Professional Documents

Culture Documents

Steam Turbine Protection

Uploaded by

Rajesh PCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Turbine Protection

Uploaded by

Rajesh PCopyright:

Available Formats

SAFE LOGIC, TRIP PERMISSIVES AND STEAM TURBINE

PROTECTIONS

Aayush Deshmukh1, Dr. Vijay Gaikwad2

1,2

Vishwakarma Institute of Technology, Pune

Abstract The Turbine Protection System (TPS) provides

In a complex system of machinery there are an additional independent protection function

numerous components which work together for the steam turbine and generator. The TPS

in a definite fashion to achieve ultimately detects undesirable operating conditions and

process control .However some time due to initiates trips to avoid damaging the steam

error or malfunctioning of instrument the turbine [4]. Besides establishing control it is very

parameters which are essential for the important to ensure that all instruments are

process to continue gets deviated from the failure free. Permissives , sequence , trip are

normal range. At such times a proper logic logic instructions needed to ensure overall safe

flow becomes very essential from safety point operating procedure [6]. While designing a

of view. An uncontrolled deviation may cause particular sequence of actions all the factors

significant economical, environmental and should be considered such as normal operating

human life loss. The article discuss about environment and various possible failures that

some of the many aspects of logical may occur [1]. The system should be able to

permissives and safety inclusions which helps handle all abnormalities and undergo proper

to provide annunciation to the operator and shutdown if needed.

may even abort the process after certain The function of the steam turbine protection

programmed time interval if not acted upon. system is often confused with the control system,

Index Terms:Interlock, Permissives, PLC but the two systems are entirely separate [9]. The

,Tripping ,Turbine protection protection system operates only when any of the

control system set point parameters are

I. INTRODUCTION exceeded, and the steam turbine will be damaged

Power plants rely on a sophisticated network of if it continues to operate [8]. A multi-valve,

instruments each having specific functions, multi-stage turbine protection system

every instrument has their own control incorporates a mechanical overspeed device (trip

mechanism [7]. In a power plant having steam pin) to shut down the turbine on overspeed (10

turbine numerous factors such as boiler, fuel percent above maximum continuous speed)[2].

handling, temperature and pressure sensors ,

control valves play important role in electricity II. TRIP, PERMISSIVES AND SEQUENCE

generation process. To allow proper functioning Tripping is an action that is initiated by the

of the system it is necessary that they should be control system and which forces a single or

regulated and their parameters should be looked multiple devices into a safe or pre determined

into real time [3]. Generally these elements are state .The safety instrument system generally

governed by a Programmable Logic Controller initiate trips , however Programmable logic

(PLC) which should be appropriately controller (PLC) may also initiate trip provided

programmed to maintain synchronization they are feed with the necessary logic and

amongst the instruments. receive sets of inputs from the instrument they

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-1, 2018

55

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

are suppose to govern .Once a device or devices 1. Stop the feed pump

have been forced to a predetermined state by the 2. Close the filling valve

action of Trip they will remain in that state till 3. Stop agitator

the Trip is manually acknowledged or the 4. Wait for 60 seconds or as specified

problem has been rectified by human 5. Open discharge valve

interference .

B. Cyclic sequence

An interlock is a self resetting trip. Interlocks 1. Low level in a vessel opens the filling valve

are not deemed safety related and can be used for 2. The valve remains open until high level is

on/off control. Interlocks are normally initiated detected

by the PLC, but if an interlock is deemed to be 3. On high level the valve closes

safety related it may be implemented in the SIS 4. The valve remains closed until low level is

or a hardwire system .An interlock forces a detected

device to a pre determined state .Once a device 5. On low level the valve opens and the sequence

has been brought to a pre determined state by the is repeated

action of an interlock they remain in that state

until the cause of the fault returns to healthy

state, the interlock will then automatically be

removed .It is possible to override the interlock.

