Professional Documents

Culture Documents

Sikasil SG-18: Structural Silicone Adhesive

Uploaded by

Mochamad Ardie Noegroho0 ratings0% found this document useful (0 votes)

38 views2 pagesSealent

Original Title

Sikasil

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSealent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views2 pagesSikasil SG-18: Structural Silicone Adhesive

Uploaded by

Mochamad Ardie NoegrohoSealent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Product Data Sheet

Version 1 (07 / 2009)

Sikasil® SG-18

Structural silicone adhesive

Technical Product Data

Chemical base 1-C silicone

1

Colour (CQP 001-1) Black

Cure mechanism Moisture-curing

Cure type Neutral

Density (uncured) (CQP 006-4) 1.48 kg/l approx.

Non-sag properties (CQP 061-4 / ISO 7390) < 2 mm approx.

Application temperature 5 – 40°C (40 - 105°F)

Skin time2 (CQP 019-2) 30 min approx.

2

Tack-free time (CQP 019-1) 90 min approx.

Curing speed (CQP 049-1) See diagram 1

Shore A-hardness (CQP 023-1 / ISO 868) 44 approx.

2

Tensile strength (CQP 036-1 / ISO 37) 1.8 N/mm approx.

Elongation at break (CQP 036-1 / ISO 37) 350% approx.

Tear propagation resistance (CQP 045-1 / ISO 34) 6 N/mm approx.

100% modulus (CQP 036-1 / ISO 37) 1.1 N/mm2 approx.

Movement accommodation capability (ASTM C 719) ± 12.5%

Thermal resistance (CQP 513-1) long term 180°C (356°F) approx.

Short term 4 hour 220°C (430°F) approx.

1 hour 250°C (480°F) approx.

-40 - 150°C approx.

Service temperature

(-40 - 300°F)

2

16 g H2O/m ·24 h·2

Moisture vapor transmission rate (CQP 520-2 / ISO 12572)

mm approx.

Shelf life (storage below 25°C) (CQP 016-1) Cartrid ge/Pail 12 months

Unipack 15 months

1) 2)

CQP = Corporate Quality Procedure 23°C (73°F) / 50% r.h.

Description Product Benefits Areas of Application

® ®

Sikasil SG-18 is a neutral-curing - Meets requirements of EOTA Sikasil SG-18 can be used as

silicone adhesive with excellent ETAG 002, EN 13022 and ASTM structural glazing adhesive and for

adhesion to a wide range of sub- C 1184 other bonding applications where

strates. - Outstanding UV and weathering superior resistance to UV radiation,

®

Sikasil SG-18 is manufactured in resistance high temperatures and weathering

accordance with ISO 9001 / 14001 - Bonds well to glass, metals and is required.

quality assurance system and the coated metals This product is suitable for profes-

responsible care program. sional experienced users only.

Test with original substrates and

conditions have to be performed to

ensure adhesion and material

compatibility.

Sikasil® SG-18 1 / 2

Cure Mechanism The above information is offered Further Information

® for general guidance only. Advice

Sikasil SG-18 cures by reaction Copies of the following publications

with atmospheric moisture. The on specific applications will be are available on request:

reaction thus starts at the surface given on request. - Material Safety Data Sheets

and proceeds to the core of the - General Guidelines “Structural

®

joint. The curing speed depends on Method of Application Silicone Glazing with Sikasil

the relative humidity and the tem- Surface preparation Adhesives”

perature (see diagram 1 below). Surfaces must be clean, dry and

Heating above 50°C to speed-up free from oil, grease and dust. Packaging Information

the vulcanization is not advisable Advice on specific applications and Cartridge 300 ml

as it may lead to bubble formation. surface pretreatment methods is

available from the Technical Ser- Unipack 600 ml

At low temperatures the water

content of the air is lower and the vice Department of Sika Industry. Pail 26 kg

curing process proceeds more

Application

slowly. Value Bases

After suitable joint and substrate

All technical data stated in this

10 preparation, Sikasil® SG-18 is

50°C 35°C 23°C Product Data Sheet are based on

gunned into place. Joints must be

Curing speed [mm]

8 laboratory tests. Actual measured

properly dimensioned as changes

data may vary due to circumstan-

6

8°C are no longer possible after con-

ces beyond our control.

struction. Basis for calculation of

4 the necessary joint dimensions are

50°C / 95% r.h.

