)

7 - 1t2"

(191 mm)

6 - 314"

(171 mm)

2"

Conduit Hole

(51 mm)

4 - 15116"

(125 mm)

Dimensions

@ Indicates change

Form 404005 Page Number - 5

GENTRO.MATIC@

Lube without Alarm Mon

]ondltion rossible Gause )orrective Action

)ontroller does not ooerate. {o electric power to controller. 'urn on electric power to pump. "Powe/' L.E.D.

;hould light, 'PUMP ON' L.E.D. should light when

MANUAL LUBE" is pressed.

PUMP ON' L.E.D. lights, but load )rinted circuit board failure. lemove and replace.

>onnected to terminals 3 & 4 will

rot energize.

-oad connected to terminals 3 & 4 )rinted circuit board failure or lemove and replace.

:nergized, but "PUMP ON" L.E.D. ieypad failure.

loes not light.

3earing points are over lubricated. fimer/Controller memory mode furn on memory mode of timer/controller.

s set to off.

njector output adjustment setting teadjust to lower setting.

oo hiqh.

Seadng points are under l'imer/Controller cycle time iet to longer cycle time or reevaluate lube

ubricated. ;etting too low. equirements.

njector output adjustment setting ieadjust to right setting.

oo tow.

fimer/Controller cycle timer iet to shorter cycle time or reevaluate lube

;etting does not deliver lubricant equirements.

lften enouqh.

iystem too large for pump output. lalculate system requirements per planning

nanual.

Additional when Alarm is used

lome, but not all, of the injectors fimer/Controller is set to "Time/'. iet Timer/Controller to "Controller Mode.

lre delivering lubricant. There is )ressure switch setting is too low. \djust pressure setting to setting high enough for

ro alarm condition. rll injectors to cycle.

Lube Alarm" L.E.D. turns and lad electrical connection between lheck all wiring between Pressure Switch and

itays on. )ressure Switch and Timer/ fimer/Controller.

lontroller.

)ressure switch setting is too \djust pressure switch to setting high enough for

rish. rll injectors to cycle.

rressure Switch is defective lepair or replace.

)rinted circuit board is defective. leplace printed circuit board.

-ow level switch wired incorrectlv lheck low level switch wiring and correct if

lecessary. Contact closure must be on low level

;ondition.

-ow system air pressure ncrease arr pressure.

Americas: Europe/Africa: Asia/Pacific:

One Lincoln Way Heinrich-Hertz-Slr 2-8 51 Changi Business Park

Central 2

St. Louis, MO 63120-'1578 D-69183 Walldorf

#09-06 The Signature O Copyright 2006

USA Germany Singapore 486066 Printed in USA

Phone +1 .314.6794200 Phone +49.6227.33.0 Phone +65.6588.0188 Web site: www.lincolnindustrial.com

Fax +1.800.424.5359 Fax +49.6227.33.259 Fax +65 6588.3438

Page Number - G Form 404005

You might also like

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- G2 Pulse Lubrication Controller Programming & Wiring GuideDocument4 pagesG2 Pulse Lubrication Controller Programming & Wiring GuideNova Kurniawan100% (1)

- Cat 793D PDFDocument32 pagesCat 793D PDFmark towerNo ratings yet

- 994H Plano Hidráulico DWC PDFDocument4 pages994H Plano Hidráulico DWC PDFCarlos GajardoNo ratings yet

- Caex Cat 775fDocument40 pagesCaex Cat 775fMax Tapia Castillo100% (3)

- D8T Track-Type Tractor TA2 Technical InspectionDocument12 pagesD8T Track-Type Tractor TA2 Technical InspectionWillian Ticlia RuizNo ratings yet

- D275a 5R - Cen00228 05Document16 pagesD275a 5R - Cen00228 05Nacer NacerNo ratings yet

- DW90ADocument2 pagesDW90AIrhas Zulfikar100% (1)

- KOMPONEN - HD785-7 SippDocument23 pagesKOMPONEN - HD785-7 Sippziky dun100% (1)

