Professional Documents

Culture Documents

Samsung 2600mah ICR18650-26C

Uploaded by

Street_skOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Samsung 2600mah ICR18650-26C

Uploaded by

Street_skCopyright:

Available Formats

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

SPECIFICATION OF PRODUCT

for Lithium-ion Rechargeable Cell Model : ICR18650-26C

Distributed by http://www.batteryspace.com 2700 Rydin Road, unit C , Richmond, CA,94804 Tel:510-525-2328 Fax:510-439-2808

-SAMSUNG SDI Confidential Proprietary

Spec. No.

1. Scope

ICR18650-26C

Version No.

1.0

This product specification has been prepared to specify the rechargeable lithium-ion cell ('cell') to be supplied to customer 2. Description and Model 2.1 Description 2.2 Model Cell (lithium-ion rechargeable cell) ICR18650-26C

3. Nominal Specifications Item Specification

3.1 Nominal Capacity

2600mAh (0.2C, 2.75V discharge)

3.2 Minimum Capacity

2550mAh (0.2C, 2.75V discharge)

3.4 Nominal Voltage

3.7V

3.5 Charging Method

3.6 Charging Current

3.7 Charging Time

CC-CV (constant voltage with limited current) Standard charge : 1300mA Rapid charge : 2600mA Standard charge : 3hours Rapid charge : 2.5hours

3.9 Max. Discharge Current

5200mA(ambient temperature 25

3.10 Discharge Cut-off Voltage

2.75V

3.11 Cell Weight

47.0g max

3.12 Cell Dimension

3.13 Operating Temperature

3.14 Storage Temperature

Height : 65.00mm max Diameter : 18.40mm max Charge : 0 to 45 Discharge : -10 to 60 1 year : -20~25 (1*) 3 months : -20~45 (1*) 1 month : -20~60 (1*)

Note (1): If the cell is kept as ex-factory status (50% of charge), the capacity recovery rate is more than 80%.

3.8 Max. Charge Current

2600mA(ambient temperature 25

3.3 Charging Voltage

4.2

0.05 V

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

4. Outline Dimensions See the attachment (Fig. 1) 5. Appearance There shall be no such defects as scratch, rust, discoloration, leakage which may adversely affect commercial value of the cell. 6. Standard Test Conditions 6.1 Environmental Conditions Unless otherwise specified, all tests stated in this specification are conducted at temperature 25 3 and humidity 65 20%. 6.2 Measuring Equipment (1) Ammeter and Voltmeter The ammeter and voltmeter should have an accuracy of the grade 0.5 or higher. (2) Slide caliper The slide caliper should have 0.01 mm scale. (3) Impedance meter The impedance meter with AC 1kHz should be used. 7. Characteristics 7.1 Standard Charge This "Standard Charge" means charging the cell with charge current 1300mA and constant voltage 4.2V at 25 for 3hours. 7.2 Standard Discharge Capacity The standard discharge capacity is the initial discharge capacity of the cell, which is measured with discharge current of 520mA with 2.75V cut-off at 25 within 1hour after the standard charge. Standard Discharge Capacity 2550mAh 7.3 Initial internal impedance Initial internal impedance measured at AC 1kHz after rated charge.

7.4 Temperature Dependence of Discharge Capacity Capacity comparison at each temperature, measured with discharge constant current 520mA and 2.75V cut-off after the standard charge is as follows. Charge Temperature Discharge temperature

25 Relative Capacity

-10 50%

0 80%

Initial internal impedance

100m

25 100%

40 80%

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

Note: If charge temperature and discharge temperature is not the same, the interval for temperature change is 3 hours. Percentage as an index of the capacity at 25 (=2550mAh) is 100%. 7.5 Temperature Dependence of Charge Capacity Capacity comparison at each temperature, measured with discharge constant current 520mA and 2.75V cut-off after the standard charge is as follows. Charge temperature Discharge temperature

Relative Capacity

80%

100%

80%

Note: If charge temperature and discharge temperature is not the same, the interval for temperature change is 3 hours. Percentage as an index of the capacity at 25 (=2550mAh) is 100%. 7.6 Charge Rate Capabilities Discharge capacity is measured with constant current 520mA and 2.75V cut-off after the cell is charged with 4.2V as follows.

