Professional Documents

Culture Documents

1 PTW Procedure PDF

Uploaded by

Khalid AwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 PTW Procedure PDF

Uploaded by

Khalid AwanCopyright:

Available Formats

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision:6

Part : 1 Date:Dec 2014

Section : Table of contents Page:2 of 105

PROCEDURE MANUAL 10/3A, PART 1 TITLE: PERMIT TO WORK

THE BUSINESS OWNER OF THIS CORPORATE PROCEDURE IS:

HEALTH, SAFETY, ENVIRONMENT & RISK MANAGEMENT FUNCTION

THE CUSTODIAN OF THIS CORPORATE PROCEDURE IS:

CORPORATE GOVERNANCE DIVISION

CORPORATE SUPPORT FUNCTION

IMPORTANT

BEFORE USING THIS MANUAL, CHECK THAT ALL THE PAGES ARE CURRENT BY

REFERRING TO THE RECORD OF CHANGES

Endorsed by : Khalid Al Bisher __________ ___________

VP(CHSE) Signature Date

Abdulla Al Marzooqi ___________ ___________

SVP (HSE&RM) Signature Date

Revision History

The table below is a brief summary of the most recent revisions to this document.

Details of all revisions are held on file by the issuing department.

Revision Date Author Scope / Remarks

No

3 05/02 PTWRC – SE (S&M) Review by PTW Review committee

4 03/07 PTWRC Review by PTW Review Committee, above

HSE Advisor (S&M) standing instruction had been incorporated in

Revision 4

5 04/12 PTWC, Review by PTW Committee to incorporate ePTW

application

SSE (S&M) and

HSE Team Leader

(BAB)

6 12/14 SE (S&M) and Reviewed to capture lessons learned from the

HSEM (NEB) ePTW pilot and issued standing orders.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision:6

Part : 1 Date:Dec 2014

Section : Table of contents Page:3 of 105

TABLE OF CONTENTS

1. INTRODUCTION .................................................................................................................................... 6

2. PURPOSE & SCOPE ............................................................................................................................. 7

3. SAFETY STANDARDS .......................................................................................................................... 8

4. DEFINITIONS & OTHER EXPLANATORY NOTES.............................................................................. 9

5. ROLES & RESPONSIBILITIES ........................................................................................................... 24

6. PERMITS/CERTIFICATES & THEIR APPLICATIONS ....................................................................... 35

7. HOT WORK PERMIT (HWP) ............................................................................................................... 41

7.1 PRECAUTIONS PRIOR TO ISSUING A HOT WORK PERMIT ...................................................... 41

7.2 SAFE HOT WORK PRACTICES ............................................................................................ 44

8 COLD WORK PERMIT (CWP) .................................................................................................................. 46

8.1 PRECAUTIONS PRIOR TO ISSUING COLD WORK PERMIT ....................................................... 46

8.2 SAFE COLD WORK PRACTICES .......................................................................................... 46

9 ISOLATION CERTIFICATES (IC’S) .......................................................................................................... 47

9.1 GENERAL ....................................................................................................................... 47

9.2 PRECAUTIONS PRIOR TO ISSUING THE ISOLATION CERTIFICATE .......................................... 47

9.3 PRECAUTIONS PRIOR TO PERFORMING “DE-ISOLATION FOR TEST” ....................................... 50

10.0 LOCKOUT AND TAGOUT PROCEDURE ........................................................................................... 51

10.1 INTRODUCTION ............................................................................................................ 51

10.2 PURPOSE AND SCOPE .................................................................................................... 51

10.3 GENERAL ..................................................................................................................... 51

10.4 LOCKOUT ..................................................................................................................... 52

10.5 TAGS ........................................................................................................................... 53

10.6 ENERGY ISOLATION – NON ELECTRICAL EQUIPMENT ......................................................... 54

10.7 ENERGY ISOLATION – ELECTRICALLY DRIVEN EQUIPMENT.................................................. 54

10.8 DISCONNECT SWITCHES / CIRCUIT BREAKER ................................................................... 55

10.9 EXCEPTIONS ................................................................................................................ 56

10.10 DE-ISOLATION ............................................................................................................ 56

11. CONTROL PROTECTION INHIBITION CERTIFICATE –CPIC............................................................. 57

11.1 ISSUING A CONTROL PROTECTION INHIBITION CERTIFICATE ............................................. 57

12. HIGH VOLTAGE ELECTRICAL CERTIFICATE (HVEC) ...................................................................... 58

12.1 PREFACE ...................................................................................................................... 58

12.2 AUTHORITY FOR ISSUE .................................................................................................. 58

12.3 WORK ON HIGH VOLTAGE ELECTRICAL APPARATUS ........................................................... 59

12.4 LIVE LINE WORK ........................................................................................................... 59

13.CONFINED SPACE ENTRY CERTIFICATE (CSEC) ................................................................... 63

13.1 PRECAUTIONS PRIOR TO ISSUING CONFINED SPACE ENTRY CERTIFICATE ............................ 63

13.2 SAFE WORK PRACTICES IN CONFINED SPACES .................................................................. 66

13.3 SAFETY RULES TO CONDUCT GT IN CONFINED SPACE ........................................................ 68

13.4 STANDBY PERSON AND RESCUE ...................................................................................... 68

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision:6

Part : 1 Date:Dec 2014

Section : Table of contents Page:4 of 105

14. EXCAVATION CERTIFICATE (EXC) ..................................................................................................... 70

14.1 SAFE WORK PRACTICES IN EXCAVATIONS ........................................................................ 70

14.2 PROTECTING EXISTING ADCO SERVICES ......................................................................... 72

14.2.1 EXCAVATION IN THE VICINITY OF BURIED ELECTRICAL CABLES ....................................... 72

14.2.2 CROSSING OR WORKING NEAR OVERHEAD POWER LINES ................................................ 72

15. RADIOGRAPHY / NORM HANDLING CERTIFICATE - RNC ............................................................... 74

15.1 PRECAUTIONS PRIOR TO ISSUING RADIOGRAPHY & NORM CERTIFICATE .............................. 75

15.2 SAFE WORK PRACTICES IN RADIOGRAPHY AND NORM ....................................................... 75

16. PTW / CERTIFICATE ADMINISTRATION AND DOCUMENTATION CONTROL ............................... 76

16.1.1 PERMIT ISSUE AND DISTRIBUTION ............................................................................... 77

16.1.2 PERMIT REVALIDATION ............................................................................................... 77

16.1.3 PERMIT SUSPENSION .................................................................................................. 77

16.1.4 PERMIT CANCELLATION/ CLOSE-OUT AND FILING ........................................................... 79

16.2 CLASSIFICATIONS......................................................................................................... 80

16.2.1 JOBS WHICH REQUIRE PTW/CERTIFICATES.................................................................... 80

16.2.2 JOBS WHICH REQUIRE HIGHER MANAGEMENT APPROVAL ................................................ 80

16.2.3 JOBS WHICH DO NOT REQUIRE PTW/ CERTIFICATES ....................................................... 81

16.2.3.1 FORMAL PROCEDURES ............................................................................................. 82