- D10T 2 Operation Manual Compressed - Compressed PDFDocument218 pagesD10T 2 Operation Manual Compressed - Compressed PDFrafael sa100% (1)

- Auto Lube RENR8396-00-01-ALL 777FDocument24 pagesAuto Lube RENR8396-00-01-ALL 777FemsonNo ratings yet

- d11t Manual de MantenimientoDocument4 pagesd11t Manual de MantenimientoAnonymous SpT4OHYMyNo ratings yet

- Manual Armado PC5500 PDFDocument104 pagesManual Armado PC5500 PDFclaudioNo ratings yet

- PC1250-8 Eess018304 1011Document20 pagesPC1250-8 Eess018304 1011Ioannis Zorzos100% (2)

- SANY SRT95C Rigid Dump TruckDocument4 pagesSANY SRT95C Rigid Dump TruckTLK Channel100% (1)

- 777GDocument15 pages777GJuan Ricardo Bolivar Pilco100% (1)

- 2202-12 14M Implement Sterring Valve ModulDocument9 pages2202-12 14M Implement Sterring Valve ModulAhmad Salimin100% (1)

- Komatsu D85EX-15 - D85PX-15 Shop ManualDocument924 pagesKomatsu D85EX-15 - D85PX-15 Shop ManualJovie GrohlNo ratings yet

- Caterpillar Monitoring System DashboardDocument41 pagesCaterpillar Monitoring System DashboardAlejandro Alberto Robalino Mendez100% (1)

- MODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Document4 pagesMODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Putro 10100% (1)

- Series: Hydraulic ExcavatorDocument16 pagesSeries: Hydraulic ExcavatorForomaquinas50% (4)

- VHMS technical analysis tool box setup guideDocument19 pagesVHMS technical analysis tool box setup guideTeguh Imam Adri100% (1)

- Lockup 777Document2 pagesLockup 777Husi Niha100% (1)

- 775g Diagrama HidraulicoDocument18 pages775g Diagrama HidraulicoAlexter AyalaNo ratings yet

- Manual de Operación y Mantenimiento WB97R-5E0 (Inglés)Document338 pagesManual de Operación y Mantenimiento WB97R-5E0 (Inglés)Carlos Juarez ChungaNo ratings yet

- Plano Power Train D8TDocument2 pagesPlano Power Train D8Talexander_1985100% (3)

- Vdocuments - MX - Cummins k38 Manual k50 qsk38 qsk50 Workshop Service Cummins KDocument2 pagesVdocuments - MX - Cummins k38 Manual k50 qsk38 qsk50 Workshop Service Cummins KRauf Khan lakhweraNo ratings yet

- Plano Hidraulico D10T PDFDocument2 pagesPlano Hidraulico D10T PDFJHOSMAR_22No ratings yet

- 773EDocument31 pages773EWilliams ArayaNo ratings yet

- Vims - Renr2630-04-01-AllDocument112 pagesVims - Renr2630-04-01-Allnilton acNo ratings yet

- PC450 (LC, HD) - 8 UEN02644-00 Testing & AdjustingDocument130 pagesPC450 (LC, HD) - 8 UEN02644-00 Testing & Adjustingdatphuong100% (1)

- PM Parts For Dp30hs ForkliftDocument1 pagePM Parts For Dp30hs Forkliftclyde justine cayabanNo ratings yet

- Plano Electrico Motoniveladora 16MDocument6 pagesPlano Electrico Motoniveladora 16MMiguel Anibal Mejia Bravo100% (1)

- PC500LC 8 - Cen00722 00Document20 pagesPC500LC 8 - Cen00722 00vitaliy100% (1)

- EX 2500 Especificaciones TecnicasDocument16 pagesEX 2500 Especificaciones TecnicasElvis Eberth Huanca Machaca100% (2)

- Of F-Highway Truck: FeaturesDocument8 pagesOf F-Highway Truck: Featuresmario palondonganNo ratings yet