Current

0.2C (520mA)

Charge Condition 0.5C 1.0C (1300mA) (2600mA)

2.0C (5200mA)

Cut-off

7h or 100mA

3h or 100mA 2.5h or 100mA 2.5h or 100mA

Relative Capacity

100%

95%

90%

7.7 Discharge Rate Capabilities Discharge capacity is measured with the various currents in under table and 2.75V cut-off after the standard charge.

Current

0.2C (520mA)

Discharge Condition 0.5C 1.0C (1300mA) (2600mA)

Relative Capacity

100%

95%

Note: Percentage as an index of the capacity at 25

Note: Percentage as an index of the capacity at 25

(=2550mAh) is 100%.

2.0C (5200mA)

90%

(=2550mAh) is 100%.

25

45

25

80%

80%

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

7.8 Cycle Life Each cycle is an interval between the charge (charge current 1300mA) with 2.5h or 100mA cut-off and the discharge (discharge current 1300mA) with 2.75V cut-off. Capacity after 299cycles and plus 1 day, measured under the same condition in 7.2 Capacity 1785mAh(70% of the capacity at 25 )

7.9 Storage Characteristics Capacity after storage for 30days at 25 from the standard charge, measured with discharge current 1300mA with 2.75V cut-off at 25 .

7.10 Status of the cell as of ex-factory The cell should be shipped in 50% charged state. In this case, OCV is from 3.65V to 3.85V. 8. Mechanical Characteristics 8.1 Drop Test Test method: Cell(as of shipment or full charged) drop onto the oak-board (thickness: 30mm) from 1.5m height at a random direction 6 times. Criteria: No leakage 8.2 Vibration Test Test method: Cell(as of shipment) is vibrated along 2 mutually perpendicular axes with total excursion of 1.6mm and with frequency cycling between 10Hz and 55Hz by 1Hz/min. Criteria: No leakage 9. Safety 9.1 Overcharge Test Test method: To charge the standard charged cell with 12V and 2.6A at 25 for 2.5 hours. Criteria: No fire, and no explosion.

9.2 External Short-circuit Test Test method: To short-circuit the standard charged cell by connecting positive and negative terminal by less than 50m wire for 3hours. Criteria: No fire, and no explosion. 9.3 Reverse Charge Test Test method: To charge the standard charged cell with charge current 2.6A By 12V for 2.5 hours. Criteria: No fire, and no explosion.

4

Capacity retention(after the storage)

2040mAh (80% of the capacity at 25

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

10. Warranty Will be responsible for replacing the cell against defects or poor workmanship for 3months from the date of shipping. Any other problem caused by malfunction of the equipment or mix-use of the cell is not under this warranty. The warranty set forth in proper using and handling conditions described above and excludes in the case of a defect which is not related to manufacturing of the cell.

11. Others 11.1 Storage for a long time If the cell is kept for a long time(3months or more), It is strongly recommended that the cell is preserved at dry and low-temperature. 11.2 Other Any matters that specifications does not have, should be conferred with between the both parties. 11.3 PTC Specification PTC Specification (in the Cell) Power Resistance Dissipation

Item

Hold Current

Resistance After Trip

12. Packing See Fig.2, Package Drawing

Spec.

2.7A

9~18m

Max. 2.5W

Max. 33m

9.4 Heating Test Test method: To heat up the standard charged cell at heating rate 5 130 and keep the cell in oven for 60 minutes. Criteria: No fire, and no explosion.

per minute up to

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

Max. 18.40

Max. 65.0

Unit : mm

Fig.1. Outline Dimensions of ICR18650-26C

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

100 PCS in small box

Tape

Master carton (200PCS)

Fig.2. Package Drawing

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

Pack Quality Requirement for safety and quality epidemic issue.

1-1 The battery packs consumption current. - Sleep Mode : Under 250uA. - Shut Down Mode : Under 10uA / Under 3.0V. Under 1uA / Under 2.5V. 1-2 SOC 0% - Cell voltage in SOC 0% of Pack should be Min. 3.0V. (Discharging Cut-off Voltage) 1-3 Operating Charging Voltage of a cell. - Normal operating voltage of a cell is 4.20V - Max operating voltage of a cell is 4.25V. 1-4. No continuous charge - Charge cut-off condition : Cut-off Current over than 1/20C - (Charging method:CC-CV) - Initial recharging condition : Remaining Capacity under than 90% or voltage under than 4.10V 1-5. Pre-charging function - Pre-charge function should be implemented to prevent abnormal high rate charging after deep discharge. - Pre-charging condition Operation : Under 3.0V Charging current : Under 150mA/Cell.(Continuous) Pre-charge stop (Normal Charge Start) : All cells reach 3.0V 1-6. Cell voltage monitoring system. - The system (Charger or Pack) should equip a device to monitor each Cell voltage and to stop charging if a cell imbalance happened.