16.2.4 ENGINEERING & PROJECTS AREA.................................................................................. 83

16.2.5 WELL OPERATIONS HAND-OVER ................................................................................... 85

16.2.5.1 WELL HAND-OVER FOR DRILLING OPERATIONS ........................................................... 85

16.2.5.2 WELL HAND-OVER FOR RIGLESS/ WIRE-LINE OPERATIONS ........................................... 86

16.2.6 INTERFACE PROCEDURES ............................................................................................ 88

16.2.6.1INTERFACE PROCEDURES FOR WORKING ADJ TO ADCO OR GASCO COMPANY FACILITIES: 88

16.2.6.2 INTERFACE PROCEDURES FOR GASCO WORKING IN AN ADCO ....................................... 89

16.2.6.3 INTERFACE PROCEDURES FOR WORKING IN SHARED PTW INTERFACE AREAS .................. 91

16.2.7 AREA PERMIT/ AREA CERTIFICATE ................................................................................ 92

16.2.8 CONTRACTOR’S CAMPS ............................................................................................... 94

16.3 CLARIFICATIONS .......................................................................................................... 95

16.4 TRAINING AND LICENSING OF PERMIT TO WORK SIGNATORIES .......................................... 98

16.5 PTWS AUDITING AND REVIEW ...................................................................................... 102

16.6.1 AUDIT REGISTER ...................................................................................................... 102

16.6.2 AUDIT FREQUENCY ................................................................................................... 103

16.7 EXAMPLES ON HOW TO DETERMINE TYPE OF PTW & SUPPORTING CERTIFICATE(S) .............. 103

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision:6

Part : 1 Date:Dec 2014

Section : Appendices Page 5 of 105

Appendices

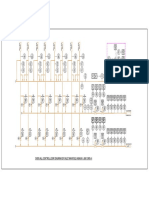

A – Work Categorization Chart

B – PTW Procedures Flow Chart

C – Hot Work Permit (HWP) Refer to e-PTW

D – Cold Work Permit (CWP) Refer to e-PTW

E1 – Electrical/ Control Isolation Certificate (ECIC) Refer to e-PTW

E2 – Process/ Mechanical Isolation Certificate (PMIC) Refer to e-PTW

E3 – De-isolation for Test Certificate (DTC)

F1 – Control Protection Inhibition Certificate (CPIC)

F2 – CPIC Risk assessment Form

G – High Voltage Electrical Certificate (HVEC) Refer to e-PTW

H – Confined Space Entry Certificate (CSEC) Refer to e-PTW

I – Excavation Certificate (EXC) Refer to e-PTW

J – Radiography and NORM Handling Certificate (RNC) Refer to e-PTW

K – Formal Procedure Template/ Form (FPF) Refer to e-PTW

L – Formal Procedure Certificate (FPC) Refer to e-PTW

M – Guidance on criteria for exceeding ceiling number of permits

N – Jobs Not Requiring PTW

O – PTW Audit Checklist

P – “EP Area” Hand-over Certificate

S – High Risk Jobs and Countersignature Requirements

T – Gas testing Procedures and Requirements

U1– PTW Signatory Licensing Form for AA/IA

U2– PTW Signatory Licensing Form for JO/JP

V – Tool Box Talks Record and Checklist Refer to e-PTW

W – Vehicle Entry Certificate

X – List of Hazards and Precautions in Section 2 of PTW Refer to e-PTW

Y – Use of temporary tools and equipment in hazardous area

Z - 22 Non-compliance categories applicable with the ADCO PTW

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit to Work (PTW)

Volume : 10 /3A Revision:6

Part : 1 Date: Dec 2014

Section : Introduction Page: 6 of 105

1. INTRODUCTION

The following procedure is designed to achieve the applications of particular

safety measures in a controlled sequence by the involvement of competent

and responsible persons

The Permit to Work procedure ensures that the responsibility and

accountability for safe working practices is followed in a logical sequence to

those responsible for the work being carried out at any given time and

ensures that specified and effective safeguards are provided.

The ADCO Permit to Work procedure is a “stand alone” document covering

every aspect of the ADCO Permit to Work System as a Safe System of Work.

Permit to Work is Part 1 of HSE Procedure Manual Volume 10/3A which is

accessible via ADCO intranet.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit to Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : SAFETY STANDARDS Page: 7 of 105

2. PURPOSE & SCOPE

The purpose of the Permit to Work System is to ensure that a safe working

environment is achieved by providing management control over the various

activities which may have hazardous interactions. The system provides a

formal and controlled process that identifies and communicates hazards and

risks associated with planned activity, and ensure that appropriate

precautions and measures are implemented so that the job can proceed and

be completed safely. It is important to note that a Permit to Work is not a

permission to carry out a hazardous job, but is an essential part of a

procedure that provides instruction on how to carry out a hazardous job

safely and in a managed and controlled way. The procedure has three key

features:

It allows those responsible for overall site safety to be aware of the

various hazardous activities and to take a systematic overview which

identifies interactions and allows priorities to be set for conflicting work

tasks

It limits the potentially harmful effect of the actions of the person doing

the work by specifying safety precautions and setting limits to the duration

and extent of the work;

It encourages formal and careful attention to Safe Systems of Work by

requiring the signature of specified individuals who must confirm that all

hazards have been identified and effective precautions taken.

Inevitably, the Permit to Work System will not meet every work situation

precisely, and special regulations may have to be issued to deal with

exceptional cases.

If anybody involved in the PTWS is unsure of a course of action, he

must consult a higher authority or management rather than take

risks.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 8 of 105

3. SAFETY STANDARDS

The Permit to Work procedure contains the minimum safety requirements

acceptable to ADCO. These requirements must be met using the PTWS and

the requirements may be increased at the discretion of the Area Authority or

Issuing Authority if necessary.

Deviation from the rules and regulations in the Permit to Work procedure

may be necessary in an emergency, but even during such occasions the

safety of personnel, the environment and property must not be jeopardized.

Once the emergency is contained, the rules and regulations in the PTW

procedure must be re-applied.

The rules and regulations in the PTW procedure represent the latest

recommended safe practices in the Petroleum Industry. Changes and

temporary alternatives to the rules and regulations in the Permit to

Work procedure are allowed ONLY with the written approval of the

Area Manager after consultation with Corporate HSE Vice President.

The risk assessment shall be undertaken to demonstrate that safety

standards have not been compromised.

All persons involved in the Permit to Work process should understand that it

is not the work permit that makes the work safe but the people who have

control over the work and the precautions taken make the job safe. Other

necessary elements, as follows, contribute to safe working practices.

Good communications between all involved personnel;

Detailed pre-job planning;

Systematic identification and communication of hazards and associated

risks;

Effective implementation of required precautions and close supervision of

the work;

A skilled, trained and dedicated workforce;

Regular auditing of the permit system.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 9 of 105

Note: The issue of a PTW does not relieve the Job Performer of the

responsibility for ensuring that the work is done safely. If a hazard

arises, the work must be stopped, the worksite made safe, and the

condition reported immediately to the Area/Issuing Authority. If in

doubt, individuals must STOP work rather than take risks.

4. DEFINITIONS & OTHER EXPLANATORY NOTES

The following terms are standard throughout the Permit to Work procedure to

define a condition or course of action:

The word 'MUST' expresses a mandatory requirement for a

condition or course of action.