A permissive is a particular type of interlock that

is used to prevent actions taking place until pre

determined criteria is satisfied. Ex : Preventing

pump from starting until the valve is open

.Permissives are normally initiated by the

Programmable Logic Controller , however if a Fig 1. Feed Water Pump protection logic

permissive is deemed to be safety related it can

be implemented in SIS or hardwire system .After

the permissive has been satisfied and the

corresponding action is taken , it becomes

inactive .For example once the suction valve has

been opened and the pump started the permissive

takes no further action , even if the suction valve

is the suction valve is closed while the pump is

running .It is possible to override permissives for

operational or maintenance reasons.

A sequence is a pre arranged action or a set of

multiple actions which are carried out by the

control system. They can be initiated by event or

Fig 2. FGD bypass system logic

by the operator .Alternatively PLCs can also be

programmed to carry out the set of instructions

required .This helps to reduce human III. TURBINE PROTECTIONS

intervention significantly .Sequences can be

Turbine protections are essential part of the

single pass or cyclic. Following are examples of

turbine system. Turbine is a heavy mass running

sequences for maintaining vessel level.

continuously at around 3000 rpm. It handles high

A. Single pass pressure & temperature. There is very less

A vessel reaches pre determined level. The clearances between rotating and stationary parts.

following sequence is carried out : It is very important to protect turbine during

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-1, 2018

56

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

emergencies in the grid. Over speeding of

turbine needs to be avoided in any case.

The turbine Protection System can be actuated

by any of the following trip system:-

1. Hydraulic Trip System

2. Electrical Trip System

Both the trip system when initiated act on the

hydraulic control system and cause trip oil to

drain which in turn closes the emergency stop

valves & control valves. Fig 5. Lubrication Oil system protection

Fig 3. Turbine Layout Fig 6. Condenser system

Over speed Electrical Trip: Turbine trip signal

will be initiated by DDC if Turbine speed

crosses 3200 rpm .This parameter can be called

Over speed turbine 1 or OST1 . OST2 can act as

a backup protection for OST1.

Fig 4. Annunciation taken from RTD

Fig 7. Logic for speed parameters

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-1, 2018

57

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

Turbine trip protection is provided on 320

Micron shaft vibrations by ANDing both X and

Y direction shaft vibration with a delay of 5 sec.

Fig 8. Logic for Vibration parameters

Fig 10. Tank level indications

Fig 9. Logic for Bearing Temperature

parameters

Following is a sample oil tank holding

lubrication oils. Supposing the height of the tank

to be 1500 mm. The level transmitter extends

throughout 1500 mm length. Three indications

namely Adequate, Low and Very Low are taken

from the vessel. Very Low indication is critical

Fig 11. Generator Tripping and Alarms

parameter and may cause the turbine to trip. To

increase the reliability of the logic and to avoid

Generator consists of Resistance Temperature

false alarm a 2 by 3 logic is provided, 2 by 3

Detectors (RTDs) embedded in the core

logic is most common logic protection for all

structure of stator and rotor itself. The 4-20 mA

critical readings. Satisfying 2 out of 3 logic

general output from these RTDs are taken and

initiates necessary annunciation and tripping. It

passed through 2 out 3 logic which in this case

is rightly called as ‘Trip Logic’.

will give an alarm when output current

corresponding to 45 ⁰C is obtained and will trip

the generator at 52 ⁰C in this case. 2 out of 3

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-1, 2018

58

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

logic requires output from 3 separate channels of 4. “Operation and Protection of Large Steam

RTD. Turbine Generators Under Abnormal

Conditions” , H. T. Akers; J. Dickinson;

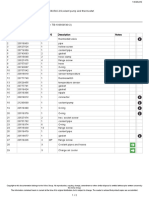

Table 1. Sample parameter deviations and their John W. Skooglund ,IEEE Transactions on

response Power Apparatus and Systems, Year:

Sr Descriptio Values 1968, Volume: PAS-87, Issue: 4

No n Normal Alarm Trip 5. “IEEE Guide for AC Generator Protection” ,

Fire IEEE Std C37.102-2006 (Revison of IEEE

1 - - Trip Std C37.102-1995) , Year: 2006

Protection

Emergency 6. “Integration of steam turbine controls into

2 Trip Push - - Trip power plant systems” , J. Klure-Jensen; R.

Button Hanisch ,IEEE Transactions on Energy

Shaft Conversion ,Year: 1991, Volume: 6, Issue:

3 Vibration <45 120 >320 1

(Microns) 7. “Sequential tripping of steam turbine

MOT oil generators”, E. Fennell; K. Kozminski; M.

level (from Bajpai; S. Easterday-McPadden; W.

4 800 850 900 Elmore; C. Fromen; J. Gardell; W.

top) 2/3

logic Hartmann; J. Hurley; P. Kerrigan; K.

Over speed Khunkhun; C. Mozina; G. Nail; S. Patel;

5 - - 110% G. Pence; A. Pierce; D. Smaha; S. Usman;

Trip

Axial Shift P. Waudby; M. Yalla ,IEEE Transactions

−0.3 ±0.5 on Power Delivery ,Year: 1999, Volume:

6 very high ±1 mm

mm mm 14, Issue: 1

+/-

8. “Sequential tripping of steam turbine

generators”, E. Fennell; K. Kozminski; M.

Bajpai; S. Easterday-McPadden; W.

IV. CONCLUSION Elmore; C. Fromen; J. Gardell; W.

Hartmann; J. Hurley; P. Kerrigan; K.

By passing the required input parameters

Khunkhun; C. Mozina; G. Nail; S. Patel;

through proper sequence of AND, OR gates

G. Pence; A. Pierce; D. Smaha; S. Usman;

annunciation can be acquired when necessary.

P. Waudby; M. Yalla ,1998 IEEE

Additionally by providing a time delay we can

Industrial and Commercial Power Systems

allow human interaction before the system

Technical Conference

tripping takes place.

9. “Five Years' Experience on the

V. REFERENCES Consolidated Edison System with

Protection of Turbine Generators and

1. “Sequential tripping of steam turbine Boilers by Automatic Tripping” ,W. C.

generators” , Industrial and Commercial Beattie; H. A. Bauman; J. M. Driscoll; P.

Power Systems Technical Conference, T. Onderdonk; R. L. Webb ,Transactions

1998 ,IEEE 3-8 May 1998 of the American Institute of Electrical

2. “Generator motoring protection - Are you Engineers. Part III: Power Apparatus and

protected?”Dale Finney; Michael Systems ,Year: 1958, Volume: 77, Issue: 3

Thompson; Normann Fischer; Amandeep

Kalra,70th Annual Conference for

Protective Relay Engineers (CPRE) , 2017

3. “Protection of Large Steam

Turbine-Generator Units on TVA System”

, M. S. Merritt; J. A. Akerman; R. C. Price;

L. E. Owen , IEEE Transactions on Power

Apparatus and Systems , Year: 1965,

Volume: 84, Issue: 4

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-5, ISSUE-1, 2018

59

You might also like

- AL4 TransmissionDocument59 pagesAL4 Transmissionericsolver97% (62)

- Essential Guide to HVAC SystemsDocument45 pagesEssential Guide to HVAC SystemsMistyNo ratings yet

- Basics of Thermal Power PlantDocument119 pagesBasics of Thermal Power Plantsiva7448163No ratings yet

- Workshop ManualDocument787 pagesWorkshop ManualGoran Apostolov92% (38)

- Steam Turbine Aux. Steam SystemDocument29 pagesSteam Turbine Aux. Steam SystemPrasanna Chikkamallaiah100% (1)

- Governingsystem 131127063004 Phpapp01 PDFDocument38 pagesGoverningsystem 131127063004 Phpapp01 PDFhari setiawan100% (1)