35°C / 90% r.h. the technical values of the adhe- Health and Safety Information

2 23°C / 50% r.h. For information and advice re-

8°C / 30% r.h.

sive and the adjacent building

0 materials, the exposure of the garding transportation, handling,

0 2 4 6 8 10 storage and disposal of chemical

Time [days] building elements, their construc-

tion and size as well as external products, users shall refer to the

Diagram 1: Curing speed 1-C-Sikasil® actual Material Safety Data Sheets

loads. Joints deeper than 15 mm

should be avoided. containing physical, ecological,

Application Limits For more information please con- toxicological and other safety-

®

Most Sikasil WS, FS, SG, IG, WT, tact the Technical Service Depart- related data.

AS and other engineering silicone ment of Sika Industry.

sealants manufactured by Sika are Legal Notes

compatible with each other and Tooling and finishing The information, and, in particular, the

®

with SikaGlaze IG sealants. For Tooling and finishing must be recommendations relating to the appli-

specific information regarding carried out within the skin time of cation and end-use of Sika products,

compatibility between various are given in good faith based on Sika's

the sealant or adhesive.

Sikasil® and SikaGlaze® products current knowledge and experience of

When tooling freshly applied the products when properly stored,

please contact the Technical ®

Sikasil SG-18 press the adhesive handled and applied under normal

Service Department of Sika to the joint flanks to get a good conditions in accordance with Sika's

Industry. All other sealants have to wetting of the bonding surface. No recommendations. In practice, the

be approved by Sika before using tooling agents may be used. differences in materials, substrates and

them in combination with Sikasil® actual site conditions are such that no

SG-18. Where two or more Removal warranty in respect of merchantability

different reactive sealants are Uncured Sikasil® SG-18 may be or of fitness for a particular purpose,

used, allow the first to cure removed from tools and equipment nor any liability arising out of any legal

® relationship whatsoever, can be in-

completely before applying the with Sika Remover-208 or an-

other suitable solvent. Once cured, ferred either from this information, or

next. from any written recommendations, or

Sikasil® SG, IG and WT sealants the material can only be removed from any other advice offered. The user

and adhesives may only be used in mechanically. of the product must test the product’s

structural glazing or window bond- Hands and exposed skin should be suitability for the intended application

®

ing applications by experienced washed immediately using Sika and purpose. Sika reserves the right to

professionals and after a detailed Handclean towels or a suitable change the properties of its products.

examination and written approval industrial hand cleaner and water. The proprietary rights of third parties

Do not use solvents! must be observed. All orders are ac-

of the corresponding project details

cepted subject to our current terms of

by the Technical Service Depart- Overpainting sale and delivery. Users must always

ment of Sika Industry. ®

Sikasil SG-18 is an elastic adhe- refer to the most recent issue of the

The compatibility of gaskets, sive and cannot be overpainted. local Product Data Sheet for the pro-

backer rods, setting blocks and duct concerned, copies of which will be

other accessory materials with supplied on request.

Sikasil® SG-18 must be tested in

advance.

Sikasil® SG-18 2 / 2

Further information available at:

www.sika.co.id

PT. Sika Indonesia, Jl. Raya Cibinong-Bekasi Km.20,

Limusnunggal, Cileungsi, Bogor - Indonesia

Tel: +62 21 8230025, Fax: +62 21 8230026

You might also like

- TDS Sikasil SG-18 Structural SealantDocument2 pagesTDS Sikasil SG-18 Structural SealantTuấn Anh NguyễnNo ratings yet

- Sikaflex - Auto: One Component Polyurethane Sealant Exclusively For CBRDocument2 pagesSikaflex - Auto: One Component Polyurethane Sealant Exclusively For CBRDavid SudarmaNo ratings yet

- Sikaflex - 252: Structural AdhesiveDocument3 pagesSikaflex - 252: Structural AdhesiveRicusNo ratings yet

