Professional Documents

Culture Documents

OSHA Leading Indicators PDF

Uploaded by

sentra transformaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OSHA Leading Indicators PDF

Uploaded by

sentra transformaCopyright:

Available Formats

Management Leadership

Using Leading Indicators

to Improve Safety and Health Outcomes

Worker Participation

Find and Fix Hazards

Occupational Safety

and Health Administration

www.osha.gov/shpguidelines

OSHA 3970 June 2019

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) i

CONTENTS

SECTION 1. INTRODUCTION TO LEADING INDICATORS ................................................................................2

1.1 What Are Leading Indicators?....................................................................................................................................2

1.2 The Benefts of Using Leading Indica tors...................................................................................................................2

1.3 Characteristics of Effective Leading Indicators .........................................................................................................2

SECTION 2. USING LEADING INDICATORS ....................................................................................................4

2.1 Leading Indicators Based on Data You Are Already Collecting ....................................................................................5

EXAMPLE: Percentage of Workers Attending Safety Refresher Training ......................................................................5

2.2 Leading Indicators for Controlling an Identifed Hazard ..............................................................................................6

EXAMPLE: Inspection and Clearing of Walkways .......................................................................................................6

EXAMPLE: Truck Brake Replacement ........................................................................................................................7

EXAMPLE: Arrival Time of Lift Teams .........................................................................................................................9

2.3 Leading Indicators to Improve an Element of Your Safety and Health Program .........................................................10

2.3.1 Management Leadership ...............................................................................................................................10

2.3.2 Worker Participation ......................................................................................................................................11

2.3.3 Hazard Identifca tion and Assessment............................................................................................................11

2.3.4 Hazard Prevention and Control.......................................................................................................................12

2.3.5 Education and Training ..................................................................................................................................12

2.3.6 Program Evaluation and Improvement ...........................................................................................................13

2.3.7 Communication and Coordination ..................................................................................................................13

2.3.8 EXAMPLES: Using Leading Indicators to Improve a Safety and Health Program Element .................................14

SECTION 3. CONCLUSION ..........................................................................................................................17

ACTION PLAN CHECKLIST ..........................................................................................................................17

This document is not a standard or regulation, and it creates no new legal obligations. It lacks the force and effect of law, except

as authorized by law or as incorporated into a contract. The recommendations are advisory in nature, informational in content, and

are intended to assist employers in providing a safe and healthful workplace. Material contained in this publication is in the public

domain and may be reproduced, fully or partially, without permission. Source credit is requested but not required.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 1

Employers are encouraged to use this document to learn not know what they are or how to use them. This document

how they can use leading indicators to improve safety and can help such businesses get started. This document may

health outcomes in the workplace. While large businesses also be useful to large businesses seeking new approaches

may already be familiar with the benef ts of using leading to using leading indicators.

indicators, many small and medium-sized businesses may

SECTION 1. INTRODUCTION TO LEADING INDICATORS

1.1 What Are Leading Indicators? In addition to the social benef ts, employers that use leading

For purposes of this document, leading indicators are proactive, indicators to f nd and f x hazards can realize direct savings

preventive, and predictive measures that provide information to their bottom line. These include savings in repair costs,

about the effective performance of your safety and health production costs, workers’ compensation costs, and other

activities. They measure events leading up to injuries, illnesses, legal and regulatory costs that are commonly associated

and other incidents and reveal potential problems in your safety with incidents. For example, by f xing hazards that lead

and health program. In contrast, lagging indicators measure the to roadblocks in production, employers may be able to

occurrence and frequency of events that occurred in the past, complete daily tasks more eff ciently and reduce production

such as the number or rate of injuries, illnesses, and fatalities. costs related to those activities.

While lagging indicators can alert you to a failure in an area

“Today, EHS practitioners continue to rely on

of your safety and health program or to the existence of a

injury rates, absenteeism, and other lagging

hazard, leading indicators allow you to take preventive action

metrics despite the growing acceptance of

to address that failure or hazard before it turns into an incident.

the fact that these failure-focused measures

A good program uses leading indicators to drive change and

are ineffective in driving continuous

lagging indicators to measure effectiveness.

improvement efforts. Leading indicators,

For example, one good leading indicator might be the amount on the other hand, appear to offer a more

of time it takes to respond to a safety hazard report. A useful gauge of EHS activity by providing

decrease in the response time may demonstrate an increased early warning signs of potential failure and,

awareness in safety and managers’ commitment to workplace thus, enabling organizations to identify and

safety. Conversely, an increase in response time could signal a correct defciencies before they mature into

lack of management concern, which could mean that hazards accidents and injuries.”

are likely to remain uncontrolled, and incidents are more likely — Campbell Institute, Transforming EHS Performance

to occur. Furthermore, workers may decide to discontinue Measurement Through Leading Indicators

reporting hazards if they feel that management is not being

responsive to their concerns. This can affect morale, which

could have broad implications for the workplace. 1.3 Characteristics of Effective Leading

Indicators

1.2 The Benefts of Using Leading Indicators Good leading indicators are based on SMART principles,

Leading indicators can play a vital role in preventing worker meaning they are Specif c, Measurable, Accountable,

fatalities, injuries, and illnesses, as well as strengthening Reasonable, and Timely:

safety and health outcomes in the workplace. Employers that

use leading indicators as a tool for achieving these goals have • Specifc: Does your leading indicator provide specif cs

a substantial advantage over their competitors. By taking for the action that you will take to minimize risk from a

deliberate and measured actions that can prevent fatalities, hazard or improve a program area?

injuries, and illnesses, these employers demonstrate their

• Measurable: Is your leading indicator presented as a

commitment to maintaining a socially responsible workplace

number, rate, or percentage that allows you to track

that values workers. By strengthening key elements of their

and evaluate clear trends over time?

safety and health programs, they also can improve their

overall organizational performance.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 2

• Accountable: Does your leading indicator track an item The chart below demonstrates how to create a SMART

that is relevant to your goal? leading indicator to address the issue that workers have not

been attending monthly safety meetings. It walks through

• Reasonable: Can you reasonably achieve the goal that a good and bad example for meeting each SMART criterion

you set for your leading indicator? using the leading indicator “Number of workers who attend

• Timely: Are you tracking your leading indicator a monthly safety meeting.”

regularly enough to spot meaningful trends from your

data within your desired timeframe?

Example Leading indicator: Number of workers who attend a monthly safety meeting

Goal: 97% worker attendance rate at monthly safety meetings

SPECIFIC: Does your leading indicator provide specif cs for the action that you will

take to minimize risk from a hazard or improve a program area?

GOOD EXAMPLE BAD EXAMPLE

Workers will attend a safety meeting every month. Safety meetings will be held monthly.

This is specifc because it clearly identifes what the activity is This is not specifc because it does not describe who needs to

and who needs to attend. attend.

MEASURABLE: Is your leading indicator presented as a number, rate, or percentage

that allows you to track and evaluate clear trends over time?

GOOD EXAMPLE BAD EXAMPLE

Workers will attend a safety meeting every month. Workers will attend safety meetings.

This is measurable because you can track the number of This is not measurable because it does not track a number,

workers that attend every month. rate, or percentage with respect to your goal.

ACCOUNTABLE: Does your leading indicator track an item that is relevant to your goal?

GOOD EXAMPLE BAD EXAMPLE

Workers will attend a safety meeting every month. Safety meetings for workers will be held monthly.

This indicator is relevant to your goal because it asks workers to This indicator is not relevant to your goal because it does not

attend the meeting. specify that your workers would be asked to attend.

