Professional Documents

Culture Documents

Alastair D Martin

Uploaded by

Nuurul LathiifahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alastair D Martin

Uploaded by

Nuurul LathiifahCopyright:

Available Formats

Understanding Anaerobic

Digestion

Alastair D. Martin BSc PhD CEng MIChemE

Director: Environment and Sustainable Technology Programmes

School of Chemical Engineering and Analytical Science

University of Manchester

The Environment and

Sustainable Technology

Fundamentals: Descriptions

• To a Biologist

– Genetically diverse eco system

• To a Civil Engineer

– Engineered environment

• To a chemical engineer

– Heterogenous auto catalytic sequence parallel reaction

system

• Reactants in multiple phases typically more than 5

• Reaction products are catalysts for the continuation of the

process

• Feedstock passes through a sequence of reactions in series

• Inside a reactor all the reactions are going on at once

– Horrendously complex!!

The Environment and

Sustainable Technology

Fundamentals: Schematic model

Organic polymers

Fats, proteins, poly-saccharides

Hydrolysis Fermentative

NH4+,S2-

micro-organisms

4% 76% 20%

Alcohols,

C3+ carboxylic acids

Acetogenesis

24% 52%

Acetogens

H2, CO2 Acetate

Hydrogenophilic Acetophilic

28% 72%

Methanogenesis methanogens methanogens

CH4, CO2

The Environment and

Sustainable Technology

Fundamentals: Issues

• Methanogenesis

– Sensitive to both high (>8) and low (<6.5) pH

– Activity virtually ceases below pH 6

– Process fails if this becomes rate controlling step

• Acidogenesis

– Rarely rate controlling step

– Stable activity even below pH4

• Hydrolysis

– Must be rate controlling step

• Systems must be engineered to maintain this status

– Catastrophic failure can occur when this ceases to be true

• Systems vulnerable during turn-up

• Increasingly vulnerable at higher digestion rates

The Environment and

Sustainable Technology

Objectives

• Product synthesis

– Bio-gas

– Volatile fatty acids

– Phosphate

– Soil conditioner

• Solids destruction

• Energy production

• Sanitisation/Pasteurisation

• Usually multiple

The Environment and

Sustainable Technology

Technologies: Wet or Dry

• Wet

– Typically less than 10% solids in the reactor

– Reasonably homogeneous mobile slurry

– Characteristic technologies

• Wastewater treatment plant digesters (MAnD)

• Dry

– Typically greater than 20% solids

– Heterogeneous fixed bed of solids

• Solids “flushed” with liquid digestate

– Characteristic technologies

• In vessel anaerobic composting

• Landfill (Flushing bio-reactor)

The Environment and

Sustainable Technology

Technologies: Mesophillic (MAnD)

• Most common technology

• Meso – middling 35 ±3oC

• Residence time greater than 10 days

– “Stability” issues at low residence time

• Very large

– Continuous stirred tank reactors (CSTR)

– Batch fed continuous reactors

• Typically 97% (1.5log) destruction of pathogens

– More an issue of hydrodynamics than bio-kinetics

The Environment and

Sustainable Technology

Technologies: Thermophilic (TAnD)

• As yet uncommon

• Thermo – warm 55 ±5oC

• Residence time 5 – 10 days

– Fast dynamics may be confused with instability

• Substantially smaller reactors – to date

– Usually batch fed

• Typically 6log destruction of pathogens

– Consistent with reaction rate rules of thumb

• Energy and odour management significant issues

The Environment and

Sustainable Technology

Technologies: Mixing

• Good mixing is critical!

• What is “good mixing”?

• Blend feed material with Overflow Draw off

reactor contents

• Homogenise reactor contents

• Eliminate bypassing

• Prevent sedimentation

• Tall order in 8000m3 tank

Circulation

• Many subtleties pump

Drain

Feed

• Beware the snake oil

salesman! Feed

pump

The Environment and

Sustainable Technology

Technologies: Phased digestion

• Better control

– If intermediate storage provided

• Better pathogen destruction

• Greater reactor productivity

– Acidogenesis residence time approximately 2 days

– Acids may be a useful product

Acidogenic Methanogenic

digestion digestion

The Environment and

Sustainable Technology

Technologies: Hydrolysis

• Enzymic hydrolysis (UU technology)

• Pathogen destruction >6log

• Useful VFA solution ex-hydrolysis stages

• Hydrolysis residence time less than 5 days

Methanogenic

digestion

35OC 35OC 35OC 35OC 35OC 55OC 35OC

Enzymic hydrolyser

The Environment and

Sustainable Technology

Conclusions

• Does Anaerobic Digestion hold the key

– Not THE MASTER KEY

– But an important key in a suite

• Performance: 1- 5kg/(m3d)

– Could do better

• Must do better to become a practical technology for BMW

10 – 100kg/(m3d)