1-7 The battery pack should have warning system for over temperature, over voltage, over current, and unexpected events would be harm to system. If battery faces harsh condition such as over temperature, Battery pack should control FET-off directly.

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

1-8 Mechanical guides. - PCBA and Cell stack should have heat insulation material between them.(Such as plastic barrier which is giving air isolation or non-thermal conductive material.) - B+ and B- wire connection should not be crossed each other. Do not make wire which had the voltage difference more than 4.0V get together. - The material such as double sided tape and rubber which are used in battery pack should be verified for its flammability

If Pack cannot meet above requirement, we cannot take responsibility for quality issue.

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

Proper Use and Handling of Lithium Ion Cells

See before using lithium-ion cell Supplied by AA Portable Power Corp

1. General This document has been prepared to describe the appropriate cautions and prohibitions, which the customer should take or employ when the customer uses and handles the lithium ion cell to be supplied by http://www.batteryspace.com in order to obtain optimum performance and safety.

2. Charging 2.1 Charging current Charging current should be less than maximum charge current specified in the product specification. 2.2 Charging voltage Charging should be done by voltage less than that specified in the product specification. 2.3 Charging time Continuous charging under appropriate voltage does not cause any loss of characteristics. However, the charge timer is recommended to be installed from a safety consideration, which shuts off further charging at time specified in the product specification. 2.4 Charging temperature The cell should be charged within a range of specified temperatures in the product specification. 2.5 Reverse charging The cell should be connected, confirming that its poles are correctly aligned. Inverse charging should be strictly prohibited. If the cell is connected improperly, it may be damaged.

3. Discharging 3.1 Discharging 3.1.1 The cell should be discharged at less than maximum discharge current specified in the product specification. 3.2 Discharging temperature 3.2.1 The cell should be discharged within a range of temperatures specified in

10

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

the product specification. 3.2.2 Otherwise, it may cause loss of characteristics. 3.3 Over-discharging 3.3.1 The system should equip with a device to prevent further discharging exceeding discharging cut-off voltage specified in the product specification.(over-discharging) 3.3.2 Over-discharging may cause loss of performance, characteristics, of battery function. 3.3.3 Over-discharging may occur by self-discharge if the battery is left for a very long time without any use. 3.3.4 The charger should equip with a device to detect cell voltage and to determine recharging procedures.

4. Storage 4.1 Storage conditions 4.1.1 The cell should be stored within a range of temperatures specified in the product specification. 4.1.2 Otherwise, it may cause loss of characteristics, leakage and/or rust. 4.2 Long-term storage 4.2.1 The cell should be used within a short period after charging because long-term storage may cause loss of capacity by self-discharging. 4.2.2. If long-term storage is necessary, the cell should be stored at lower voltage within a range specified in the product specification, because storage at higher voltage may cause loss of characteristics.

5. Cycle life 5.1 Cycle life performance 5.1.1 The cell can be charged/discharged repeatedly up to times specified in the produce specification with a certain level of capacity also specified in the product specification. 5.1.2 Cycle life may be determined by conditions of charging, discharging, operating temperature and/or storage.

6. Design of System 6.1 Connection between the cell and the battery 6.1.1 The cell should not be soldered directly with leads. Namely, the cell should be welded with leads on its terminal and then be soldered with wire or leads to soldered lead. 6.1.2 Otherwise, it may cause damage of component, such as separator and insulator, by heat generation.

