Professional Documents

Culture Documents

Calculations: Belt Conveyor Drive Sizing Calculations

Uploaded by

Rakhi MorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculations: Belt Conveyor Drive Sizing Calculations

Uploaded by

Rakhi MorCopyright:

Available Formats

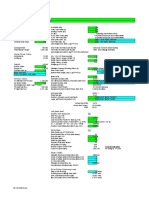

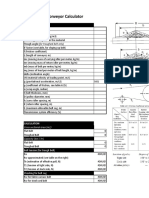

CALCULATIONS

Engineer's Stamp

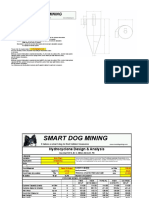

Project: Spreadsheet Quality Check Item: Example Belt Conveyor Drive Sizing

Project #: Y0000-02 Rev.#: Calculations by: TSP Date: Checked by: Date:

A 01/01/05

BELT CONVEYOR DRIVE SIZING CALCULATIONS

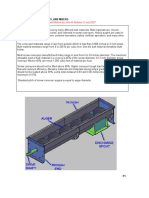

The reference material for this spreadsheet consists of Cook Engineering's Conveyor Design Manual, the article "Reclaim Power and Geometry of Bin Interfaces in Belt and Apron Feeders" in the June 1982 issue of Bulk Solids Handling and CEMA's 4th Edition of Belt Conveyors for Bulk Materials from which all of the lookup values are obtained. Design Manual Quick Sheet Reference Row #

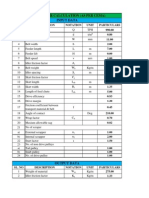

Material Conveyed: Conveying Rate: Material Density: Angle of Repose: Maximum Lump Size: Troughing Idler Info: Diameter Trough Angle Class (A-E) Load Rating # of Plows: # of Belt Cleaners (Scraper Type): L, Length of Conveyor: H, Lift of Conveyor (Negative for Declining): Belt Width: Surcharge Angle: Load Cross Sectional Area: Belt Capacity: # of Tight Side Pulleys (150o to 240o of Wrap): # of Slack Side Pulleys (150o to 240o of Wrap): # of Other Pulleys (Less than 150o of Wrap): Angle of Wrap, Drive Pulley: Lb, Length of Skirtboards (1 Side): Ambient Temperature: Belt Speed: Design Minimum Si, Load Idler Spacing: Return Idler Spacing: K1, Lump Adjustment Factor: K2, Environmental & Maintenance Factor:

Photash 2000 92 34 15 6 35 E 1800 1 1 404 3.5 60 25 1.424 8544 2 2 4 240 15

tph lb/ft3 deg in in deg

1 2 3 4 5 6 7 8 9 11 12 13 14 21 22 15 16 17 18 19 20 23 24 25 26 27

ft ft in deg ft2 ft3/hr/100fpm

deg ft

o 60 F

500 508.9 3.5 10 1.1 1.13

fpm fpm ft ft

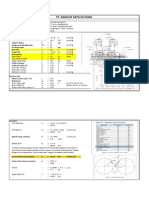

K3, Service Factor: K4, Belt Speed Factor: W b, Belt Unit Weight: W m, Material Unit Weight: Max Material Weight Actual Material Weight Idler Load: Adjusted Idler Load: Suitability of Idler Selection: Kt, Temperature Factor: Ai: Kx: Ky: Tp, Tension From Non-Driving Pulleys: Material velocity component in direction of belt travel as it is fed onto conveyor: Tam, Tension from Acceleration: Cs, Skirtboard Friction Factor: Tsb, Skirtboard Tension: Ttr, Tripper Tension: Tpl, Plow Tension: Tbc, Belt Cleaner Tension:

1.2 0.92 15 lb/ft 131.0 133.3 511.0 701.3 Selection is OK 1 2.8 0.8993 lb/ft 0.018 1100.0 lb 0 fpm 287.6 lb 0.1086 148.6 lb 0 lb 300.0 lb 300.0 lb lb/ft lb/ft lb lb

28 29 30 31 32 33 34 35 36 37 38

39 40 41 43 42

Additional Data for Scenario of Loaded Hopper (See Diagram Below) a, Aperture Size: 12 in w, Width of Hopper Outlet: 24 in l, Length of Hopper Outlet: 48 in ReP, Reclaim Power (Break-Away Power): 5.6 hp Tr, Reclaim Tension: 368.0 lb Te, Effective Tension: Shaft Power: Required Motor Power: Motor Size to be Installed: Effective Tension at Start-Up: Required Start-Up Motor Power: f, Coefficient of Friction Between Belt and Pulley: T2, Slack-Side Tension Required to Prevent Slip: 4478.7 67.9 88.7 400 10338.8 204.8 0.35 1344.1 lb lb hp hp hp 44 45 46

47

Notes and Comments:

Factors, Tensions, and Power calculated based on full theoretical max belt load cross section rather than actual belt tension this will cause very conservative horsepower calculations for long conveyors.

