Professional Documents

Culture Documents

MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mo

Uploaded by

baskaran ayyapparajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mo

Uploaded by

baskaran ayyapparajCopyright:

Available Formats

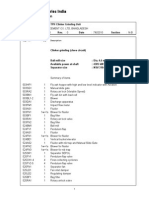

MAT 1220

MCGB - DATA SHEET FOR SUPPLIERS Old MAT Nos.: 122, -, -

Pressure Vessel Plate, Low Alloy Steel, Mo

For more information contact F.L. Smidth

PROPERTIES:

Hot rolled boiler plate, wide flats and shapes for medium temperatures.

Tensile strength Rm > 450 MPa. For low temperatures other Impact Energy values can be agreed in the order.

At increased temperature, MAT 1220 has better yield stress and higher creep strength values compared to MAT

1200 and MAT 1210.

STANDARDS:

General requirements:

When reference to this MAT NO appears on FLS Drawing or FLS Parts List or in FLS Purchace Order the data from the

Primary Standard is used as acceptance criteria.

Specific deviations in requirements made in the FLS Parts List, the FLS Purchace Order or a FLS Instruction always

overrules this data sheet.

Alternatively accepted International Standards listed in this sheet may be used if the suppliers documentation covers at

least the documentation required in the Primary Listed Standard. This means that supplementary tests in some cases

will be necessary.

Primary Standard:

EN 10028-2 (2003) , MATERIAL: 16 Mo 3 , MATERIAL No.: 1.5415

Flat products made of steel for pressure purposes - Part 2: Non-alloy and alloy steels with specified

elevated temperature properties

CHEMICAL COMPOSITION:

Dim, mm % C max % Si max % Mn max or % P max % S max % N max % Al min

or range or range range or range or range or range or range

0.12-0.2 0.35 0.4-0.9 0.025 0.01 - *

* The Al content of the cast shall be determined and given in the inspection document

Dim, mm % Cr max % Mo max % Ni max % V max % Nb max % Ti max % Cu max % Other max

or range or range or range or range or range or range or range or range

0.30 0.25-0.35 0.30 - - - 0.30

MECHANICAL PROPERTIES AT ROOM TEMPERATURE:

Condi- Dim, mm Tensile Strength Yield Strength Elong. Area M.Elas Hardness Imp. Energy

tion MPa MPa % Reduction GPa KV, min

Rm Re A5 Z Z⊥ E HRc HB HV °C J

N 0-16 440 - 590 275 - 22 - - - - - - 20 31

N 16-40 440 - 590 270 - 22 - - - - - - 20 31

N 40-60 440 - 590 260 - 22 - - - - - - 20 31

N 60-100 430 - 560 240 - 22 - - - - - - 20 31

N 100-150 420 - 570 220 - 22 - - - - - - 20 31

N 150- 410 - 570 210 - 22 - - - - - - 20 31

N: Normalised. Values of Creep Stress and Creep Strength have a scatter band of +- 20%. Yield Strength at elevated

temperatures for dimensions less than 150 mm are up to 25% higher.

Rev_No: 0,8 Issue_Date: 01-06-1998 Prepared by: AsK

Rev_Date: 15-01-2004 Approved by: ESJ Page 1 of 3

MAT 1220

MCGB - DATA SHEET FOR SUPPLIERS Old MAT Nos.: 122, -, -

Pressure Vessel Plate, Low Alloy Steel, Mo

For more information contact F.L. Smidth

ALTERNATIVE INTERNATIONAL STANDARDS TO MAT 1220

Standard Type of Material Name of Material Material No.

() Plates 15 Mo 3 1.5415

ASTM A 204 (1993) Plates Gr. A .

ASTM A 387/A 387M (1999) Plates Gr. 2, Cl. 2 .

EN 10028-2 (2003) Plates 16 Mo 3 1.5415

ISO 9328-2 (1991) Plates 16 Mo 3 .

JIS G 3103 (1987) Plates SB 46 M, SB 49 M .

ACEA: Association des Constructeurs Europeans d'Automobiles DIN: Deutsche Industrie-Norm

AGMA: American Gear Manufacturers's Association EN: European Norm

API: American Petroleum Insitute IEC: International Electrotechnical Commission

ASTM: American Society for Testing Material ISO: International Organisation for Standardizatio

BS: British Standard JIS: Japanese Industrial Standard

CCMC: Committee of Common Market Constructors NLGI: National Lubricating Grease Institute

DS: Dansk Standard SAE: Society of Automotive Engineer

DELIVERY CONDITIONS:

Products supplied according to the primary standard shall be delivered normalised or in an equivalent

condition unless otherwise agreed upon.

