Professional Documents

Culture Documents

Difference Between Isometric and P&Id

Uploaded by

Muthuram NOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Difference Between Isometric and P&Id

Uploaded by

Muthuram NCopyright:

Available Formats

DIFFERENCE BETWEEN ISOMETRIC AND P&ID

Isometric Drawing have the accurate length and path ,but in the P&ID

Drawing only having the path from where to where the pipe line

connection and also showing the instruments which are on those pipe line

connection.

Isometric drawing is a method for visually representing three-dimensional

objects in two dimensions in technical and engineering drawing. P&ID is a

flow diagram which indicates general flow of plant process and

equipment’s.

QUALITY CONTROL (QC)

Quality control is a procedure or set of procedures intended to ensure

that a manufactured product or performed service adheres to a defined set of

quality criteria or meets the requirements of the client or customer.

It is simply stated: "Fit for use or purpose." It is all about meeting the needs

and expectations of customers with respect to functionality, design, reliability,

durability.

QUALITY ASSURANCE (QA)

Assurance is nothing but a positive declaration on a product or service,

which gives confidence. It provides a guarantee that the product will work without

any problems as per the expectations or requirements.

GRP

GRP Pipes and FRP pipes is used interchangeably in the fiber glass pipe

industry. Glass fiber reinforced plastics (GRP) are a composite material made of

a polymer matrix reinforced with fibers.

RTR

RTR Pipe is a kind of composite thermosetting plastic pipe, combing Resin

with Fiberglass Roving. RTR is a thermosetting resin can be epoxy or polyester

reinforced usually with fiberglass.

Polymer Matrix Composites

Polymer Matrix Composite (PMC) is the material consisting of

a polymer (resin) matrix combined with a fibrous reinforcing dispersed phase. Polymer Matrix

Composites are very popular due to their low cost and simple fabrication methods.

Use of non-reinforced polymers as structure materials is limited by low level of their

mechanical properties: tensile strength of one of the strongest polymers - epoxy resin is

20000 psi (140 MPa). In addition to relatively low strength, polymer materials possess

low impact resistance.

Reinforcement of polymers by strong fibrous network permits fabrication of Polymer Matrix

Composites (PMC) characterized by the following properties:

High tensile strength;

High stiffness;

High Fracture Toughness;

Good abrasion resistance;

Good puncture resistance;

Good corrosion resistance;

Low cost.

The main disadvantages of Polymer Matrix Composites (PMC) are:

Low thermal resistance;

High coefficient of thermal expansion.

Two types of polymers are used as matrix materials for fabrication

composites: Thermosets (epoxies, phenolics) and Thermoplastics (Low Density Polyethylene

(LDPE), High Density Polyethylene (HDPE), polypropylene, nylon, acrylics).

According to the reinforcement material the following groups of Polymer Matrix Composites

(PMC) are used:

Fiberglasses – Glass Fiber Reinforced Polymers;

Carbon Fiber Reinforced Polymer Composites;

Kevlar (aramid) fiber reinforced polymers.

Reinforcing fibers may be arranged in different forms:

Unidirectional fibers;

Rovings;

Veil mat: thin pile of randomly orientated and looped continuous fibers;

Chopped strands: thin pile of randomly orientated and looped short (3-4 inches) fibers;

Woven fabric.

Properties of Polymer Matrix Composites are determined by:

Properties of the fibers;

Orientation of the fibers;

Concentration of the fibers;

Properties of the matrix.

Properties of Polymer Matrix Composites may be estimated by the Rule of Mixtures.

Polymer Matrix Composites (PMC) are used for manufacturing: secondary load-bearing

aerospace structures, boat bodies, canoes, kayaks, automotive parts, radio controlled

vehicles, sport goods (golf clubs, skis, tennis racquets, fishing rods), bullet-proof vests and

other armor parts, brake and clutch linings.

