Professional Documents

Culture Documents

Itp - HV Motors

Uploaded by

idontlikeebooksOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itp - HV Motors

Uploaded by

idontlikeebooksCopyright:

Available Formats

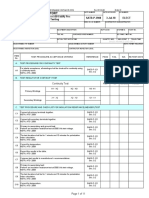

INSPECTION AND TEST PLAN DOC.

N° : 10001485698

THREE PHASE INDUCTION MOTOR VERSION: 03

MANUFACTURER: WEG INDUSTRIES INDIA PVT LTD LEGEND

1. REPORT TYPES (ACCORDING TO THE STANDARD BS EN 10204)

“TYPE 2.1” – Declaration of compliance with the order (generic report without test results);

Document in which the manufacturer (WEG or Sub-supplier) declares that the products supplied are in compliance with the requirements of the order, without inclusion of test results.

“TYPE 2.2” – Declaration of compliance with the order (generic report with test results);

Document in which the manufacturer (WEG or Sub-supplier) declares that the products supplied are in compliance with the requirements of the order and include the results of the tests. These test results may

be from any product with the same specification of the order, but not necessarily the product delivered with the machine (not traceable product).

“TYPE 3.1” – Inspection certificate not witnessed (report with test results of this specific order);

Document in which the manufacturer (WEG or Sub-supplier) declares that the products supplied are in compliance with the requirements of the order and include the test results. These test results may be from

the product specified in the order, and necessarily the product delivered (traceable product).The test unit and the test to be carried out are defined by the product specification, the official regulation and

corresponding rules and/or the order.This document is validated by the manufacturer’s authorized inspection representative (WEG or Sub-supplier). It shall be permissible to WEG to transfer on to the

inspection certificate type 3.1 relevant tests results obtained by specific inspection on primary or incoming products that WEG uses, if the manufacturer/Sub-supplier operates traceability procedures and can

provide the corresponding inspection documents required.

“TYPE 3.2” – Inspection certificate witnessed (report with test results of this specific order);

Document in which the manufacturer (WEG or Sub-supplier) declares that the products supplied are in compliance with the requirements of the order and include the test results. These test results may be from

the product specified in the order, and necessarily the product delivered with the machine (traceable product) These inspection report type 3.2 is a document prepared by the manufacturer’s authorized inspection

representative (WEG or Sub-supplier), independent of the manufacturing department, and must be submitted for review and approval to the inspection representative or to an official institution that witnessed the

inspection.

2. RESPONSIBILITIES - INSPECTION PARTICIPATION

P Prepare Responsible for prepare the inspection.

R Review Responsible for review the inspection report.

W Witness Responsible for witness the inspection. If the responsible do not be present in the stipulated date, the inspection and the production process will normally proceed.

H Hold Point Responsible for witness the inspection. The inspection just occurs in the presence of the responsible. The production process will be temporarily interrupted, to wait the

inspection, until an official authorization.

SF This sign in the field "Responsibility" is referred to WEG's supplier.

WEG INDUSTRIES INDIA PVT LTD – MOTORS AND GENERATORS

HOSUR - TN - INDIA

2 of 5

INSPECTION AND TEST PLAN DOC. N° : 10001485698

THREE PHASE INDUCTION MOTOR VERSION: 03

MANUFACTURER:

3. WEG INDUSTRIES INDIA PVT LTD

SITE OF INSPECTION

MOTORS / GENERATORS - Hosur

PDHSR Production Department

TLHSR Testing Lab (Electrical Lab)

QCHSR Quality Control Department

PUHSR Purchase Department

FO Sub-supplier (WEG's Supplier)

LX Independent External Laboratory

CONSIDERATIONS

1. To receive a inspection report, the column "CUSTOMER" in the field "RESPONSIBILITY" of the specific inspection must be comply with the letter "R". In case of witnessed inspections, "W" or "H", the report will be

provided and sent to the costumer.

2. The products defined in this Inspection and Test Plan as not traceable may be asked as a traceable during the approval of this document. All tests will be performed in accordance with the last version of this Inspection

and Test Plan. Every request after the approval of this document, that is not described here, must be agreed upon WEG and customer. This procedure is necessary to identify all the products that will be part of the

equipment to guarantee the chances to trace.

