Professional Documents

Culture Documents

Engine Lubricating System

Uploaded by

GODCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Lubricating System

Uploaded by

GODCopyright:

Available Formats

Engine lubricating system

1. Purpose, technical data, general arrangement and arrangement of the devices and instruments of the

engine lubricating system.

2. The engine lubricating system is of circulation combination type.

It is designed for store and carried-on stock of oil, and to supply it at a certain pressure to friction parts in

order to reduce their wear and to transfer heat from them.

Technical data:

Type: circulation combination type with the “dry crankcase”. Lubrication conducting with pressure and

splashing.

- Using oil type М16 IХП-3

- Capacity : - main tank – 27 L,

- additional tank – 38 L,

- outer tank – 45 L.

The minimum permissible amount of oil –20 L.

Oil pressure – 5 - 10 kg/сm2

Oil temperature:

- recommended: – 70 - 1000С;

- allowable: – 65 - 1150С;

- while the air t0 >350C - 1200C

The system consists of:

- main oil tank,

- replenishing tank,

- external oil tank,

- radiators,

- gear type oil pump,

- oil filter,

- oil-priming pump,

- oil gage transmitter,

- thermometer detector,

- pipelines.

The oil tanks serve to store and to transport oil required for the operation of the engine. Tankers can be

filled through the access hole of the replenishing tank. Oil system drying provided by the drain valve of

the main tanker. The tankers communicated with the atmosphere trough crankcase ventilation system.

The main oil tanker is provided by the coiled pipe which is connected to the preheated system by means

of branch pipes in order to heat the oil before starting the engine, oil filter, oil outlet pipe of М3Н-2 and

engine oil pump, union for discharge line, heated water inlet manifold, flange for the oil drying from

radiator, hot water discharge manifold, flange for oil feed from replenishing tank. On the outer surface of

the tanker is mounted overflow valve for oil pumping out from engine into main oil tanker avoiding

radiators. The overflow valve is adjusted on the pressure 4,35кgp/сm2.

Replenishing oil tank

It has 2 flanges in order to connect discharge pipe from main tanker to replenishing tanker and discharge

pipe from replenishing tanker to the engine. On the top of the tanker mounted filler hole, covered by the

stopper with rubber gasket. From the replenishing tanker oil flows in to the main tanker by the pipe. For

oil overflow prevention from main tanker in to replenishing tanker during the tank moving uphill in the

lower part of the replenishing tank valve is mounted.

External oil tanker, 42 L capacity, worming from exhaust manifold.

It has filling hole covered by stopper with rubber gasket and flange connected to the oil dry valve.

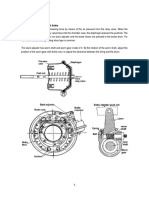

Engine oil pump.

Engine oil pump is a gear type.

It has three pairs of the gears, which is form one delivery section and two suction sections.

Delivery section push the oil from the tanker trough the МАФ filter and pipe to the engine. It has

reduction valve dedicated for creating certain pressure in crankshaft admission hole ( 5-10 kgp\сm2 ).

Oil filter МАФ – rimose type.

Dedicated for oil cleaning which is flow for the lubrication of the engine devices and instruments.

The filter consists of: body, top, three filtering sections, and sleeve for the cleaned oil outcoming,

reduction and cutout valves. The filter has two unions. One for the pipeline from delivery section, second

for discharge oil pipe from filter to the top cover of main engine oil feeding. While the pressure is 4,7 –

5,8 kgh\сm2 , the overflow valve is opening and oil starts moving from pump to the crankshaft.

Oil filter МЦ - І

Oil filter МЦ - І dedicated for additional fine oil cleaning from mechanical admixture and oleoresins.

Technical data:

- carrying capacity– 12 L/min.

- runner turning speed 5000-7000 turns/min.

Consist of:

- body,

- top cover,

- runner,

- spindle,

- drain tube.

Work procedure.

Oil with the pressure 6 кg/cm2 comes in to the lower part of the runner body. Centrifugal force throw off

the dirt on the inner walls of the runner. Cleaned oil through the pipe moves in to the crankshaft.

Oil coolers

Tank mounts two oil coolers. The oil coolers are connected in series and serve to cool the oil coming out

of the engine. The oil coolers are located in the rack over the water radiators on the right side as viewed in

the direction of the tank movement.

The oil cooler is of tube and fin type, three ways.

It consists of:

- two rows of planar tubes,

- two end plates,

- two collectors.

The front collectors have flanges.

Oil priming pump МЗН-2.

The МЗН-2 priming oil pump is designed for deliver oil to the central oil supply cover of the engine

lubricating system before starting the engine. The pump is driven by electric motor МН-1-2с. The pump

is gear-driven type with the overload valve. The pump body has double walls. The inner wall spaces is

filled with fluid from the engine preheating system through branch pipe.

The liquid worms the oil inside the pump. Overload valve adjusted for an opening pressure of 14 kgp/сm2

.

Measuring instruments.