The word 'SHOULD' expresses a strongly recommended or preferred

condition or course of action.

The word 'MAY' suggests a possible course of action or condition

where other discretionary options are available.

The following terms are also used within the Permit to Work procedure

Authorized

A person is authorized under the Permit to Work procedure when he/she is

either appointed or has permission in writing from the relevant Area Manager

to carry out PTW tasks within the Area Manager jurisdiction.

The following definitions also apply:

ADCO Employee

An employee, irrespective of his job grade, filling an established position

within the ADCO Manpower Organization.

Area Authority (AA) - an ADCO Engineer/ Supervisor or Assistant

Supervisor who is responsible for the day-to-day activities and safety of a

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 10 of 105

specified area. He is authorized in writing by the Area Manager following

satisfactory completion of the PTW Certification and licensing process 1

The Area Authority can sign as both Issuing Authority and Area Authority in

his area of responsibility in which case he also assumes all the responsibilities

of IA in work site in addition to his responsibilities as Area Authority.

Area Manager (AM) – an ADCO Divisional Manager or Vice President

appointed by ADCO Chief Executive Officer (CEO) with responsibilities for a

specified field / terminal or project.

Authorized Electrical Person (AEP) – a competent ADCO or Contractor

electrical person who has been formally and practically assessed by a

qualified and approved team, as having sufficient technical knowledge and

has been authorized by the Area Manager in writing to carry out a specific

work on electrical systems, apparatus and equipment. Critical activities

conducted by specialized contractors such as hot washing of overhead

transmission lines , contractor’s staff competency certificates / ID’s are

acceptable as equivalent to ADCO certification.

Area HSE Engineer– an ADCO employee of grade 12 and above or PMC HSE

Engineer, who provides specialized safety advice, guidance and control and

who fulfills the role of HSE Practitioner in Operations Division. He is not an

Area Authority or Issuing Authority at any circumstances for permits and

certificates. This condition applies to all field based HSE staff (Safety,

Environment and Fire members).

Area Permit / Area Certificate – a PTW or Certificate assigned for a large

volume of work associated with construction, refurbishment and shutdown

projects, or for multiple jobs of the same nature of identified hazards, under

same conditions, same Area Authority and same Job Performer. The activities

shall be limited to non-high risk activities.

Blank (Blind) Flange – a suitably rated circular plate fitted to seal the open

ends of isolated system, using bolts and gaskets.

Bleed Valve – a valve used to depressurize, drain, purge or monitor

pressure during isolation work.

1

See Appendix U

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 11 of 105

Cold Work Permit (CWP)2 the permit that must be issued for all work to

perform in Restricted and non restricted Areas which does not require a HWP.

Competent - a person is competent if he/she through relevant training

and/or experience, skills, knowledge and appropriate certification can carry

out the task as required by the Permit to Work procedures to the satisfaction

of the relevant Area Manager. A person remains competent if refresher

training is undertaken as required to maintain valid and current certification.

Confined Space – any area confined or otherwise which has potential to

permit the accumulation of flammable / toxic gases or vapours, or where an

oxygen deficiency or enrichment could occur, in additional to it has limited or

restricted means of entry or exit and has not been designed for long term occupancy.

Examples:

Vessel, tank, furnace, sewer, pit over 1.2 meter deep and other confined

spaces within ADCO area of operation

Excavation over two meters deep with a width to depth ratio less than 2

(note: the excavated hole size must be large enough to accommodate

entrant body).

Confined Space Entry Certificate (CSEC)3 the certificate, which must be

issued, regardless of location, for any confined space entry.

Control Protection Inhibition Certificate4 – CPIC – a certificate issued to

authorize the override or inhibition of safeguarding system

Contractor’s Camp – an area designated by the Municipality and approved

by ADCO for a designated Contractor to build permanent or temporary camp

facilities.

Duty Manager - an ADCO Leadership Team member who is normally a

direct subordinate of the Area Manager or Line Manager as per the

organization chain of command and who is authorized by the Area Manager

to be his delegate for administering PTW System during his absence.

2

See Appendix D

3

See Appendix H

4

See Appendix F

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 12 of 105

De-Isolation For Test – to de-isolate the plant on a temporary basis for

testing when the work has been completed, e.g. a leaking pump seal has

been replaced, to prove the repair; the pump needs to be run.

Dead – equipment at or about zero potential and disconnected from any live

power system.

e-PTW – the electronic application of PTWS

Excavation - any man-made cavity, leveling, clearing or depression in the

earth's surface, including its sides, walls, and faces, formed by earth removal

and producing unsupported earth conditions by reason of the excavation.

Excavation Certificate (ExC) 5- the certificate which must be issued,

regardless of location, for any excavation activity.

Backfilling ,Grading and leveling is considered as excavation even if it does

not result in unsupported earth conditions. Sand clearance in paved road

doesn’t require excavation certificate but it requires formal procedures.

Equipment Worked on - precise details of the equipment or plant to be

worked on i.e. crude oil storage tank No.1, production manifold No. 2, MOL

pump No. 2 etc.

Equipment /Tools – the mobile machinery, plant, equipment, vehicles and

other power tools to be used to carry out the job.

Engineering & Projects(EP) Area6 an area which has been formally

handed-over using an “EP Hand-over Certificate” from Operations to E&P

another party for major maintenance or construction work (including new

construction or new well construction). It shall be declared within a restricted

or non-restricted area. In case of deviation (e.g. interfering with restricted

area) a written approval of Area Manager will be obtained after consultation

with HSE Manager / Team Leader in the work area, and where the risk

assessment has been undertaken demonstrating that safety standards have

not been compromised. Area Authority / Issuing Authority for EP area shall

be from ADCO EP construction team or Project Management Team (PMT) or

Project Management Consultant (PMC).

5

See Appendix I

6

See Appendix P

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 13 of 105

Energy Source – any source of electrical, mechanical, hydraulic, pneumatic,

chemical, thermal, radioactive or any other energy source that could cause

injury to personnel.

Energy Isolation Devices – mechanical devices that physically prevent the

transmission or release of energy, including but not limited to the following:

Manually operated electrical circuit breakers;

Disconnect switches;

Manually operated switches;

Slide blinds;

Line valves;

Block valves

Note: Energy isolation devices do not include push buttons, selector

switches, and other control type devices.

Fire Watcher – an ADCO or Contractor individual who is trained in

firefighting and who is responsible for monitoring the working area, normally

under hot work conditions and particularly when high-energy sources of

ignition are applied.

Gas Tester (GT) – an ADCO employee or Contractor employee of

supervisory level other than the Job Performer at the discretion of AA, who is

authorized by ADCO following satisfactory completion of the Gas Testing

Training and Certification. The Gas Tester may also be the Area Authority or

Issuing Authority as long as they are suitably qualified.

Green Status Scafftag - When the scaffold has been completed and

inspected by a competent scaffold inspector, the relevant information is

entered on the status card and placed in the holder with the GREEN face

showing. This indicates that the scaffold is “SAFE FOR USE”. The inspector

cannot be the scaffolder responsible for erecting the scaffold.

