Professional Documents

Culture Documents

DC Series Installation Overview r2

Uploaded by

MIchelle SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DC Series Installation Overview r2

Uploaded by

MIchelle SmithCopyright:

Available Formats

DC Series Installation Overview r2 support@hydrogenmonkey.

com

DC Series Installation Overview

Thank you for choosing one of the most popular HHO systems available. We are continually upgrading and

improving our products and materials, so please feel free to contact us for help. Below is the order of steps to take.

1) Confirm receipt of all components against the Packing List and familiarize yourself with the name of each part.

2) Start by deciding on locations to mount the HHO generator and the water reservoir. The reservoir should be

mounted higher than the cell (or the cell can be installed lower in the car) so the water will gravity feed to the

unit and keep the electrolyte moving into the system.

3) Locate and mount the HHO generator. Trial fit the unit and then drill holes to mount it with screws.

4) Locate and mount the water reservoir. When comfortable, decide to permanently attach it to the vehicle.

Keep in mind you have about 12 feet of hose and you must use some of that to carry the HHO to the engine.

5) Route and attach the hoses. Review installation photos on your dealer's website, but it’s a good idea to allow

for three to four feet of hose from the tank to the engine connection. Confirm drain and check valve location.

6) Connect the HHO line to the air intake system. Your unit will deliver HHO to this point, and the flow of the

vehicle's air intake will pull the HHO into the combustion chamber. A general rule is to connect in front of the

throttle body and AFTER any mass air flow sensors.

7) Route and connect the electrical lines to the system. Connect your relay or solenoid to an ignition ON power

source. If you can tap into the fuel pump relay, this is the best location. This can be small gauge wire.

See diagram for electrical components including circuit breaker, relay or solenoid, service switch, amp gauge,

HHO generator and ground to the chassis. The connections on top of unit can be either order (pos or neg).

8) Mix an initial batch of electrolyte. If you are using a PWM, you can mix the solution full strength to start.

Without a PWM, start in moderation. It is easy to add more electrolyte to increase the amperage later.

Using potassium hydroxide (KOH), our general rule is to use about one (1) cup per quart, or four (4) cups per

gallon. In weight, this is about one half pound per quart, or 225 grams per liter.

You should start with these recommended amounts and check the amperage draw of the unit before adding

more electrolyte. One liter per minute of HHO production is attainable from 15 amps to 20 amps.

Note: the production of HHO from the battery at 12 volts will be much different than when the vehicle is running

and the charging system is producing from 13 to 14 volts. Also, when making any changes to your electrolyte

solution, ALWAYS drain the system, remix and then replace with the new solution. Just adding more KOH (or

more water) to the reservoir DOES NOT work.

9) Start the vehicle and test to confirm amperage, and check for leaks. Also confirm the electric current is turning

on and off with the vehicle. Review results and decide if a computer management solution is necessary.

10) Your initial break in period may generate some discoloration. If it becomes dark, feel free to drain the system

and replace with fresh mix. Refer to your dealers’ website for Frequently Asked Questions and Support.

The DC Series is installed in many vehicles around the world and provides very reliable performance.

For further information, contact your reseller, or visit us at www.HydrogenMonkey.com

Page 1

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Fuel From Water E-BookDocument20 pagesFuel From Water E-Bookperolos100% (1)

- Manual For HHO Kit For ScooterDocument6 pagesManual For HHO Kit For ScooterHHO Mart100% (5)

- High-Performance Ignition Systems: Design, Build & InstallFrom EverandHigh-Performance Ignition Systems: Design, Build & InstallRating: 4 out of 5 stars4/5 (9)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- How to Get Nigeria Passport in 40 StepsDocument42 pagesHow to Get Nigeria Passport in 40 Stepsgynn100% (1)

- Designing An Electrical Installation - Beginner GuideDocument151 pagesDesigning An Electrical Installation - Beginner GuideFrankie Wildel100% (4)

- Car PlansDocument11 pagesCar Planslaurlos100% (2)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- HHO GENERATOR 21 PLATE DRY CELL AU $200Document8 pagesHHO GENERATOR 21 PLATE DRY CELL AU $200z987456321100% (1)

- How To Make HHO Hydrogen on Demand Fuel Cell GuideDocument20 pagesHow To Make HHO Hydrogen on Demand Fuel Cell GuideWilly Ortega100% (11)

- Water FuelDocument15 pagesWater FuelThang Tong100% (1)