REASONABLE: Can you reasonably achieve the goal that you set for your leading indicator?

GOOD EXAMPLE BAD EXAMPLE

Workers will attend a safety meeting every month. Your goal is Workers will attend a safety meeting every month. Your goal is

a 97% attendance rate. a 100% attendance rate.

Your 97% goal is achievable because it takes into account that you Your 100% goal is not achievable because you know that some

will not have a make-up meeting and workers missing work will workers will occasionally miss work on the day the meeting is

not be able to attend on the day the meeting is scheduled. scheduled.

TIMELY: Are you tracking your leading indicator regularly enough to spot meaningful

trends from your data within your desired timeframe?

GOOD EXAMPLE BAD EXAMPLE

You decide to track meeting attendance monthly. You decide to track meeting attendance twice a year.

This is timely; because you track your meetings monthly, you Because you only tracked two meetings, you cannot see any

can identify meaningful trends before the end of the year, which meaningful trends until at least the following year.

is when you wanted to analyze your data.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 3

SECTION 2. USING LEADING INDICATORS

There is no “one size f ts all” way to use leading indicators. This document will explain three approaches for developing

Employers with newer programs may use indicators that leading indicators. The order in which they are listed

focus on starting a program, while employers with more does not suggest that any one approach is better. OSHA

mature programs may use them to monitor how close recommends using an approach that works best for you,

they are to achieving higher performance targets. Some or even a combination of two or more, that may help you to

employers may also f nd it helpful to limit the number of achieve a specif c safety or health outcome.

leading indicators they start out with or how many they use

at any one time. How employers assign who will track and • Leading indicators using data that you already collect to

carry out goals for leading indicators can vary based on the achieve a safety or health goal (Section 2.1).

size of the business, who the business has on staff, whether • Leading indicators for controlling an identif ed hazard

the business has a safety manager, and the scope of job (Section 2.2).

duties of the employers’ workforce. • Leading indicators for improving a safety and health

program element (Section 2.3).

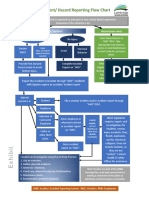

THE STEPS FOR USING LEADING INDICATORS

PLAN

Choose a Leading Indicator

Choose the leading indicator you will use. (See Sections 2.1–2.3 for examples of approaches for developing leading indicators.)

Set a Goal

After you have decided on the leading indicator, set a goal for that indicator.

DO

Communicate

Talk with your workers about the indicator, the goal, and how you will track it. Be sure to explain why you choose that specif c indicator.

Start Using Your Leading Indicators

1. Collect the data.

2. Periodically measure progress toward your goal and take action if you are not meeting it.

3. Communicate your progress with workers. For example, you may post graphs of the data in comparison to your goal over time.

If you are not meeting your goal, talk to your workers about how to get on track.

CHECK

Periodically Reassess Your Goal and Indicator

After tracking your indicator for a while, evaluate progress toward your goal and assess whether you have been meeting it. For some

indicators and goals, it can take longer to see progress. You should review it regularly, and consider whether you need more time to

assess its effectiveness.

ACT

Respond to What You Learn

Respond to what you learn from the results of your leading indicator, share the information with relevant personnel in your

organization and, when necessary, change your leading indicator based on what you learn.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 4

2.1 Leading Indicators Based on Data You Are workers that receive refresher training, and your goal is

Already Collecting 100% of your workers completing the refresher training by

If you are just getting started with leading indicators, you the end of each quarter.

may f nd it easier to work with data that you already collect,

Step 3: Start Using Your Leading Indicators

whether it is data that can improve an element of your safety

and health program or data that can help address a hazard or 1. Collect the data.

achieve some other safety or health outcome. The following

example shows how you can turn this data into a leading To collect the data, you may decide to review the attendance

indicator to help you to achieve any one of these goals. sheet that workers use to sign in before the training begins.

EXAMPLE: Percentage of Workers Attending Safety

Attendance Sheet

Refresher Training

Ron Dufresne

Step 1: Choose a Leading Indicator Zhihao Chan

Every quarter, you ensure that you have administered Kim Layton

mandatory safety refresher training to your workers; however, Martino Nunez

in the past you noticed that some of your workers did not Rebecca Morigny

attend these trainings. Because you already keep track of

2. Periodically measure progress toward your goal and

who attends training, and you want to ensure that you provide

take action if you are not meeting it.

adequate training to your workers, you decide that this might

be good data to turn into a leading indicator. Therefore, you Count the number of workers that attended the refresher

def ne your leading indicator as the percentage of workers training in each quarter. If some workers did not attend

that receive quarterly refresher training. the training, f nd out why and try to address the issue.

Step 2: Set a Goal Step 4: Periodically Reassess Your Goal and Indicator

In this example, your leading indicator is the percentage of Check whether you are meeting your 100% attendance rate.

ATTENDANCE RATE (35 WORKERS TOTAL)

100

100% Attendance rate (goal)

50

Percentage of workers

attending training (leading

indicator)

0

1st Quarter 2nd Quarter 3rd Quarter 4th Quarter

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 5

Below are three scenarios that could arise after you start

tracking this leading indicator. Each scenario shows the kind

of insights you can obtain and actions you can take once

you start using your leading indicator.

• Scenario 1: You reviewed the attendance sheet

from the last quarter. 70% of workers attended the

mandatory refresher training—good, but below

your goal of 100%. After discussing this with your

workers, you learn that some of them did not attend

because they were out from work that day. For the

future sessions, you ensure that makeup sessions are

scheduled and continue to track your leading indicator.

• Scenario 2: You reviewed the attendance sheet from

the last quarter. The number of workers that attended

the refresher training improved from the previous

quarter, but you did not achieve your goal of 100%.

After discussing this with your workers, you learn that

some of them had already left work at the time the

training was scheduled. You remind your workers that hazards. In deciding which hazard to start with, consider the

the training is mandatory and instruct them to notify a severity of potential outcomes if a hazard is not addressed

supervisor if they are unable to attend. You continue to in a timely manner, the likelihood that an event or exposure

track your leading indicator. could occur, and the number of workers that could be

exposed to this hazard.

• Scenario 3: You reviewed the attendance sheet from

the last quarter. The percentage of workers that EXAMPLE: Inspection and Clearing of Walkways

attended the refresher training was 100%. You decide

whether to continue tracking attendance every quarter Step 1: Select a Leading Indicator

after it has become routine (or consider decreasing the

You operate an automotive assembly line. During your

tracking frequency to every two quarters). Then begin

hazard identification process, you identified trips and

to develop and track a new leading indicator for other

falls that are occurring on your assembly line floor as a

data that you already collect.

top incident leading to injuries. A review of your injury

2.2 Leading Indicators for Controlling an records showed that 22 workers were hurt from trips

Identifed Hazard and falls in the past year. Due to the frequency of injuries

Leading indicators can help you improve your safety or health caused by tripping hazards, you decide this might be a

performance in work areas or activities where you have good hazard to start with. The number of trips and falls

is a lagging indicator that you hope to drive down with a

identif ed hazards. Below are some examples that walk you

leading indicator.

through the steps for using leading indicators to control the

hazards that you have identif ed. Consider referring to the After discussing it with your workers, you learned that

“Hazard Identif cation and Assessment” section of OSHA’s most of the trips and falls were caused by f oors cluttered

Recommended Practices for Safety and Health Programs1 for with tools and equipment that workers used to assemble

an overview of how to identify and assess your workplace automotive parts, including air hoses used for pneumatic

tools. You decide that a good f rst step to address this hazard

1 https://www.osha.gov/shpguidelines/docs/OSHA _ SHP_ might be to inspect and clear assembly line f oors daily.