- Small Catalog OHT CAT 773E PDFDocument4 pagesSmall Catalog OHT CAT 773E PDFSupriyono Abdullah100% (1)

- 777D Air ComponentDocument10 pages777D Air ComponentHeppryn WidiastoNo ratings yet

- Consumo Combustible Equipos CaseDocument16 pagesConsumo Combustible Equipos CaseVicente Quintero Ramírez100% (1)

- BOMAG Finisher BF 800. The Heavy Weight ChampionDocument20 pagesBOMAG Finisher BF 800. The Heavy Weight ChampionVany LunaNo ratings yet

- CLG4215D (Gcic Ii) Om 201902000-EnDocument160 pagesCLG4215D (Gcic Ii) Om 201902000-EnTalita Yasmin Talita67% (3)

- Scematic 777E PDFDocument31 pagesScematic 777E PDFAdi HindartoNo ratings yet

- 793C - ATY - Hoist Cylinder - Remove and InstallDocument7 pages793C - ATY - Hoist Cylinder - Remove and InstallCarlos LoboNo ratings yet

- D155AX-6 Shop ManualDocument1,569 pagesD155AX-6 Shop ManualJorge Calderon Rojas100% (6)

- 330C & 330C L Excavators KDD00001-UP (MACHINE) POWERED by C-9 Engine (SEBP3365 - 49) - Sistemas y ComponentesDocument6 pages330C & 330C L Excavators KDD00001-UP (MACHINE) POWERED by C-9 Engine (SEBP3365 - 49) - Sistemas y ComponentesDaniel Rafael Torres Regardiz100% (1)

- Cat 16MDocument24 pagesCat 16MLeandro Sal0% (1)

- Manual de Partes 16MDocument1,033 pagesManual de Partes 16MJuan Perez100% (1)

- 773 HarnesDocument35 pages773 HarnesMuhammad NovanNo ratings yet

- FlowMasterII - Rotary - Driven - 24 - V - DC - Electric - Pump - 85736 - 85737 - 85738 - 85739 - 85740 - 404517 - Version 2 PDFDocument20 pagesFlowMasterII - Rotary - Driven - 24 - V - DC - Electric - Pump - 85736 - 85737 - 85738 - 85739 - 85740 - 404517 - Version 2 PDFrd100% (1)

- Guide 2 2e PDFDocument57 pagesGuide 2 2e PDFKhaleel KhanNo ratings yet

- Hitachi Ex1200-6 Hydraulic Excavator Service ManualDocument1 pageHitachi Ex1200-6 Hydraulic Excavator Service ManualAnis Trihandayani50% (2)

- SERIES RL4000D1 LIGHT TOWER OPERATION/SERVICE & PARTS MANUALDocument60 pagesSERIES RL4000D1 LIGHT TOWER OPERATION/SERVICE & PARTS MANUALEnry HmNo ratings yet

- 2.a PM CLINIC Guideline HD785-7 Rev29112017Document20 pages2.a PM CLINIC Guideline HD785-7 Rev29112017Devid Waladan Sholehan100% (1)

- Komatsu PC 2000Document6 pagesKomatsu PC 2000Davyda VedaNo ratings yet

- (CLM054) Cat 320C Vs Komatsu PC200-6 Future ComparisonDocument68 pages(CLM054) Cat 320C Vs Komatsu PC200-6 Future ComparisonSabito KunnNo ratings yet

- Centro-Matic: Model 85535 Controller Series "C"©Document6 pagesCentro-Matic: Model 85535 Controller Series "C"©SIDI ahmedou yahyaNo ratings yet

- BARD S8201 169 InstructionsDocument2 pagesBARD S8201 169 InstructionsFotografias WONo ratings yet

- FHP Upm IDocument10 pagesFHP Upm IAbdulSattarNo ratings yet

- 2.2 System Descript: On (Electrical)Document1 page2.2 System Descript: On (Electrical)Дмитрий МещерскихNo ratings yet

- Pump Control Model FPC 30010Document4 pagesPump Control Model FPC 30010vstojnicNo ratings yet