- Denison (P6, P7, P8, P11, P14, P24, P30) Axial Piston PumpsDocument11 pagesDenison (P6, P7, P8, P11, P14, P24, P30) Axial Piston PumpsANDRESNo ratings yet

- KWU Steam Turbine Module DesignDocument14 pagesKWU Steam Turbine Module Designbhaskar100% (1)

- Unit Emergencies: Condensate Desk Emergencies Can BeDocument9 pagesUnit Emergencies: Condensate Desk Emergencies Can Bealoknitp04No ratings yet

- Steam Purity Turbine OperationDocument37 pagesSteam Purity Turbine Operationak_thimiri100% (1)

- TG Speed and Load Controls OverviewDocument32 pagesTG Speed and Load Controls Overview06nikhil100% (1)

- Turbines - New Module Hay PDFDocument191 pagesTurbines - New Module Hay PDFThái Mai Đình100% (1)

- Vibrations in Steam TurbinesDocument11 pagesVibrations in Steam TurbinesAnudeep Chittluri100% (1)

- Steam Turbine Over Speed Trip SystemsDocument11 pagesSteam Turbine Over Speed Trip SystemsPRASAD326100% (17)

- 6.1 Overspeed Trip Pre-Test Checks: 104 Operator's Guide To General Purpose Steam TurbinesDocument3 pages6.1 Overspeed Trip Pre-Test Checks: 104 Operator's Guide To General Purpose Steam Turbinessppram100% (1)

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiNo ratings yet

- Turbine ManualDocument399 pagesTurbine ManualSandeep Kumar100% (2)

- GE Steam Turbine Extraction Check Valves DesignDocument8 pagesGE Steam Turbine Extraction Check Valves DesignGaneshmohite123No ratings yet

- MHPS Jac GTDocument7 pagesMHPS Jac GTkp pkNo ratings yet

- Bhel TrainingDocument41 pagesBhel TrainingArun AroraNo ratings yet

- Turbine CW Pipe Status Updated2Document21 pagesTurbine CW Pipe Status Updated2vivekpathak101No ratings yet

- Over Current Protection Relay Using Pic Micro ControllerDocument25 pagesOver Current Protection Relay Using Pic Micro Controllersaranaccel1100% (1)

- Operating Manual 670 MW Coal Fired Power Plant Training SimulatorDocument134 pagesOperating Manual 670 MW Coal Fired Power Plant Training SimulatorsprotkarNo ratings yet

- Turbine QuestionsDocument64 pagesTurbine QuestionsLyn Serwaah Gorni100% (1)

- APHDocument1 pageAPHsai987650No ratings yet

- Steam Turbine Generator Fundamental PDFDocument202 pagesSteam Turbine Generator Fundamental PDFAlex Seguida100% (1)

- Governing System of TurbineDocument8 pagesGoverning System of Turbinebimal213100% (1)

- LNGC - Inigo Tapias - Machinery Systems Manual PDFDocument383 pagesLNGC - Inigo Tapias - Machinery Systems Manual PDFpNo ratings yet

- Steam Turbines: LMZ's Creation Experience and Development ProspectsDocument27 pagesSteam Turbines: LMZ's Creation Experience and Development Prospectsduhaim100% (3)

- Lesson Main Stop Valve & Servomotor, Governing Valves and ServomotorDocument41 pagesLesson Main Stop Valve & Servomotor, Governing Valves and Servomotormister pogiNo ratings yet

- Boiler exam practice questions and answersDocument2 pagesBoiler exam practice questions and answersJoydev GangulyNo ratings yet

- Thermodynamic Analysis of Triple Pressure Heat Recovery Steam GeneratorDocument7 pagesThermodynamic Analysis of Triple Pressure Heat Recovery Steam GeneratorIJIRSTNo ratings yet

- Auto Reclosing ConceptsDocument7 pagesAuto Reclosing ConceptssrinivasaphanikiranNo ratings yet

- C&I in CFBC-1Document25 pagesC&I in CFBC-1Prudhvi RajNo ratings yet

- HRSG DescriptionDocument25 pagesHRSG DescriptionFahim Kazmi100% (1)