Recommended_Practices.pdf

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 6

Step 2: Set a Goal • Scenario 1: Workers are cleaning the assembly f oors

once daily, but trips and falls are still occurring. After

In this example, your leading indicator is the frequency of discussing this with your workers, you f nd that they are

inspecting and clearing the f oors, and your goal is once daily. completing the cleanups in the afternoon, but the f oors

Step 3: Start Using Your Leading Indicators are cluttered again by the time work starts in the morning.

Based on this discussion, you change your policy to

1. Collect the data. require workers to clean f oors just before leaving work,

and revise your leading indicator to the frequency of daily

To collect the data, you may decide to use a checklist,

cleanups that occur at the end of the work day.

marking off tasks as you complete them each day.

• Scenario 2: Workers are cleaning assembly f oors once

daily, and trips and falls have decreased but are still

DAILY CLEANUP CHECKLIST

occurring. After discussing this with your workers, you

Rewind air hoses learn that the daily cleanups are helping, but tools and

X Package tools and equipment away from work

equipment are being stored in areas that create narrow

station f oors work stations and introduce new trip and fall hazards.

Store unused car parts in storage areas away from You f nd other places to store tools and equipment

f oors and continue to track your leading indicator. You also

invest in automatically retracting pneumatic hose reels

X Sweep f oors of debris and other objects that can

and overhead connections to keep hoses off the f oor,

lead to slips or falls

and consider converting to battery-operated tools to

eliminate the use of hoses altogether.

2. Periodically measure progress toward your goal and

• Scenario 3: Workers are cleaning assembly f oors once

take action if you are not meeting it.

daily, and trips and falls have decreased signif cantly.

Every week, you review your checklists to make sure you You decide whether to continue tracking the daily

have completed all daily tasks. If you have not completed cleanups after they have become routine (or consider

a task on any given day, f nd out why and try to address decreasing the tracking frequency from daily to

the issue. weekly). Then begin to develop and track a leading

indicator for a different hazard.

Step 4: Periodically Reassess Your Goal and Indicator

EXAMPLE: Truck Brake Replacement

Determine if you are seeing a decrease in your number of

trips and falls. Step 1: Select a Leading Indicator

Below are three scenarios that could arise after you start During your hazard identif cation process, you review recent

tracking this leading indicator. Each scenario shows the kind worker injuries caused by trucks that failed to properly stop

while being operated. In discussions, your injured workers tell

of insights you can obtain and actions you can take once

you that they heard squeaking brakes before the trucks failed

you start using your leading indicator.

to stop. Recognizing that squeaking brakes could result from

worn brake pads, you review your inspection records and

NUMBER OF TRIPS AND FALLS

30

20 Number of daily cleanups

per week (leading indicator)

10

Number of trips and falls

(lagging indicator)

0

Week 1 Week 2 Week 3 Week 4

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 7

learn that you were not replacing brake pads every 30,000 TRUCK MILEAGE SINCE LAST BRAKE CHANGE

miles as recommended by the truck manufacturer. You decide # of miles since last

Goal met?

that a good way to address this hazard might be to track the brake change

number of trucks that have the brake pads replaced every Truck A 26,000

30,000 miles. The number of incidents and injuries caused by Truck B 30,200

trucks failing to stop is the lagging indicator that you hope to

drive down with a leading indicator.

Truck C 27,300

Step 2: Set a Goal Truck D 29,000

In this example, your leading indicator is the number of

2. Periodically measure progress toward your goal and

trucks with brake pads that are changed every 30,000

take action if you are not meeting it.

miles, and your goal is 100%.

On the f rst of each month, you count the number of

Step 3: Start Using Your Leading Indicators

trucks that had brake pads changed at the 30,000-mile

1. Collect the data. mark. If you did not change the brake pads every 30,000

miles, f nd out why and try to address the issue.

To collect the data, you decide to submit a maintenance

request to record the number of miles driven since the last Step 4: Periodically Reassess Your Goal and Indicator

time brake pads were changed. You check each truck on

To assess your goal, determine if you are seeing a decrease

the f rst of each month, and use a sheet to check off the

in the frequency of worker incidents and injuries from trucks

trucks that had brake pads changed every 30,000 miles.

failing to stop.

NUMBER OF INCIDENTS OR INJURIES FROM TRUCKS FAILING TO STOP

10

8 Number of trucks with brake

6 pads changed every 30,000

miles (leading indicator)

4

Incidents or injuries due to

2 trucks failing to stop (lagging

indicator)

0

January February March April

Below are three scenarios that could arise after you start weeks instead of every month, and continue to track

tracking this leading indicator. Each scenario shows the kind your leading indicator.

of insights you can obtain and actions you can take once

• Scenario 2: Every month, you review the number

you start using your leading indicator.

of trucks with brake pads that were changed every

• Scenario 1: Every month, you review the number of 30,000 miles. While the number of incidents and

trucks with brake pads that were changed every 30,000 injuries have decreased, some are still occurring.

miles. While incidents and injuries have decreased, After discussing this with your workers, you learn that

some are still occurring. After discussing this with your checking the miles on a monthly basis has helped;

workers, you learn that maintenance only checks the however, maintenance staff did not receive the keys to

brake pads at the beginning of the month and some the trucks to prevent their use beyond 30,000 miles,

trucks reached 30,000 miles two weeks before the next because no procedure was in place that required the

month’s review. Based on this discussion, you begin trucks to be taken out of service when they reached a

requiring maintenance to review the miles every two mileage threshold. Consequently, workers continued to

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 8

use the trucks without any knowledge of this hazard, Step 2: Set a Goal

and the brakes were never replaced. You start giving

your maintenance staff the keys to trucks that require In this example, your leading indicator is the arrival time of

maintenance as soon as you identify this issue, and your lift team, and your goal is for arrival to be within f ve

continue to track your leading indicator. minutes.

• Scenario 3: Every month, you review the number of Step 3: Start Using Your Leading Indicators

trucks with brakes that were changed every 30,000 1. Collect the data.

miles, and incidents and injuries have decreased

signif cantly. You decide whether to keep tracking the To collect the data, you may decide to have nurses use a

brake pad changes every month after it has become timer that tracks how long it takes for a lift team to arrive

routine (or consider changing the tracking frequency to a room after the team has been paged. The nurses then

from monthly to quarterly). Then begin to develop and note the time on a daily sheet that is posted on a board in

track a leading indicator for a different hazard. the hallway and shared by all nurses on the f oor.

EXAMPLE: Arrival Time of Lift Teams LIFT TEAM ARRIVAL TIMES

Monday Tuesday Wednesday Thursday Friday

Step 1: Select a Leading Indicator

5 minutes 5 minutes 5 minutes 11 minutes 9 minutes

During your hazard identif cation process, your hospital

identif ed manually lifting patients as a hazard. A review 4 minutes 5 minutes 5 minutes 5 minutes 10 minutes

of your injury log showed that in the past year 15 hospital

workers suffered from back injuries after manually lifting or 12 minutes 4 minutes 7 minutes 5 minutes 5 minutes

repositioning patients. Due to the frequency of injuries from

15 minutes 8 minutes 6 minutes 5 minutes 5 minutes

manual lifting, you decide that this might be a good hazard

to start with. The number of back injuries from patient lifting

is the lagging indicator that you hope to drive down with a 2. Periodically measure progress toward your goal and

leading indicator. take action if you are not meeting it.