You might also like

- Design of ConveyorsDocument15 pagesDesign of ConveyorsRamachandran VenkateshNo ratings yet

- JSW Toranagallu 24m Gallery DesignDocument5 pagesJSW Toranagallu 24m Gallery DesignvivekNo ratings yet

- 00 HVAC CalcDocument52 pages00 HVAC Calcibson045001256No ratings yet

- Motor Selection CalculatorDocument5 pagesMotor Selection Calculatorjay100% (5)

- SDM Cyclone SizingDocument7 pagesSDM Cyclone Sizingmohamed_sahnoun_enisNo ratings yet

- M 275 ContentDocument40 pagesM 275 ContentAnonymous DQ4wYUmNo ratings yet

- Chain Conveyor ExampleDocument4 pagesChain Conveyor ExampledeeptidhaNo ratings yet

- Esp Main Reference MaterialDocument132 pagesEsp Main Reference Materialmishra_198250% (2)

- Conveyor Screws PDFDocument9 pagesConveyor Screws PDFldavilaluceralNo ratings yet

- Bulk Solids HandlingDocument303 pagesBulk Solids HandlingDr_M_Soliman100% (12)

- Conveyor Design Summary ReportDocument53 pagesConveyor Design Summary ReportTotok ChemScoutNo ratings yet

- Screw Conveyor CalculationDocument2 pagesScrew Conveyor CalculationJK71% (7)

- Maximize crusher capacity with optimal roll speedDocument2 pagesMaximize crusher capacity with optimal roll speedWaris La Joi Wakatobi100% (1)

- Slat ConveyorDocument8 pagesSlat ConveyorpkjddjsydNo ratings yet

- The Basics of The Calculations of Conveyor Belt Design ParametersDocument5 pagesThe Basics of The Calculations of Conveyor Belt Design ParametersHITESH GAHLOTNo ratings yet

- Cyclone Design and AnalysisDocument21 pagesCyclone Design and Analysisjorge FranciscpNo ratings yet

- 5T X 25.5m DG CraneDocument10 pages5T X 25.5m DG CraneRv VaghasiaNo ratings yet

- Belt Conveyor Capacity CalculatorDocument5 pagesBelt Conveyor Capacity CalculatorramsaiNo ratings yet

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- Hoist DesignDocument16 pagesHoist DesignluisparedesNo ratings yet

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension IngoscarjofkNo ratings yet

- Belt Feeder Calculation CEMADocument7 pagesBelt Feeder Calculation CEMANAITIK100% (4)

- Motor Sizing Calculations PDFDocument9 pagesMotor Sizing Calculations PDFGaleano CesarNo ratings yet

- Conveyor Belt Scale Data SheetDocument2 pagesConveyor Belt Scale Data SheetEDUARDONo ratings yet

- DAT Belt ConveyorDocument8 pagesDAT Belt ConveyorEDUARDONo ratings yet

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- Screw Conveyor CalculationDocument1 pageScrew Conveyor CalculationRavindra RautNo ratings yet

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGuptaNo ratings yet

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- BELT CONVEYOR POWER ESTIMATEDocument7 pagesBELT CONVEYOR POWER ESTIMATEgullipalli srinivasa raoNo ratings yet

- CONVEYOR CALCULATION SHEET DraftDocument24 pagesCONVEYOR CALCULATION SHEET DraftRaghava0% (1)

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Conveyor design parameters for slag ash materialDocument33 pagesConveyor design parameters for slag ash materialMustafa AkbarNo ratings yet

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Apron FeederDocument2 pagesApron FeederRaji Suri100% (1)

- Conveying Material Screw Conveyor HP CalculationDocument36 pagesConveying Material Screw Conveyor HP CalculationMugurelVasilescuNo ratings yet

- Conveyor CalculationDocument46 pagesConveyor CalculationBuditama Chandranegara100% (1)

- Konveyör Hesabı 7.24Document9 pagesKonveyör Hesabı 7.24Salih HasNo ratings yet

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcspandu_chemengNo ratings yet

- Conveyor Chains TsubakiDocument184 pagesConveyor Chains Tsubakitepu msosaNo ratings yet

- BELT CONVEYOR DESIGN FORMULASDocument3 pagesBELT CONVEYOR DESIGN FORMULASwidyaditya8No ratings yet

- Screw Conveyor Equipment Design DataDocument7 pagesScrew Conveyor Equipment Design DataTots HolaresNo ratings yet

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcsjnmanivannan100% (4)

- Bulk material chain conveyors design and maintenanceDocument11 pagesBulk material chain conveyors design and maintenancesgupta_61579683% (6)

- Bulk Material Conveyor Design Guide - Belt Selection, Idlers, Pulleys, Curves & MoreDocument56 pagesBulk Material Conveyor Design Guide - Belt Selection, Idlers, Pulleys, Curves & MoresigisyahNo ratings yet