Hot Work Permit (HWP)7 – the permit which must be issued for jobs in

restricted and non restricted areas requiring an ignition source for

7

See Appendix C

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 14 of 105

execution, or which will or can produce during execution a possible source of

ignition (flame – heat – spark) capable of igniting flammable materials.

High Voltage Electrical Certificate (HVEC)8 – a form of declaration issued

by a Senior Authorized Electrical Person (SAEP) to Authorized Electrical

Person (AEP) to work on High Voltage equipment, apparatus and system (650

V or above) following an assessment of the hazards and risk of the activity.

Hand Tools – tools used to perform the work, which are hand-held and are

not provided with any power source (mechanical, electrical, pneumatic, or

hydraulic).

Hazardous Areas - areas as defined on the Hazardous Area Classification

Drawings as being Class I, Div. 1 (Zone 0 & 1) or Class I, Div. 2 (Zone 2).

Hazardous Area Class I, Division 1 (Zone 0 & 1) - areas likely to have

flammable gases or vapours present continuously under normal conditions.

Hazardous Area Class I, Division 2 (Zone 2) - areas likely to have

flammable gases or vapours present only under abnormal conditions, such as

failure or rupture of equipment.

High Voltage Electrical Equipment – any electrical equipment which is

normally operated at a voltage exceeding 650 volts.

Issuing Authority (IA) - an ADCO employee who is a direct subordinate of

the Area Authority or dedicated reporting to the Area Authority (eg. Project

Issuing Authority, or PMT or PMC) and who is authorized in writing by the

Area Manager following satisfactory completion of the PTW Certification and

licensing process9. He authorizes the job to proceed after checking and

certifying that the worksite is safe.

Isolating / De-Isolating Authority (IDA) - a competent ADCO employee

who is authorized in writing by the Area Manager and who is responsible for

the isolation and de-isolation of plant and equipment in accordance with the

Area Authority’s request under an Electrical-Control Isolation Certificate

(ECIC) or Process Mechanical Isolation Certificate (PMIC). His discipline can

be electrical, cathodic protection, instrument, process, or mechanical. In High

8

See Appendix G

9

See Appendix U

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 15 of 105

voltage isolation, for multidiscipline work using ECIC/ HVEC, the Electrical

IDA must be classified as Authorized Electrical Person (AEP)/ Senior

Authorized Electrical Person (SAEP) – See definitions of AEP and SAEP.

IDA Supervisor: an ADCO Engineer or equivalent from Operations,

Electrical, Mechanical, Instrument, HSE who is responsible to appoint

competent subordinates from his team to carry out the isolation as indicated

in the Isolation Certificate of the PTW procedure.

Isolation Certificates (IC)10 - the certificate which must be issued,

regardless of location, when the unexpected operation of

mechanical/electrical/process/control equipment that can be started by

automatic, manual or remote control may result in injuries to persons

working on the equipment or who are in the vicinity due to release of energy.

The certificate may be Process / Mechanical Isolation Certificate - PMIC or

Electrical/ Control Isolation Certificate – ECIC

Inhibition Performer – the authorized person performing the inhibition or

override

Inhibition – the isolation of the HSE Critical Equipment and System (e.g. fire

/ gas detection system, firefighting system, process alarms or Emergency

Shutdown “ESD” system, etc.)

Isolated – physically separated from the source of supply / energy in such a

manner that inadvertent re-energisation is excluded.

Job Originator (JO) – an ADCO Engineer/ Supervisor or Assistant

Supervisor or ADCO representative employee or PMC who is competent in the

ADCO PTW system and who signs the Work Permit request confirming the

requirement to carry out the work by a competent Job Performer (JP) whom

he is fully aware of his capabilities and his PTW implementation competency.

The Job Originator in conjunction with Area Authority, initiates and leads the

Task Risk Assessment (TRA) as required by ADCO TRA Procedure

Job Originator Cases

If the Job Performer is ADCO, JP direct Supervisor will be the Job

Originator and will share JP responsibility regarding quality and the safety

of the job;

10

See Appendices E1, E2, E3

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 16 of 105

If the JP is a contractor working for operations, JO shall be the ADCO

Contract Administrator or his team representative .

If the Job Performer is an Engineering & Projects (E&P) contractor, JO

shall be a member of the Project Management Team (PMT) or one of the

ADCO E&P Contract Administrator team;

If the Job Performer is a contractor working for governmental authority

such as Municipality, Etisalat, CICPA or ADWEA and carrying out activities

not supervised by ADCO (no direct contract with ADCO), JO shall be a

focal point assigned by the above authority or a Project Management

Consultant (PMC) if available, provided they are trained and certified. If

the Job Performer is a contractor working for a sister company such as

GASCO and carrying out activities not supervised by ADCO (no direct

contract with ADCO) and not in a shared (interface) area, JO shall be a

focal point assigned by the sister company even from major contractors or

a PMC if available.

Job Performer (JP) – an ADCO employee or Contractor who is authorized

by ADCO, following satisfactory completion of the PTW Training and

Certification and to whom the PTW/Certificate is issued. The Job Performer is

directly responsible for the quality and safety of the work to be performed

and for conducting a Toolbox Talk (TBT) immediately before commencing the

work.

The Job Performer cannot be the Area Authority, Issuing Authority or the Gas

Tester.

Line Manager (LM) - an ADCO direct subordinate of an Area Manager

Location of Work - the precise area where the work is to be performed such

as BUH CDS, RDS-3 station, power station, Bb-152 Well, etc.

Live – electrically charged or pipeline with product.

Lockout and Tag-out – a mean to partially or entirely isolate a piece of

equipment, plant or process to allow work to proceed safely on an alternative

section of the equipment, plant or process.

Low Voltage Electrical Equipment – any electrical equipment which is

normally operated at a voltage not exceeding 250 volts.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 17 of 105

Lockout Box – a lockable box designed to securely hold isolation keys,

interlock control keys, fuses, and safety equipment used to secure the means

of isolation.

Medium Voltage Electrical Equipment - any electrical equipment which is

normally operated at a voltage between 250-650 volts.

Mechanical Isolation – include spade insertion, and physical disconnection.

Naked Flame and High Energy Sparks – work involving burning, flame,

arc cutting / welding.

NORM – stands for Naturally Occurring Radioactive Materials

Permit To Work System (PTWS) – the means of providing the formal

written instructions, and authorization to the personnel carrying out the

hazardous job or a defined job in a hazardous environment, or both.

Primary Energy Isolation – the energy isolation point that has been

established as the point in which all sections will install their locks and tags to

the system to ensure the protection against re-activation. Some examples

may be a main breaker or pump inlet valve.

PDA – stands for Personal Digital Assistant: a communication tool used in

e-PTW to transfer data to the Permits data base.

Radiography/NORM Handling Certificate (RNC) 11- the certificate that

must be issued, regardless of the location, for any radiography work or when

handling NORM.

Red Status Scafftag -the Scafftag holder is placed on the scaffold after the

first lift has been erected. This indicates RED condition and states “DO NOT

USE SCAFFOLD”.

Restricted areas:

Restricted areas are defined based on the potential risk due to existence of

Hydrocarbon / Toxic Gases, chemicals .electrocution etc.