You might also like

- Polymer Matrix CompositesDocument3 pagesPolymer Matrix CompositesTalib AleemNo ratings yet

- Introduction To Composite Materials Subject Code: 18AE54 Prepared by Dr. Vijaya Kumar R & MR - Gopinath BDocument111 pagesIntroduction To Composite Materials Subject Code: 18AE54 Prepared by Dr. Vijaya Kumar R & MR - Gopinath BpavanNo ratings yet

- Vinidex - Section 2 MaterialsDocument27 pagesVinidex - Section 2 MaterialsMatthew ButlerNo ratings yet

- MS PDF KiTEC Product ManualDocument54 pagesMS PDF KiTEC Product ManualDeepak Builders Ludhiana Railway StationNo ratings yet

- Manisa Celal Bayar University Department of Metallurgy and Materials Engineering 2020Document30 pagesManisa Celal Bayar University Department of Metallurgy and Materials Engineering 2020Bilim KapsülüNo ratings yet

- Municipal Fiberglass Pipe Standards and PerformanceDocument4 pagesMunicipal Fiberglass Pipe Standards and PerformanceMichael VillaluzNo ratings yet

- RF CableDocument28 pagesRF Cablerahul_2005No ratings yet

- Ceramic Fibre BlanketDocument17 pagesCeramic Fibre BlanketToni0% (1)

- Astm D578Document10 pagesAstm D578MaRy Ge50% (2)

- Mechanical Behaviour of Bagasse Fiber Epoxy Composites3Document19 pagesMechanical Behaviour of Bagasse Fiber Epoxy Composites3shivaNo ratings yet

- EMM Project (PF)Document18 pagesEMM Project (PF)DHRUV SINGHALNo ratings yet

- Manufacturing Automotive Applied Composite Materials 2013Document23 pagesManufacturing Automotive Applied Composite Materials 2013AshutoshNo ratings yet

- Preparation and Characterization of Tio2 Particulate Filled Polyester Based Glass FiberDocument4 pagesPreparation and Characterization of Tio2 Particulate Filled Polyester Based Glass FiberArun KumarNo ratings yet

- Mfgil - GRP Brochure PDFDocument24 pagesMfgil - GRP Brochure PDFmay lintoNo ratings yet

- Specifications, Test Methods and Codes For PE Piping SystemsDocument38 pagesSpecifications, Test Methods and Codes For PE Piping Systemsrizviabbas2012No ratings yet

- What Are PlasticsDocument84 pagesWhat Are PlasticsBhuvanesh PonnanNo ratings yet

- PC 23090Document14 pagesPC 23090Ze MariNo ratings yet

- MRTS59Document26 pagesMRTS59jayryansantos2No ratings yet

- Hdpe Conduit SystemsDocument10 pagesHdpe Conduit SystemsKevinNo ratings yet

- Technical Brochure on Fiberglass Piping SystemsDocument22 pagesTechnical Brochure on Fiberglass Piping SystemsMazwan Che MansorNo ratings yet

- Kanha Plastics Pvt. LTD.: Manufacturer and Exporters of Commercial & Industrial PPR Pipes & FittingsDocument20 pagesKanha Plastics Pvt. LTD.: Manufacturer and Exporters of Commercial & Industrial PPR Pipes & FittingsAshok NagpalNo ratings yet

- Fiber and TextileDocument43 pagesFiber and Textileinfo.akira.ictNo ratings yet

- Fibre Reinforced Plastics 124Document6 pagesFibre Reinforced Plastics 124RajaramNo ratings yet

- PMC PPT 230205102125 d04b2c86Document28 pagesPMC PPT 230205102125 d04b2c86vincealiyacandelariaNo ratings yet

- Fibre Reinforced PlasticsDocument6 pagesFibre Reinforced Plasticsamirthraj74No ratings yet

- Corruge Pipe Report PDFDocument24 pagesCorruge Pipe Report PDFyojuandaNo ratings yet

- An Overview of Burst, Buckling, Durability and Corrosion Analysis of Lightweight FRP Composite Pipes and Their ApplicabilityDocument28 pagesAn Overview of Burst, Buckling, Durability and Corrosion Analysis of Lightweight FRP Composite Pipes and Their ApplicabilitysamanehNo ratings yet

