Professional Documents

Culture Documents

Mason Industries, Inc.: TYPE "C" Spring Mountings Provide A Packaged Solution To

Uploaded by

Anunay BhatiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mason Industries, Inc.: TYPE "C" Spring Mountings Provide A Packaged Solution To

Uploaded by

Anunay BhatiaCopyright:

Available Formats

MASON INDUSTRIES, Inc.

Manufacturers of Vibration Control Products

350 Rabro Drive Hauppauge, NY 11788 631/348-0282 FAX 631/348-0279 Info@Mason-Ind.com www.Mason-Ind.com 2101 W. Crescent Ave., Suite D Anaheim, CA 92801 714/535-2727 FAX 714/535-5738 Info@MasonAnaheim.com www.MasonAnaheim.com

HOUSED SINGLE and MULTIPLE SPRING MOUNTS

TYPE

C-210-2 BULLETIN

TYPE C Spring Mountings provide a packaged solution to troublesome vibration problems. Since the static deflection of the spring element is much greater than that provided by most rubber materials, these units will perform where it is necessary to establish low natural frequencies or to use a mounting that is more yielding than the supporting floor. Type C mountings are specifically designed for noise and vibration free application in critical areas on light concrete or wooden floors.

TYPE CS mountings have built in adjustable snubbers for shock absorbing and high horizontal thrust applications. The damping, or housing drag, is varied by means of end adjustment bolts which change the pressure on the solid neoprene inserts. Tightening the snubbers reduces vertical movement and limits bounce. The same adjustment controls side motion and rock. Wear is negligible as damping is provided by the viscous-distortion of the neoprene inserts rather than by friction. Adjustable snubbers are recommended for applications under punch presses, drop hammers, clickers and other industrial equipment.

Semi-circular Neoprene sponge inserts limit movement during start and stop and prevent contact between the projections of the upper and lower semi-steel castings. These inserts are designed for a minimum of damping in all directions to allow the springs to function properly and develop installed efficiencies that are very close to the theoretical. Non-adjustable inserts are recommended for all air conditioning applications under compressors, air handling units, centrifugal fans and most other constant frequency vibration problems.

EXTERNAL adjustment mountings are used when equipment mounting holes are well centered and the mounting leveling and adjustment bolt is accessible from above.

Other oil-resistant stocks may be substituted for Neoprene as new elastomers are developed.

INTERNAL adjustment mountings provide a means of attachment when it is preferable to shift the center of the mounting in relation to the equipment mounting hole or where there is no access for adjustment from above. Attachment to the equipment may be made either by an individually located tapped hole or by a type W friction pad cemented on top of the mounting. The internal spring adjustment bolt is reached through the side opening by means of an open end wrench. Both external and internal adjustment mountings are provided with type W acoustical friction pads on bottom to eliminate the need for bolting down on most installations.

C, CI, CIP, CIW, CS & CSI

1 & 2 Deflection SINGLE and MULTIPLE SPRING MOUNTS

MASON INDUSTRIES

Dowel Pin is 38 dia for CIP-A & 12 thereafter FRICTION PAD (Bolting to Equipment is not necessary)

TOP ACCESS ADJUSTMENT BOLT Turn clockwise to load spring and maintain Free & Operating Height. Bolt length is suitable for 1 maximum Equipment Base thickness.

"B" TAP

A

LOCKNUT EQUIPMENT BASE FERROUS HOUSING

CI

CIP

CIW

W

Free & Operating Height

CI, CIP & CIW Mounts have SIDE ACCESS INTERNAL ADJUSTMENT BOLTS. Turn clockwise to load spring and maintain Free & Operating Height.