You have six two-person lift teams with lifting equipment You decide to review this sheet every week. If lift teams

available throughout the hospital. After discussing back are not arriving within f ve minutes, f nd out why and try

injuries with your workers, you learn that it takes too long to address the issue.

for a lift team to arrive to a patient’s room after being

paged. Consequently, many workers continue to manually Step 4: Periodically Reassess Your Goal and Indicator

lift patients on their own. You decide that a good way to

To assess your goal, determine if you are seeing a decrease

address this hazard might be to ensure that lift teams arrive

in the number of back injuries among nurses and counting

within f ve minutes of being paged, which is a reasonable

the number of arrivals past f ve minutes.

goal given the size of your hospital.

NUMBER OF BACK INJURIES FROM LIFTING PATIENTS

15

Number of lift team arrivals

10 past 5 minutes (leading

indicator)

5

Number of back injuries from

lifting patients (lagging

0

indicator)

January February March April

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 9

Below are three scenarios that could arise after you start • Hazard identif cation and assessment

tracking this leading indicator. Each scenario shows the kind • Hazard prevention and control

of insights you can obtain and actions you can take once

• Education and training

you start using your leading indicator.

• Program evaluation and improvement

• Scenario 1: You review the sheet every week to make

• Communication and coordination for host employers,

sure that lift teams are arriving within f ve minutes.

contractors, and staff ng agencies

While back injuries have decreased since you last

checked your progress, they are still occurring. After Leading indicators can help you improve on these core

discussing this with your workers, you learn that elements of your safety and health program. Tying elements

although lift teams are arriving within f ve minutes, you of a safety and health program directly to lagging indicators

need additional lift teams because there are not enough such as injury rates may be diff cult, but experience shows

available to get to the next patient when they are that better programs do improve safety. 3 This section

paged. Based on this discussion, you review your staff focuses on how to use leading indicators to improve the

levels, decide to add three more lift teams with lifting elements of a program outlined in OSHA’s Recommended

equipment, and continue to track your leading indicator. Practices. However, they can be applied to any safety and

• Scenario 2: You review the sheet every week, and health program regardless of what elements the program

back injuries have decreased further since the last includes.

progress update but are still occurring. After discussing

Exemplary safety and health programs use all the core

this with your workers, you learn that some lift teams

elements outlined in OSHA’s Recommended Practices.

are not using the equipment properly, causing them to

fall behind on getting to the next patient. You plan a Sections 2.3.1–2.3.7 summarize the recommended

training session so that your lift teams can learn how to practices for each core element and provide examples

correct errors in using the equipment, and continue to of leading indicators that you can use to measure your

track your leading indicator. implementation of these practices. Section 2.3.8 provides

examples of how to use a leading indicator you have chosen

• Scenario 3: You review the sheet every week, and

and how to measure your performance for that indicator.

back injuries have decreased signif cantly. You decide

whether to continue tracking lift team arrival times 2.3.1 MANAGEMENT LEADERSHIP

after it has become routine (or consider changing the

tracking frequency from monthly to quarterly). Then, RECOMMENDED PRACTICES FOR

begin to develop and track a leading indicator for a MANAGEMENT LEADERSHIP

different hazard. • Communicate your commitment to a safety

and health program.

2.3 Leading Indicators to Improve an Element of

• Defne program goals.

Your Safety and Health Program

Effective safety and health programs incorporate all of the • Allocate resources.

core elements outlined in OSHA’s Recommended Practices • Expect performance.

for Safety and Health Programs:2

• Management leadership

• Worker participation

2 https://www.osha.gov/shpguidelines/docs/OSHA_SHP_ 3 Benchmarking Organizational Leading Indicators for the

Recommended_Practices.pdf (OSHA also has a recommended Prevention and Management of Injuries and Illnesses: Final

practices document for the construction industry, available Report, Institute for Work & Health, 2011, available at https://

at https://www.osha.gov/shpguidelines/docs/8524_OSHA_ www.iwh.on.ca/sites/iwh/fles/iwh/reports/iwh _ report _

Construction_Guidelines_R4.pdf) benchmarking_organizational_leading _ indicators _ 2011.pdf

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 10

Leading Indicators That Support Management Leading Indicators That Support Worker Participation

Leadership Below are some suggested leading indicators for measuring

Below are some suggested leading indicators for measuring the implementation of recommended practices for worker

the implementation of recommended practices for participation:

management leadership:

• Number of workers asked for feedback on good safety

• Percentage of managers and supervisors who attend goals ahead of safety meetings.

mandatory safety and health training for workers. • Number of workers involved in developing safety

• Number of times each month that top management procedures.

initiates discussion of a safety and health topic. • Number of workers participating in tool box talks.

• Average score on survey questions related to workers’ • Number of workers participating in injury investigations.

perception of management’s safety and health

• Safety perception survey participation rate.

commitment.

• Number of workers involved in developing task-specif c

• Number of worker-reported hazards or concerns for

job safety analyses/job hazard analyses on how to

which employers initiated corrective action within 48

perform routine tasks safely.

hours (compared to the total number of such reports).

• Number of workers participating in accident

• Average time between worker report of a hazard or

investigation teams and helping to identify/implement

concern and management acknowledgement of the

corrective actions to eliminate hazards.

report.

• Number of safety-related line items in budget and Take Action

percentage of these fully funded each year. Take action when trends indicate that you could improve

worker participation. For example, if workers have not been

Take Action

participating in hazard prevention meetings, you should f nd

Take action when trends indicate that you could improve

out why. For example, some workers may feel that their

your management leadership. For example, if a busy owner

managers do not value their opinions. In such instances,

or CEO skipped the safety meeting last year, note this year’s

you could take actions to change that perception and

meeting in their schedule ahead of time so they prioritize

meaningfully increase worker participation rates in safety

attendance. Similarly, if workers are reporting hazards that

meetings.

are not ultimately addressed due to lack of resources or

competing priorities, it may be wise to determine what, if 2.3.3 HAZARD IDENTIFICATION AND ASSESSMENT

any, additional resources you can allocate to control those

hazards, or manage competing priorities. RECOMMENDED PRACTICES FOR HAZARD

IDENTIFICATION AND ASSESSMENT

2.3.2 WORKER PARTICIPATION • Collect existing information about workplace

hazards.

RECOMMENDED PRACTICES FOR WORKER PARTICIPATION • Inspect the workplace for safety hazards.

• Encourage workers to participate in the • Identify health hazards.

program. • Conduct incident investigations.

• Encourage workers to report safety and • Identifed hazards associated with emergency

health concerns. and non-routine situations.

• Give workers access to safety and health • Characterize the nature of identifed hazards,

information. identify interim control measures, and

• Involve workers in all aspects of the program. prioritize the hazards for control.

• Remove barriers to participation.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 11

Leading Indicators that Support Hazard Identifcation Leading Indicators that Support Hazard Prevention

and Assessment and Control

Below are some suggested leading indicators for measuring Below are some suggested leading indicators for measuring

the implementation of recommended practices for hazard the implementation of recommended practices for hazard

identif cation and assessment: prevention and control:

• Frequency with which preventive equipment maintenance • Length of time interim controls have been in place.

tasks are initiated and completed on schedule. • Percentage of recommendations implemented that

• Number of hours passed after an incident before an pertain to PPE hazard controls, administrative controls,

investigation is started. engineering controls, substitution, and elimination.

• Number of hours passed after an incident before an • Number of special work permits f lled out.

investigation is completed. • Number of cartridge f lers with an end of service life

• Percentage of incident investigations that include a root indicator that were returned or replaced before the

cause investigation. indicator turned red.

• Percentage of daily/weekly/monthly inspections • Number of hazards identif ed where you used leading

completed. indicators to control the hazard.

