Professional Documents

Culture Documents

Stormpowercomponents Product Guide Busbar

Uploaded by

dhruvCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stormpowercomponents Product Guide Busbar

Uploaded by

dhruvCopyright:

Available Formats

------------------

BACK TO CUSTOM COMPONENTS ---------------------

BACK TO ENGINEERING AND TESTING ------------------

BACK TO PRODUCT RESOURCES

CUSTOM BUSBAR MADE OF COPPER AND ALUMINUM

Copper & Aluminum Bus Bar Specifications & Busbar Types

Metal Alloys: Capacitor Bus Bar

C11000 - Electrolytic Tough IGBT Bus Bar

Pitch Copper

Power Distribution Bus Bar

6101 Electrical Grade Aluminum

Armature Bus Bar

Structural Differences:

Drive Bus Bar

When using Aluminum Bus Bar Backplane Bus Bar

the WIDTH must be increased

by 27%. Ex: To achieve the same Circuit Breaker Bus Bar

temperature rise, a S" x 1/4"

AL busbar will equal a 4" x 1/4" Router Bus Bar

CU bus bar.

Multilayer Bus Bar

When using Aluminum Bus Bar

the THICKNESS must increase Laminated Bus Bar

by 50%. Ex: To achieve the same

How to build the best quality busbar at a lower price temperature rise, 4" x 3/8" AL Rack Mounted Bus Bar

busbar will equal a 4" x 1/4"

CU bus bar.

SOURCING -As one of the Largest electrical components manufacturers in

NorthAmerica, Storm Power Components sources more than seven Plating Available:

Fabrication Process Paths:

million pounds of copper and aluminum every year. This advance sourcing

eliminates inventory overhead from your production costs. Forming & Bending; Medium phsphorus electroless

Conventional, Offset & Side Nickel Plating

FINISHING - Most fabricators can't offer in-house plating and bus bar

insulation Like Storm. Having these capabilities under one roof reduces Stamping; Coil Line Process Full immersion electroplating

transport, waste, pollution, and time.And because we don't finish 75 & In-House Die Fabrication

Strike plating

different types of metal-we finish COPPER andALUMINUM, and we

Cold Cutting & Shearing;

do it right. High & Low Volume Sawing Material Choices:

FABRICATION - Storm's precision machining means we can affordably Machine Punching: CNC, Bright Tin or Matte Tin

manufacture a single prototype part or the mass-produced parts you Automated, & Single Stroke Nickel

need. We do it all, and we specialize in flexibility and responsiveness. Turret Style Silver

100% Lead

Precision CNC Machining; Various T in/lead Alloys

DESIGN AND ENGINEERING SUPPORT - YOU DESIGN Turning & Milling with

Storm manufactures OEM's designs to precise specifications. Our Multi-Axis Capability

engineers can Liaison between your design team and our manufacturing

group, to enable you to focus on strategic projects.

Precision Machining;

Remember Storm engineers have built bus systems for high-current draw Turning and Milling with

Swiss-Style Screw Machine

applications for a generation. Storm can provide critical input that

Leads to greater design for manufacturing flexibility. Press/Fused Welding

& Brazing

VALUE ENGINEERING IS ANOTHER KEY TO SAVING COSTS

Through our value engineering methods we employ a systematic process CNC Water Jet

designed improve the ratio of function to cost. Value is then increased by

1. improving the function or 2. reducing the cost. Laser

LINK TO BUSBAR AMPACITY TABLES>

� STORM.

POWER COMPONENTS

Storm Power Components/ 240 Industrial Park Lane, Decatur, TN 37322

® 2019 Storm Power Components. All Rights Reserved DUNS: 62·393-3397 NAICS: 332116 CAGE/NCAGE : 1Y2KO

You might also like

- Diffrent CapacitorDocument4 pagesDiffrent CapacitordhruvNo ratings yet

- Annex A Step by Step Guide For ISO 9001 2015 NG FG AGDocument39 pagesAnnex A Step by Step Guide For ISO 9001 2015 NG FG AGRt Saragih100% (1)

- AH Series CatalogDocument2 pagesAH Series CatalogdhruvNo ratings yet

- Earthing CalculationDocument4 pagesEarthing Calculationanandpurush100% (1)