11

See Appendix J

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 18 of 105

Restricted areas used under this procedure are listed below

30 meter radius of any oil, gas, or non-potable water wellhead irrespective

of service;

30 meter on either side of any surface layed/exposed oil, gas and non-

potable water flow-line or transfer line or trunk line or main oil line;

10 Meters on either side of the overhead electrical transmission line;

Exclusion zone of flares , vents, burn and oil saver pits;

GASCO company facilities and 30 m around;

TAKREER company oil facilities and 50 m around;

Any electric generating station or substation;

Oil lab and chemical store (for non-routine work);

Sewage Treatment Plant (STP);

Control room (due to its impact on operations, for non-routine work);

Any confined space regardless of location

Non-Restricted Area shall normally include:

Shallow water supply wells for domestic purposes;

Residential areas such as camps;

Office building or compound;

Workshop, stores and fire water pumps, fire water tank areas and fire

training ground;

Any area outside 30 meter radius of any oil, gas or non-potable water

wellhead, production equipment, surface/ exposed oil, gas and non-potable

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 19 of 105

water pipeline / transfer line / trunk line / main oil line, flare tips, vents,

burn and oil saver pits;

Buried (not exposed) oil, gas and water pipelines/transfer line/trunk line/

main oil line;

Any area outside 30 m of OPCO's pipelines corridor or sister company

oil/gas facilities.

MECO reverse osmosis plant and water tank farms;

Other facilities which are not covered by the definition of "Restricted Area."

Routine Jobs Not Requiring a Permit – certain tasks, normally of a

routine, repetitive and low risk nature, do not require PTW. However the list

of such jobs is to be approved in writing by the Area Manager. These tasks

can be conducted under formal procedures or job safety checklist or work

practices (Appendix N) without the issue of a Permit.

Permits – there are two types of permits: Hot Work Permit (HWP) and Cold

Work Permit (CWP).

Certificates – there are nine types of certificates:

1. Confined space entry certificate

2. Excavation certificate

3. Isolation certificate

4. Radiography certificate

5. NORM certificate

6. High voltage electrical certificate

7. Control protection inhibition certificate

8. Formal procedure certificate

9. Vehicle entry certificate

Certificates 1-6 must be attached to permits. Permits 7-9 are standalone and

do not require permit to be attached to each of them as mandatory.

Senior Authorized Electrical Person (SAEP) – an ADCO engineer or

supervisor of grade 11 or above, who has sufficient academic qualification,

technical knowledge, experience, training and certification and has been

authorized by the Area Manager in writing to issue and cancel the High

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 20 of 105

Voltage Electrical Certificate (HVEC).

Scafftag- the Scafftag System is a simple means of indicating whether or not

a scaffold is safe to use. A Scafftag must be used, regardless of location, for

any scaffolding above 2 m high.

Spade – a suitably rated circular metal plate fitted between flange faces

using bolts and gaskets to secure mechanical isolation.

Standby Person (Confined Space) – a person whether ADCO or Contractor

(other than the Job Performer-JP) who is trained in confined space, rescue

procedures, communications and B.A use.

Team Leader (TL) – an ADCO direct subordinate of Division Manager or Line

Manager

Task Risk Assessment (TRA) - is a systematic approach conducted by the

Job Originator, Job Performer, Area Authority , Safety Engineer& F&R Team

if job requires confined space entry or any kind of rescue or standby

arrangements to identify hazards and the necessary control measures

required prior to issuing PTW/ Certificate for any high risk jobs. For

Engineering and projects area, the construction manager from the contractor

or his representative shall attend. The TRA must be prepared in advance,

documented and attached to PTW. The key risks and precautions

identified during the TRA shall be considered as part of in the PTW and

communicated to the Issuing Authority. JP should communicate hazards and

precautions to his work crew during the TBT and prior commencing the task.

For details on TRA, please refer to Task Risk Assessment Guidelines.

Tool Box Talks (TBT) – is a short safety briefing which must be given at the

work site to all personnel involved in the work controlled by the

PTW/Certificate immediately prior to commencing the job.

The TBT will normally be given by the Job Performer but may, where

appropriate, be given by the Job Performer supervisor, the Area Authority or

Issuing Authority. For high risk jobs, the TBT should cover the points

identified during the TRA

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 21 of 105

The TBT must be documented 12 (Appendix - V) with a record of the topics

discussed and the names of the attendees, and the completed "toolbox talks

record sheet & checklist" must be attached to PTW and displayed with the

PTW at the work site.

The TBT should cover, at a minimum, the following five key elements:

1. the work plan and procedures for the task to be undertaken;

2. the individual responsibilities of the personnel involved;

3. the identified hazards, risks and control measures;

4. the emergency procedures and specific actions to be undertaken in the

event of fire, gas leak, incident and/or activation of general alarm.

5. the life protection rules (LPR) applicable to the activity

The TBT must be repeated on shift change, prior to recommencing work if the

permit is extended for additional days and prior to any critical task or activity.

The TBT is in addition to other necessary pre-job safety and work planning

meetings and briefings including those between the Area Authority, Issuing

Authority or Job Performer in an office environment prior to issuing the

permit.

Validity Time of PTW - must not exceed daylight hours of the day of the

work. If the need arises for the time extension beyond the day light hours the

extension shall be appropriately authorized by the Area Authority Team

Leader / Line Manager/ Area Manager/ Duty Manager in this priority order for

the first day only. Permits for high risk activities will require the respective

manager approval on the first day only and revalidation can be done by the

Area Authority himself without the need of further management approval.

Only the time required for completing the job should be specified so that the

PTW is not left open for the whole daylight hours. All timings shall be

specified in 24hr clock e.g. 1400hrs.

The start and finish time of the PTW shall take care of the travel time to get

to and from the work location. (I.e. if the travel time back to camp/ residence

take an hour, the validity of the PTW shall end 1 hour before the sun set

maximum)

12

Refer to Tool Box Talks Record and Checklist – Appendix V

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Definitions & Other Explanatory Note Page: 22 of 105

Validity Period of PTW – permits are valid on the day of issue and can be

extended, subject to obtaining necessary approvals, on a day by day basis,

for a further 7 days giving a total validity of 8 days.

Validity Period of Certificates - certificates are valid on the day of issue

and can be extended, subject to obtaining necessary approvals, on a day by

day basis, for a further 7 days giving a total validity of 8 days for Excavation,

Confined Space Entry Certificates, and Radiography/NORM. Formal Procedure

Certificates is valid for one day ONLY while Isolation, High Voltage Electrical

and Control Protection Inhibition Certificates have open validity

Vehicle Entry Certificate –

Entry of a vehicle as require for conducting work within a Hazardous Areas

classified as Class I, Division 1 (Zone 1) or Class I, Division 2 (Zone 2),

irrespective of the work to be carried out for the required period only.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit to Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : SAFETY STANDARDS Page: 23 of 105

Work Categorization Chart13 – a chart used by personnel to define work

categorized under the PTWS (HWP or CWP)

Yellow Status Scafftag - during subsequent statutory inspections the status

card is reversed showing its yellow face. On satisfactory completion the

inspection is recorded on the card before it is reversed in the holder to show

the GREEN (safe) status. Assuming the inspection indicated that remedial

work was required before re-commissioning the structure, the card is

completely removed to show the RED (unsafe) status once more.

