Professional Documents

Culture Documents

IAQ - Duct Cleaning

Uploaded by

Kuku BirdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IAQ - Duct Cleaning

Uploaded by

Kuku BirdCopyright:

Available Formats

feature IAQ

maintaining IAQ

a serious business

Cleaning and decontaminating commercial and industrial HVAC systems is a serious

business, with many associated risks and hazards. As Sean McGowan discovered,

it’s an area largely unregulated in Australia and one which requires high levels of training.

Jeremy Stamkos

12 EcoLibrium™ December 2004

I

f the idea of abseiling down a 150 metre cliff isn’t

frightening enough, imagine abseiling down a

commercial building’s HVAC duct with a breathing

�����������������

apparatus while cleaning the hazardous contamination

that has accumulated over the years.

That’s the task facing the staff of companies like Enviro

Air Pty Ltd, which provide specialist air system cleaning

solutions for commercial and industrial environments.

����������������

According to Enviro Air’s managing director, Jeremy

Stamkos, the lack of Australian regulations has led to the

company acquiring NADCA (National Air Duct Cleaners

Association U.S.A.) accreditation, and seeking a host of

other training options for its staff to ensure it satisfies the

NADCA requirements.

“Along with NADCA accreditation, our international

training covers areas such as property mould

remediation, biohazardous recovery, certified air systems

cleaning, ventilation systems mould remediation,

certified ventilation inspection and attendance at regional

workshops,” explains Stamkos. �������������������������

��������������������������

“It can be quite a complicated and time ��������������������

consuming activity to send technicians

��������

into ductwork”

“Due to the difficulties encountered when accessing ���������������������������������

HVAC systems, our teams must also be qualified in

general and mechanical plumbing, as well as asbestos

�������������������������������������������������

awareness and friable and non-friable asbestos removal.” �������������������������������������������

Along with training specific to mould and other potentially ���������������������������

hazardous contaminants, remediation technicians must

�������������������������

also have undertaken training in twin-rope industrial

access, safe working at heights and within confined ������������������������

spaces, as well as the use of specialised personal

���������������������������

protection equipment (PPE) such as breathing apparatus.

����������������������������������������

“If necessary, it can be quite a complicated and time

consuming activity to send technicians into ductwork,” ��������������������������������������������������

says Stamkos. ����������������������������

“Along with all their cleaning equipment when cleaning ����������������������������������������������

vertical riser shafts, they must wear respiratory

protection; as well as carry ascension devices because

they not only have to go down 26 storeys, but they have

to climb all the way back up. There’s a lot of specialised

equipment involved to be able to go down safely and

come back up again.”

“The remote robots work effectively up to

about 50 metres at a time”

Due to the obviously high OH&S risks associated with

sending cleaning technicians into HVAC ducts, the

company utilises cleaning robots wherever possible.

These robots (as pictured) are sent into ducts with a

range of tools to dislodge microbial growth and other

contaminants. As contaminants are dislodged, they

�������������������������

are extracted out of the system using HEPA equipped ����������������������������

negative air units.

������������������

������������������

Inset and next page – some of the equipement used in HVAC system cleaning

��������������������������

��������������������������

feature IAQ

“The remote robots generally only Such is the experience of Enviro Air how you control it – there is nothing

work effectively up to about 50 metres and their use of personal protection existing in Australia,” says Stamkos.

at a time. You then need to find or equipment and engineering controls

“In the US, you must validate your

create another access point to resume (to contain airborne contaminants,

cleaning process by three different

cleaning,” says Stamkos. dust and fumes), that the company is

methods – by visual assessment; surface

now providing other areas of hazardous

“Unfortunately access points comparison testing; or by

are not installed for cleaning having a swab analysed

unless specified, so in many independently.”

instances, we have to install

“Their standard also

them ourselves or use

regulates the use of anti-

existing access provisions

microbial products. Here,

such as inspection

there is no regulation as

openings. We keep them to

to what can be used to

a minimum to maintain the

disinfect HVAC systems.

integrity of the system, so

As such, we only use

the further you can go with

products that have been

your cleaning equipment,

authorized by the US EPA

the more efficient you are

(Environment Protection

going to be.”

Agency) or by the

Robots are able to clean Therapeutic Goods Authority

the ductwork effectively by here in Australia and

using a series of brushes designed for use in HVAC

and whips powered by systems.”

compressed air and other

Stamkos believes the

gases, while a small camera mounted on material removal, such as microbial and

Australian industry should adopt the

top of the robot allows the controller to asbestos removal.