• Percentage of inspections that include a follow-up • Percentage of hazards abated on the same day, week,

inspection to ensure that the hazard has been controlled. or month in which the hazard was identif ed.

• Number of workers required to wear respiratory

Take Action

protection.

Take action when trends indicate that you could improve your

hazard identif cation and assessment methods. For example, if • Number of unacceptable risks identif ed during risk

your goal is to complete all investigations within a week of the assessments.

incident, and you are f nding that the average investigation has Take Action

taken over two weeks, talk to your workers about the delay and Take action when trends indicate that you can improve your

develop a plan to complete them faster. Similarly, if workers hazard prevention and control methods. For example, if some

only conduct root cause investigations 50% of the time, but recommendations continue to remain open past their due

your goal is 100% of the time, try to f nd out why they did not date, f nd out why this might be the case and try to correct

always conduct them and develop a plan that will ensure that the issue so that you can address recommendations on time.

they become a routine part of your investigations. Similarly, if you have not been using leading indicators as

2.3.4 HAZARD PREVENTION AND CONTROL a tool for controlling hazards, you may want to implement

a leading indicator program, and start with just one or two

RECOMMENDED PRACTICES FOR HAZARD leading indicators during the program’s f rst year.

PREVENTION AND CONTROL

2.3.5 EDUCATION AND TRAINING

• Identify control options.

• Select controls. RECOMMENDED PRACTICES FOR

• Develop and update a hazard control plan. EDUCATION AND TRAINING

• Select controls to protect workers during • Provide program awareness training.

nonroutine operations and emergencies. • Train employers, managers, and supervisors

• Implement selected controls in the workplace. on their roles in the program.

• Follow up to confrm that controls are effective. • Train workers on their specifc roles in the

safety and health program.

• Train workers on hazard identifcation and

controls.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 12

Leading Indicators that Support Education and Training • Number of inspections completed to identify hazards or

Below are some suggested leading indicators for measuring program weaknesses.

the implementation of recommended practices for education • Number of lagging indicator rates that improved as a

and training: result of using leading indicators to take action.

• Number of trainings provided to workers on hazard • Number of goals achieved, number of goals in need

recognition and control as compared to worker of revision, or new goals that you should set for the

attendance rates at these trainings. following year.

• Percentage of workers receiving mandatory training on Take Action

schedule. Take action when trends indicate that you could improve an

• Percentage of incident investigations listing insuff cient aspect of your program. For example, if you only conduct

Number of workers trained on how to recognize and an audit once a year, this may not be enough to track how

report a hazard or near miss as compared to the number well your program is doing over time. Similarly, if you have

of workers that report understanding the training they not achieved an important goal, it may make more sense to

have received. continue working on that goal before pursuing a new one.

• Percentage of improvement on post-training assessment

scores over pre-training assessment scores. 2.3.7 COMMUNICATION AND COORDINATION

Take Action RECOMMENDED PRACTICES FOR

Take action if trends indicate that you are not effectively COMMUNICATION AND COORDINATION

administering training. For example, a leading indicator may • Establish effective communication.

reveal that you offer regular training on how to recognize • Establish effective coordination.

and report hazards, but workers still do not clearly

understand how to recognize and report certain hazards Leading Indicators That Support Communication

after completing the training. In this example, you may want and Coordination

to ask workers that have experience or knowledge of the Below are some suggested leading indicators for

hazard for suggestions on hands on training approaches and measuring implementation of recommended practices for

simulations that could be more effective. communication and coordination among host employers,

contractors, and staff ng agencies:

2.3.6 PROGRAM EVALUATION AND IMPROVEMENT

• Frequency of discussions between the staff ng agency/

RECOMMENDED PRACTICES FOR PROGRAM contractor and the host employer that address efforts

EVALUATION AND IMPROVEMENT to ensure workers have a safe and healthy work

• Monitor performance and progress. environment at the host site.

• Verify that the program is implemented and is • Frequency of discussions about worker safety between

operating. contract workers and host site supervisors.

• Correct program shortcomings and identify • Frequency of contract employer visits to the host

opportunities to improve. employer site to conduct inspections and collect safety

and health information before workers are sent to the

Leading indicators That Support Program Evaluation work site.

and Improvement • Number of workers trained on how to avoid exposure

Below are some suggested leading indicators for measuring to potential hazards before the worker begins work at

the implementation of recommended practices for program the host site, including identifying whom to contact to

evaluation and improvement: report a hazard on site.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 13

• Number of hazards reported by contract/temporary and give an update on safety and health performance.

workers versus total site workers. The update could include status of your safety and health

• Number of audits conducted to ensure contractors are leading indicators and a discussion of any new health and

following site safety and health policies to include in safety issues.

their own safety policies. Step 2: Set a Goal

Take Action In this example, your leading indicator is the percentage of

Take action if a trend indicates that you could improve monthly safety meetings in which a manager attends and

communication and coordination activities. For example, you gives a health and safety update. You hope to strengthen the

might f nd that contract workers and host employers are not management leadership element of your program. Using results

having frequent discussions about worker safety because from the next survey, you intend to measure your success by

the contract workers are not comfortable discussing their looking for a higher percentage of workers who agree that

concerns with the host site supervisor. In this example, management communicates its commitment to safety.

you might plan a meeting between your workers and the

Step 3: Start Using Your Leading Indicators

supervisor to discuss what actions the supervisor can take

to help the workers feel more comfortable about having 1. Collect the data.

these discussions.

To collect the data, you may decide to keep a sheet that

2.3.8 EXAMPLES: USING LEADING INDICATORS notes whether a manager attended a monthly meeting,

TO IMPROVE A SAFETY AND HEALTH including a section on what safety and health updates the

PROGRAM ELEMENT manager provided.

Sections 2.3.1–2.3.7 provided examples of leading MANAGER SAFETY MEETINGS ATTENDANCE AND DISCUSSION

indicators that you can use to measure the implementation JANUARY

of a recommended practice for each of the core elements

Discussion points:

of a safety and health program. This section provides

examples of how to use a leading indicator that you have FEBRUARY

chosen from that section, and how to measure progress on Discussion points:

your performance goal for that indicator.

MARCH

Tracking Monthly Safety and Health Updates for Discussion points:

Workers to Improve Management Leadership

Step 1: Select a Leading Indicator 2. Periodically measure progress toward your goal and

take action if you are not meeting it.

While evaluating your safety and health program, you

decide to review your management leadership practices You decide to review your sheet every few months. If the

and identify areas for improvement. In a survey, you manager did not attend and adequately discuss safety

ask workers whether management communicates its and health progress and performance, f nd out why and

commitment to the health and safety program, and only try to address the issue.

50% of workers agree or answer “yes.” Because you have

a written policy for workplace safety and health, it seems Step 4: Periodically Reassess Your Goal and Indicator

that workers may not believe that your management team

To assess progress toward your goal, determine if you

takes it seriously. You decide to focus on demonstrating

see an increase in the percentage of “yes” responses to

management commitment to the program. You set a goal

your survey. Since it can be diff cult to change worker

to have a manager attend all monthly safety meetings

perceptions of management commitment to safety in a

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 14

MANAGER SAFETY MEETINGS AND SURVEY RESPONSES

120

100

Percentage of monthly safety

80 meetings including manager

60 update

40 Percentage of “yes” survey

responses

20

0

January February March April

short time, it may take longer to determine whether your Tracking Completion of Action Items from Inspections to

indicator is effective in achieving this goal. You should review Improve Hazard Prevention and Control

the results regularly, but consider whether you need more time

to assess effectiveness. Step 1: Select a Leading Indicator

Below are three scenarios that could arise after you start While evaluating your safety and health program, you decide

to review your program evaluation and improvement practices

tracking this leading indicator. Each scenario shows the kind

and identify areas for improvement. You decide to track the

of insights you can obtain and actions you can take once you

number of past-due action items since your last inspection.

start using your leading indicator.