- Sil SG-500Document2 pagesSil SG-500Inggrid P.ChristyNo ratings yet

- Sikasil AS-60: Industrial Assembly Sealant & AdhesiveDocument2 pagesSikasil AS-60: Industrial Assembly Sealant & AdhesivedushyantbbaisNo ratings yet

- Sikatack Panel: Panel Adhesive For Ventilated FaçadesDocument2 pagesSikatack Panel: Panel Adhesive For Ventilated FaçadeselpibematadorNo ratings yet

- Sikaflex-260 N eDocument2 pagesSikaflex-260 N eTrung Trinh BaoNo ratings yet

- Pds Sikasil As-770 eDocument2 pagesPds Sikasil As-770 eArdiansyah ARNo ratings yet

- Sikaflex - 552 AT: High-Performance Assembly AdhesiveDocument2 pagesSikaflex - 552 AT: High-Performance Assembly AdhesiveRicusNo ratings yet

- Sika Tack Go4it En12-20171Document2 pagesSika Tack Go4it En12-20171victorNo ratings yet

- SIK3287 Sikaflex 221 TDSDocument2 pagesSIK3287 Sikaflex 221 TDSardabiliNo ratings yet

- SF 254 Booster GBDocument2 pagesSF 254 Booster GBmilanbrasinaNo ratings yet

- Sikasil SG-500: High Performance Structural Silicone AdhesiveDocument2 pagesSikasil SG-500: High Performance Structural Silicone Adhesivethe enverNo ratings yet

- Sikaflex - 521 UV: Excellent Adherent, Weathering Resistant SealantDocument2 pagesSikaflex - 521 UV: Excellent Adherent, Weathering Resistant SealantMuruga SriNo ratings yet

- Sikafast 5211 PdsDocument2 pagesSikafast 5211 PdskonstruksiNo ratings yet

- Pds Sikasil Gasket Black e 06-14Document2 pagesPds Sikasil Gasket Black e 06-14Roger SchvepperNo ratings yet

- Sikaflex p2gDocument2 pagesSikaflex p2goscarjcoNo ratings yet

- PDS SikaForce-7818 L7 e 2013Document2 pagesPDS SikaForce-7818 L7 e 2013FBNo ratings yet

- Fast-5211 NT PdsDocument2 pagesFast-5211 NT PdsGino TironiNo ratings yet

- Sikaflex 256Document2 pagesSikaflex 256aboali8686No ratings yet

- Sikasil RTV Gasket PdsDocument2 pagesSikasil RTV Gasket PdsAhmad Ikhsan KurniantoNo ratings yet

- Sikaflex - 521 UV: Excellent Adherent, Weathering Resistant SealantDocument2 pagesSikaflex - 521 UV: Excellent Adherent, Weathering Resistant SealantmilanbrasinaNo ratings yet

- Sikaflex - 252Document2 pagesSikaflex - 252oddo_mneNo ratings yet

- Sikasil® IG-25 HM Plus: Product Data SheetDocument2 pagesSikasil® IG-25 HM Plus: Product Data SheetKhin Sandi KoNo ratings yet

- Sikamelt 700Document2 pagesSikamelt 700Ionut StoicaNo ratings yet

- PDS SikaPower-492 EnglishDocument2 pagesPDS SikaPower-492 EnglishpetkoNo ratings yet

- Sikaflex - 223Document2 pagesSikaflex - 223Ahmad HavidNo ratings yet

- Sikaflex - 221Document2 pagesSikaflex - 221ESTRELLA MaricelNo ratings yet

- Sikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementDocument2 pagesSikaflex - 256: The Primerless Windscreen Adhesive System For Direct Glazing in Automotive Glass ReplacementAlper GmNo ratings yet

- Sikasil Ig 25Document2 pagesSikasil Ig 25Amjad AlQasrawiNo ratings yet

- Sikaflex®-221: Product Data SheetDocument2 pagesSikaflex®-221: Product Data SheetNurdin YusupNo ratings yet