- Earthing Resistance Value: Size of Capacitor For Power Factor CorrectionDocument17 pagesEarthing Resistance Value: Size of Capacitor For Power Factor Correctiondhruv100% (2)

- Changing IGBTDocument7 pagesChanging IGBTdhruvNo ratings yet

- Annex A Step by Step Guide For ISO 9001 2015 NG FG AGDocument39 pagesAnnex A Step by Step Guide For ISO 9001 2015 NG FG AGRt Saragih100% (1)

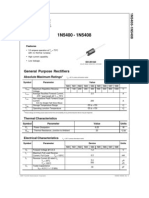

- General Purpose Rectifiers: Absolute Maximum RatingsDocument3 pagesGeneral Purpose Rectifiers: Absolute Maximum Ratingsapi-3749263No ratings yet

- Compact NS630b to 1600 connection diagramsDocument1 pageCompact NS630b to 1600 connection diagramsdhruvNo ratings yet

- DC To DC Converters and Its Application For Railway System-A ReviewDocument9 pagesDC To DC Converters and Its Application For Railway System-A ReviewdhruvNo ratings yet

- EMC Design of IGBT Model PDFDocument20 pagesEMC Design of IGBT Model PDFKen OhNo ratings yet

- Calculate Cable Size and Voltage DropDocument4 pagesCalculate Cable Size and Voltage DropdhruvNo ratings yet

- Harmonic Filtering - Electrical Installation GuideDocument4 pagesHarmonic Filtering - Electrical Installation GuidedhruvNo ratings yet

- 5 - AC Motor Starter PDFDocument10 pages5 - AC Motor Starter PDFPrem KumarNo ratings yet

- Calculate Size of ContactorDocument3 pagesCalculate Size of ContactordhruvNo ratings yet

- Hard Switching Behaviour of MOSFETs and IGBTsDocument6 pagesHard Switching Behaviour of MOSFETs and IGBTsdhruvNo ratings yet

- Polytechnic Hub: Electrical Slip RingsDocument3 pagesPolytechnic Hub: Electrical Slip RingsdhruvNo ratings yet

- A Space Vector Modulation Based Three-Level PWM Rectifier Under Simple Sliding Mode Control StrategyDocument8 pagesA Space Vector Modulation Based Three-Level PWM Rectifier Under Simple Sliding Mode Control StrategydhruvNo ratings yet

- HV Igbt Includes Active ClampingDocument2 pagesHV Igbt Includes Active ClampingdhruvNo ratings yet

- Usefulness of The Various Indicators of Harmonic Distortion: From Electrical Installation GuideDocument2 pagesUsefulness of The Various Indicators of Harmonic Distortion: From Electrical Installation GuidedhruvNo ratings yet

- Basic Solutions To Mitigate Harmonics - Electrical Installation GuideDocument3 pagesBasic Solutions To Mitigate Harmonics - Electrical Installation GuidedhruvNo ratings yet

- R.M.S. Values - Electrical Installation Guide PDFDocument1 pageR.M.S. Values - Electrical Installation Guide PDFdhruvNo ratings yet

- Origin of Harmonics - Electrical Installation Guide PDFDocument3 pagesOrigin of Harmonics - Electrical Installation Guide PDFdhruvNo ratings yet

- Experimental Investigation On The Behaviour of IGBT at Short Circuit During On StateDocument6 pagesExperimental Investigation On The Behaviour of IGBT at Short Circuit During On StatedhruvNo ratings yet

- Origin and Effects of Harmonic Currents in Electrical SystemsDocument3 pagesOrigin and Effects of Harmonic Currents in Electrical SystemsdhruvNo ratings yet

- Selection of A Circuit-Breaker - Electrical Installation GuideDocument11 pagesSelection of A Circuit-Breaker - Electrical Installation GuidedhruvNo ratings yet

- Design of Igbt Based LLC Resonant InverterDocument7 pagesDesign of Igbt Based LLC Resonant InverterdhruvNo ratings yet

- Isc at The Receiving End of A Feeder As A Function of The Isc at Its Sending End - Electrical Installation GuideDocument3 pagesIsc at The Receiving End of A Feeder As A Function of The Isc at Its Sending End - Electrical Installation GuidedhruvNo ratings yet

- Current Source LLC InverterDocument6 pagesCurrent Source LLC InverterdhruvNo ratings yet

