Professional Documents

Culture Documents

Soft Lithography

Uploaded by

Mostafij RajibOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soft Lithography

Uploaded by

Mostafij RajibCopyright:

Available Formats

COURSE 146C

Laboratory Experiment #7

Soft Lithography: Patterning

Please read the lab procedure before your experiment!

References: 1. Xia, Y. N. and Whitesides, G. M. Soft Lithography. Annu. Rev. Mater. Sci. 28, 153184 (1998) 2. Gerber, R. W. and Oliver-Hoyo, M. T. Selective Etching via Soft Lithography of Conductive Multilayered Gold Films with Analysis of Electrolyte Solutions. Journal of Chemical Education 85, 1108-1111 (2008) 3. Campbell, D. J. et al. Replication and compression of bulk and surface structures with polydimethylsiloxane elastomer. J. Chem. Educ. 76, 537-541 (1999)

Experiment #7 Soft Lithography: Patterning

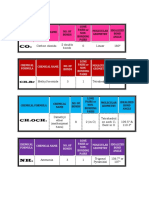

I. Introduction Soft lithography represents a non-photo or e-beam lithographic strategy based on self assembly and replica molding for carrying out micro- and nanofabrication.1 It provides a convenient, effective, and low-cost method for the formation and manufacturing of micro- and nanostructures. Soft lithography uses an elastomeric block with patterned relief structures on its surface to generate patterns and structures with feature sizes ranging from 30 nm to 100 m. using this technique, at least five techniques have been demonstrated: microcontact printing, replica molding, microtransfer molding, micromolding in capillaries, and solvent-assisted micromolding. In this experiment, we will learn the principle of soft lithography and the fabrication of poly(dimethylsiloxane) (PDMS) stamp. We will use the microcontact printing technique to create patterned metal features (e.g. electrodes) on a substrate, which can be further used for electrical measurements. II. PDMS Stamp An elastomeric block with patterned relief structures on its surface is the key to soft lithography. PDMS is one of the most important materials for making the elastomeric block for soft lithography. PDMS is a viscous liquid, consists of long chain-like polymer molecules. They have very low glass transition temperatures and hence are fluids at room temperature. These liquid materials can be readily converted into solid elastomers by adding a curing agent (e.g., a mixture of a platinum complex and copolymers of methylhydrosiloxane and dimethylsiloxane) and heat to a elevate temperature, which lead to the formation of chemical bonds between polymer molecules (cross-linking). The elastomeric block is prepared by molding, as shown in Figure 1. The PDMS liquid will be poured over a master having relief structure on its surface, then cured and peeled off. The master is, in turn, fabricated using microlithographic techniques such as photolithography, micromachining, e-beam writing, or from available relief structures. PDMS blocks having relief patterns on their surfaces can be used in a number of different processes for patterning: for example, in this experiment we will use stamps to print patterns of self-assembled monolayers (SAMs) on metal film.

Figure 1. Schematic illustration of the procedure for fabricating PDMS stamps from a master having relief structures on its surface. [ref. 1]

2

III. Making Metal Thin Films Metal thin films that are used for microcontact printing are typically made of gold and silver since they are easier to form SAMs. Metal films can be prepared by thermal/e-beam evaporation, sputtering, electrochemical deposition and chemical deposition. In this experiment, we will use chemical reduction approach to make thin films of Ag on glass slides. This process is called Tollens process, which involves chemical reduction of silver ions to silver metal by using glucose (C6H12O6) as the reducing agent. We need to prepare two solutions A and B for the experiment. Solution A contains a mixture of AgNO3 and NH4NO3, Solution B is NaOH and Solution C is glucose. When solution A and B are mixed, the hydroxide will react with ammonium ion to give free ammonia, which will further react with silver ion to form diamminesilver(I) complex [Ag(NH3)2]+ (Tollens reagent). When solution C is added, glucose will be oxidized to the form of gluconic acid (C6H12O7) and reduce the silver (I) ion to silver metal. The thickness of the film on glass slide depends on the time the glass slide is immersed in solution mixture. IV. Microcontact Printing of SAMs The concept of microcontact printing is to use the relief pattern on the surface of a PDMS stamp to form patterns of SAMs on the surfaces of substrates by contact. Alkylthiol on Au and Ag surfaces is the best characterized and understood system of SAMs. Both Au and Ag have strong affinity for sulfur. When the thin film of thiol is bought into contact with Au and Ag metal surface, covalent bond will be formed between the sulfur atom and metal atom on surface, and the alkyl chains extend from the plane of the surface in a nearly all-trans configuration to maximize the Van der Waals force between alkyl chains (Figure 2). In microcontact printing, PDMS stamp will be wetted with the thiol containing ink (solution of hexadecanethiol in ethanol) and is brought into contact with the surface of Ag on the glass slide for 1020s. The hexadecanethiol (CH3(CH2)15SH) transfers from the stamp to the Ag upon contact, forms a hexadecanethiolate (CH3(CH2)15S-), and generates patterns of SAMs on the surface of Ag.