Rev_No: 0,8 Issue_Date: 01-06-1998 Prepared by: AsK

Rev_Date: 15-01-2004 Approved by: ESJ Page 2 of 3

MAT 1220

MCGB - DATA SHEET FOR SUPPLIERS Old MAT Nos.: 122, -, -

Pressure Vessel Plate, Low Alloy Steel, Mo

For more information contact F.L. Smidth

Revisions:

Rev. No Rev. Date Change Responsible

0,6 31-01-2002 Text editions AnJo

Prepared & Approved changed

References to Alternative Standards added to supplier version

Added temp requirements for 300 oC.

0,7 12-03-2003 Welding electrode number changed by adding 9000. Welding electrodes are AsK

transfered to Purchase Parts.

0,8 15-01-2004 Standards updated AsK

Rev_No: 0,8 Issue_Date: 01-06-1998 Prepared by: AsK

Rev_Date: 15-01-2004 Approved by: ESJ Page 3 of 3

You might also like

- 2600: The Hacker Quarterly (Volume 2, Number 11, November 1985)Document8 pages2600: The Hacker Quarterly (Volume 2, Number 11, November 1985)Ranko Kohime100% (1)

- 2600 2-12 PDFDocument8 pages2600 2-12 PDFBobHoskinsNo ratings yet

- PULLEY LAGGING RUBBER SHEETDocument1 pagePULLEY LAGGING RUBBER SHEETSanatha AgungNo ratings yet

- Mat 2640 For Suppliers PDFDocument3 pagesMat 2640 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Abrasion Resistant Cast Iron Data SheetDocument3 pagesAbrasion Resistant Cast Iron Data Sheetbaskaran ayyapparaj100% (1)

- Call Center MetricsDocument16 pagesCall Center MetricspratimNo ratings yet

- Mat 3422 For Suppliers PDFDocument3 pagesMat 3422 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Chapter 5 Final A5 EditDocument8 pagesChapter 5 Final A5 EditkINGNo ratings yet

- Strip Assess Report TK HPGR Template Rev0Document18 pagesStrip Assess Report TK HPGR Template Rev0Alison Taype100% (1)

- MAT 3420 Data SheetDocument3 pagesMAT 3420 Data SheetDiógenes da Silva PereiraNo ratings yet

- MS 06 16 PDFDocument4 pagesMS 06 16 PDFPrateek RajNo ratings yet

- Thermal Insulation Application GuideDocument7 pagesThermal Insulation Application GuideAbhishek KumarNo ratings yet

- Commissioning Guide LinesDocument53 pagesCommissioning Guide LinesthurawinNo ratings yet

- Mat 2660 For Suppliers PDFDocument3 pagesMat 2660 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Mat 3800 For Suppliers PDFDocument3 pagesMat 3800 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Mat 3810 For Suppliers PDFDocument3 pagesMat 3810 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Aramco Electrical Safety HandbookDocument5 pagesAramco Electrical Safety HandbookFarhan M100% (1)

- Tech Spec. of EOT CraneDocument7 pagesTech Spec. of EOT CraneSuresh MuttaNo ratings yet

- Cleaner Production Techniques and Strategies for Cement IndustryDocument5 pagesCleaner Production Techniques and Strategies for Cement IndustryBECCA2908No ratings yet

- Hempadur 15570Document2 pagesHempadur 15570Edwin HarrisNo ratings yet

- Ecodial Advance Calcualtion IndiaDocument16 pagesEcodial Advance Calcualtion IndiaJosé Mendes da Silva100% (1)

- Chapter12 David Operational GeometallurgyDocument9 pagesChapter12 David Operational GeometallurgyOROSCOROCANo ratings yet

- Transfer of Solids Pipeline DesignDocument8 pagesTransfer of Solids Pipeline DesignKevin Alberto Tejera PereiraNo ratings yet

- MAT 2520 MCGB - Data Sheet For Suppliers Old MAT No.: 321: PropertiesDocument3 pagesMAT 2520 MCGB - Data Sheet For Suppliers Old MAT No.: 321: PropertiesDiógenes da Silva PereiraNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon SteelDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedgraduateNo ratings yet

- Preheater Installation Check List: PlantDocument11 pagesPreheater Installation Check List: PlantJCSNo ratings yet

- AUMUND Bucket Elevators 180801Document16 pagesAUMUND Bucket Elevators 180801Tino TorehNo ratings yet

- Rev0 - Repair-Instructions PDFDocument8 pagesRev0 - Repair-Instructions PDFZantar AbdelhaqNo ratings yet

- PFI HFB High Flow Pleated Bag Filter CartridgeDocument2 pagesPFI HFB High Flow Pleated Bag Filter Cartridgebennypartono407No ratings yet