To check the operation of the lubrication system, the tank is equipped with remote-indicating electric

pressure gauge ТЕМ-15 and electric temperature gage ТУЕ48Т.

The detector of the pressure gage is located on the gear case of the left gear-box and connected to central

oil supply cover trough a flexible hose and a specific pipe provided with swivel elbow.

The detector of the temperature gage is installed in scavenge line of the oil pump.

Both of the indicators are located on the driver’s control panel inside the driver’s compartment.

2. Operation of the lubricating system.

With the engine running, the delivery section of oil pump takes oil from main oil tank through filter and

delivers it under pressure trough the МАФ oil filter through the central oil supply cover, from where oil

comes to the friction parts of the engine.

Oil drippings from the crankshaft to the bearing journals and bearing inserts and to the bottom end of the

auxiliary connecting rod.

A part of oil flows to the vertical upper shaft, fuel injection pump and air distributor drive shaft,

tachometer generator drive shaft and to the inclined shafts of the valve timing mechanism through the

orifices made in the crankcase and pipelines.

Oil gravity in to the crankcase, lubricate the gears and the supercharger.

Oil collected in the rear and front oil sumps of the crankcase half is sucked by the oil pump section and is

delivered to main oil tank through the pipeline and oil coolers.

A portion of oil (20-30 %) is delivered under the pressure from the pump section to centrifugal oil

cleaner where it is cleaned of mechanical impurities and returns back in to the lower half of the engine

crankcase.

When oil priming pump is cut in (prior to starting the engine), oil is sucked by the oil priming pump

from the oil tank and delivered directly to the central oil supply cover past МАФ.

As oil is being consumed by the engine from the main oil tank oil flows from replenishing tank to main

oil tank through the oil pipeline.

To prevent overflow of oil from the main tank to the replenishing tank (when moving upgrade) the

replenishing tank is provided whit non-return valve.

The engine lubricating system is of an open type. The system communicates with the atmosphere

through vent pipeline, the return pipe running from the centrifugal oil filter and trough the crankcase of

the engine. The crankcase communicates with the atmosphere through the crankcase ventilation system.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PH Miracle Complete Whole Body Alkalizing Program-1201724Document20 pagesPH Miracle Complete Whole Body Alkalizing Program-1201724joao carlos100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- AT 43 CH 24 Fuel Injection System DiagnosisDocument30 pagesAT 43 CH 24 Fuel Injection System DiagnosisGODNo ratings yet

- ENGINE TUNING OPTIMIZATIONDocument39 pagesENGINE TUNING OPTIMIZATIONTomás Sebastián Sanhueza Vásquez100% (2)

- ENGINE TUNING OPTIMIZATIONDocument39 pagesENGINE TUNING OPTIMIZATIONTomás Sebastián Sanhueza Vásquez100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Aveva Installation GuideDocument48 pagesAveva Installation GuideNico Van HoofNo ratings yet

- Aircraft Gas Turbine Tecnology by IRWINE TREAGER PDFDocument684 pagesAircraft Gas Turbine Tecnology by IRWINE TREAGER PDFJai Deep87% (67)

- Complex Numbers GuideDocument17 pagesComplex Numbers GuideGus EdiNo ratings yet

- Precision MeasurementDocument33 pagesPrecision MeasurementGOD100% (1)

- Alternative Fuels LNG, LPG, HydrogenDocument69 pagesAlternative Fuels LNG, LPG, HydrogenGODNo ratings yet

- Project On International BusinessDocument18 pagesProject On International BusinessAmrita Bharaj100% (1)

- Buyers FancyFoodDocument6 pagesBuyers FancyFoodvanNo ratings yet

- 4th Summative Test Science 6Document5 pages4th Summative Test Science 6ANNALIZA FIECASNo ratings yet

- SRS documentation of Virtual Classroom System , SRS documentation of Personal Identity Management ,SRS documentation of EMentoring for women system , SRS Documentation of Employee Performance Management SRS Documentation of Online TicketingDocument79 pagesSRS documentation of Virtual Classroom System , SRS documentation of Personal Identity Management ,SRS documentation of EMentoring for women system , SRS Documentation of Employee Performance Management SRS Documentation of Online Ticketingsaravanakumar1896% (26)

- T72-B1 Tank Electrical Systems GuideDocument6 pagesT72-B1 Tank Electrical Systems GuideGODNo ratings yet

- Automotive Maintenance Management CourseDocument2 pagesAutomotive Maintenance Management CourseGODNo ratings yet

- Automotive Electrical Systems TrainingDocument3 pagesAutomotive Electrical Systems TrainingGODNo ratings yet

- 6-Automotive UnderchassisDocument3 pages6-Automotive UnderchassisGOD100% (1)

- Types of TeamsDocument9 pagesTypes of TeamsGODNo ratings yet

- Defense University, College of Engineering Project Proposal OnDocument15 pagesDefense University, College of Engineering Project Proposal OnGODNo ratings yet

- 5-Automotive Power TrainDocument3 pages5-Automotive Power TrainGODNo ratings yet