Figure 2. Schematic procedures for Contact Printing of hexadecanethiol (HDT) on the surface of gold. [ref. 1] SAMs that are 23 nm thick serve as resists to protect the underlying substrates effectively from attack by certain wet etchants. For Ag metal film, aqueous solutions containing K2S2O3/K3Fe(CN)6/K4Fe(CN)6 is an effective etchant. The oxidizing agent of Fe(CN)63- can be reduced to Fe(CN)63- and oxidize the Ag to Ag(I) ion, which will further form a stable dithiosulfatosilver(I) complex Ag(S2O3)23-. After etching process, only the patterned features (electrode in this case) protected by SAMs remains on glass slide, as shown in Figure 3.

Figure 3. Optical image patterned electrodes on substrate. [ref. 2] Procedure I. Preparation of PDMS Pattern Stamp 1. Mix 15 ml PDMS base (large syringe) and 1.5 ml PDMS curing agent (small syringe) in a plastic cup. Wipe up any spills with a dry paper towel. 2. Stir the PDMS mixture thoroughly with glass rod. Place the cup with PDMS into vacuum desiccators and evacuate it for at least 20 minutes until it is free of bubbles. 3. Put a PDMS master in a petri dish and fix the master position. 4. Put a cylinder plastic frame on the PDMS master. Pour the PDMS carefully into the plastic frame, and cover the dish. 5. Cure the PDMS at 130 C for at least 20 mins. 6. Peel the PDMS stand away from the master and plastic frame. II. Deposition of Metal Film on Substrates 1. Take a glass slide and petri dish. Wash the glass slide with soap and water, and then rinse them very thoroughly with D.I. water. 2. Submerge the clean glass slide in the saturated solution of tin(II) chloride, and rinse it with D.I. water. 3. Put the glass slide (still wet) in the petri dish. 4. You will find bottles containing solutions A (mixture of AgNO3 and NH4NO3), B (NaOH) and C (C6H12O6). 5. Add 20 ml solution A in a empty 50 ml disposable tube, add 8 ml of solution B in a empty 15 ml disposable tube and add 5 ml of solution C in another empty 15 ml tube. 6. Pour solution B in the tube containing solution A, and mix them. And then add solution C in the tube and mix them again. 7. Pour the solution mixture into the petri dish containing glass slide. 8. Put the lid on and swirl the petri dish. 9. After 15 seconds, remove the slide from the solution using your gloves. 10. Rinse the slide with D.I. water and then with ethanol. Put the slide face up on a paper towel to dry. III. Microcontact Printing of Self-assembled Monolayers 1. A solution of 1-hexadecanethiol dissolved in ethanol will be provided.

2. Paint the textured surface of PDMS stamp with the solution using a cotton swab, and allowed it to dry. 3. Once it is dry, transfer the stamp and press it down to the glass slide with Ag film for approximately 1 minute to form a self-assembled monolayer. 4. Remove the stamp. 5. Breath on the stamp, can you see the pattern? (Lab report question #2) 6. A etchant solution Fe(CN)63- will be provided. 7. Fill a 250 ml plastic beaker with about 200 ml etching solution. Hold the glass slide with your gloves and immerse the part containing pattern in the solution and swirl the slide gently. 8. Check the progress of etching. Stop until you should see the pattern. 9. Remove the slide from the etching solution and rinse it with D.I. water.