- Insert Able Jet Pulse FilterDocument4 pagesInsert Able Jet Pulse FilterM.IBRAHEEMNo ratings yet

- Kast O Lite 30 Li GDocument2 pagesKast O Lite 30 Li GaamirsaddiqNo ratings yet

- Copper Slag MSDSDocument1 pageCopper Slag MSDSanon_302374528No ratings yet

- IBR Sec 385 PDFDocument9 pagesIBR Sec 385 PDFgokul_raamNo ratings yet

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 pagesElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- Bijur Delimon KatalogDocument24 pagesBijur Delimon Katalogdamian_k19No ratings yet

- Cast Central Pipe - EN - SmidthDocument4 pagesCast Central Pipe - EN - SmidthLuis Orlando Villarroel TorrezNo ratings yet

- Rubber Lining PrinciplesDocument5 pagesRubber Lining PrinciplesTushar MangratiNo ratings yet

- HSMS DescriptionDocument2 pagesHSMS DescriptionVũ Văn Thành100% (1)

- Rotary Valves ZRSDocument7 pagesRotary Valves ZRSkosmcNo ratings yet

- B Boehler X 70-IG de en 5Document1 pageB Boehler X 70-IG de en 5Jorge RushNo ratings yet

- Aftermarket Services For Furnaces and Incinerators: CertificationDocument2 pagesAftermarket Services For Furnaces and Incinerators: Certificationaziman1991No ratings yet

- Q245R PDFDocument2 pagesQ245R PDFAnonymous 9zykaX6T100% (1)

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Document1 pageAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNo ratings yet

- Maintain Slide Gate ManuallyDocument22 pagesMaintain Slide Gate ManuallyRahmat YusufNo ratings yet

- Install and Maintain Premium Helical Geared MotorsDocument8 pagesInstall and Maintain Premium Helical Geared MotorsKUNALJAYNo ratings yet

- Rockwool Insulation LRB MatressDocument1 pageRockwool Insulation LRB MatressJaveed KhanNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Sintering ProcessDocument4 pagesSintering ProcessNicollas Matheus100% (1)

- Application Procedure ROCKHARD-90Document4 pagesApplication Procedure ROCKHARD-90JCSNo ratings yet

- HK 40 SSDocument3 pagesHK 40 SSsonara mansukhNo ratings yet

- Arcelormittal Pressure VesselDocument10 pagesArcelormittal Pressure VesselkokopirokoNo ratings yet

- Ash Handling CatalogueDocument8 pagesAsh Handling CatalogueVaijayanti JoshiNo ratings yet

- Major Project-1Document177 pagesMajor Project-1api-19884175No ratings yet

- Design of Main GirderDocument58 pagesDesign of Main GirderovikbasuNo ratings yet

- Dokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerDocument8 pagesDokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerjulianoducaNo ratings yet

- Is Code List - ConveyorDocument4 pagesIs Code List - Conveyorpinksp5No ratings yet

- E-302B leakage repair scheduleDocument7 pagesE-302B leakage repair schedulesaadpervaiz14No ratings yet

- Cement Production Technology PapersDocument0 pagesCement Production Technology PapersBruno Vilas BoasNo ratings yet

- Material Safety Data Sheet: MSDS: Lafarge Portland CementDocument6 pagesMaterial Safety Data Sheet: MSDS: Lafarge Portland Cementazer100% (1)

- Westcar PDFDocument40 pagesWestcar PDFrrrdrigoNo ratings yet

- HVAC Catalogue 2016Document233 pagesHVAC Catalogue 2016Vincent GabrielNo ratings yet

- Vacuum Pumps Common Problems and TroubleshootingDocument18 pagesVacuum Pumps Common Problems and TroubleshootingAV kayanNo ratings yet

- Cemtec 190 SPDocument2 pagesCemtec 190 SPpravi3434No ratings yet

- Thyssenkrupp Industries India: Polysius Cement DivisionDocument23 pagesThyssenkrupp Industries India: Polysius Cement DivisionunimarinesNo ratings yet

- CB Continental CatalogueDocument69 pagesCB Continental CatalogueAina LikuntatiNo ratings yet

- 718 Stangard Egf (NV)Document5 pages718 Stangard Egf (NV)Sandeep gangulyNo ratings yet

- Cement Mills Inspection ReportDocument4 pagesCement Mills Inspection Reportzain140No ratings yet

- HSLA Steel Specifications and PropertiesDocument3 pagesHSLA Steel Specifications and Propertiesbaskaran ayyapparajNo ratings yet

- 16MO3 Data Sheet PDFDocument1 page16MO3 Data Sheet PDFMohamedNo ratings yet

- Holiday List 2020Document1 pageHoliday List 2020baskaran ayyapparajNo ratings yet