- Diesel Engine BasicsDocument50 pagesDiesel Engine BasicsHtauk Lann NaingNo ratings yet

- Obajana Limestone MineDocument34 pagesObajana Limestone MineveereshNo ratings yet

- Komatsu 980E-4 SuspensionsDocument28 pagesKomatsu 980E-4 Suspensionsveeresh100% (1)

- Understanding Oil Analysis Tests PDFDocument4 pagesUnderstanding Oil Analysis Tests PDFAnonymous XtvvG80zuNo ratings yet

- Off-Highway Truck: Engine Model Operating SpecificationsDocument28 pagesOff-Highway Truck: Engine Model Operating SpecificationsSandip MaitiNo ratings yet

- Heavy Equipment Repair Technician Jobs ZambiaDocument1 pageHeavy Equipment Repair Technician Jobs ZambiaveereshNo ratings yet

- Health StatusDocument2 pagesHealth StatusveereshNo ratings yet

- Circular For Prep-1, Prep-2 - Reading Competion.2020.Document10 pagesCircular For Prep-1, Prep-2 - Reading Competion.2020.veereshNo ratings yet

- Statutory Amendments at a GlanceDocument17 pagesStatutory Amendments at a GlanceveereshNo ratings yet

- Salaries Allowances of Ministers Act 1952Document4 pagesSalaries Allowances of Ministers Act 1952Latest Laws TeamNo ratings yet

- BHASKAR Wedding InvitationDocument4 pagesBHASKAR Wedding InvitationveereshNo ratings yet

- 5 Tonne Diesel Forklift TruckDocument2 pages5 Tonne Diesel Forklift TruckveereshNo ratings yet

- Channel List 20210427Document13 pagesChannel List 20210427drpnnreddyNo ratings yet

- MCDR Amendments 2021Document52 pagesMCDR Amendments 2021veeresh100% (1)

- STC system uses rail pressure to control engine timingDocument3 pagesSTC system uses rail pressure to control engine timingmanoj262400/295% (20)

- Multistage Pump - Kirloskar PDFDocument63 pagesMultistage Pump - Kirloskar PDFpsuvarnasNo ratings yet

- Caterpillar C9-C12 Engine Electronic SpecificationsDocument215 pagesCaterpillar C9-C12 Engine Electronic Specificationsveeresh67% (3)

- 4087461Document2 pages4087461p41005679No ratings yet

- Rear Axle Brake Parts ListDocument1 pageRear Axle Brake Parts ListveereshNo ratings yet

- Krutika Homework 09 Sep 2020Document2 pagesKrutika Homework 09 Sep 2020veereshNo ratings yet

- Schwing Stetter Parts Price ListDocument1 pageSchwing Stetter Parts Price ListveereshNo ratings yet

- 330C Hyd Sys OpDocument164 pages330C Hyd Sys Opvasanth kumarNo ratings yet

- Overview of Opencast MiningDocument78 pagesOverview of Opencast MiningveereshNo ratings yet

- Tax Invoice: Savita Indane Gas Services (0000118201)Document1 pageTax Invoice: Savita Indane Gas Services (0000118201)veeresh100% (1)

- Osb 613 e IiDocument180 pagesOsb 613 e Iidanish khanNo ratings yet

- Sodium Hypochlorite As A DisinfectantDocument1 pageSodium Hypochlorite As A DisinfectantDanish Ahmed Alvi100% (1)

- Osb 613 e IiDocument180 pagesOsb 613 e Iidanish khanNo ratings yet

- Datsun GOplus CVT Brochure - A4 - BS VI - Revised - WebDocument2 pagesDatsun GOplus CVT Brochure - A4 - BS VI - Revised - WebRajesh ChoudharyNo ratings yet

- Datsun GOplus CVT Brochure - A4 - BS VI - Revised - WebDocument2 pagesDatsun GOplus CVT Brochure - A4 - BS VI - Revised - WebRajesh ChoudharyNo ratings yet

- Beml BH50 Electrical ManualDocument33 pagesBeml BH50 Electrical ManualveereshNo ratings yet