- PDS SikaTherm 4225 eDocument2 pagesPDS SikaTherm 4225 eMarian ComaniciNo ratings yet

- Interzinc 22Document4 pagesInterzinc 22dexterisNo ratings yet

- Sikaflex-291 - PDSDocument2 pagesSikaflex-291 - PDSRade PesteracNo ratings yet

- Resist 86: Technical Data SheetDocument5 pagesResist 86: Technical Data SheetantonyfmNo ratings yet

- Sikafast®-555 L05: Product Data SheetDocument2 pagesSikafast®-555 L05: Product Data SheetAbhi LashNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Sikaflex 255 UltraDocument2 pagesSikaflex 255 UltraVictor GladunNo ratings yet

- Astar 02Document5 pagesAstar 02HAKANNo ratings yet

- Sikaflex - 221Document2 pagesSikaflex - 221MarhendraNo ratings yet

- Resist 65: Technical Data SheetDocument5 pagesResist 65: Technical Data Sheetchristian210789No ratings yet

- Technical Data Sheet SummaryDocument6 pagesTechnical Data Sheet SummaryshahoorhussainNo ratings yet

- Sikaflex - 292iDocument2 pagesSikaflex - 292iLin LinNo ratings yet

- Sikatack Drive 60minDocument2 pagesSikatack Drive 60minVictor GladunNo ratings yet

- Sikacryl® 620 Fire - PDSDocument3 pagesSikacryl® 620 Fire - PDSMuhammad YasirNo ratings yet

- Thwi Tds (JK r2 0315) EnglishDocument2 pagesThwi Tds (JK r2 0315) EnglishMasood KhanNo ratings yet

- Durafide 6165A6 TDSDocument6 pagesDurafide 6165A6 TDSCassianNo ratings yet

- Sikaflex - 221Document2 pagesSikaflex - 221Abdul Wahid PaperwalaNo ratings yet

- Sikatack PanelDocument2 pagesSikatack PanelFrancsico MeloNo ratings yet

- Loctite 384Document2 pagesLoctite 384A DamiánNo ratings yet

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- SikaMelt 9670Document2 pagesSikaMelt 9670Gicuţă Şi Geta ZvîncăNo ratings yet

- TDS Stainless Steel Paint Jotamastic 70Document5 pagesTDS Stainless Steel Paint Jotamastic 70rndsb.aopNo ratings yet

- Muki Z 2001: Technical Data SheetDocument5 pagesMuki Z 2001: Technical Data SheetIan PerdanaNo ratings yet

- Natural Rubber Lining: Technical Data SheetDocument2 pagesNatural Rubber Lining: Technical Data SheetJaveed KhanNo ratings yet

- Pds Sikaflex-265 Uk v01-07Document2 pagesPds Sikaflex-265 Uk v01-07Tomas MoralesNo ratings yet

- Jotatemp 1000 CeramicDocument5 pagesJotatemp 1000 CeramicBiju_PottayilNo ratings yet

- Sika TS Plus PDFDocument4 pagesSika TS Plus PDFPhuc AnNo ratings yet

- Sikadur 31 CF NormalDocument6 pagesSikadur 31 CF NormalMochamad Ardie NoegrohoNo ratings yet

- Plastiment® VZ: 产品数据表 (Product Data Sheet)Document3 pagesPlastiment® VZ: 产品数据表 (Product Data Sheet)Mochamad Ardie NoegrohoNo ratings yet

- Antisol® S: 产品数据表 (Product Data Sheet)Document2 pagesAntisol® S: 产品数据表 (Product Data Sheet)Mochamad Ardie NoegrohoNo ratings yet

- Antisol E 125-MandarinDocument3 pagesAntisol E 125-MandarinMochamad Ardie NoegrohoNo ratings yet

- Plastocrete RT 6 Plus-MandarinDocument3 pagesPlastocrete RT 6 Plus-MandarinMochamad Ardie NoegrohoNo ratings yet

- SikaBond NV-mandarin PDFDocument1 pageSikaBond NV-mandarin PDFMochamad Ardie NoegrohoNo ratings yet

- Sika Viscocrete 8007Document3 pagesSika Viscocrete 8007Muhammad Haris MustofaNo ratings yet