Questions for Lab Report To be completed and handed in within one week

1. Write down the redox reactions in the deposition and etching of silver film. 2. Search internet to find out whats the current resolution limit of soft lithography technique? 3. Why PDMS is a good elastomer to make stamps? 4. List at least three applications of soft lithography? 5. If you wish to make a series of hollow silver squares on a glass slide. Describe and draw the master you should be used to create this pattern. 6. Explain why you can see the SAM pattern when you breathed on the silver film surface.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Course 8 9Document27 pagesCourse 8 9Bogdan Cel MicNo ratings yet

- Higgs BosonDocument22 pagesHiggs BosonMehjabin AbdurrazaqueNo ratings yet

- List of Tables 5 List of Figures 7 List of Plates 8 Nomenclature 9Document170 pagesList of Tables 5 List of Figures 7 List of Plates 8 Nomenclature 9ethulasiNo ratings yet

- Technical Data Sheet Hly90Aaa 220-240V 50Hz 1 R600A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Hly90Aaa 220-240V 50Hz 1 R600A: Compressor Model Voltage RefrigerantGeri SulanjakuNo ratings yet

- Determination of Total, Temporary and Permanent Hardness in Water Sample Using EDTA MethodDocument8 pagesDetermination of Total, Temporary and Permanent Hardness in Water Sample Using EDTA MethodNaresh kumarNo ratings yet

- Is Iso 5983 1 2005Document16 pagesIs Iso 5983 1 2005laboratorium operasionalNo ratings yet

- Agitation Laboratory ReportDocument34 pagesAgitation Laboratory ReportLouie G Navalta100% (4)

- Previous Year Questions Acids, Bases & SaltsDocument21 pagesPrevious Year Questions Acids, Bases & Saltskingbakugou0No ratings yet

- Gel Filtration ColumnDocument2 pagesGel Filtration ColumnkostrenarijekaNo ratings yet

- SYNOPSIS On Effect of Leachate On SoilDocument32 pagesSYNOPSIS On Effect of Leachate On SoilAbhilashaNo ratings yet

- Determination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationDocument16 pagesDetermination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationpeterNo ratings yet

- Chen 1982Document3 pagesChen 1982Jaime GonzalezNo ratings yet

- TDS R 996 en 1Document1 pageTDS R 996 en 1Osmar ContrerasNo ratings yet

- Using Waste Coffee Grounds in ElectrodesDocument6 pagesUsing Waste Coffee Grounds in ElectrodesHuynh Nghiep ThanhNo ratings yet

- Redox Titration QuizDocument1 pageRedox Titration QuizChen Lit YangNo ratings yet

- Kami Export - Abdullah Mohammedi - Webquest 3Document5 pagesKami Export - Abdullah Mohammedi - Webquest 3api-525970410No ratings yet

- 6 Physics PDFDocument91 pages6 Physics PDFKervDhanKervNo ratings yet

- Science Experiments 4th GradeDocument8 pagesScience Experiments 4th GradeNarayanNo ratings yet

- Terrock InfrastructureDocument39 pagesTerrock Infrastructurerohit ThakurNo ratings yet

- 7.1 Properties of Electric Charge TemplateDocument4 pages7.1 Properties of Electric Charge TemplateAyman HalimeNo ratings yet

- Latihan Uas CH 4-6Document16 pagesLatihan Uas CH 4-6rizkaNo ratings yet

- Module 1 Property Relationship PDFDocument32 pagesModule 1 Property Relationship PDFManideep DuggiNo ratings yet

- Admixture Effect On Concrete PDFDocument9 pagesAdmixture Effect On Concrete PDFaditya kumar jhaNo ratings yet

- Hydraulic Fluid Properties and ApplicationsDocument31 pagesHydraulic Fluid Properties and ApplicationsMawada RashedNo ratings yet

- Molecular Geometry ChartDocument3 pagesMolecular Geometry ChartJoyci CauilanNo ratings yet

- Copper Guard 4: Subtitle SubtitleDocument1 pageCopper Guard 4: Subtitle Subtitleharvinder singhNo ratings yet

- Atp and Coupled ReactionDocument3 pagesAtp and Coupled ReactionBhea Mariel CaipangNo ratings yet

- ASETAZOLAMIDDocument9 pagesASETAZOLAMIDfarmasiNo ratings yet

- 13X 30403 A CertificateDocument4 pages13X 30403 A CertificatePhạm DươngNo ratings yet

- x2.6. - Strouhal Instability - Von Karman Vortex StreetDocument4 pagesx2.6. - Strouhal Instability - Von Karman Vortex StreetcteranscribdNo ratings yet