11

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

6.2 Positioning the battery in the System 6.2.1 The battery should be positioned as possible as far from heat sources and high temperature components. 6.2.2 Otherwise, it may cause loss of characteristics. 6.3 Mechanical shock protection of the battery 6.3.1 The battery should equip with appropriate shock absorbers in order to minimize shock. 6.3.2 Otherwise, it may cause shape distortion, leakage, heat generation and/or rupture. 6.4 Short-circuit protection of the cell 6.4.1 The cell equips with an insulating sleeve to protect short-circuit which may occur during transportation, battery assembly and /or system operation. 6.4.2 If the cell sleeve is damaged by some cause such as outside impact, it may cause short-circuit with some wiring inside the battery. 6.5 Connection between the battery and charger/system 6.5.1 The battery should be designed to be connected only to the specified charger and system. 6.5.2 A reverse connection of the battery, even in the specified system, should be avoided by employing special battery design such as a special terminals.

7. Battery Pack Assembly 7.1 Prohibition of usage of damaged cell 7.1.1 The cell should be inspected visually before battery assembly. 7.1.2 The cell should not be used if sleeve-damage, can-distorsion and/or electrolyte-smell is detected. 7.2 Terminals handling 7.2.1 Excessive force on the negative terminal should be avoided when external lead is welled. 7.3 Transportation 7.3.1 If the cell is necessary to transported to order place, such as the battery manufacturer, careful precautions should be taken to avoid damage of cell.

8. Others 8.1 Disassembly 8.1.1 The cell should not be dismantled from the battery pack. 8.1.2 Internal short-circuit caused by disassembly may lead to heat generation and/or venting.

12

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

8.1.3 When the electrolyte is coming in contact with the skin or eyes, flush immediately with fresh water and seek medical advice. 8.2 Short-circuiting 8.2.1 Short-circuit results in very high current which leads to heat generation. 8.2.3 An appropriate circuitry should be employed to protect accidental short-circuiting. 8.3 Incineration 8.3.1 Incinerating and disposing of the cell in fire are strictly prohibited, because it may cause rupture. 8.4 Immersion 8.4.1 Soaking the cell in water is strictly prohibited, because it may cause melt of components to damaged to functions. 8.5 Mixing use 8.5.1 Different types of cell, or same types but different manufacturer's cell may lead to cell rupture or damage to system due to the different characteristics of cell. 8.6 Battery exchange 8.6.1 Although the cell contains no environmentally hazardous component, such as lead or cadmium. the battery should be disposed according to the local regulations when it is disposed. 8.6.2 The cell should be disposed with a discharged state to avoid heat generation by an inadvertent short-circuit. 8.7 Caution - The Battery used in this device may present a risk of fire or chemical burn if mistreated. Do not disassemble, heat above 100 or incinerate. Replace battery with Samsung SDI battery only. Use of another battery may present a risk of fire or explosion. Dispose of used battery promptly. Keep away from children. Do not disassemble and do not dispose of in fire.

8.8 Warning Attached

13

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

Handling Precaution and Prohibitions of Lithium Ion & Lithium Ion Polymer Rechargeable Cells and Batteries

Inaccurate handling of lithium ion and lithium ion polymer rechargeable battery may cause leakage, heat, smoke, an explosion, or fire. This could cause deterioration of performance or failure. Please be sure to follow instructions carefully.

1.1 Storage

corrosive gas atmosphere.

1.2 Safety precaution and prohibitions To assure product safety, describe the following precautions in the instruction manual of the application.

[ Danger!] Electrical misusage Use dedicated charger. Use or charge the battery only in the dedicated application. Don't charge the battery by an electric outlet directly or a cigarette lighter charger. Don't charge the battery reversely. Environmental misusage Don't leave the battery near the fire or a heated source. Don't throw the battery into the fire. Don't leave, charge or use the battery in a car or similar place where inside of temperature may be over 60 . Don't immerse, throw, wet the battery in water / seawater.

others Don't fold the battery cased with laminated film such as pouch and Polymer. Don't store the battery in a pocket or a bag together with metallic objects such as keys, necklaces, hairpins, coins, or screws. Don't short circuit (+) and (-) terminals with metallic object intentionally. Don't pierce the battery with a sharp object such as a needle, screw drivers. Don't heat partial area of the battery with heated objects such as soldering iron. Don't hit with heavy objects such as a hammer, weight. 14

Store the battery at low temperature (below 20

is recommended), low humidity, no dust and no

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

Don't step on the battery and throw or drop the battery on the hard floor to avoid mechanical shock. Don't disassemble the battery or modify the battery design including electric circuit. Don't solder on the battery directly. Don't use seriously scared or deformed battery. Don't put the battery into a microwave oven, dryer ,or high-pressure container. Don't use or assemble the battery with other makers' batteries, different types and/or models of batteries such as dry batteries, nickel-metal hydride batteries, or nickel-cadmium batteries. Don't use or assemble old and new batteries together.