- EDC Pump Testing ProceduresDocument8 pagesEDC Pump Testing ProceduresCadet Raparivo100% (7)

- Didactico - Water Car Engine Plans Manual - Hydrogen Fuel - Use Tap Water (En Inglés)Document14 pagesDidactico - Water Car Engine Plans Manual - Hydrogen Fuel - Use Tap Water (En Inglés)Manuel BolonNo ratings yet

- AUS Ford Vehicle Communication Software ManualDocument112 pagesAUS Ford Vehicle Communication Software ManualMIchelle SmithNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Steering Gear Selection and Installation GuideDocument37 pagesSteering Gear Selection and Installation GuideJorgelino ParkerNo ratings yet

- 6F35 - 6F55 Installation Guide: Read This Entire Document Before Installing Your TransmissionDocument8 pages6F35 - 6F55 Installation Guide: Read This Entire Document Before Installing Your TransmissionPedro Isai Vega100% (2)

- How To Build An EV Car - ZadikDocument21 pagesHow To Build An EV Car - Zadikadolfoc261100% (1)

- HHO Book - John NeimannDocument41 pagesHHO Book - John Neimannmolera0000No ratings yet

- Waterfuel: Introduction & OverviewDocument27 pagesWaterfuel: Introduction & Overviewtbang458928No ratings yet

- Financial Market and Portfolio Management Assignment 2Document6 pagesFinancial Market and Portfolio Management Assignment 2leeroy mekiNo ratings yet

- LL Baby Carrier Corner Drool Pads TutorialDocument9 pagesLL Baby Carrier Corner Drool Pads TutorialBryan DerryNo ratings yet

- Citizen Instruction Manual E870 PDFDocument28 pagesCitizen Instruction Manual E870 PDFMIchelle SmithNo ratings yet

- Igt - Boot Os List Rev B 10-28-2015Document5 pagesIgt - Boot Os List Rev B 10-28-2015Hector VillarrealNo ratings yet

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Monarch Repair ManualDocument21 pagesMonarch Repair ManualZeck0% (1)

- Alternador Delco Remy Installation Instructions 24si 28siDocument6 pagesAlternador Delco Remy Installation Instructions 24si 28sijorge_chaparro_1No ratings yet

- Data Science Machine LearningDocument15 pagesData Science Machine LearningmagrinraphaelNo ratings yet

- Proposed Construction of New Kutulo Airstrip - RetenderDocument112 pagesProposed Construction of New Kutulo Airstrip - RetenderKenyaAirportsNo ratings yet

- Harvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsFrom EverandHarvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsNo ratings yet

- Electrical Power System Design For Industrial FacilitiesDocument29 pagesElectrical Power System Design For Industrial Facilitiesgusgon521292100% (1)

- CircuPool Salt Manual Si - Plus - 20150516Document32 pagesCircuPool Salt Manual Si - Plus - 20150516Salsa_Picante_Baby100% (1)

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Laude vs. Ginez-Jabalde (MCLE)Document29 pagesLaude vs. Ginez-Jabalde (MCLE)Justin CebrianNo ratings yet

- Zero Energy Swimming Pool System Using Solar PowerDocument16 pagesZero Energy Swimming Pool System Using Solar PowerMelissa RadoveckiNo ratings yet

- Draft Horse Primer Guide To Care Use of Work Horses and Mules 1977Document396 pagesDraft Horse Primer Guide To Care Use of Work Horses and Mules 1977Radu IliescuNo ratings yet

- Dry Fuel Cell ManualDocument27 pagesDry Fuel Cell ManualMaiman LatoNo ratings yet

- Design Guide For Slug Force Calculation ProcedureDocument6 pagesDesign Guide For Slug Force Calculation ProcedurePratik PatreNo ratings yet

- HHO Kit Installation Manual For 2 WheelerDocument7 pagesHHO Kit Installation Manual For 2 WheelerHho MartNo ratings yet

- Install Hydrogen Generator for Diesel CarsDocument0 pagesInstall Hydrogen Generator for Diesel CarsAlejandro Valera MarinNo ratings yet

- Hhoinstructions 3Document5 pagesHhoinstructions 3Stoicescu CristianNo ratings yet

- Walbro 255lph InstallationDocument6 pagesWalbro 255lph InstallationAaron BessonNo ratings yet

- Hho ManualDocument23 pagesHho ManualtononoinkNo ratings yet

- Dry Cell Installation ManualDocument13 pagesDry Cell Installation ManualHho MartNo ratings yet