- Hadighi AliDocument66 pagesHadighi AliMousaNo ratings yet

- Better Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production KDocument10 pagesBetter Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production Kani putkaradzeNo ratings yet

- Homework 3 data analysis and interpretationDocument111 pagesHomework 3 data analysis and interpretationFebriNo ratings yet

- Mas and e PDFDocument5 pagesMas and e PDFtulasi saladiNo ratings yet

- Sesame ProteinDocument10 pagesSesame ProteinJulius BudiNo ratings yet

- SJPO General Round 2010 PDFDocument19 pagesSJPO General Round 2010 PDFziwei_from_chinaNo ratings yet

- Organic Reducing Agents ListDocument10 pagesOrganic Reducing Agents ListJatin BhasinNo ratings yet

- Elastomers: Dr. Dmitri KopeliovichDocument10 pagesElastomers: Dr. Dmitri KopeliovichBara Giat PrakarsaNo ratings yet

- AC Transformer LectureDocument4 pagesAC Transformer LectureDE VERA, KENNETH GABRIEL D.No ratings yet

- Introduction to MEMS Etching TechniquesDocument16 pagesIntroduction to MEMS Etching TechniquesArjit GoswamiNo ratings yet

- LPG PropertiesDocument2 pagesLPG Propertiesvvk557No ratings yet

- Test Questions in Engineering MechanicsDocument2 pagesTest Questions in Engineering Mechanicsbasanth babuNo ratings yet

- CemCRETE Internal Presentation Apr 2004Document42 pagesCemCRETE Internal Presentation Apr 2004Muhammad ImranNo ratings yet

- Cover Page: Liquids and SolidsDocument20 pagesCover Page: Liquids and SolidsCHELSEA NEUMANNNo ratings yet

- Nature of Adherence of Porcelain Enamels To MetalsDocument22 pagesNature of Adherence of Porcelain Enamels To MetalsFernando BarreraNo ratings yet

- Math3104 Part1 2023 Lecture2 SlidesDocument23 pagesMath3104 Part1 2023 Lecture2 SlidesWriter CourseNo ratings yet

- Performance Testing of An Inline Electrocoalescer Device With Medium and Heavy CrudesDocument10 pagesPerformance Testing of An Inline Electrocoalescer Device With Medium and Heavy CrudesAlvaro Andres Blanco GomezNo ratings yet

- What Is Pyrophoric Iron OxidationDocument9 pagesWhat Is Pyrophoric Iron OxidationGhuna Uciha100% (1)

- Eges485 DTCDocument9 pagesEges485 DTCeng_hamada_4uNo ratings yet

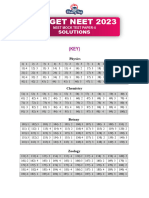

- Mock Test 4 Paper Neet SolDocument16 pagesMock Test 4 Paper Neet Solspamhater566No ratings yet

- Blood Brain BarrierDocument25 pagesBlood Brain BarrierAdlai PappyNo ratings yet

- Networking Newsletter by SlidesgoDocument38 pagesNetworking Newsletter by SlidesgoHenrique AlvesNo ratings yet

- Copernican PrincipleDocument7 pagesCopernican Principlemaddy555No ratings yet

- 2.0 Electric FieldsDocument4 pages2.0 Electric FieldsEdAnNo ratings yet

- Cementation in Fixed Partial Denture - 01Document28 pagesCementation in Fixed Partial Denture - 01Akshay GajakoshNo ratings yet

- Circulation Rates in Thermosiphon ReboilerDocument7 pagesCirculation Rates in Thermosiphon ReboilersNo ratings yet

- Laboratory Exercise No. 1 AggregatesDocument11 pagesLaboratory Exercise No. 1 AggregatesHaha HahahahNo ratings yet

- Mineral Physics ModuleDocument17 pagesMineral Physics ModuleDanielle CardiñoNo ratings yet

- Sensors 3Document59 pagesSensors 3zubairawNo ratings yet

- Colorimetry 1Document23 pagesColorimetry 1Denise CssNo ratings yet