WEG INDUSTRIES INDIA PVT LTD – MOTORS AND GENERATORS

HOSUR - TN - INDIA

3 of 5

INSPECTION AND TEST PLAN DOC. Nº: 10001485698

THREE PHASE INDUCTION MOTOR VERSION: 03

RESPONSIBILITIES

PART/COMPONENT REFERENCE REPORT INSPECTION

ITEM SITE REMARKS

POINT OF INSPECTION STANDARD SF WEG CUSTOMER TYPE RANGE

1 RAW MATERIAL

1.1 ELECTRIC CABLE

1.1.1 Dimensional Drawing P R _ 2.2 FO Sample

IEC 60092-350

1.1.2 Electrical resistance P R _ 2.2 FO Sample

IEC 60092-350

1.1.3 Insulation resistance P R _ 2.2 FO Sample

IEC 60092-350

1.1.4 High voltage P R _ 2.2 FO Sample

1.2 SHAFT STEEL BAR

1.2.1 Visual and dimensional Drawing P R _ 2.2 FO 100%

1.2.2 Chemical composition TES-183M P R _ 2.2 FO 100%

ASTM-A-370

1.2.3 Tensile strength P R _ 2.2 FO 100%

ASTM-23

ASTM-A-370

1.2.4 Hardness P R _ 2.2 FO 100%

ASTM-23

1.2.5 Ultrasonic test ASME VIII P R _ 2.2 FO 100%

1.3 STATOR FRAME PLATES

1.3.1 Visual and dimensional Drawing P R _ 2.2 FO Sample

1.3.2 Chemical composition ASTM-A-36 P R _ 2.2 FO Sample

1.3.3 Tensile strength ASTM-A-36 P R _ 2.2 FO Sample

1.4 MAGNETIC SHEET

1.4.1 Magnetic losses IEC 60404-2 P R _ 2.2 FO Sample

2 IN PROCESS INSPECTION

2.1 MACHINED FRAME

2.1.1 Visual and dimensional Drawing _ P _ 2.2 QCHSR 100%

WEG INDUSTRIES INDIA PVT LTD – MOTORS AND GENERATORS

HOSUR - TN - INDIA

4 of 5

INSPECTION AND TEST PLAN DOC. Nº: 10001485698

THREE PHASE INDUCTION MOTOR VERSION: 03

RESPONSIBILITIES

PART/COMPONENT REFERENCE REPORT INSPECTION

ITEM SITE REMARKS

POINT OF INSPECTION STANDARD SF WEG CUSTOMER TYPE RANGE

2.2 MACHINED SHAFT

2.2.1 Visual and dimensional Drawing _ P _ 2.2 QCHSR 100%

2.3 MACHINED ENDSHIELDS

2.3.1 Visual and dimensional Drawing _ P _ 2.2 QCHSR 100%

2.4 WOUND STATOR AFTER IMPREGNATION

IEEE 118 /

2.4.1 Ohmic resistance _ P _ 2.2 QCHSR 100%

IS 4029

IEEE 43 /

2.4.2 Insulation resistance _ P _ 2.2 QCHSR 100%

IS 7816

IEC 60034-1 /

2.4.3 High voltage _ P _ 2.2 QCHSR 100%

IS 4722 & 4029

IEEE 522

2.4.4 Surge test _ P _ 2.2 QCHSR 100%

section 6.1

2.4.5 Visual and dimensional Drawing _ P _ 2.2 QCHSR 100%

2.5 COMPLETE ROTOR

2.5.1 Balancing ISO 1940 _ P _ 2.2 PDHSR 100%

3 FINAL INSPECTION

3.1 ASSEMBLED MACHINE - ELECTRICAL TESTS

3.1.1 Routine tests Test Procedure _ P R 3.1 TLHSR 100%

3.2 ASSEMBLED MACHINE - FINAL INSPECTION

3.2.1 Dimensional Drawing _ P R 3.1 QCHSR 100%

3.2.2 Visual inspection Check list _ P R 3.1 QCHSR 100%

3.2.3 Paint coat thickness TIM-0531 _ P _ 3.1 QCHSR 100%

3.2.4 Painting adherence TIM-222 _ P _ 3.1 QCHSR 100%

WEG INDUSTRIES INDIA PVT LTD – MOTORS AND GENERATORS

HOSUR - TN - INDIA

5 of 5

You might also like

- Electrical MotorDocument35 pagesElectrical MotorTshering Peljor100% (3)

- Solo Run For MotorsDocument8 pagesSolo Run For MotorsMohamed Haleem100% (1)

- Test Procedure of Generator - For U#1,2,3&4 PDFDocument14 pagesTest Procedure of Generator - For U#1,2,3&4 PDFPrince SharmaNo ratings yet