- Ex PaintDocument1 pageEx PaintGODNo ratings yet

- 6-Automotive UnderchassisDocument3 pages6-Automotive UnderchassisGODNo ratings yet

- Inline Injection Pump RemovalDocument3 pagesInline Injection Pump RemovalGOD100% (2)

- WKT MFGDocument4 pagesWKT MFGGODNo ratings yet

- Hydraulic Control and Lubricating System of Power Train1Document21 pagesHydraulic Control and Lubricating System of Power Train1GODNo ratings yet

- Electronic Diesel Control: Eng. Fu'ad DaoudDocument23 pagesElectronic Diesel Control: Eng. Fu'ad DaoudNimesh SilvaNo ratings yet

- Konsep El Diagnosis PDFDocument30 pagesKonsep El Diagnosis PDFJulius RonaldoNo ratings yet

- At 43 CH 4 Diesel Engine OperationDocument46 pagesAt 43 CH 4 Diesel Engine OperationGODNo ratings yet

- Stimulating Creative ThinkingDocument12 pagesStimulating Creative ThinkingGODNo ratings yet

- Engine Cooling SystemDocument16 pagesEngine Cooling SystemGODNo ratings yet

- Driving in Complicated AreaDocument14 pagesDriving in Complicated AreaGODNo ratings yet

- H 38Document3 pagesH 38Matei AlexandruNo ratings yet

- ABS: How Antilock Braking Systems WorkDocument20 pagesABS: How Antilock Braking Systems WorkGODNo ratings yet

- Record KeepingDocument12 pagesRecord KeepingGODNo ratings yet

- Aouto Shop Hand Tools and Precesion Measuring Tools: Chapter-TwoDocument48 pagesAouto Shop Hand Tools and Precesion Measuring Tools: Chapter-TwoGODNo ratings yet

- Konsep El Diagnosis PDFDocument30 pagesKonsep El Diagnosis PDFJulius RonaldoNo ratings yet

- Air Brake (5Document1 pageAir Brake (5GODNo ratings yet

- Rivalry and Central PlanningDocument109 pagesRivalry and Central PlanningElias GarciaNo ratings yet

- What Is Chemical EngineeringDocument4 pagesWhat Is Chemical EngineeringgersonNo ratings yet

- Service: Audi A6 1998Document256 pagesService: Audi A6 1998Kovács EndreNo ratings yet

- Roll Covering Letter LathiaDocument6 pagesRoll Covering Letter LathiaPankaj PandeyNo ratings yet

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDocument18 pagesTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonNo ratings yet

- Hilton 5-29 Case SolutionDocument4 pagesHilton 5-29 Case SolutionPebbles RobblesNo ratings yet

- IBM Systems Journal PerspectivesDocument24 pagesIBM Systems Journal PerspectivesSmitha MathewNo ratings yet

- Amniotic Membrane in Oral and Maxillofacial SurgeryDocument13 pagesAmniotic Membrane in Oral and Maxillofacial SurgerySooraj SNo ratings yet

- Online Music Courses With NifaDocument5 pagesOnline Music Courses With NifagksamuraiNo ratings yet

- Chapter 04Document3 pagesChapter 04gebreNo ratings yet

- Liu030 Nepal Bans Solo Mountain ClimbersDocument2 pagesLiu030 Nepal Bans Solo Mountain Climberssanti.miranda.parrillaNo ratings yet

- Expected OutcomesDocument4 pagesExpected OutcomesPankaj MahantaNo ratings yet

- Deep Learning Based Eye Gaze Tracking For Automotive Applications An Auto-Keras ApproachDocument4 pagesDeep Learning Based Eye Gaze Tracking For Automotive Applications An Auto-Keras ApproachVibhor ChaubeyNo ratings yet

- Project Final Report: Crop BreedingDocument16 pagesProject Final Report: Crop BreedingAniket PatilNo ratings yet

- Goes 300 S Service ManualDocument188 pagesGoes 300 S Service ManualШурик КамушкинNo ratings yet

- METRIC_ENGLISHDocument14 pagesMETRIC_ENGLISHKehinde AdebayoNo ratings yet

- Network Theory - BASICS - : By: Mr. Vinod SalunkheDocument17 pagesNetwork Theory - BASICS - : By: Mr. Vinod Salunkhevinod SALUNKHENo ratings yet

- Abend CodesDocument8 pagesAbend Codesapi-27095622100% (1)

- AP World History: Islamic Empires and Scientific AdvancementDocument55 pagesAP World History: Islamic Empires and Scientific AdvancementJa'TasiaNo ratings yet

- Cuplock Scaffold 18mPHx1.6mx2.5m SafetyDocument1 pageCuplock Scaffold 18mPHx1.6mx2.5m SafetyDIGITAL SIRNo ratings yet

- Insert BondingDocument14 pagesInsert BondingHelpful HandNo ratings yet

- Team Dynamics and Behaviors for Global ExpansionDocument15 pagesTeam Dynamics and Behaviors for Global ExpansionNguyênNo ratings yet