- Pacific - Pipes IndiaDocument7 pagesPacific - Pipes IndiaAli Mammadov100% (1)

- Numerical Simulation and Experimental Test Burst Pressure of ASME A106 Steel PipeDocument10 pagesNumerical Simulation and Experimental Test Burst Pressure of ASME A106 Steel PipenapoleonmNo ratings yet

- Cost Study Infusion Vs PrepregDocument17 pagesCost Study Infusion Vs PrepregAjith Krishnan100% (1)

- 141667-FAF-SPE-EOH-000013 OEE Aluminium Stranded Conductor Specification...Document12 pages141667-FAF-SPE-EOH-000013 OEE Aluminium Stranded Conductor Specification...marigusatuNo ratings yet

- Composites Science and TechnologyDocument7 pagesComposites Science and TechnologyZhiwei ZhangNo ratings yet

- Introduction To Composite MaterialsDocument93 pagesIntroduction To Composite MaterialsabhiNo ratings yet

- Advanced Composite Materials in Typical Aerospace Applications-LibreDocument10 pagesAdvanced Composite Materials in Typical Aerospace Applications-LibrezaujahaminNo ratings yet

- GFRP NCODE Designlife DigimatDocument11 pagesGFRP NCODE Designlife DigimatKruthika K CNo ratings yet

- Project Report PMCDocument7 pagesProject Report PMCShafiq Ahmed ShahbazNo ratings yet

- RTRDocument3 pagesRTRRaziKhanNo ratings yet

- PE Piping Standards GuideDocument28 pagesPE Piping Standards Guidenrd9771No ratings yet

- Composite Materials Sandwich GuideDocument16 pagesComposite Materials Sandwich GuideOwen StevensNo ratings yet

- Types of FRP pipes classified by resin usedDocument1 pageTypes of FRP pipes classified by resin usedanasseeksNo ratings yet

- Comparativo Pvc-O Molecor Vs Hdpe - SedapalDocument25 pagesComparativo Pvc-O Molecor Vs Hdpe - SedapalBeatrice CarrollNo ratings yet

- BME (B) Project Report PDFDocument24 pagesBME (B) Project Report PDFMohul KatyalNo ratings yet

- HDPE Pipe Material SpecificationDocument7 pagesHDPE Pipe Material SpecificationEduardo Lubo100% (2)

- Materials Used in PBR ConstructionDocument8 pagesMaterials Used in PBR ConstructionLaura DsbNo ratings yet

- Publication 6Document6 pagesPublication 6Nagaraj K CNo ratings yet

- Experimental and To Evaluate Mechanical Properties of Switch Box by Using Polymer Matrix CompositeDocument16 pagesExperimental and To Evaluate Mechanical Properties of Switch Box by Using Polymer Matrix Compositek eswariNo ratings yet

- C 582 - 95 - Qzu4mi1sruqDocument8 pagesC 582 - 95 - Qzu4mi1sruqGovinda RajNo ratings yet

- Stress Analysis For GRP Piping Systems - Literature Review: JournalDocument7 pagesStress Analysis For GRP Piping Systems - Literature Review: JournalAMRUTA PATILNo ratings yet

- HDPE GuideDocument78 pagesHDPE GuideCarlos Herrera100% (1)

- SMART MATERIALS MERITSDocument6 pagesSMART MATERIALS MERITSRahul Darshan Srt100% (2)

- The Use of Reinforced Thermoplastic Pipe in Co2 Flood Enhanced Oil RecoveryDocument7 pagesThe Use of Reinforced Thermoplastic Pipe in Co2 Flood Enhanced Oil RecoveryOsama AshourNo ratings yet

- Application of Carbon-Powder-Polymer Composite Application of Carbon-Powder - Polymer CompositeDocument4 pagesApplication of Carbon-Powder-Polymer Composite Application of Carbon-Powder - Polymer Compositema08136No ratings yet