You set a goal not to exceed 10% on past-due action items

• Scenario 1: The manager attends the meetings and before completing your next review.

provides safety and health updates to all your workers

Step 2: Set a Goal

monthly, but the percentage of “yes” responses to your

survey has not signif cantly improved. After discussing In this example, your leading indicator is the percentage of past-

this with your workers, you learn that some would like due action items, and you set a goal of no more than 10%.

a more detailed explanation about why you are using

certain leading indicators. You add this to your discussion Step 3: Start Using Your Leading Indicators

points and continue to track your leading indicator. 1. Collect the data.

• Scenario 2: The manager attends the meetings and You collect the open action items and calculate the

provides safety and health updates to all your workers percentage past due.

monthly, but the percentage of “yes” responses to your

survey has only marginally improved. After discussing ACTION ITEMS COMPLETED SINCE LAST INSPECTION

this with your workers, you learn that they would prefer

to receive updates more frequently. You start providing Action Item Due Date Status

updates every two weeks instead of every month, and

you continue to track your leading indicator. Repair electrical

Completed by due

hazard at main March 15

• Scenario 3: The manager attends the meetings and date

entrance

provides safety and health updates to all your workers

Install new fre

monthly, and the number of “yes” responses to your Not completed by

protection equipment March 15

survey improves dramatically. You continue the monthly due date

in work spaces

updates but develop and track a leading indicator for Provide training on

another management leadership practice, or begin Completed by due

updated emergency April 15

working on a different element of your safety and health date

procedures

management program. Conduct a root cause

Not completed by

analysis of recent fre May 15

due date

incident

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 15

2. Periodically measure progress toward your goal and

take action if you are not meeting it.

Each quarter of the year, you calculate your percentage of

past-due action items. If you did not complete at least 90%

of your action items, f nd out why and try to address the

issue.

Step 4: Periodically Reassess Your Goal and Indicator

To assess your goal, determine what percentage of

outstanding action items you have not completed. Is it no

more than 10%?

Below are three scenarios that could arise after you start

tracking this leading indicator. Each scenario shows the kind

of insight you can obtain and actions you can take once you

start using your leading indicator.

• Scenario 1: Before completing your next review, you

check your results and notice that your percentage of

total action items not completed is above 10%. After

discussing this with your workers, you learn that no this with your workers, you learn that the equipment,

procedure exists to ensure that you would complete your parts, or tools needed to complete some of the action

action items on time. You also learn that it may be helpful items were not available. You take appropriate actions to

to give the action item list to a manager to ensure that ensure the parts or tools needed to complete the action

workers meet the due dates. You set a meeting with your items are available, and continue tracking your leading

workers to come up with a procedure for completing indicator.

action items on time, begin giving the list of action items

to a manager at the conclusion of each inspection, and • Scenario 3: You review your results before your next

continue to track your leading indicator. You also make review, and your percentage of total action items not

this tracking log available to workers so they can become completed is below 10%. You decide whether to continue

more involved with ensuring timely completion dates. tracking your leading indicator, develop and track a

leading indicator for another hazard prevention and

• Scenario 2: Before completing your next review, you control item, or begin working on a different element of

check your results but your percentage of total action your safety and health program.

items not completed is above 10%. After discussing

PERCENT COMPLETION OVER TIME

30

20

Goal = 10%

15

10

Q1 Q2 Q3 Q4

Number of action items not completed Percentage of action items not completed

(leading indicator)

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 16

SECTION 3. CONCLUSION

Leading indicators are a valuable tool that you can use have a safety or health program, what you have included

to make measurable and long-lasting improvements to in your program, or what stage you may be at in your

safety and health outcomes in the workplace. Leading program. Use the checklist below to get started today.

indicators can be valuable regardless of whether you

ACTION PLAN CHECKLIST

■ Identify your top problem areas. For hazards, review your injury logs, and

results from your hazard assessments. Start with the hazard with the greatest risk

of harming workers by evaluating the severity of the potential exposure and the

likelihood that an incident could occur. Prioritize hazards over other areas of your

program, particularly if a threat is imminent.

■ For other program elements, talk with your workers about what areas you

could improve. For data that you are already collecting, determine whether it is an

area that you should prioritize.

■ Consider what actions you could take to address your key areas. Talk with

your workers and anyone else with knowledge of the issue that can provide

suggestions.

■ Set a goal, and use leading indicators to reach it. Make an informed decision on

what your goal should be and how long it might take to achieve. Choose a leading

indicator that can help you to achieve your goal over time.

■ Collect the data. Begin collecting the leading indicator data for the time period you

decided on as well as the data for your goal during that same time period.

■ Periodically review the results. Assemble the results into a graph to determine

whether there is a positive relationship between your leading indicator and

your goal. Did the action that you took help you to achieve your goal? If not, try

something else.

■ Remember that just one or two indicators can make a positive impact.

OSHA recommends getting started today and customizing the type and number of

indicators to your needs, resources, and abilities as they evolve over time.

U.S. Department of Labor n www.osha.gov n (800) 321-OSHA (6742) 17

You might also like

- Oil & Gas Safety GuideDocument29 pagesOil & Gas Safety GuidedinuveraNo ratings yet

- PPE Guide for Managers and EmployeesDocument4 pagesPPE Guide for Managers and Employeesnadar nagarNo ratings yet

- DemoDocument28 pagesDemoAlbertDatuNo ratings yet

- Safety in the Chemical Laboratory and Industry: A Practical GuideFrom EverandSafety in the Chemical Laboratory and Industry: A Practical GuideNo ratings yet

- Employee Safety, Health and Security Act (OSHADocument7 pagesEmployee Safety, Health and Security Act (OSHAspecies09No ratings yet

- BSI-ISO50001-Assessment-Checklist-UK-EN v2Document4 pagesBSI-ISO50001-Assessment-Checklist-UK-EN v2Ismail SultanNo ratings yet

- Complete Safe@Work General Module TestDocument5 pagesComplete Safe@Work General Module TestcammcbeanNo ratings yet

- Standard For Old Age PDFDocument65 pagesStandard For Old Age PDFRendani VeleNo ratings yet

- Occupational HealthDocument8 pagesOccupational HealthIya JoyNo ratings yet

- Proposal For ImprovementDocument22 pagesProposal For ImprovementJohn Ervin AgenaNo ratings yet

- Kitchen Safety: Preventing Cuts, Burns, Spills & MoreDocument21 pagesKitchen Safety: Preventing Cuts, Burns, Spills & MoreTara NahNo ratings yet

- Unit Ig1: Management of Health and SafetyDocument15 pagesUnit Ig1: Management of Health and SafetyVikash Kumar RayNo ratings yet

- hsg129 PDFDocument138 pageshsg129 PDFmanimeczNo ratings yet

- Module 2Document29 pagesModule 2AlbertDatuNo ratings yet

- 2 Consequence Management ProcedureDocument10 pages2 Consequence Management ProcedureriyazaliNo ratings yet

- 5 Key Points About PpeDocument1 page5 Key Points About PpeAldus Andrew MorrisNo ratings yet

- HSE ViolationDocument1 pageHSE ViolationBrian GiduduNo ratings yet

- Principles of Employee WelfareDocument9 pagesPrinciples of Employee Welfarefahd_alam005No ratings yet