• Integration

– Product utilisation

• Other bio and/or chemical processes

– Energy

• Products

– Not just bio-gas

The Environment and

Sustainable Technology

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Activity 1 DIASSDocument3 pagesActivity 1 DIASSLJ FamatiganNo ratings yet

- Offer Letter for Tele Sales ExecutiveDocument3 pagesOffer Letter for Tele Sales Executivemamatha vemulaNo ratings yet

- Technical Contract for 0.5-4X1300 Slitting LineDocument12 pagesTechnical Contract for 0.5-4X1300 Slitting LineTjNo ratings yet

- Should Animals Be Banned From Circuses.Document2 pagesShould Animals Be Banned From Circuses.Minh Nguyệt TrịnhNo ratings yet

- Complicated Grief Treatment Instruction ManualDocument276 pagesComplicated Grief Treatment Instruction ManualFrancisco Matías Ponce Miranda100% (3)

- Ultramat 2 instructions for useDocument2 pagesUltramat 2 instructions for useBalaji BalasubramanianNo ratings yet

- 12.1 MagazineDocument44 pages12.1 Magazineabdelhamed aliNo ratings yet

- Lesson 2 Globalization of World EconomicsDocument17 pagesLesson 2 Globalization of World EconomicsKent Aron Lazona Doromal57% (7)

- Classen 2012 - Rural Space in The Middle Ages and Early Modern Age-De Gruyter (2012)Document932 pagesClassen 2012 - Rural Space in The Middle Ages and Early Modern Age-De Gruyter (2012)maletrejoNo ratings yet

- B2 WBLFFDocument10 pagesB2 WBLFFflickrboneNo ratings yet

- Ethiopian Civil Service University UmmpDocument76 pagesEthiopian Civil Service University UmmpsemabayNo ratings yet

- Topic 4: Mental AccountingDocument13 pagesTopic 4: Mental AccountingHimanshi AryaNo ratings yet

- Pale Case Digest Batch 2 2019 2020Document26 pagesPale Case Digest Batch 2 2019 2020Carmii HoNo ratings yet

- The Effects of Cabergoline Compared To Dienogest in Women With Symptomatic EndometriomaDocument6 pagesThe Effects of Cabergoline Compared To Dienogest in Women With Symptomatic EndometriomaAnna ReznorNo ratings yet

- University of Wisconsin Proposal TemplateDocument5 pagesUniversity of Wisconsin Proposal TemplateLuke TilleyNo ratings yet

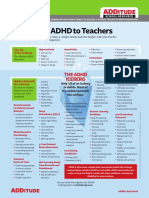

- Explaining ADHD To TeachersDocument1 pageExplaining ADHD To TeachersChris100% (2)

- Adic PDFDocument25 pagesAdic PDFDejan DeksNo ratings yet

- Labov-DIFUSÃO - Resolving The Neogrammarian ControversyDocument43 pagesLabov-DIFUSÃO - Resolving The Neogrammarian ControversyGermana RodriguesNo ratings yet

- Strategies To Promote ConcordanceDocument4 pagesStrategies To Promote ConcordanceDem BertoNo ratings yet

- The Wild PartyDocument3 pagesThe Wild PartyMeganMcArthurNo ratings yet

- Heidegger - Nietzsches Word God Is DeadDocument31 pagesHeidegger - Nietzsches Word God Is DeadSoumyadeepNo ratings yet

- Note-Taking StrategiesDocument16 pagesNote-Taking Strategiesapi-548854218No ratings yet

- Notes Socialism in Europe and RussianDocument11 pagesNotes Socialism in Europe and RussianAyaan ImamNo ratings yet

- Classification of Boreal Forest Ecosystem Goods and Services in FinlandDocument197 pagesClassification of Boreal Forest Ecosystem Goods and Services in FinlandSivamani SelvarajuNo ratings yet

- LTD Samplex - Serrano NotesDocument3 pagesLTD Samplex - Serrano NotesMariam BautistaNo ratings yet

- 4AD15ME053Document25 pages4AD15ME053Yàshánk GøwdàNo ratings yet

- IB Theatre: The Ilussion of InclusionDocument15 pagesIB Theatre: The Ilussion of InclusionLazar LukacNo ratings yet

- Kedudukan Dan Fungsi Pembukaan Undang-Undang Dasar 1945: Pembelajaran Dari Tren GlobalDocument20 pagesKedudukan Dan Fungsi Pembukaan Undang-Undang Dasar 1945: Pembelajaran Dari Tren GlobalRaissa OwenaNo ratings yet

- Sigma Chi Foundation - 2016 Annual ReportDocument35 pagesSigma Chi Foundation - 2016 Annual ReportWes HoltsclawNo ratings yet

- Faxphone l100 Faxl170 l150 I-Sensys Faxl170 l150 Canofax L250seriesDocument46 pagesFaxphone l100 Faxl170 l150 I-Sensys Faxl170 l150 Canofax L250seriesIon JardelNo ratings yet