- T&C ManualDocument65 pagesT&C ManualKarthikeyan S100% (1)

- Field Inspection Testing Electrical EquipmentDocument21 pagesField Inspection Testing Electrical Equipmentkisan singh100% (2)

- AC Motor Inspection/Testing & Commissioning Check ListDocument9 pagesAC Motor Inspection/Testing & Commissioning Check ListAdnan AhmadNo ratings yet

- Inspection and Test Plan For Induction MotorDocument5 pagesInspection and Test Plan For Induction MotorDino PedutoNo ratings yet

- DC - Traction Motor 752RS1A-Final Test ReportDocument5 pagesDC - Traction Motor 752RS1A-Final Test ReportGaurav ChaudharyNo ratings yet

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (2)

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser MahamidNo ratings yet

- E201 - Elec Inspection Test Plan Template Rev 00 11.11Document15 pagesE201 - Elec Inspection Test Plan Template Rev 00 11.11Arbaaz KhanNo ratings yet

- Testing of TransformersDocument5 pagesTesting of Transformersjinojk100% (1)

- AC Motor Repair SpecificationDocument13 pagesAC Motor Repair SpecificationErgys Lika100% (1)

- HT MotorDocument25 pagesHT MotorgaladrialNo ratings yet

- STANDARD QUALITY ASSURANCE PLAN FOR AC MOTORSDocument6 pagesSTANDARD QUALITY ASSURANCE PLAN FOR AC MOTORSSonti Mani kumar100% (1)

- Motor Operated Valves Course Manual PDFDocument20 pagesMotor Operated Valves Course Manual PDF련서긔100% (2)

- CHARGING CHECKLISTDocument4 pagesCHARGING CHECKLISTKanagaraj Ravi0% (1)

- T C Procedure For TransformerDocument11 pagesT C Procedure For TransformerĐặng Xuân ViệtNo ratings yet

- Switchgear Inspection and Test Procedure: MV SystemsDocument20 pagesSwitchgear Inspection and Test Procedure: MV Systemsramadani bimaNo ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Instrument Loop Testing ProcedureDocument9 pagesInstrument Loop Testing ProcedureSusanto Pausinugroho100% (1)

- Inspection and Test Plan (ITP) Sample IPAL PalembangDocument3 pagesInspection and Test Plan (ITP) Sample IPAL PalembangBudi TooleeNo ratings yet

- NGR Routine Test ProcedureDocument6 pagesNGR Routine Test Procedurezaheer ahamedNo ratings yet

- Inspection and Test Procedure of SwitchgearDocument4 pagesInspection and Test Procedure of SwitchgearShahadat HossainNo ratings yet

- Inspection and Test Plan For Battery Charger PDFDocument5 pagesInspection and Test Plan For Battery Charger PDFkrit_kasemNo ratings yet

- Inspection and Test Plan For Power Transformer PDFDocument6 pagesInspection and Test Plan For Power Transformer PDFSiva Kumar100% (1)

- Saudi Aramco Transformer TestingDocument11 pagesSaudi Aramco Transformer Testingkarthi51289100% (1)

- Electrical Itp FormDocument7 pagesElectrical Itp FormshayanNo ratings yet

- ASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFDocument89 pagesASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFFabiano Lebkuchen100% (2)

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- HFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanDocument97 pagesHFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanAmmar AlkindyNo ratings yet

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- Testing and Commissioning of MCC PanelDocument25 pagesTesting and Commissioning of MCC PanelWin100% (1)

- ITP Electrical New MCCDocument3 pagesITP Electrical New MCCMpuwh 'Riczky Syaputra'No ratings yet

- ITP - Control PanelDocument2 pagesITP - Control PanelHoras Canman Sianipar100% (1)

- Saudi Aramco LV Panelboard TestingDocument4 pagesSaudi Aramco LV Panelboard TestingheikelNo ratings yet

- Check List For Power TransformerDocument7 pagesCheck List For Power Transformermatthew_7No ratings yet

- FAT Procedure (En)Document2 pagesFAT Procedure (En)wado11No ratings yet

- Cable TerminationDocument2 pagesCable Terminationapandey070273No ratings yet

- The Wankel Engine Design Development AppDocument271 pagesThe Wankel Engine Design Development AppFurqanNo ratings yet

- Gms Ele Itp 001 HV & LV SwitchgearDocument12 pagesGms Ele Itp 001 HV & LV Switchgearnidnitrkl051296100% (1)