- Module 1 - Osh and Bosh FrameworkDocument5 pagesModule 1 - Osh and Bosh FrameworkJohn Ray CuevasNo ratings yet

- Physical Layout and Housekeeping HazardsDocument16 pagesPhysical Layout and Housekeeping HazardsabhilashNo ratings yet

- PPE ProgramDocument8 pagesPPE ProgramAldrin BanaayNo ratings yet

- Accident Incident Reporting FlowchartDocument1 pageAccident Incident Reporting Flowchartsyamimi balkhisNo ratings yet

- Permitto Work Roof AccessDocument2 pagesPermitto Work Roof AccesslisaconnollyNo ratings yet

- Safety Management - PDFDocument43 pagesSafety Management - PDFMansi PatelNo ratings yet

- HIRACDocument5 pagesHIRACJeanvy Alrence BinallaNo ratings yet

- Hse Emergency Preparedness and ResponseDocument6 pagesHse Emergency Preparedness and ResponsenagaaNo ratings yet

- Intel Construction EHS: Processes and Procedures ManualDocument116 pagesIntel Construction EHS: Processes and Procedures ManualbasshotNo ratings yet

- Explosive Safety EssentialsDocument40 pagesExplosive Safety EssentialsLolita Mamore-gandiaNo ratings yet

- SDS Freezetone Degreaser Purple Lightning ENG 2020Document7 pagesSDS Freezetone Degreaser Purple Lightning ENG 2020Darwin Turcios100% (1)

- ILO - PPE PresentationDocument69 pagesILO - PPE PresentationLeo Mr-ChuốiNo ratings yet

- Health and Safety Standard Assignment BriefDocument13 pagesHealth and Safety Standard Assignment BriefMuhammad SadatNo ratings yet

- Guess The Word ActivityDocument28 pagesGuess The Word ActivityChris GarciaNo ratings yet

- B-711 Purpose: Agency Name Chapter No./Name Part No./Name Section No./Name Document No./Name Dates Issue EffectiveDocument3 pagesB-711 Purpose: Agency Name Chapter No./Name Part No./Name Section No./Name Document No./Name Dates Issue EffectiveJoyjoy C LbanezNo ratings yet

- LCM 48 Hours Advance OSH CourseDocument6 pagesLCM 48 Hours Advance OSH CourseLenaj Ebron50% (2)

- Topic 1 - Introduction Osh LegislationDocument47 pagesTopic 1 - Introduction Osh LegislationNanta MacNo ratings yet

- Identifying and Controlling Workplace HazardsDocument45 pagesIdentifying and Controlling Workplace HazardsAijaz Ahmed ShaikhNo ratings yet

- Bloodborne and Airborne Pathogens: (Universal Precautions)Document2 pagesBloodborne and Airborne Pathogens: (Universal Precautions)roberto_00643557No ratings yet

- Unsafe and Unhealthy Acts and ConditionsDocument41 pagesUnsafe and Unhealthy Acts and ConditionsclandestineamorousNo ratings yet

- Monthly Camp Inspection ChecklistDocument2 pagesMonthly Camp Inspection ChecklistZaki Azizi100% (1)

- 17 - Principles of Fire Risk Assessment PPT For LearnerDocument38 pages17 - Principles of Fire Risk Assessment PPT For LearnerSophie-Louise Mercedes100% (1)

- Emergency Action Plan TEMP1 - 16Document17 pagesEmergency Action Plan TEMP1 - 16Kim ClaresseNo ratings yet

- NEBOSH International Diploma For Occupational Health & Safety For Occupational Health & Safety Management Professionals Management ProfessionalsDocument3 pagesNEBOSH International Diploma For Occupational Health & Safety For Occupational Health & Safety Management Professionals Management ProfessionalsOsman KantheNo ratings yet

- hsg245 PDFDocument88 pageshsg245 PDFYousef OlabiNo ratings yet

- Risk - Assessment - Form 14th Oct 2017Document2 pagesRisk - Assessment - Form 14th Oct 2017hunstreteNo ratings yet

- Letter MESH (08.17.19)Document5 pagesLetter MESH (08.17.19)Jbdc4 OhsecNo ratings yet

- Fire ProtectionDocument42 pagesFire Protectionsodalime01No ratings yet

- Application For Safety PractitionerDocument4 pagesApplication For Safety PractitionerMark Rusiana100% (1)

- Near Miss Reporting Procedure 1664210216Document10 pagesNear Miss Reporting Procedure 1664210216richardNo ratings yet

- Welding PPE GuideDocument9 pagesWelding PPE Guidecyrelle rose jumentoNo ratings yet

- Kent Uni health and safety inductionDocument20 pagesKent Uni health and safety inductionMijanur RahmanNo ratings yet

- Cost of Accident190423Document46 pagesCost of Accident190423Jallela SomeshNo ratings yet

- Risk Assessment Template: Silicon Beach TrainingDocument1 pageRisk Assessment Template: Silicon Beach TrainingMuhammad Adnan AliNo ratings yet

- Fire Safety SeminarDocument11 pagesFire Safety SeminarJoy Angelique JavierNo ratings yet

- EHS Manual - EngDocument149 pagesEHS Manual - EngEduardo GarzaNo ratings yet

- OSH Standards in the PhilippinesDocument58 pagesOSH Standards in the PhilippinesSophia Rosales (ezzemm)100% (1)

- Safety AuditSDocument5 pagesSafety AuditSsanjeev kumarNo ratings yet

- Accident InvestigationDocument89 pagesAccident InvestigationDan EtteteNo ratings yet

- ISO 7010:2019 (E) : Table 2 - Summary of All Safety SignsDocument19 pagesISO 7010:2019 (E) : Table 2 - Summary of All Safety SignseerrddeemmNo ratings yet

- NORSOK Standard Technical Safety S001Document68 pagesNORSOK Standard Technical Safety S001Ho Ngoc Thanh Quang100% (1)

- Daily Safety TalkDocument102 pagesDaily Safety TalkShabin ShabiNo ratings yet

- IAFID12PrinciplesRemoteAssessment22122015 PDFDocument11 pagesIAFID12PrinciplesRemoteAssessment22122015 PDFSelvaraj SimiyonNo ratings yet

- Standart Anzi Eyewash PDFDocument12 pagesStandart Anzi Eyewash PDFDwiki Yanuar Ramadhan100% (1)

- Idip DatasheetDocument3 pagesIdip DatasheeteerrddeemmNo ratings yet

- Scaffold Ladder Safety 1569604009Document128 pagesScaffold Ladder Safety 1569604009eerrddeemmNo ratings yet

- Occupational Health & Safety Implementation GuideDocument36 pagesOccupational Health & Safety Implementation GuideeerrddeemmNo ratings yet

- Environment, Health and Safety Supplement To The TOE Guidebook - English PDFDocument180 pagesEnvironment, Health and Safety Supplement To The TOE Guidebook - English PDFJohn RajeshNo ratings yet

- OSHA 300 - Record Keeping DecisionTreeDocument1 pageOSHA 300 - Record Keeping DecisionTreeeerrddeemmNo ratings yet

- SGS CBE ISO 45001 Readiness Checklist LR 19Document28 pagesSGS CBE ISO 45001 Readiness Checklist LR 19eerrddeemmNo ratings yet

- Not The Place To Be Surprised: Locking Out Confined SpacesDocument24 pagesNot The Place To Be Surprised: Locking Out Confined SpaceseerrddeemmNo ratings yet