- Piping Handbook PDFDocument39 pagesPiping Handbook PDFmishra_1982100% (1)

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- 10 Drag Conveyor Section VIIDocument11 pages10 Drag Conveyor Section VIIBUDAPESNo ratings yet

- For Bulk Materials: Belt Conveyor Capacity and PowerDocument40 pagesFor Bulk Materials: Belt Conveyor Capacity and PowerBayari ArNo ratings yet

- Line-by-line conveyor code for material handling parameters and calculationsDocument4 pagesLine-by-line conveyor code for material handling parameters and calculationskmats2No ratings yet

- AWS ELECTRODE CLASSIFICATION GUIDEDocument8 pagesAWS ELECTRODE CLASSIFICATION GUIDEFuaz Sukarya Abu Fatih100% (1)

- Bucket Elevator Design StudyDocument24 pagesBucket Elevator Design StudyVeena100% (1)

- Apron Feeder Power Calculations PDFDocument4 pagesApron Feeder Power Calculations PDFtuba25% (4)

- Chain Conveyor Design Calculation for 400 TPH Drag ConveyorDocument3 pagesChain Conveyor Design Calculation for 400 TPH Drag Conveyorsudip giriNo ratings yet

- Belt Tension CalculationDocument5 pagesBelt Tension Calculationmanoj983@gmail.comNo ratings yet

- Check Cyclone Efficiency Using Standard FormulaDocument1 pageCheck Cyclone Efficiency Using Standard Formulah2503649No ratings yet

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Conveyor CalculatorDocument3 pagesConveyor CalculatorBayuNo ratings yet

- Belt Conveyors With Shaft SizingDocument5 pagesBelt Conveyors With Shaft SizingArun Chopra100% (1)

- C 107 - Pulley Catalog - 04 2014Document46 pagesC 107 - Pulley Catalog - 04 2014kawula alit100% (1)

- BELT CONVEYOR - Discharge TrajectoryDocument1 pageBELT CONVEYOR - Discharge TrajectoryEslam FaroukNo ratings yet

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDocument92 pagesKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoNo ratings yet

- Bucket Elevators 150520Document16 pagesBucket Elevators 150520RICARDOALEXBORGESNo ratings yet

- Engineering - Catalog - Screw Conveyor PDFDocument64 pagesEngineering - Catalog - Screw Conveyor PDFanxaanNo ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument3 pagesBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNo ratings yet

- Belt Conveyor PowerDocument10 pagesBelt Conveyor PowerRyukiNo ratings yet

- Apron Weigh FeederDocument4 pagesApron Weigh FeederRaji SuriNo ratings yet

- Perhitungan ConveyorDocument88 pagesPerhitungan ConveyorLukmanulHakimNo ratings yet

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSDocument1 pageRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- C3048 PNJ CAL B 0002 B Conveyor 11 CV 01Document30 pagesC3048 PNJ CAL B 0002 B Conveyor 11 CV 01Joel MooreNo ratings yet

- BearingsDocument5 pagesBearingspramodkb_cusatNo ratings yet

- Pump and Pump System GlossaryDocument62 pagesPump and Pump System Glossarymishra_1982No ratings yet

- Dedusting Hood Size Calc.Document3 pagesDedusting Hood Size Calc.mishra_1982No ratings yet

- Astm A106 PDFDocument9 pagesAstm A106 PDFmishra_1982No ratings yet

- Standard Specification Storage Tank PDFDocument16 pagesStandard Specification Storage Tank PDFmishra_1982No ratings yet

- Re90220 1 PDFDocument6 pagesRe90220 1 PDFmishra_1982No ratings yet

- Fan Laws and Fan HP Rev1Document3 pagesFan Laws and Fan HP Rev1mishra_1982No ratings yet

- Standard Specification Storage TankDocument16 pagesStandard Specification Storage Tankmishra_1982No ratings yet

- Steel Weight CalculatorDocument4 pagesSteel Weight Calculatormishra_1982No ratings yet

- History of Sintering 1990Document15 pagesHistory of Sintering 1990mishra_1982No ratings yet

- 6533 2Document23 pages6533 2vidhyakamaleshNo ratings yet

- 6533 2Document23 pages6533 2vidhyakamaleshNo ratings yet

- 02 - Heat ExchangersDocument88 pages02 - Heat ExchangersDana GuerreroNo ratings yet

- Is 5.2007Document20 pagesIs 5.2007mishra_1982No ratings yet

- 6533 - P.1 - 1989 Steel Stack PDFDocument23 pages6533 - P.1 - 1989 Steel Stack PDFmishra_1982No ratings yet

- Asme Sec ViiiDocument12 pagesAsme Sec Viiimishra_1982No ratings yet

- Material Properties of SteelDocument33 pagesMaterial Properties of Steelpinku_thakkarNo ratings yet

- Conversions (ALL Purpose Worksheet)Document28 pagesConversions (ALL Purpose Worksheet)mishra_1982No ratings yet