13

See Appendix A

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work(PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Roles and Responsibilities Page :24 of 105

5. ROLES & RESPONSIBILITIES

General Responsibilities

All personnel carrying out work within the PTWS have general responsibilities,

which include:

Ensuring all work is undertaken in accordance with the specified work

scope, method statement and conditions defined on the PTW/Certificate.

Being aware of other work going on in the same area and of the potential

for hazardous interactions.

Knowing the location of the nearest fire extinguishers, communications

equipment, fire call points and emergency shutdown points.

Being aware of changes in environmental/process conditions at the

workplace.

Knowing the emergency assembly points, wind direction and escape

routes from the work area.

Knowing the emergency procedures and emergency contact numbers.

Listening for general alarms, knowing the significance of different tones

and warning/hazard status lights.

Using the appropriate Personal Protective Equipment (PPE) and

appropriate tools for all work activities.

Everyone is responsible for making sure that the PTWS is operated correctly.

If you see anything unsafe, you should stop the activity and seek for

correction immediately, if you cannot correct it yourself you must inform one

level up (e.g. any person in the work crew will inform JP, and Job Performer

will inform the JO and IA, and the Issuing Authority will inform the Area

Authority.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work(PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Roles and Responsibilities Page :25 of 105

Job Originator (JO) carries out the following:

o Plans the activities under his supervision

o In conjunction with Area Authority, initiates / leads the Task Risk

Assessment (TRA) as required by ADCO TRA Procedure

o Nominates competent JP, whether ADCO or contractor, who will be

responsible to carry out the task safely.

o Attend the PTW meeting with the AA & HSE on the day before start of the

activity to review the permit & revalidate the TRA in case of high risk

activity.

o Approve the permit / certificate one day in advance and submit to Area

Authority during the daylight hours

Note

Job Performer competency shall include technical skills in his discipline

and understanding of PTW procedure with associated task hazards.

o Regularly, visits the work location where the task under his responsibility

is carried out and ensures compliance with HSE rules. During the visit to

the worksite , signs the PTW hard copy or tick the JO site visit in the PDA

at the location. Full time supervision shall be maintained as indicated in

the high risk activities table / Appendix S.

o Completes, in conjunction with the Job Performer, the PTW/Certificate

parts indicated as "Permit Request by Job Performer / Job Originator",

o Ensuring that the correct type of PTW has been selected, that the task

description is complete and thorough and that copies of relevant TRA,

area/equipment drawings and procedures are attached as required.

o Closes out (cancels) the permit / certificate on ePTW system shortly after

JP cancellation.

o Approves PTW if Job Performer replacement is required.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work(PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Roles and Responsibilities Page :26 of 105

Job Performer (JP) carries out the following:

o Ensures that he is aware of ADCO HSE rules and regulations, work

procedures, job locations, equipment to be worked on, tools and

equipment to be used and defining the anticipated start and finish time /

date and number of days.

o Shall submit permits / certificates (new request or for revalidation) for

Area Authority (AA) approval one day in advance and during daylight

hours .

Remark

Area Authority has the right not to accept permits / certificates that will be

submitted after the daylight hours

o Attend the PTW meeting with the JO ,AA & HSE on the day before start of

the activity to revalidate the TRA in case of high risk activity.

o Shall attach the TRA for HRA along with the submission of the permit /

certificates

o On the following day, and before the start time of the task, the Job

Performer shall print out the permit/ certificate and proceed to the work

location directly waiting arrival of Issuing Authority (IA) and Authorized

Gas Tester (AGT) if gas test is required.

o The presence of JP or his crew at site does not mean to start the task,

before approving and issuing the permit / certificates officially to him by

IA. JP who starts the task before the permit / certificate are issued will be

considered a violator of PTW procedure and Life Protection Rules.

Equipment entry into the well site (apart from hazardous area) is covered

by the permit approved by AA and does not consider a violation to PTW

procedure although the permit is not yet approved by IA.

Warning

Running up equipment / engines that can produce heat, flame or spark

within the hazardous (classified area) is considered part of hot work

activities and shall not be allowed prior to issuance of HWP

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work(PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Roles and Responsibilities Page :27 of 105

o JP is directly responsible for the safety and quality of work and must

ensure that the conditions specified on the PTW / Certificates are

adhered to and remained unchanged at all time.

o Ensures that no other task is performed or other tool is used except as

specifically described on the PTW / Certificate.

o Implements the Work Site Precautions as identified by the Area

Authority and checked by Issuing Authority on the PTW / Certificate

and TRA.

o Visibly displays the printed out copy of permit / certificate at the

worksite during the duration of the work.

o It is required to use PDA at remote areas to accept permit / certificates

Note:

The hard copy displayed at worksite will be the controlled document that shall

be referred to in case of inspection, audit, incident investigation, etc. however

the ePTW on the system shall be updated (online or offline) daily accordingly.

o Conducts a Toolbox Talk (TBT) immediately before commencing the job

o Remains at the worksite during the duration of the work and obtains

Job Originator / Area Authority signature if Job Performer replacement

is required.

o Immediately suspends work in the event of the Emergency Siren or

General Alarm being activated.

o JP shall keep using the 1st day permit / certificates copy for the whole

duration period as stipulated in permit / certificates and to be signed

daily at location by him, Issuing Authority and Authorized Gas Tester (if

applicable).

o Shall daily re-validate permits / certificates through the ePTW system

without making new prints.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date : Dec 2014

Section : Permits/Certificates and Their Applications Page :28 of 105

o On completion or suspension of the job he must ensure that the work

site is left in a clean - clear and safe condition.

o Closes out the permit / certificate in the e-PTW system on the same

day of the completion of the work or on expiry of the permit /

certificates.

o On the last day of work, the hard copy shall be returned to the

concerned AA .

Area Authority (AA) carries out the following:

o Upon receipt of the permit request, undertakes hazard assessment and

identifies site preparedness/ precautions to be met by Issuing Authority

and the Job Performer. Completes Section 2 in e-PTW stating specific

precautions to be taken by ticking the 'REQ.' boxes on the permit and

completes certificates 'Parts' indicated as "By Area Authority". Advises the

Issuing Authority/Job Performer on the key risks and precautions to be

observed.

o Attend the PTW meeting with the JO & HSE on the day before start of the

acitivity to review the permit / revalidate the TRA in case of high risk

activity.

o Shall approve the permits and certificates (whether new or re-validated)

one day in advance. Area Authority has the right not to accept permits /

certificates that will be submitted after daylight hours of the working day

or next day morning unless there are good reasons;

o Shall assign permits / certificates equally and fairly amongst IA’s to

facilitate quicker issuance of all permits and certificates.

o Ensures IAs to start moving to the work location not later than half hour

from the daily starting working hours, after collecting copies of the permits

for clearing and approval at the work sites.

o Conduct regular visits to the worksites where PTW has been issued. During

the visit to the worksite signs the PTW hard copy or tick the JO site visit in

the PDA at the location Full time attendance is required as indicated in the

high risk activities table / appendix S;

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 29 of 105

o Ensures other work being performed in the vicinity simultaneously with the

work covered by the PTW will not cause a hazard.

o Defines the need and arranges for Gas Tests.

o Consults with the Area Safety Engineer and Fire Officer for Confined Space

Entry Certificates, Area Permits, Area Certificates and high-risk jobs.

o Approves PTW if Job Performer replacement is required after JO approval

and accepts Issuing Authority replacement from his discipline / section

without the need for further approval.

o Approves extension of permit within the daylight hours as long as the

worksite conditions remain unchanged.

o Evaluates, endorse and advise his Line Team Leader or his direct line

Manager or Area Manager or Duty Manager to approve night work in this

listed priority order.

o Approves online re-validation of the permit, one day in advance, day after

day as long as worksite conditions remain unchanged.

o Closes out (cancels) the permit / certificate on e-PTW system shortly after

JP, JO and IA cancellation.

o Can act as the Job Originator (JO), the Issuing Authority (IA), and the Gas

Tester (GT) as long as he is authorized as a (Gas Tester) but he CANNOT

be the Job Performer on the same permit / certificate i.e. he can't issue

permit/certificate to himself.

o Sends the hard copies of closed permits /certificates within 2 days to line

HSE for 30 days retention.