SW HCW C

NON-SKID NEOPRENE ACOUSTICAL ISOLATION PAD (Bolting to floor is not necessary on indoor applications)

L T

HCL SBC

MAX BOLT DIA - MBD

BASE PLATE DIMENSIONS FOR C, CI, CIP & CIW (Top Plate Dim. for CI Only)

TYPE C, CI, CIP & CIW DIMENSIONS (inches) CI Onlyllll B C L T W 3/8 1 53/4 1/2 21/8 1/2 11/4 81/4 1/2 23/4 1/2 11/4 87/8 9/16 31/2 5/8 9/16 12 31/2 5/8 2 123/4 5/8 65/8 3/4 5/8 16 7 3/4 193/4 3/4 10

CS & CSI sizes start at C-1000. A & B sizes are not manufactured. Type C dimensions below apply. Type C Adj. HCW MBD SBC Bolt 1/4 3/8 x 4 1 5 11/2 3/8 71/4 1/2 x 4 13/4 3/8 77/8 5/8 x 41/2 5/8 x 41/2 13/4 3/8 11 3/4 x 5 51/8 1/2 51/8 5/8 Internal 81/4 5/8 Adj. Only 1 Free & Op. Ht. C CI&CIP CIW 41/2 47/8 51/8 55/8 61/8 63/8 55/8 61/8 63/8 61/8 61/2 63/4 61/8 61/2 63/4 63/8 63/4 7 63/8 63/4 7

Rated Capacity (Ibs) 20 26 35 50 65 85 115 150 210 290 450 680 125 170 210 260 330 460 610 880 1210 1540 1870 2420 3080 3740 3520 4840 6160 7480 Rated De (in) 2.40 2.18 2.20 2.20 2.10 2.10 2.00 2.00 2.12 2.00 2.00 2.00 2.50 2.40 2 30 2 20 2.00 2.00 2.00 2.00 2.00 2 00 2 00 2.00 2.00 2.00 2.00 2.00 2.00 2.00

Size A A 4 B & B2 53/4 CC & C2 65/8 CID & D2 93 CIP- E & E2 121/4 /8 CIW- F 16 G 193/4

Type

SW 5/16 7/16 7/16 7/16

HCL 43/4 61/2 71/4 103/8 113/8 141/2 183/8

2 Free & Op. Ht. C CI&CIP CIW 53/4 61/8 63/8 61/2 63/4 7 67/8 71/2 73/4 67/8 71/2 73/4 71/8 73/4 8 71/8 73/4 8

Casting Dimensions vary 18.

Hole is in center.

TYPE 2 DEFL. C, CI, CIP & CIW RATINGS

Mount Constant (Ibs/in) 8 12 16 24 31 40 57 75 99 144 224 340 50 70 90 120 165 230 305 440 605 770 935 1210 1540 1870 1260 2420 3080 3740 Spring Color/Stripe Tan White/Blue Purple White/Red Brown White/Black Silver Orange Silver Blue Tan Gray Purple Brown Red White Black Blue Green Gray Silver Gray* Silver* Silver Gray* Silver* Gray Silver Gray* Silver*

TYPE 1" DEFL. C, CI, CIP & CIW RATINGS

Rated Capacity (Ibs) 45 75 125 200 310 400 510 625 65 85 115 150 280 450 750 1000 1250 1650 1000 1350 1750 2100 2385 2650 2935 3500 4200 4770 5300 5870 7000 8400 9540 10600 11740 12600 14310 15900 17610 18900 21465 23850 26415 Rated De (in) 1.60 1.50 1.33 1.15 1.00 1.00 1.00 1.00 2.10 2.10 2.00 2.00 1.60 1.31 1.12 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 Mount Constant (Ibs/in) 28 50 94 174 310 400 510 625 31 40 57 75 174 344 670 1000 1250 1650 1000 1350 1750 2100 2385 2650 2935 3500 4200 4770 5300 5870 7000 8400 9540 10600 11740 12600 14310 15900 17610 18900 21465 23850 26415 Type Spring Color/Stripe Blue Orange Brown Black Yellow Green Red White Brown White/Black Silver Orange Green Red White Blue Gray Black Black Yellow Black Yellow* Yellow** Red* Red** Black* Yellow* Yellow** Red* Red** Black* Yellow* Yellow** Red* Red** Yellow* Yellow** Red* Red** Yellow* Yellow** Red* Red** Size B-20 B-26 B-35 B-50 B-65 B-85 B-115 B-150 B2-210 B2-290 B2-450 B2-680 C2-125 C2-170 C2-210 C2-260 C2-330 C2-460 C2-610 C2-880 C2-1210 C2-1540 C2-1870 D-C2-2420 D-C2-3080 D-C2-3740 E-C2-3520 E-C2-4840 E-C2-6160 E-C2-7480