- VF1 Technicalspecifications 031997 EN PDFDocument43 pagesVF1 Technicalspecifications 031997 EN PDFelectricistNo ratings yet

- Media Planning BasicDocument142 pagesMedia Planning BasicHanif Lakdawala100% (1)

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Code of Conduct at Pizza HutDocument2 pagesCode of Conduct at Pizza HutAdeel Chaudhary0% (1)

- MARSIC300 trainingDocument31 pagesMARSIC300 trainingDenys Podlevskykh100% (1)

- Electronics QuestionnaireDocument4 pagesElectronics QuestionnaireRenie FedericoNo ratings yet

- John Deere 125 HP PDFDocument2 pagesJohn Deere 125 HP PDFJulio TovarNo ratings yet

- 3.B Coating Maintenance CHEMCODocument51 pages3.B Coating Maintenance CHEMCOMeleti Meleti MeletiouNo ratings yet

- AKA DP Close Bus Ring SolutionsDocument2 pagesAKA DP Close Bus Ring Solutionssun qiNo ratings yet

- Physics Roller Coaster ProjectDocument13 pagesPhysics Roller Coaster Projectapi-348624957No ratings yet

- Accenture Inside Corporate MandADocument28 pagesAccenture Inside Corporate MandAshshanksNo ratings yet

- Parts List CMX1402Document36 pagesParts List CMX1402Jayden BarnesNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- 7 Strategies For Developing Your Own Curriculum As A New TeacherDocument5 pages7 Strategies For Developing Your Own Curriculum As A New TeacherKhusnul KhotimahNo ratings yet

- LTE UMTS GSM Network OptimizationDocument44 pagesLTE UMTS GSM Network OptimizationAvi Shetty100% (1)

- Marketing Research of Pre-Start-UpDocument2 pagesMarketing Research of Pre-Start-UpafsalpkgroupNo ratings yet

- RecruitmentDocument73 pagesRecruitmentArif Ryhan100% (1)

- Tapered Roller Bearings, RBC Tapered Thrust Bearings: Producing High-Quality Products Since 1929Document16 pagesTapered Roller Bearings, RBC Tapered Thrust Bearings: Producing High-Quality Products Since 1929eblees100No ratings yet

- Installation - Operation - Maintenance - Instructions - 30 HXC PDFDocument36 pagesInstallation - Operation - Maintenance - Instructions - 30 HXC PDFNurmansyah Dwi Cahyono100% (3)

- 220 KV GSS, HeerapuraDocument56 pages220 KV GSS, Heerapurapikeshjain33% (3)

- United States Patent (19) : HoferDocument7 pagesUnited States Patent (19) : Hoferjoel marshallNo ratings yet

- First Stereo LPDocument6 pagesFirst Stereo LPadorno5No ratings yet

- Tube Upsetting Machines BrochureDocument10 pagesTube Upsetting Machines BrochuredemirilkNo ratings yet

- F. M. 1Document3 pagesF. M. 1Aashish PardeshiNo ratings yet

- Understanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryDocument21 pagesUnderstanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryRidzuan DolahNo ratings yet

- Dwg. No. 63170016 - ER-15Document1 pageDwg. No. 63170016 - ER-15GiantcanaNo ratings yet

- Nokia 7368 ISAM ONT G-010G-A For Optical LAN Data Sheet enDocument3 pagesNokia 7368 ISAM ONT G-010G-A For Optical LAN Data Sheet enMirado AndriamihasinoroNo ratings yet

- Sevice Manual BOBCAT S630 PDFDocument890 pagesSevice Manual BOBCAT S630 PDFArtemio Garcia Barrientos100% (11)

- Julian Assange Why The World Needs Wikileaks: General InstructionsDocument1 pageJulian Assange Why The World Needs Wikileaks: General InstructionsChris CiervoNo ratings yet

- Slabs Are Plate Elements Forming Floors andDocument5 pagesSlabs Are Plate Elements Forming Floors andyasas89No ratings yet