Issuing Authority (IA) carries out the following:

o Shall check the e-PTW and know the permits / certificates assigned to

him, preferably one day in advance, and arrange logistics such as

transportation.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 30 of 105

o Starts moving to the work location not later than half hour from the daily

starting working hours, after collecting copies of the permits / certificates

for clearing and approval at the work sites.

o Carries out proper observations, tests and investigation in worksite prior

to issue of PTW/Certificates ensuring conditions and precautions marked

as 'REQ.' by AA on the PTW/Certificates together with any additional

precautions indicated on TRA are fulfilled. He ticks the “check” boxes on

the PTW/ Certificate confirming that the required precautions are in place.

o Signs and issues the JP printed copy of the permit/certificate at the work

location(noting date and time) and using PDA at remote areas to enter

and update data in e-PTW system such as precautions checking and gas

test results.

o All permits and certificates shall be cleared and signed by IA to allow JP to

start the work within the first two hours of the day

o Ensures that Job Performer conducted effective Tool Box Talks for work

staff.

o Ensures Job Performer and his crew are aware of Emergency Procedures

and Emergency Response contact numbers prior to issuing the permit

o The 1st day permit / certificates copy shall remain utilized for the whole

duration period stipulated in permit/ certificate and signed daily at location

by IA and JP and AGT (if applicable).

o Re-validation of permits / certificates still has to be done through the

e-PTW system on daily basis.

o IA shall daily confirm that AA has approved the re-validation before IA

signs the permit on location.

o Ensures that gas tests and precautions are acceptable for the job to

continue safely when AA re-validates or extends the permit/ certificate.

o In case the gas test result does not meet the company set figures for

LEL%, H2S and O2; IA shall not approve the permit/certificate and the

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 31 of 105

relevant AA shall be immediately informed.

o IA to check all precautions identified by AA and to add more precautions if

required but can’t remove any of those already specified by AA. Any

suggested deletion or additional precautions made by IA shall be

communicated to the respective AA who issued / approved the permit that

day.

o Closes out (cancels) the permit / certificate shortly after JP cancellation.

Gas Tester (GT) carries out the following:

o Coordinating with JP and IA, starts moving to the work location not later

than half hour from the starting working hours;

o Conducts gas testing as stipulated on the PTW / Certificates;

o Ensures that gas test is done at the right place and the right equipment as

advised by AA or IA;

o Gas test results shall be recorded on the JP hard copy permit/certificate

(noting date and time) and then entered directly into the e-PTW system

through the employee’s computer or results transmitted remotely through

PDA;

o Signs 'Testing Requirements' box in Section 3. (For confined space entry,

results to be entered on the certificate);

o In case the gas test result does not meet the company set figures for LEL,

H2S and O2; IA must be immediately informed not to approve the

permit/certificate and the relevant AA shall be also informed.

o In consultation with the Job Performer, sets up stand alone continuous gas

monitor(s) as required by the permit. Advises the Job Performer on the

operation and alarm functions of the monitor.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 32 of 105

Area Safety Engineer / Safety Foreman (SE/SF) carries out the

following:

o Maintains adequate stock of (3) days average consumption of PTW and

supplementary Certificate forms generated from the e-PTW system for

contingency use in case the e-PTW system shuts down and controls the

distribution amongst PTW users as deemed necessary.

o Rolls out up-to-date versions of PTW procedure and system to the end

users.

o Provides advice and guidance on PTWS and collates revisions/amendments

for dispatch to corporate Health Safety & Environment Division (CHSE);

via the Asset or Area Line HSE Manager / Team Leader; for inclusion in

next reviews.

o Carries out PTWS audits on a regular basis (minimum 1 permit a week by

each duty Safety Engineer) and communicate findings and lessons learned

to PTW users and Line Management.

o Informs corporate HSED and Line Management on the gaps in the system

to be considered in HSE procedures.

o Advises and is consulted by the Area Authority for Confined Space Entry

Certificates, Area Permits and high-risk jobs.

o Attend the PTW meeting with the JO & AA on the day before start of the

acitivity to review the permit / revalidate the TRA in case of high risk

activity.

o Participate in TRA development.Ensure TRA are developed / validated in a

session jointly with all the stakeholders (AA,JO& JP) against the scope of

work/ method statement.

o Safety Engineer signs and approves Confined Space Entry Certificates

including those belongs to Integrity & Pipeline Division (IPD) after

ensuring the correct identification of precautions. For Projects PMT or PMC

Safety engineers signs and approves the Confined space entry certificate.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 33 of 105

o Safety Foreman signs and approves confined space entry certificates

including those belongs to Integrity & Pipeline Division (IPD) after visiting

the site and confirming precautions are attended and gas test results are

safe for people entry. Fire Fighters can play the role of Safety Foreman

“whenever required” provided they are trained and authorized in confined

space.

Fire Officer (FO) carries out the following:

o Responsible for preparing / reviewing the evacuation and rescue plan for

confined space entry

o Fire Officers can play the role of Safety Engineers “whenever required”

provided they are trained and authorized in confined space.

Isolating/De-Isolating Authority (IDA) carries out the following:

o Responsible for isolation and de-isolation under Isolating Certificates

(Electrical Control Isolating Certificate - ECIC or Process Mechanical

Isolating Certificate - PMIC or De-isolation for Test Certificate - DTC)14.

Area Manager carries out the following:

o Defines areas of responsibility for Area Authorities.

o Approves, in writing competent ADCO personnel and Contractors who are

qualified in ADCO PTW as authorized Area Authorities, Issuing Authorities

Job Performers, Job Originators and Gas Testers.

o Approves, in writing, the "List of Jobs, which do not require

PTW/Certificates".

o Approves the "List of High Risk Jobs" requiring higher management

approval/counter-signature. List of High Risk Jobs as per appendix (S) is

the minimum to comply with.

o Approves and counter-signs PTW/Certificates and Task Risk Assessments

for work involving High Risk Jobs15

14

See Appendices E1, E2, E3

15

See Appendix S: List of High Risk Jobs and Countersignature Requirements

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 34 of 105

o Authorizes, in writing, the Area Authority and the Issuing Authority to

exceed his ceiling limit of permits as per the defined criteria 16

Department Line Manager / Team Leader carries out the following:

o Ensures that all personnel under their authority, inclusive of contractors,

are adequately trained / assessed in the operation of PTWS17

o Determines key personnel eligible for the authorization of permit

Signatories.

o Extends, as required, the PTW validity time to exceed daylight hours for

his direct subordinates.

o Establishes and maintains the list of "High Risk Jobs requiring Higher

Management Approval / Counter –signature.

o Approves and counter-signs PTW/Certificates and Task Risk Assessments

for work involving High Risk Jobs.