Type

Size A-45 A-75 A-125 A-200 A-310 A-400 A-510 A-625 B-65 B-85 B-115 B-150 B-280 B-450 B-750 B-1000 B-1250 B-1650 C-1000 C-1350 C-1750 C-2100 C-2385 C-2650 C-2935 D-3500 D-4200 D-4770 D-5300 D-5870 E-7000 E-8400 E-9540 E-10600 E-11740 F-12600 F-14310 F-15900 F-17610 G-18900 G-21465 G-23850 G-26415

2" Defl. CCICIPCIW-

1" Defl. CCICIPCIW-

All springs without "" have additional travel to solid equal to 50% of the rated deflection. *with RED core spring

*with RED core spring **with GREEN core spring

Published ratings allow minimum 25% additional travel to solid. For a full 50% specified minimum use the following ratings: Derated De Derated De Size Capacity (Ibs) (in) Size Capacity (Ibs) (in) B2-450 410 1.83 D-C2-3080 2570 1.67 B2-680 565 1.66 D-C2-3740 3120 1.67 C2-880 800 1.82 E-C2-3520 3200 1.82 C2-1210 1010 1.67 E-C2-4840 4040 1.67 C2-1540 1285 1.67 E-C2-6160 5145 1.67 C2-1870 1560 1.67 E-C2-7480 6245 1.67 D-C2-2420 2020 1.67

Tm401 4/01

Printed in U.S.A.

You might also like

- BSP 05 UK (Nov-11) PDFDocument20 pagesBSP 05 UK (Nov-11) PDFhepcomotionNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Double Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMDocument6 pagesDouble Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMTeun HaperenNo ratings yet

- Industrial Penstocks GuideDocument19 pagesIndustrial Penstocks Guidedundee2012No ratings yet

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- Gate Valves: Ips Carbon Steel Pipe - Fire Protection ValvesDocument8 pagesGate Valves: Ips Carbon Steel Pipe - Fire Protection ValvesROBNo ratings yet

- Hose Ends - Field AttachableDocument64 pagesHose Ends - Field AttachableSasan AbbasiNo ratings yet

- Inertia Dynamics 2011 CatalogDocument40 pagesInertia Dynamics 2011 CatalogElectromateNo ratings yet

- TSGE - TLGE - TTGE - Reduce Moment High Performance CouplingDocument6 pagesTSGE - TLGE - TTGE - Reduce Moment High Performance CouplingazayfathirNo ratings yet

- F79UDocument4 pagesF79URezi SyahputraNo ratings yet

- SwingClamp BottomFlangeDocument4 pagesSwingClamp BottomFlangePeter CusimanoNo ratings yet

- Cable Gland Selection and SpecificationsDocument1 pageCable Gland Selection and SpecificationsAyman Ibrahim Moh.No ratings yet

- Circular Duct Attenuators: Performance Data - Open TypeDocument3 pagesCircular Duct Attenuators: Performance Data - Open TypePaul ShermanNo ratings yet

- CONTROL ACCESSORIES GUIDEDocument57 pagesCONTROL ACCESSORIES GUIDEpbontyNo ratings yet

- Jet Nozzle New CatalogueDocument3 pagesJet Nozzle New Cataloguedikran33No ratings yet

- MBB50 50Document45 pagesMBB50 50dgfggfhghgdfhtNo ratings yet

- JKV-2300 Series Hydraulic Cylinders Technical SpecificationsDocument44 pagesJKV-2300 Series Hydraulic Cylinders Technical Specificationsmedi38No ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- Pressfit 316 Stainless Steel Pipe SystemDocument12 pagesPressfit 316 Stainless Steel Pipe SystemFaull JackmanNo ratings yet

- Compact solenoid valves for commercial applicationsDocument16 pagesCompact solenoid valves for commercial applicationsJorge Jarpa VNo ratings yet

- CP CatalogDocument20 pagesCP CatalogCentral Hydraulics100% (1)