- Steam TurbineDocument10 pagesSteam TurbineBilal Qasim0% (1)

- Super Critical Boiler Technology SKDDocument35 pagesSuper Critical Boiler Technology SKDSwapnil TingusleNo ratings yet

- XA(T,V)S 650-750-850 JD7 Compressors Oil Injected Systems OverviewDocument61 pagesXA(T,V)S 650-750-850 JD7 Compressors Oil Injected Systems Overviewamerica1591100% (1)

- Turning Gear An Operation Point of ViewDocument22 pagesTurning Gear An Operation Point of ViewAshwin Narayan100% (1)

- Back Pressure TurbinesDocument4 pagesBack Pressure TurbinesSharath Kota100% (1)

- Comparison Between Single&multi Shaft Turbine PDFDocument12 pagesComparison Between Single&multi Shaft Turbine PDFcobrasrkNo ratings yet

- Alstom New Designs PDFDocument18 pagesAlstom New Designs PDF55312714100% (1)

- Fundamentals of Moisture Measurement in Industrial ApplicationsDocument62 pagesFundamentals of Moisture Measurement in Industrial Applicationsraghukk1988No ratings yet

- Turbine Turning Gear ModuleDocument13 pagesTurbine Turning Gear ModulePrasanna Chikkamallaiah100% (1)

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDocument26 pagesLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNo ratings yet

- Steam Turbine Q&ADocument46 pagesSteam Turbine Q&Ahoangduythanhqb100% (1)

- Chapter I General Information of Pump UnitDocument42 pagesChapter I General Information of Pump UnitRahmat Budi HartantoNo ratings yet

- What Is The Work of Accumulator in Turbines - QuoraDocument4 pagesWhat Is The Work of Accumulator in Turbines - QuoraEr Suraj KumarNo ratings yet

- Turbine Lube Oil System ExplainedDocument15 pagesTurbine Lube Oil System ExplainedNitish Kumar100% (1)

- Steam Turbine Theory ExplainedDocument17 pagesSteam Turbine Theory ExplainedbhaskarNo ratings yet

- Syed Ammal Engineering College Power Plant Engineering Question BankDocument16 pagesSyed Ammal Engineering College Power Plant Engineering Question BankNizam MANo ratings yet

- Boiler Types and ClassificationsDocument26 pagesBoiler Types and ClassificationshardikNo ratings yet

- Poor Oil Gun Performance in BoilersDocument3 pagesPoor Oil Gun Performance in BoilersRAPRATSINNo ratings yet

- Lesson Guide For Periodic InspectionDocument3 pagesLesson Guide For Periodic Inspectionmister pogiNo ratings yet

- Soot BlowerDocument6 pagesSoot BlowerSamNo ratings yet

- Thermal Power StatonDocument15 pagesThermal Power StatonShiv ashish sharmaNo ratings yet

- Steam Turbine Q & ADocument37 pagesSteam Turbine Q & Amy shift D0% (1)

- Diesel Engines 13Document26 pagesDiesel Engines 13Thiet PhamNo ratings yet

- 03 - Steam Turbines Types PDFDocument49 pages03 - Steam Turbines Types PDFVimleshKumarSharma100% (1)

- Cold-Start Up of Coal Fired PowerplantsDocument6 pagesCold-Start Up of Coal Fired PowerplantsAbdulyunus AmirNo ratings yet

- Turbine overspeed trip protection design standardsDocument12 pagesTurbine overspeed trip protection design standardsKubra ĖdrisNo ratings yet

- Top 50 Boiler Information Booster Question Answers - ASKPOWERPLANTDocument19 pagesTop 50 Boiler Information Booster Question Answers - ASKPOWERPLANTRaju MaityNo ratings yet

- Thermodynamic Analysis of A Steam TurbineDocument3 pagesThermodynamic Analysis of A Steam TurbinePhil Engel100% (1)