American model and the American

guide it through the ducts and verify the

Stamkos says that until the industry Standard ACR-2005, which is called

effectiveness of

is regulated in Australia, however, up as regulation by ASHRAE and other

the cleaning process.

some service providers will continue to US state authorities. He says it is an

“We try and do the majority of our work only clean what building owners and extremely comprehensive guideline that

with remote cleaning due to the OH&S operators can see, leaving the more only needs minor alterations for the local

issues, but where we are required to difficult to access areas to continue industry.

clean a shaft in a multi-storey building, to build up with mould and other

“Aside from cutting holes in ductwork,

robots become obsolete and sending a contaminants.

working at heights and so on, it’s the

technician down is required to get the

“The only regulations and standards associated endemic health and safety

job done.”

existing refer to the installation or risks to building occupants, and also the

Not only are there risks in what teams servicing of mechanical ventilation involved contractors, that should be the

find within ducts, but there are also systems, hence the need for our biggest catalyst for Australian regulations

risks in the processes of cleaning, technicians to be trained in mechanical to get up and running relatively quickly.”

especially when considering the use of plumbing. As far as how clean a HVAC

antimicrobials and other chemicals. system should be, how you clean it and

14 EcoLibrium™ December 2004 /January 2005

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Roles and Functions of FestivalsDocument5 pagesRoles and Functions of FestivalsCristina Rodica100% (1)

- Nouns Pronouns Articles Quantifiers TEST5Document6 pagesNouns Pronouns Articles Quantifiers TEST5Selin Saygın KayaNo ratings yet

- Engine Oil Additive Technology Summary.Document4 pagesEngine Oil Additive Technology Summary.Adid PunyaNo ratings yet

- Soal UTSDocument2 pagesSoal UTSRohman 134No ratings yet

- ESS Pollution Detection MethodsDocument3 pagesESS Pollution Detection MethodsarctusshadeNo ratings yet

- Presentation On: Air Pollution - Issues and Its ControlDocument19 pagesPresentation On: Air Pollution - Issues and Its Controlyogesh100% (1)

- Sustainable Development Strategies at IBMDocument10 pagesSustainable Development Strategies at IBMSakshi GuptaNo ratings yet

- Ayesha's Biology Research Project - Oil SpillDocument16 pagesAyesha's Biology Research Project - Oil SpillAyesha JannahNo ratings yet

- Report 1 533191Document283 pagesReport 1 533191Ana DraghiciNo ratings yet

- Module 1.1 Phillipine Environmental LawsDocument9 pagesModule 1.1 Phillipine Environmental LawsArbeeChrystelV.AleraNo ratings yet

- California Retailers Guide To Hazardous Waste ComplianceDocument4 pagesCalifornia Retailers Guide To Hazardous Waste ComplianceStericycle100% (1)

- 380-425 MW Combined Cycle Power Plant Pollution Control MeasuresDocument4 pages380-425 MW Combined Cycle Power Plant Pollution Control MeasuresChava TejaNo ratings yet

- European Biochar Market Report 2021/2022: March 2022Document44 pagesEuropean Biochar Market Report 2021/2022: March 2022Anshul AgarwalNo ratings yet

- We Should Only Be Allowed To Drive 4 Days A WeekDocument2 pagesWe Should Only Be Allowed To Drive 4 Days A WeekMallo KaiNo ratings yet

- Urban Sprawl and How It Affects The EnvironmentDocument5 pagesUrban Sprawl and How It Affects The EnvironmentSylvan CuregNo ratings yet

- Groundwater Monitoring Well DrillingDocument39 pagesGroundwater Monitoring Well DrillingJoan Sifuentes0% (1)

- Q2 EnviDocument17 pagesQ2 EnvijnikkoNo ratings yet

- Kamareddy DEP PlanDocument15 pagesKamareddy DEP PlanArun Jyothi CNo ratings yet

- Why The Underdogs Came Out AheadDocument7 pagesWhy The Underdogs Came Out Aheadterminator1000bcNo ratings yet

- Towards Free Carbon-Dioxide and More Sustainable EnvironmentDocument2 pagesTowards Free Carbon-Dioxide and More Sustainable EnvironmentRowan SalemNo ratings yet

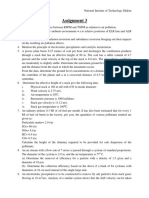

- Assignment 3Document3 pagesAssignment 3HARINo ratings yet

- LNG value chain and shipping overviewDocument28 pagesLNG value chain and shipping overviewAbhinav Gupta100% (1)

- MUKEDocument17 pagesMUKEShridhar HattiNo ratings yet

- Toolbox On Drum Handling: Facilitator: Kikile Masomese Henry. Date: 5 August, 2014Document1 pageToolbox On Drum Handling: Facilitator: Kikile Masomese Henry. Date: 5 August, 2014Masomese Henry KikileNo ratings yet

- Course Outline Preventive ConservationDocument36 pagesCourse Outline Preventive ConservationDan Octavian PaulNo ratings yet

- PGDIS Safety Diploma Chemical Engineering IndustriesDocument3 pagesPGDIS Safety Diploma Chemical Engineering IndustriesSt. Xavier's Public SchoolNo ratings yet

- Revised Senior PaperDocument7 pagesRevised Senior Paperapi-457162233No ratings yet

- Method 17 - Determination of Particulate Matter Emissions From Stationary SourcesDocument7 pagesMethod 17 - Determination of Particulate Matter Emissions From Stationary SourcesElizabeth Cares LiraNo ratings yet

- I. Project Title: The 4R's (Reduce, Reuse, Recycle, Recover)Document4 pagesI. Project Title: The 4R's (Reduce, Reuse, Recycle, Recover)Eka MagsigayNo ratings yet