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Example Vessel Re RatingDocument9 pagesExample Vessel Re RatingRBKUMARNo ratings yet

- Model 770 Ordering GuideDocument2 pagesModel 770 Ordering GuideSkiFy AlexNo ratings yet

- Butterfly Valve, Grooved End, Globe, Model GLR300GDocument9 pagesButterfly Valve, Grooved End, Globe, Model GLR300Grahu2260No ratings yet

- Series 510 Specification SheetDocument2 pagesSeries 510 Specification SheetFEBCONo ratings yet

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDocument2 pagesButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsNo ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineFranklin Avendaño ArapaNo ratings yet

- T101 Drilling Machine BrochureDocument4 pagesT101 Drilling Machine BrochureRicardo OrtegaNo ratings yet

- Rotorseal Tech Specs PDFDocument19 pagesRotorseal Tech Specs PDFMykola TitovNo ratings yet

- Rexnord-Viva Vs enDocument2 pagesRexnord-Viva Vs enDenis AugustoNo ratings yet

- Series 30-31 Butterfly ValveDocument6 pagesSeries 30-31 Butterfly ValveJercy SanchezNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

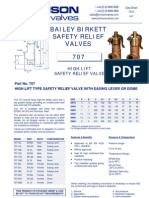

- Johnson Valves 707 High Lift Safety Relief Valve Data SheetDocument1 pageJohnson Valves 707 High Lift Safety Relief Valve Data SheetPaul SinclairNo ratings yet

- Eaton Hansen CatalogoDocument80 pagesEaton Hansen Catalogorubens0001No ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- Air Mite CatalogDocument56 pagesAir Mite Catalogtemoc128No ratings yet

- 10 SEER air conditioner specsDocument4 pages10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- 2010B 2020B VB15 PDFDocument5 pages2010B 2020B VB15 PDFbnjaimahNo ratings yet

- Acoplamientos TSK PDFDocument4 pagesAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- Ceiling Diffusers GuideDocument47 pagesCeiling Diffusers GuideEng Chiew Peng67% (3)

- Model 770: Incremental EncoderDocument2 pagesModel 770: Incremental EncoderwintermacNo ratings yet

- ATC BrochureDocument24 pagesATC BrochureCésar HermosoNo ratings yet

- 23.bladder AccumlatorDocument12 pages23.bladder AccumlatorM S GokulNo ratings yet

- Pgi M 675 M 775 M 678 GS 3Document6 pagesPgi M 675 M 775 M 678 GS 3Juan Carlos Enríquez BarragánNo ratings yet

- HiSpeedD Sub CatalogDocument12 pagesHiSpeedD Sub CatalogSmiths ConnectorsNo ratings yet

- Bombas Dosificadoras Milton Roy Lmi CDocument2 pagesBombas Dosificadoras Milton Roy Lmi CErikLjNo ratings yet

- Series 825YA Specification SheetDocument4 pagesSeries 825YA Specification SheetFEBCONo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Geberit HDPE Installation GuideDocument78 pagesGeberit HDPE Installation GuideSong ThomsonNo ratings yet

- Bras Somatic CompressionDocument4 pagesBras Somatic CompressionThiruvalluvan VembianNo ratings yet

- Metric Section BDocument26 pagesMetric Section BniladriprasadrNo ratings yet

- 09.20 Suction Diffuser Fisa TehnicaDocument13 pages09.20 Suction Diffuser Fisa TehnicadanateoNo ratings yet

- 08 CouplingsDocument30 pages08 Couplingswenny_tpdNo ratings yet

- YOKOHAMA Motorsport Tires Catalogue 2014Document8 pagesYOKOHAMA Motorsport Tires Catalogue 2014gd007200No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- STS 2 Right Deconvolution PDFDocument24 pagesSTS 2 Right Deconvolution PDFHamidatul Husna MatondangNo ratings yet

- A Guide To Mechanical Impedance and Structural Response TechniquesDocument18 pagesA Guide To Mechanical Impedance and Structural Response TechniquesRodrigoNo ratings yet