- KG-DWN-98 - 2 - Stalk Fabrication - DPR 78 Dated 23.01.20Document1 pageKG-DWN-98 - 2 - Stalk Fabrication - DPR 78 Dated 23.01.20baskaran ayyapparajNo ratings yet

- Holiday List 2021Document1 pageHoliday List 2021baskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon SteelDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparaj100% (1)

- Holiday List 2019Document1 pageHoliday List 2019baskaran ayyapparajNo ratings yet

- MAT 2130 - Heat-treatable Carbon Steel Data SheetDocument3 pagesMAT 2130 - Heat-treatable Carbon Steel Data Sheetbaskaran ayyapparajNo ratings yet

- Cold-Rolled Steel Data SheetDocument3 pagesCold-Rolled Steel Data Sheetbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 140, - , - : Bright Steel, Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 140, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 282, - , - : Carbon Steel For Large ForgingsDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 282, - , - : Carbon Steel For Large Forgingsbaskaran ayyapparajNo ratings yet

- MAT 2002 Data SheetDocument3 pagesMAT 2002 Data Sheetbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, MachinedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, Machinedbaskaran ayyapparajNo ratings yet

- Cold-rolled steel data sheetDocument3 pagesCold-rolled steel data sheetbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- Bright Steel Data SheetDocument3 pagesBright Steel Data Sheetbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Structural Steel, Carbon Steel, Killedbaskaran ayyapparajNo ratings yet

- Mat 2650 For Suppliers PDFDocument3 pagesMat 2650 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Mat 3820 For Suppliers PDFDocument3 pagesMat 3820 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Mat 2630 For Suppliers PDFDocument3 pagesMat 2630 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Mastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingEngTamerNo ratings yet

- JMeter OAuth SamplerDocument3 pagesJMeter OAuth SamplerFredy NataNo ratings yet

- AART To Revitalize Aarhus Port District With TerracedDocument4 pagesAART To Revitalize Aarhus Port District With TerracedaditamatyasNo ratings yet

- Nikola Tesla PaperDocument6 pagesNikola Tesla Paperapi-302403539No ratings yet

- Ryu RingkasanDocument20 pagesRyu RingkasanBest10No ratings yet

- Lobbying Vacations For CongressDocument54 pagesLobbying Vacations For CongressBigMamaTEANo ratings yet

- Kollmorgen PMA Series CatalogDocument6 pagesKollmorgen PMA Series CatalogElectromateNo ratings yet

- 10-20 Belt Scale MT9101 8017.0113Document4 pages10-20 Belt Scale MT9101 8017.0113RickNo ratings yet

- Journal 1 - Laganzo, Escarez, TabilangonDocument35 pagesJournal 1 - Laganzo, Escarez, Tabilangoncloy aubreyNo ratings yet

- Portfolio Ross ReevesDocument17 pagesPortfolio Ross ReevesRoss ReevesNo ratings yet

- Ubd WonderDocument13 pagesUbd Wonderapi-422461005100% (1)

- Joybook A52 Series EnglishDocument44 pagesJoybook A52 Series EnglishTudor VladNo ratings yet

- SNMP Tutorial PDFDocument24 pagesSNMP Tutorial PDFSrivignessh PssNo ratings yet

- Sfrac Notes 61 SolDocument73 pagesSfrac Notes 61 Soldean-stiNo ratings yet

- Legendary Units 1.1Document5 pagesLegendary Units 1.1Alejandro Sanchez GarciaNo ratings yet

- RemoteDocument16 pagesRemotetok222222No ratings yet

- Account Statement 220422 210722Document14 pagesAccount Statement 220422 210722Meherun BibiNo ratings yet

- Wind Load On Cable TraysDocument10 pagesWind Load On Cable TraysAaron EasleyNo ratings yet

- Cross Country Sheets1Document2 pagesCross Country Sheets1Anonymous 10cG5eRp8No ratings yet

- Proceeding 4th Ismei - FinalDocument412 pagesProceeding 4th Ismei - FinalAchmad NizarNo ratings yet

- Oracle® Database: 2 Day + Security Guide 11g Release 1 (11.1)Document130 pagesOracle® Database: 2 Day + Security Guide 11g Release 1 (11.1)arwahannanNo ratings yet

- Imperial SugarDocument44 pagesImperial SugargerardoNo ratings yet

- Bifold Corporate - CatalogueDocument6 pagesBifold Corporate - CatalogueZeeshan KhanNo ratings yet

- Android Snake With Kivy, PythonDocument14 pagesAndroid Snake With Kivy, Pythontsultim bhutiaNo ratings yet