Fire Watcher carries out the following:

o Closely monitors work being carried out under a HWP and ensure that the

work is not left unattended.

o Ensures that fire extinguishers are healthy, operable and sited nearby.

o Notes the position of other firefighting appliances and nearest fire alarm

and emergency shutdown buttons.

o Ensures that the specified PPE is being used at all times and safety

equipment is fit for purpose and is being used correctly.

16

Refer to Section 3.6.3: Maximum Number of Permits and Criteria for Exceeding Ceiling

17

Refer to Section 3.19 of this Part

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 35 of 105

6. PERMITS/CERTIFICATES & THEIR APPLICATIONS

The main objective of the PTWS is to ensure that any work, which has to be

undertaken, is carried out safely. It also ensures that those responsible for

operations have control over the safety of work being conducted within their

area of responsibility.

PTW/Certificates should be considered whenever it is intended to carry out

any work, which may adversely affect the safety of personnel, the

environment or the plant.

The PTWS should also be considered when two or more individuals or

disciplines, perhaps from different trades or different contractors, need to co-

ordinate their activities to ensure that their work is completed safely.

It is not intended that PTWS be applied to all activities as experience has

shown that the overall effectiveness may be weakened and may lead to Area

Authorities/Issuing Authorities being overloaded with activities of a routine,

low risk nature.

It is therefore recommended that all areas assess the risk of their activities

and list specific operations and types of jobs that may be covered by using

formal procedure certificates, job safety checklists and safe practice

processes and which do not require PTW/Certificates. The Work

Categorization Chart18 and definitions of different types of Permits /

Certificates can help in that direction.

Only the Area Authority/Issuing Authority responsible for the area in which

the work is to be performed shall issue Work Permits. The Originator of a

permit shall be responsible for obtaining any additional certificates required,

and they shall become part of the initial Work Permit. The additional

certificate's numbers shall be inserted on to the Hot/Cold Work Permit.

18

See Appendix A

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 36 of 105

All PTW/ Certificates and associated attachments (method statements,

sketches, drawings etc.) must be specific for the location and scope of the

work to be carried out.

For all high-risk jobs, a Task Risk Assessment (TRA)19 must be carried out

and lead by the Job Originator (Job Performer Supervisor) in consultation

and coordination with JP, Area Authority, Safety Engineer and other relevant

parties.

Where required by the TRA, method statements and other supporting

documentation should be attached to the PTW/ Certificate.

The Job Originator and Area Authority responsible for the area in which the

work is to be performed shall approve the Job Performer replacement is

whenever takes place. The Job Originator must check that the replacement

Job Performer is competent, certified and approved by ADCO.

Since the PTW is administrated electronically and to avoid updating the

procedure whenever minor change are done on the forms, The Electronic

copies of the following PTW/certificates in the e-PTW are the approved

version:

C – Hot Work Permit (HWP) Refer to e-PTW

D – Cold Work Permit (CWP) Refer to e-PTW

E1– Electrical/ Control Isolation Certificate (ECIC) Refer to e-PTW

E2– Process/ Mechanical Isolation Certificate (PMIC) Refer to e-PTW

F – Control Protection Inhibition Certificate (CPIC) Refer to e-PTW

G – High Voltage Electrical Certificate (HVEC) Refer to e-PTW

H – Confined Space Entry Certificate (CSEC) Refer to e-PTW

I – Excavation Certificate (EXC) Refer to e-PTW

J – Radiography and NORM Handling Certificate (RNC) Refer to e-PTW

K – Formal Procedure Template/ Form (FPF) Refer to e-PTW

L – Formal Procedure Certificate (FPC) Refer to e-PTW

V – Tool Box Talks Record and Checklist Refer to e-PTW

If the e-PTW is not available, hard copies from the system can be generated

for use.

19

Refer to Task Risk Assessment Guidelines

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page: 37 of 105

PTW/Certificates are to be issued only after visiting the worksite and carrying

out proper observation, tests and investigation, by the Area Authority or the

appointed Issuing Authority.

A register of competent people’ authorized and qualified to carry out gas

tests, Area Authorities, Issuing Authorities and Job Performers (ADCO &

Contractor) shall be maintained. ePTW is accepted as an official register;

however evidences shall be maintained to support the registration record.

General statements on PTW such as "Close supervision is required" and

"Follow ADCO procedures or safety rules at all times" do not add any value

and they are not acceptable.

On completion of the work, expiration of the permit, or if the PTW/Certificates

have been suspended, the Job Performer shall return the original copy of

PTW/Certificates to the Line HSE Department through the relevant Area

Authority for reference, however the PTW/ Certificates should be closed out

through ePTW System.

The daily valid Permits / Certificates and open Isolating Certificate (short

term or long term isolation) shall be displayed on Plasma screen located at

both Control Room and Line HSE Department.

Note:

The Original copy of PTWs/Certificates, once closed-out, should be retained in

the Line HSE Department for a minimum of 30 days and then shredded.

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10/3A Revision 6

Part : 1 Date : Dec 2014

Section : Permits/Certificates and Their Applications Page :38 of 105

6.1 Types of PTW and Certificates

Types of PTW and Certificates (and its abbreviation) to be issued are as

follows:

- Hot Work permit - HWP

- Cold Work Permit - CWP

- Electrical-Control Isolation Certificate – ECIC

- Process-Mechanical Isolation Certificate – PMIC

- De-isolation for Test Certificate - DTC

- Confined Space Entry Certificate - CSEC

- Excavation Certificate - ExC

- Radiography and NORM Handling Certificate – RNC

- High Voltage Electrical Certificate – HVEC

- Control Protection Inhibition Certificate – CPIC

- Formal Procedures Certificate – FPC

- Vehicle Entry Certificate – VEC

6.2 Colour Coding of PTW/Certificates – (If paper prints have to be

used – for example: because of electronic system shutdown)

The following colour coding of the PTW and Certificates shall be adopted:

Hot Work Permit Pink with red edge

Cold Work Permit Pale blue with dark blue edge

Certificates* Yellow

*

Except for HVEC, See Section 3.11

CPR-HSE-OS-10/3A Part 1 Rev 6.doc

ADCO–Procedure Manual Volume 10(HSE)

Permit To Work (PTW)

Volume : 10 /3A Revision 6

Part : 1 Date: Dec 2014

Section : Permits/Certificates and Their Applications Page :39 of 105

6.3 Maximum Number of Permits

The maximum number of PTW’s (including revalidation) to be administered

and issued by each Area Authority and Issuing Authority and performed by JP

on a shift basis is given below.

Maximum Number of Permits

JP AA IA

PTW Type

Total numbers of *1 25 13

PTW (Maximum 4 Naked (Maximum 2