- ITP For MCC - HV - LV-switchgear Boards-PaneDocument2 pagesITP For MCC - HV - LV-switchgear Boards-Panerodel100% (1)

- Itp TransformerDocument2 pagesItp TransformerDwi Mulyanti DwimulyantishopNo ratings yet

- Lvac-Sat Procedure For Equipment Test-Ss1Document39 pagesLvac-Sat Procedure For Equipment Test-Ss1Balamurugan SelvarajNo ratings yet

- Plastics as a Building Material GuideDocument24 pagesPlastics as a Building Material GuideVinod Nair100% (1)

- Gold Medallion Assessors Guide v1.2 2023Document9 pagesGold Medallion Assessors Guide v1.2 2023idontlikeebooksNo ratings yet

- HV Switch GearDocument46 pagesHV Switch GearSayuti SidikNo ratings yet

- Maintenance of 132 KV SwitchgearDocument34 pagesMaintenance of 132 KV SwitchgearMuhammad Abdul Rauf100% (1)

- Pre-Commissioning Tests AC Equipment ListDocument5 pagesPre-Commissioning Tests AC Equipment ListnagarajanNo ratings yet

- Sedimentation: Engr. Nadeem Karim BhattiDocument23 pagesSedimentation: Engr. Nadeem Karim BhattiEngr Sarang Khan100% (1)

- Test Procedure TXDocument4 pagesTest Procedure TXVasu100% (1)

- Inspection Test Plan (ITP) Procedure-DigabungkanDocument9 pagesInspection Test Plan (ITP) Procedure-Digabungkanpankrasius herbudiNo ratings yet

- Department of Electrical & InstrumentationDocument18 pagesDepartment of Electrical & InstrumentationIzul Hakim100% (1)

- Testing Procedure For Potential Transormer: Prepared byDocument1 pageTesting Procedure For Potential Transormer: Prepared byGuru MishraNo ratings yet

- Status of power plant equipment testing June 2022Document2 pagesStatus of power plant equipment testing June 2022SureshYarlagaddaNo ratings yet

- Form No. 102B - Solenoid ValveDocument1 pageForm No. 102B - Solenoid ValveVictor NairNo ratings yet

- Oil Type Pre Commissioning ReportDocument3 pagesOil Type Pre Commissioning ReportAtluri Naga Sai Saran Kumar100% (1)

- Appendix-2 (POWER PANEL Test Report)Document2 pagesAppendix-2 (POWER PANEL Test Report)hafed baccoucheNo ratings yet

- SAIC-P-3701 Rev 0Document3 pagesSAIC-P-3701 Rev 0mkalidas2006No ratings yet

- IMS FORM Inspection and Test PlanDocument8 pagesIMS FORM Inspection and Test PlanKrisnandha RahardianNo ratings yet

- Commissioning of XLPE Power Cables (69kV to 380kVDocument16 pagesCommissioning of XLPE Power Cables (69kV to 380kVMakesh Indhu0% (1)

- Saudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202nadeem shaikhNo ratings yet

- How To Use A Megger Insulation TesterDocument2 pagesHow To Use A Megger Insulation TesterRakesh Babu0% (1)

- IEC61683 Efficiency CertificateDocument20 pagesIEC61683 Efficiency CertificatearunghandwalNo ratings yet

- Hitachi 3.3-12K - EMC VERDocument2 pagesHitachi 3.3-12K - EMC VERvenkatraman JNo ratings yet

- SMPC Delivery and Assessment Guide v1 June 2022Document37 pagesSMPC Delivery and Assessment Guide v1 June 2022idontlikeebooksNo ratings yet

- Psar35 m5 Rescue V December 2022Document37 pagesPsar35 m5 Rescue V December 2022idontlikeebooksNo ratings yet

- Water Safety Risk Assessment Guide v1.0Document4 pagesWater Safety Risk Assessment Guide v1.0idontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- Bronze Medallion (BM) Theory Questions (Assessment Task 1)Document23 pagesBronze Medallion (BM) Theory Questions (Assessment Task 1)idontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- TeSys Giga Contactors - LC1G225KUENDocument5 pagesTeSys Giga Contactors - LC1G225KUENidontlikeebooksNo ratings yet

- NL48Document1 pageNL48idontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- CA6 ContactorsDocument36 pagesCA6 ContactorsAbhishek mishraNo ratings yet