- Continental Lithosphere - Deep Seismic Reflections PDFDocument434 pagesContinental Lithosphere - Deep Seismic Reflections PDFFabrício CastroNo ratings yet

- Auditory Neuroscience - Jan SchnuppDocument367 pagesAuditory Neuroscience - Jan SchnuppLuisAlfonsoMorales100% (3)

- Vibration Analysis of 2 WheelerDocument7 pagesVibration Analysis of 2 WheelervivekpattniNo ratings yet

- Damped Pendulum EquationDocument10 pagesDamped Pendulum EquationDhruv AgrawalNo ratings yet

- Rotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemDocument72 pagesRotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemTarkan KaragozNo ratings yet

- Modal Analysis Training: Natural Frequencies, Mode Shapes, Extraction MethodsDocument40 pagesModal Analysis Training: Natural Frequencies, Mode Shapes, Extraction MethodsDesmond Chang100% (1)

- Chapter 15【Oscillations】Document20 pagesChapter 15【Oscillations】陳慶銘No ratings yet

- Control System 400 Objective Questions From GATE & IESDocument125 pagesControl System 400 Objective Questions From GATE & IESKiran Kumar100% (7)

- Rotating ImbalanceDocument3 pagesRotating ImbalanceGem CarpioNo ratings yet

- Nonlinear Dynamics of A Duffing-Like Negative StifDocument13 pagesNonlinear Dynamics of A Duffing-Like Negative StifPietro TestaNo ratings yet

- Solutions For Homework Set 7: X Z X I (K X+K Z)Document3 pagesSolutions For Homework Set 7: X Z X I (K X+K Z)rahul krNo ratings yet

- Chapter 3 - Forced-VibrationsDocument68 pagesChapter 3 - Forced-VibrationsNanang Ali SutisnaNo ratings yet

- Hydroelastic Analysis of Flexible Floating Interconnected Structures - 2Document16 pagesHydroelastic Analysis of Flexible Floating Interconnected Structures - 2Wael Fawzy MohamedNo ratings yet

- Solving Differential Equations with Undetermined Coefficients and Variation of ParametersDocument2 pagesSolving Differential Equations with Undetermined Coefficients and Variation of ParametersPei FernNo ratings yet

- 11th Physics PB PapersDocument18 pages11th Physics PB PapersMunir Ul Haq BabbarNo ratings yet

- Dynamic Modeling of A Springboard During A 3 M Dive: Procedia EngineeringDocument6 pagesDynamic Modeling of A Springboard During A 3 M Dive: Procedia Engineering0paulo0No ratings yet

- 2005-IfX-Muenker-Spurious Sidebands Phase Noise Basics 20051220Document195 pages2005-IfX-Muenker-Spurious Sidebands Phase Noise Basics 20051220ChipmuenkNo ratings yet

- Abb PDFDocument24 pagesAbb PDFFreddy Mauricio LucayNo ratings yet

- The Ordinary Differential Equations Project - Thomas W. JudsonDocument365 pagesThe Ordinary Differential Equations Project - Thomas W. JudsonBcalh3No ratings yet

- Virtual Machine ToolDocument25 pagesVirtual Machine Tooljuntosidekoik4100% (1)

- 1st Year Physics All in One Notes-87-151Document65 pages1st Year Physics All in One Notes-87-151Zoya NaeemNo ratings yet

- 6.3.2 Implicit Dynamic Analysis Using Direct Integration Products: Abaqus/Standard Abaqus/CAEDocument9 pages6.3.2 Implicit Dynamic Analysis Using Direct Integration Products: Abaqus/Standard Abaqus/CAEZiad Al SarrafNo ratings yet

- Vibration EngineeringDocument194 pagesVibration EngineeringSaptarshi Basu100% (1)

- Jack Up RigsDocument57 pagesJack Up Rigsnehan245No ratings yet

- 09 Frequency StabDocument49 pages09 Frequency StabirfanWPKNo ratings yet

- IBDP PHYSICS Internal Assessment – Determining 'g' with the Simple PendulumDocument8 pagesIBDP PHYSICS Internal Assessment – Determining 'g' with the Simple PendulumJasmeetSinghNo ratings yet