- Let'S Get Familiar With Your New H.O.G. Fuel Cell InstallationDocument4 pagesLet'S Get Familiar With Your New H.O.G. Fuel Cell Installationgabriela69sNo ratings yet

- Attention: 6R140 Installation GuideDocument4 pagesAttention: 6R140 Installation GuideAlex Maceira GraterolNo ratings yet

- User Manual for Power Units and Hydraulic SystemsDocument24 pagesUser Manual for Power Units and Hydraulic SystemsAli AliNo ratings yet

- The Ideal Power Steering InstallationDocument4 pagesThe Ideal Power Steering InstallationFordiNo ratings yet

- Installation Guide for Boosting Your Vehicle with HydroxyDocument4 pagesInstallation Guide for Boosting Your Vehicle with HydroxyMitesh PhalakNo ratings yet

- Installation Instructions 30-3000Document12 pagesInstallation Instructions 30-3000Toni RodriguezNo ratings yet

- 183 2610 0revaDocument5 pages183 2610 0revamarranNo ratings yet

- Amsoil Automatic Transmission Flush ProcedureDocument2 pagesAmsoil Automatic Transmission Flush ProcedureThomas JohnsonNo ratings yet

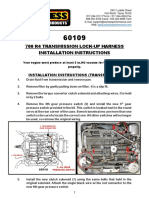

- 700 R4 Transmission Lock-Up Harness Installation InstructionsDocument4 pages700 R4 Transmission Lock-Up Harness Installation InstructionsWillem DuijsNo ratings yet

- Deutsche Hydra Pro Superior Braking PowerDocument21 pagesDeutsche Hydra Pro Superior Braking PowerHydra ProNo ratings yet

- Controller Operating Instructions 16442Document4 pagesController Operating Instructions 16442Abdo RsvNo ratings yet

- 211-00 General InfoDocument8 pages211-00 General InfoMiguel AngelNo ratings yet

- Enginer PHEV User Manual Generation 1 PriusDocument14 pagesEnginer PHEV User Manual Generation 1 Priusmiksi7906No ratings yet

- Literature Review Hydraulic SystemDocument5 pagesLiterature Review Hydraulic Systemafdtfgkbv100% (1)

- PHEV Conversion Kit Manual for 2010 PriusDocument16 pagesPHEV Conversion Kit Manual for 2010 PriusPootey ReinaresNo ratings yet

- PHEV User Manual for Gen 3 PriusDocument16 pagesPHEV User Manual for Gen 3 PriusCosminNo ratings yet

- Weber Carb Troubleshooting GuideDocument8 pagesWeber Carb Troubleshooting GuideRyan Hadi WicaksonoNo ratings yet

- Marine Steering Gear Installation and Selection GuideDocument37 pagesMarine Steering Gear Installation and Selection GuideHaris StavrouNo ratings yet

- 12V Water PumpDocument11 pages12V Water PumpOrganic MechanicNo ratings yet

- DUI INstall Manual 232ci - 6516-3Document2 pagesDUI INstall Manual 232ci - 6516-3EdwinNo ratings yet

- How To Change Power Steering Fluid On A Car - Replacement TutorialDocument7 pagesHow To Change Power Steering Fluid On A Car - Replacement TutorialvefarkasNo ratings yet

- Weber Carb Troubleshooting GuideDocument8 pagesWeber Carb Troubleshooting Guideleechyza100% (1)

- Dry Fuel Cell ManualDocument24 pagesDry Fuel Cell ManualniculaenicuNo ratings yet

- Smith LovelessDocument24 pagesSmith Lovelesstn7625No ratings yet

- 6700XTR Service ManualDocument40 pages6700XTR Service Manualfuck offNo ratings yet

- Ashish Jivanbhai Zalavadiya Pleads Guilty To Messenger Northern Adelaide Australia November 2 2020Document2 pagesAshish Jivanbhai Zalavadiya Pleads Guilty To Messenger Northern Adelaide Australia November 2 2020MIchelle SmithNo ratings yet

- Fir 594 Yash Dhana AhirDocument4 pagesFir 594 Yash Dhana AhirMIchelle SmithNo ratings yet

- KSG 5K DM3 Installation Manual PDFDocument2 pagesKSG 5K DM3 Installation Manual PDFMIchelle SmithNo ratings yet

- ABG Shipyard Limited-16419Document186 pagesABG Shipyard Limited-16419MIchelle SmithNo ratings yet

- BL 8503e InstructionsDocument2 pagesBL 8503e InstructionsMIchelle SmithNo ratings yet