- Lime Slaking 101 Whitepaper 4-06-22Document8 pagesLime Slaking 101 Whitepaper 4-06-22idontlikeebooksNo ratings yet

- STT Vertimill Retrofit 03282022Document2 pagesSTT Vertimill Retrofit 03282022idontlikeebooksNo ratings yet

- 2023 State Age Championships Final Event Information 1Document10 pages2023 State Age Championships Final Event Information 1idontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- Memo 2023 Age Championships Water Safety RosterDocument3 pagesMemo 2023 Age Championships Water Safety RosteridontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Ieee 841 2001 Nema Premium Efficiency Motors With Inproseal Usa841 Brochure EnglishDocument8 pagesWEG Ieee 841 2001 Nema Premium Efficiency Motors With Inproseal Usa841 Brochure EnglishidontlikeebooksNo ratings yet

- Complete Blood Count (CBC) Normal Laboratory Study Values: DefinitionDocument6 pagesComplete Blood Count (CBC) Normal Laboratory Study Values: DefinitionGlare RhayneNo ratings yet

- Um Centuris Pro Li900b1 - enDocument70 pagesUm Centuris Pro Li900b1 - enOsires Ferreira100% (1)

- Solving Motion ProblemsDocument5 pagesSolving Motion ProblemsAkshat Kumar AgarwalNo ratings yet

- 51-11-15-001-Data Recording of Allowable Damage and Repairs-A320Document6 pages51-11-15-001-Data Recording of Allowable Damage and Repairs-A320FredNo ratings yet

- PRIMAL™ NT-6035: Floor Care PolymersDocument2 pagesPRIMAL™ NT-6035: Floor Care PolymersPeter MatareNo ratings yet

- Trapezoidal Rule for Numerical IntegrationDocument8 pagesTrapezoidal Rule for Numerical IntegrationGian SanchezNo ratings yet

- Presentation by Harshal Sethiya N Mitul UpadhyayDocument26 pagesPresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- KS1 A Good Bubbling CauldronDocument11 pagesKS1 A Good Bubbling CauldronViktoriia PolushkoNo ratings yet

- Processing and Characterization of Recycled Poly (Ethylene Terephthalate) BlendsDocument3 pagesProcessing and Characterization of Recycled Poly (Ethylene Terephthalate) BlendsJason WilliamsNo ratings yet

- Installation Manual-Perfect YORKDocument19 pagesInstallation Manual-Perfect YORKjesNo ratings yet

- Rizal 6Document11 pagesRizal 6Alexa LeeNo ratings yet

- Report of Mechanics of Machines 1Document12 pagesReport of Mechanics of Machines 1muhammaduzairNo ratings yet

- BE AMC-34-All Branches With IndexDocument223 pagesBE AMC-34-All Branches With IndexSrikanth RangdalNo ratings yet

- Tuto Traktor Arduino enDocument11 pagesTuto Traktor Arduino enlexetaNo ratings yet

- 571470-29 Linear Encoders For Numerically Controlled Machine ToolsDocument60 pages571470-29 Linear Encoders For Numerically Controlled Machine ToolsIjabiNo ratings yet

- Meter Moving CoilDocument4 pagesMeter Moving Coilabecdf100% (1)

- Tots FaqDocument12 pagesTots FaqkbsnNo ratings yet

- Question-7 MA CompreviewDocument18 pagesQuestion-7 MA CompreviewBrigham JervosoNo ratings yet

- Precious Metals AlfaDocument83 pagesPrecious Metals AlfaPraveenNo ratings yet

- Project Report On Employee Management SystemDocument58 pagesProject Report On Employee Management Systemprivate69raghavNo ratings yet

- q4_tleDocument65 pagesq4_tleAngelica TaerNo ratings yet

- Operation and Analysis of The Three Phase Fully Controlled Bridge ConverterDocument24 pagesOperation and Analysis of The Three Phase Fully Controlled Bridge Convertermohammed aliNo ratings yet

- Seating Arrangement Rani MamDocument44 pagesSeating Arrangement Rani Mamnagendra thelagariNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument10 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingBradyNo ratings yet

- Managing Demand Uncertainty in Supply Chain PlanningDocument6 pagesManaging Demand Uncertainty in Supply Chain PlanningSuraj NamdeoNo ratings yet

- BRP-1 Final Report Borjan Private LimitedDocument38 pagesBRP-1 Final Report Borjan Private LimitedArsalan IqbalNo ratings yet