- UntitledDocument18 pagesUntitled21P410 - VARUN MNo ratings yet

- Manufacture of Composites: Submitted To - S.S GodaraDocument37 pagesManufacture of Composites: Submitted To - S.S GodaraRais Alfiansyah TaufiqNo ratings yet

- Composite Aircraft Structures - A Design Perspective - GM KamathDocument38 pagesComposite Aircraft Structures - A Design Perspective - GM KamathTarik Hassan ElsonniNo ratings yet

- Mechanical Properties of TRM Inorganic MatrixDocument36 pagesMechanical Properties of TRM Inorganic MatrixManisha ShewaleNo ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionFrom EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNo ratings yet

- 1.mohammed Alimur RezaDocument2 pages1.mohammed Alimur RezaMuthuram NNo ratings yet

- 2.asadul MD Hafijul HaqueDocument1 page2.asadul MD Hafijul HaqueMuthuram NNo ratings yet

- Grating Weight - CalculationDocument1 pageGrating Weight - CalculationMuthuram NNo ratings yet

- Bolt Torques Tightening ProcedureDocument3 pagesBolt Torques Tightening ProcedureLinhNguyenVietNo ratings yet

- TEE & ELBOW PROCESS - (ACCIONA AGUA CO. - SWCC KHOBAR PROJECT) - Rev.01 PDFDocument2 pagesTEE & ELBOW PROCESS - (ACCIONA AGUA CO. - SWCC KHOBAR PROJECT) - Rev.01 PDFMuthuram NNo ratings yet

- Astm f436 Type 1 Washers PDFDocument1 pageAstm f436 Type 1 Washers PDFMuthuram NNo ratings yet

- Difference Between Isometric and P&IdDocument3 pagesDifference Between Isometric and P&IdMuthuram NNo ratings yet

- Fabrication of Steel Pole StructuresDocument9 pagesFabrication of Steel Pole Structuresiergun80No ratings yet

- High Strength Bolt Assembly For Main SteelDocument1 pageHigh Strength Bolt Assembly For Main SteelMuthuram NNo ratings yet

- Difference Between Isometric and P&IdDocument3 pagesDifference Between Isometric and P&IdMuthuram NNo ratings yet

- Mos - PaintingDocument11 pagesMos - PaintingMuthuram NNo ratings yet

- Saep 324Document13 pagesSaep 324Hansel Francis100% (4)

- Bolt Torques Tightening ProcedureDocument3 pagesBolt Torques Tightening ProcedureLinhNguyenVietNo ratings yet

- ASTM D2992-06 Standard Practice For Obtaining Hydrostatic Pressure Design Basis For Fiberglass Pipe & Fittings PDFDocument11 pagesASTM D2992-06 Standard Practice For Obtaining Hydrostatic Pressure Design Basis For Fiberglass Pipe & Fittings PDFChengkc2014100% (1)

- Method Statement of Installation of RO PRESSURE VESSELSDocument11 pagesMethod Statement of Installation of RO PRESSURE VESSELSMuthuram N100% (1)

- Method Statement of Installation of UNDER DRAINSDocument8 pagesMethod Statement of Installation of UNDER DRAINSMuthuram NNo ratings yet

- Barcol Hardness Test - 3101Document2 pagesBarcol Hardness Test - 3101Muthuram NNo ratings yet

- Method Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1Document8 pagesMethod Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1abimanyubawonoNo ratings yet

- Idges 1973Document506 pagesIdges 1973hcabanillaspNo ratings yet

- 12 Samss 005 PDFDocument6 pages12 Samss 005 PDFfetihNo ratings yet

- Expose Anglais M DiarrassoubaDocument7 pagesExpose Anglais M DiarrassoubaBadra Ali Sanogo100% (1)

- NO. Judul Shop Drawing STATUS Diajukan Tanggal Aproval Nomor Shop DrawingDocument34 pagesNO. Judul Shop Drawing STATUS Diajukan Tanggal Aproval Nomor Shop DrawingAhmadNo ratings yet