- Major RiskDocument7 pagesMajor RiskeerrddeemmNo ratings yet

- Fema P-1078 PDFDocument1 pageFema P-1078 PDFeerrddeemmNo ratings yet

- Integrated Management System & Safety Culture Experiences of OJSC "Hlebny Dom" and Fazer Group RussiaDocument40 pagesIntegrated Management System & Safety Culture Experiences of OJSC "Hlebny Dom" and Fazer Group RussiaeerrddeemmNo ratings yet

- Combustible Dust in Industry PDFDocument9 pagesCombustible Dust in Industry PDFeerrddeemmNo ratings yet

- AUST Process Safety Guidance - Final December 2008Document14 pagesAUST Process Safety Guidance - Final December 2008piolinwallsNo ratings yet

- Math Motivators - Investigations in Geometry 1982Document82 pagesMath Motivators - Investigations in Geometry 1982eerrddeemm100% (1)

- AUST Process Safety Guidance - Final December 2008Document14 pagesAUST Process Safety Guidance - Final December 2008piolinwallsNo ratings yet

- Machinery Safety Guide Sponsored by TÜV SÜD Product ServiceDocument52 pagesMachinery Safety Guide Sponsored by TÜV SÜD Product ServiceAli ÖzgençNo ratings yet

- Combustible Dust in Industry PDFDocument9 pagesCombustible Dust in Industry PDFeerrddeemmNo ratings yet

- Machinery Safety Guide Sponsored by TÜV SÜD Product ServiceDocument52 pagesMachinery Safety Guide Sponsored by TÜV SÜD Product ServiceAli ÖzgençNo ratings yet

- Machinery Safety Guide Sponsored by TÜV SÜD Product ServiceDocument52 pagesMachinery Safety Guide Sponsored by TÜV SÜD Product ServiceAli ÖzgençNo ratings yet

- Chilworth Guide To Process SafetyDocument40 pagesChilworth Guide To Process SafetyeerrddeemmNo ratings yet

- Hazardous Chemicals Awareness LevelDocument59 pagesHazardous Chemicals Awareness LeveleerrddeemmNo ratings yet

- Safety InductionDocument29 pagesSafety Inductioneerrddeemm100% (1)

- Festo Safety EngineeringDocument43 pagesFesto Safety EngineeringeerrddeemmNo ratings yet

- 50 Tips To Stop Global WarmingDocument5 pages50 Tips To Stop Global Warminggkm0097745No ratings yet

- The Ballad of Reading Gaol: Oscar WildeDocument33 pagesThe Ballad of Reading Gaol: Oscar WildeMaria DoukaNo ratings yet

- Brochure For Graduate DIploma in Railway Signalling 2019 v1.0 PDFDocument4 pagesBrochure For Graduate DIploma in Railway Signalling 2019 v1.0 PDFArun BabuNo ratings yet

- (Coffeemaker) Tas5542uc - Instructions - For - UseDocument74 pages(Coffeemaker) Tas5542uc - Instructions - For - UsePolina BikoulovNo ratings yet

- KAMAGONGDocument2 pagesKAMAGONGjeric plumosNo ratings yet

- HED - PterygiumDocument2 pagesHED - Pterygiumterry johnsonNo ratings yet

- 1995 - Legacy SystemsDocument5 pages1995 - Legacy SystemsJosé MªNo ratings yet

- Introduction To ResearchDocument5 pagesIntroduction To Researchapi-385504653No ratings yet

- Military Divers ManualDocument30 pagesMilitary Divers ManualJohn0% (1)

- Managing Remuneration MCQDocument5 pagesManaging Remuneration MCQlol100% (1)

- Hays Grading System: Group Activity 3 Groups KH PS Acct TS JG PGDocument1 pageHays Grading System: Group Activity 3 Groups KH PS Acct TS JG PGkuku129No ratings yet

- Cast Copper Alloy Solder Joint Pressure Fittings: ASME B16.18-2018Document41 pagesCast Copper Alloy Solder Joint Pressure Fittings: ASME B16.18-2018crescon designNo ratings yet

- English Literature RevisionDocument61 pagesEnglish Literature RevisionAlex Cobain Glinwood100% (1)

- Recommender Systems Research GuideDocument28 pagesRecommender Systems Research GuideSube Singh InsanNo ratings yet

- CRUSADE of PRAYERS 1-170 Litany 1-6 For The Key To Paradise For DistributionDocument264 pagesCRUSADE of PRAYERS 1-170 Litany 1-6 For The Key To Paradise For DistributionJESUS IS RETURNING DURING OUR GENERATION100% (10)

- National Train Enquiry System: 12612 Nzm-Mas Garib Rath Exp Garib Rath 12434 Nzm-Mas Rajdhani Exp RajdhaniDocument1 pageNational Train Enquiry System: 12612 Nzm-Mas Garib Rath Exp Garib Rath 12434 Nzm-Mas Rajdhani Exp RajdhanishubhamformeNo ratings yet

- Cost Accounting - LabourDocument7 pagesCost Accounting - LabourSaad Khan YTNo ratings yet

- Yoga Practice Guide: DR - Abhishek VermaDocument26 pagesYoga Practice Guide: DR - Abhishek VermaAmarendra Kumar SharmaNo ratings yet

- Mobile Services Tax Invoice for Dr Reddys LaboratoriesDocument3 pagesMobile Services Tax Invoice for Dr Reddys LaboratoriesK Sree RamNo ratings yet

- 04 - JTC Template On Project ProposalDocument10 pages04 - JTC Template On Project Proposalbakelm alqamisNo ratings yet

- Fernando Medical Enterprises, Inc. v. Wesleyan University Phils., Inc.Document10 pagesFernando Medical Enterprises, Inc. v. Wesleyan University Phils., Inc.Clement del RosarioNo ratings yet

- FACS113 MineralswebDocument51 pagesFACS113 MineralswebMohammad Amjad KhanNo ratings yet

- Midterm Exam ADM3350 Summer 2022 PDFDocument7 pagesMidterm Exam ADM3350 Summer 2022 PDFHan ZhongNo ratings yet

- Compilation of Activities UBCVDocument13 pagesCompilation of Activities UBCVRenell Vincent RamosNo ratings yet

- AIX For System Administrators - AdaptersDocument2 pagesAIX For System Administrators - Adaptersdanielvp21No ratings yet

- Abalone Report InfographicDocument1 pageAbalone Report InfographicjanetNo ratings yet

- Eric Bennett - Workshops of Empire - Stegner, Engle, and American Creative Writing During The Cold War (2015, University of Iowa Press) - Libgen - LiDocument231 pagesEric Bennett - Workshops of Empire - Stegner, Engle, and American Creative Writing During The Cold War (2015, University of Iowa Press) - Libgen - LiÖzge FındıkNo ratings yet

- Public Policy For Nigerian EnviromentDocument11 pagesPublic Policy For Nigerian EnviromentAbishai Auta GaiyaNo ratings yet

- Symphonological Bioethical Theory: Gladys L. Husted and James H. HustedDocument13 pagesSymphonological Bioethical Theory: Gladys L. Husted and James H. HustedYuvi Rociandel Luardo100% (1)

- Presentation 1Document13 pagesPresentation 1lordonezNo ratings yet

- Chippernac: Vacuum Snout Attachment (Part Number 1901113)Document2 pagesChippernac: Vacuum Snout Attachment (Part Number 1901113)GeorgeNo ratings yet

- Magnetic Suspension System With Electricity Generation Ijariie5381Document11 pagesMagnetic Suspension System With Electricity Generation Ijariie5381Jahnavi ChinnuNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)