- Enhanced Features and Function GuideDocument18 pagesEnhanced Features and Function GuideMIchelle SmithNo ratings yet

- BL 8503e InstructionsDocument2 pagesBL 8503e InstructionsMIchelle SmithNo ratings yet

- Adult gliomas guide for patientsDocument123 pagesAdult gliomas guide for patientsWidya WidyariniNo ratings yet

- Rights Under Inheritance and Succession Laws and Rights Relating To Marriage and Property in IndiaDocument18 pagesRights Under Inheritance and Succession Laws and Rights Relating To Marriage and Property in IndiaMIchelle SmithNo ratings yet

- About The Project Presentation by ILFSDocument26 pagesAbout The Project Presentation by ILFSMIchelle SmithNo ratings yet

- Harvard Referencing Guide Unisa: Developed by Learning Advisers and Librarians © Unisa, January 2017Document37 pagesHarvard Referencing Guide Unisa: Developed by Learning Advisers and Librarians © Unisa, January 2017spookywack4883No ratings yet

- Medication Management Plan ReviewDocument1 pageMedication Management Plan ReviewMIchelle SmithNo ratings yet

- Current evidence for medicinal cannabisDocument10 pagesCurrent evidence for medicinal cannabisMIchelle SmithNo ratings yet

- Dilution Conc and Alligation 15Document8 pagesDilution Conc and Alligation 15pmilyNo ratings yet

- ADSL Internet Broadband ISP - ADSL2 ADSL2+ Naked DSL Mobile VoIPDocument1 pageADSL Internet Broadband ISP - ADSL2 ADSL2+ Naked DSL Mobile VoIPMIchelle SmithNo ratings yet

- 0 - Theories of MotivationDocument5 pages0 - Theories of Motivationswathi krishnaNo ratings yet

- Hangup Cause Code Table: AboutDocument5 pagesHangup Cause Code Table: Aboutwhatver johnsonNo ratings yet

- 19286711Document8 pages19286711suruth242100% (1)

- Mr. Arshad Nazer: Bawshar, Sultanate of OmanDocument2 pagesMr. Arshad Nazer: Bawshar, Sultanate of OmanTop GNo ratings yet

- Validate Internet Backbone Routing and SwitchingDocument27 pagesValidate Internet Backbone Routing and SwitchingThành Trung NguyễnNo ratings yet

- DB51 BTP 160 8PDocument1 pageDB51 BTP 160 8Pnagaraj.ss@quest-global.comNo ratings yet

- Block P2P Traffic with pfSense using Suricata IPSDocument6 pagesBlock P2P Traffic with pfSense using Suricata IPSEder Luiz Alves PintoNo ratings yet

- CANDIDATE'S BIO DATADocument2 pagesCANDIDATE'S BIO DATAAamir ArainNo ratings yet

- Online Job Interviews For International Careers: Business MeetingDocument8 pagesOnline Job Interviews For International Careers: Business Meetingintercultural_c2593No ratings yet

- Wireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossDocument5 pagesWireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossN Azzati LabibahNo ratings yet

- Đề Số 1 - Đề Phát Triển Đề Minh Họa 2023Document20 pagesĐề Số 1 - Đề Phát Triển Đề Minh Họa 2023Maru KoNo ratings yet

- PM on Union BudgetDocument84 pagesPM on Union BudgetAshok SutharNo ratings yet

- Section 2 in The Forest (Conservation) Act, 1980Document1 pageSection 2 in The Forest (Conservation) Act, 1980amit singhNo ratings yet

- Chpter 06 QuizDocument3 pagesChpter 06 QuizGall AnonimNo ratings yet

- ISB - PM - Week 4 - Required Assignment 4.2 - TemplateDocument2 pagesISB - PM - Week 4 - Required Assignment 4.2 - Templatesriram marinNo ratings yet

- Customer Channel Migration in Omnichannel RetailingDocument80 pagesCustomer Channel Migration in Omnichannel RetailingAlberto Martín JiménezNo ratings yet

- Reconciling Informal and Formal TradeDocument194 pagesReconciling Informal and Formal TradeBaterias BateriasNo ratings yet

- Create Email Alerts For Mulitple People or Group - XpoDocument79 pagesCreate Email Alerts For Mulitple People or Group - XponiravmodyNo ratings yet

- Piroxicam (Wikipedia)Document4 pagesPiroxicam (Wikipedia)Adrian ArnasaputraNo ratings yet