- Standards and Description of Circuit-Breakers: From Electrical Installation GuideDocument3 pagesStandards and Description of Circuit-Breakers: From Electrical Installation GuidedhruvNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Machining Process-Ii: (Assignment)Document5 pagesMachining Process-Ii: (Assignment)Sobia JamilNo ratings yet

- SCHLENKER Katalog 2022 EN - WEBDocument136 pagesSCHLENKER Katalog 2022 EN - WEBhosseinNo ratings yet

- Electroless Nickel Plating On Abs Plastic by Using Environmentally Friendly Chemicals (#350219) - 379925Document8 pagesElectroless Nickel Plating On Abs Plastic by Using Environmentally Friendly Chemicals (#350219) - 379925miguelin9169No ratings yet

- ME 3393 - Manufacturing ProcessesDocument24 pagesME 3393 - Manufacturing ProcessesSupervisor Dr.M.MahendraBoopathiNo ratings yet

- 1108 Metric Data SheetDocument1 page1108 Metric Data SheetVoele paterNo ratings yet

- Electrical Discharge MachiningDocument14 pagesElectrical Discharge MachiningHamdhan Syawal Mohd SuhaimiNo ratings yet

- ASSAB PM 30 SuperClean Brochure EnglishDocument12 pagesASSAB PM 30 SuperClean Brochure EnglishnithiNo ratings yet

- Drilling & BoringDocument14 pagesDrilling & BoringDanur M' PahleviNo ratings yet

- Foundry and CastingDocument72 pagesFoundry and CastingGreethu BabyNo ratings yet

- Metal Price ListDocument4 pagesMetal Price ListZedd V De JuanNo ratings yet

- Common G Codes and M Codes For CNC Machine ControlsDocument2 pagesCommon G Codes and M Codes For CNC Machine ControlsIrudhayarajAnthonySamy100% (1)

- Terrano 6.4 GX Parts Catalog 2018Document94 pagesTerrano 6.4 GX Parts Catalog 2018Juli PNo ratings yet

- 3.1 Metal RemovalDocument40 pages3.1 Metal RemovalMichael Kearney50% (2)

- Gold Plating Guide - Types, Thickness & StandardsDocument7 pagesGold Plating Guide - Types, Thickness & StandardsbirgulNo ratings yet

- Introduction Lathe MachineDocument20 pagesIntroduction Lathe Machineswap198383% (6)

- Jeep-Willys DmiDocument14 pagesJeep-Willys DmiGabriel Fodor100% (1)

- Chapter 5 WeldingDocument16 pagesChapter 5 Weldingchoriya007No ratings yet

- Drilling-Machine Group 5Document19 pagesDrilling-Machine Group 5Chandra Kiran HjNo ratings yet

- RF Tvmlpt03v2 RF Tvmlpt03v2 C Manual enDocument20 pagesRF Tvmlpt03v2 RF Tvmlpt03v2 C Manual engurdeeNo ratings yet

- Page 0004Document1 pagePage 0004has sasNo ratings yet

- Igo 11 MemoDocument169 pagesIgo 11 Memowildcatamir11100% (1)

- Standard Tap Drill SizesDocument2 pagesStandard Tap Drill SizesArchie TanglaoNo ratings yet

- ToolexVises PDFDocument44 pagesToolexVises PDFdiegomilitojNo ratings yet

- Grinding Machine & Engine Lathe ProcessesDocument71 pagesGrinding Machine & Engine Lathe ProcessesChester Evangelista Iman IINo ratings yet

- Metal Joining Processes: List Types of Welding, Description With Sketches of Arc Welding, Soldering and Brazing and Their ApplicationsDocument21 pagesMetal Joining Processes: List Types of Welding, Description With Sketches of Arc Welding, Soldering and Brazing and Their ApplicationseldhosekjnitNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- Dapra Metric Series EnglishDocument18 pagesDapra Metric Series EnglishPuneeth KumarNo ratings yet

- Paintry Finance Room Floor PlanDocument1 pagePaintry Finance Room Floor PlanSanjay JangirNo ratings yet

- Technical Data On Galv BoltsDocument40 pagesTechnical Data On Galv BoltsClaudioDuarteNo ratings yet

- 4 Jaw ChuckDocument3 pages4 Jaw Chuckavksekar_701032284No ratings yet