- Lesson Turbine Mainte0Ance ProgramDocument2 pagesLesson Turbine Mainte0Ance Programmister pogiNo ratings yet

- Difficulties FacedDocument6 pagesDifficulties FacedAnonymous pKsr5vNo ratings yet

- 7.1 Tripping Modes PDFDocument6 pages7.1 Tripping Modes PDFsulemankhalid100% (1)

- Case Study: Vibration Trip and Post-Event Analysis With Auto-Associative Neural Networks On A Large Steam TurbineDocument10 pagesCase Study: Vibration Trip and Post-Event Analysis With Auto-Associative Neural Networks On A Large Steam Turbinehegde10No ratings yet

- Chapman ErrataDocument3 pagesChapman Erratamat_pranNo ratings yet

- K48 Eng 1009Document2 pagesK48 Eng 1009Yazeed Saad AlrasheedNo ratings yet

- FEVISA Cast Ball ValvesDocument106 pagesFEVISA Cast Ball ValvesVictor Hugo BarzolaNo ratings yet

- Direct Torque Control of Double Star Synchronous MachineDocument5 pagesDirect Torque Control of Double Star Synchronous MachineMohamed NabilNo ratings yet

- Revista Renovetec 1Document66 pagesRevista Renovetec 1Arturo de la VegaNo ratings yet

- Komatsu D65PX-0C K0210-0201 PageDocument2 pagesKomatsu D65PX-0C K0210-0201 PageGégé di TPNo ratings yet

- 9780L12 Hydraulic and Pneumatic Systems Maintenance and TroubleshootingDocument29 pages9780L12 Hydraulic and Pneumatic Systems Maintenance and Troubleshootingمعلومة على الماشىNo ratings yet

- Valvula TermostáticaDocument2 pagesValvula TermostáticaSuyla CabralNo ratings yet

- 6cyl English PDFDocument16 pages6cyl English PDFking852No ratings yet

- Broaching PDFDocument7 pagesBroaching PDFBalaji Karunakaran100% (1)

- Washing Mashine DWD-M-1051-smDocument29 pagesWashing Mashine DWD-M-1051-smMihai Lungu100% (1)

- LMI Pump ManualDocument44 pagesLMI Pump ManualRajiv SooklalNo ratings yet

- Mooney Operators Manual Model M20CDocument96 pagesMooney Operators Manual Model M20CAngela MachillandaNo ratings yet

- C2500CBE Hydrostatic Drive-OM-EN-09Document26 pagesC2500CBE Hydrostatic Drive-OM-EN-09ВиталийNo ratings yet

- Appendix VI Diagram For Class I, Div. 1 Lighting InstallationDocument3 pagesAppendix VI Diagram For Class I, Div. 1 Lighting InstallationcassianohcNo ratings yet

- SERIES 4000: Oil & GasDocument3 pagesSERIES 4000: Oil & GasSarita IndustriesNo ratings yet

- Operator Manual: Qsx15 Engine With Powercommand® Control 2100Document16 pagesOperator Manual: Qsx15 Engine With Powercommand® Control 2100Zubair RajpootNo ratings yet

- IndexingDocument4 pagesIndexingzahidNo ratings yet

- Stealth International Inc: Model STJDocument8 pagesStealth International Inc: Model STJVeer GangjiNo ratings yet

- Transmission of Motion and PowerDocument62 pagesTransmission of Motion and PowerVishith ReddyNo ratings yet

- List of Experiments: Mandava Institute of Engineering and TechnologyDocument2 pagesList of Experiments: Mandava Institute of Engineering and TechnologyrkNo ratings yet

- 2007 Ranger 500 Service Manual 9920851 - Chapter - 08Document20 pages2007 Ranger 500 Service Manual 9920851 - Chapter - 08Anonymous ZS72lgKENo ratings yet

- P-014 Filter MinderDocument3 pagesP-014 Filter MinderCarlos MontalvoNo ratings yet