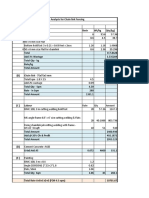

- Polavaram Bridges Project Cost AbstractDocument41 pagesPolavaram Bridges Project Cost Abstractharsha vardhanNo ratings yet

- TOP BUILDING MATERIALSDocument8 pagesTOP BUILDING MATERIALSabdulsalam alqhtaniNo ratings yet

- Heavy Duty Brick Paving Design GuideDocument48 pagesHeavy Duty Brick Paving Design Guidevprajan82No ratings yet

- Datasheet of Al Form Oil CDocument3 pagesDatasheet of Al Form Oil CSunil75% (4)

- DSR 2012 SupplementDocument59 pagesDSR 2012 SupplementNagaraju PogulakondaNo ratings yet

- IR Unified Standard Schedule of Rates 2019 Cement CoefficientsDocument11 pagesIR Unified Standard Schedule of Rates 2019 Cement CoefficientsLAXMI NARAYAN PRADHAN100% (1)

- Case Study - MineSched at SebukuDocument27 pagesCase Study - MineSched at SebukuBlank Kusuma100% (1)

- Unit - 1: General Features of Reinforced ConcreteDocument36 pagesUnit - 1: General Features of Reinforced ConcretemdaashuNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Thermal InsulationDocument14 pagesThermal Insulationannayya.chandrashekar Civil EngineerNo ratings yet

- Construction Practises of Himachal PradeshDocument11 pagesConstruction Practises of Himachal PradeshPalak JaiswalNo ratings yet

- MS of Tower Facade - 2016-05-30Document126 pagesMS of Tower Facade - 2016-05-30Nguyễn SơnNo ratings yet

- Investments made in listed equity stocks provide for better liquidityDocument4 pagesInvestments made in listed equity stocks provide for better liquidityVIJAYA KUMAR YNo ratings yet

- Rate Analysis: SL. No Labour/Material/Others Day Quatity/10m3 Rate Per Amount in RsDocument9 pagesRate Analysis: SL. No Labour/Material/Others Day Quatity/10m3 Rate Per Amount in Rsmuralidhar munireddyNo ratings yet

- Ale Aug 2021Document5 pagesAle Aug 2021RG POTES CONSTRUCTIONNo ratings yet

- 2 4 1 P Structuraldesign2015finDocument14 pages2 4 1 P Structuraldesign2015finapi-261438812100% (5)

- Masterrheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteDocument2 pagesMasterrheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteweamNo ratings yet

- Pedestal FootingDocument2 pagesPedestal FootingMarisela BurkeNo ratings yet

- Section 03 06 00-Division 03Document39 pagesSection 03 06 00-Division 03Alexander MasongsongNo ratings yet

- Expamet ConstructionDocument95 pagesExpamet Constructionanele_amisNo ratings yet

- Safe Working Loads for Props Loaded Eccentrically or ConcentricallyDocument1 pageSafe Working Loads for Props Loaded Eccentrically or Concentricallykj55No ratings yet

- Asphalt Road Reinforcement - Maccaferri MalaysiaDocument3 pagesAsphalt Road Reinforcement - Maccaferri MalaysiaLynn MailNo ratings yet

- 1 Houses of Goa PDFDocument1 page1 Houses of Goa PDFSuraj Chaturvedi100% (1)

- Making Pervious Concrete Placement Easy: Using A Novel Admixture SystemDocument5 pagesMaking Pervious Concrete Placement Easy: Using A Novel Admixture SystemCassandra Valmadrid0% (1)

- Tds - Rheofit 703Document2 pagesTds - Rheofit 703Alexi ALfred H. TagoNo ratings yet

- Concrete Silo DwgsDocument12 pagesConcrete Silo DwgsAnonymous fLgaidVBhzNo ratings yet

- WWW Architectureboard PHDocument37 pagesWWW Architectureboard PHJ. O. M. Salazar100% (1)

- Rate Analysis for 1 Sqm Chain link FencingDocument6 pagesRate Analysis for 1 Sqm Chain link Fencingsri projectssNo ratings yet