[ Warning! ] Stop charging the battery if charging isn't completed within the specified time. Stop using the battery if the battery becomes abnormally hot, order, discoloration, deformation, or abnormal conditions is detected during use, charge, or storage. Keep away from fire immediately when leakage or foul odors are detected. If liquid leaks onto your skin or cloths, wash well with fresh water immediately. If liquid leaking from the battery gets into your eyes, don't rub your eyes and wash them with clean water and go to see a doctor immediately. If the terminals of the battery become dirty, wipe with a dry cloth before using the battery. The battery can be used within the following temperature ranges. Don't exceed these ranges.

Discharge Temperature ranges : -20

Store the battery at temperature below 60

Cover terminals with proper insulating tape before disposal.

[ Caution! ] Electrical misusage Battery must be charge with constant current-constant voltage (CC/CV). Charge current must be controlled by specified value in Cell specification. Cut-off Voltage of charging must be 4.2V. Charger must stop charging battery by detecting either charging time or current specified in Cells specification. Discharge current must be controlled by specified value in Cells specification. Cut-off Voltage of discharging must be over 2.5V.

others Keep the battery away from babies and children to avoid any accidents such as swallow. 15

~ 60

Charge temperature ranges

:0

~ 45

-SAMSUNG SDI Confidential Proprietary

Spec. No.

ICR18650-26C

Version No.

1.0

If younger children use the battery, their guardians should explain the proper handling method and precaution before using. Before using the battery, be sure to read the user's manual and precaution of it's handling. Before using charger, be sure to read the user's manual of the charger. Before installing and removing the battery from application, be sure to read user's manual of the application. Replace the battery when using time of battery becomes much shorter than usual. Cover terminals with insulating tape before proper disposal. If the battery is needed to be stored for an long period, battery should be removed from the application and stored in a place where humidity and temperature are low. While the battery is charged, used and stored, keep it away from object materials with static electric chargers.

Safety Handling Procedure for the Transporter

Quarantine : Packages that are crushed, punctured or torn open to reveal contents should not be transported. Such packages should be isolated until the shipper has been consulted, provided instructions and, if appropriate, arranged to have the product inspected and repacked. Spilled Product : In the event that damage to packaging results in the release of cells or batteries, the spilled products should be promptly collected and segregated and the shipper should be contacted for instructions.

Design of positioning the battery pack in application and charger

To prevent the deterioration of the battery performance caused by heat, battery shall be positioned away from the area where heat is generated in the application and the charger.

Design of the Battery Pack

Be sure adopting proper safe device such as PTC specified type or model in Cell Specification. If you intend to adopt different safety device which is not specified in Cell Specification, please contact Samsung SDI to investigate any potential safety problem. Be sure designing 2nd protective devices such as PTC & PCM at the same time to protect Cell just in case one protective device is fault. Please contact following offices when you need any help including safety concerns.

Samsung SDI Emergency Contact Information

16

You might also like

- Battery Test Procedures 1997Document7 pagesBattery Test Procedures 1997Tara P. PradhanNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- Introduction To Wireless Communication - Radio CommunicationDocument21 pagesIntroduction To Wireless Communication - Radio CommunicationYas773No ratings yet

- Create SOAP Notes Using Medical TerminologyDocument4 pagesCreate SOAP Notes Using Medical TerminologyLatora Gardner Boswell100% (3)

- Rechargeable Batteries Applications HandbookFrom EverandRechargeable Batteries Applications HandbookRating: 2 out of 5 stars2/5 (1)

- TP IEC - Routine Motor TestsDocument5 pagesTP IEC - Routine Motor Tests123peniscolaNo ratings yet

- GX Audit Internal Audit Risk and Opportunities For 2022Document26 pagesGX Audit Internal Audit Risk and Opportunities For 2022Muhammad SamiNo ratings yet

- She Walks in BeautyDocument6 pagesShe Walks in Beautyksdnc100% (1)

- 220V DCDocument15 pages220V DCsekhar_ntpcNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Short-Circuit Current Making and Breaking TestsDocument16 pagesShort-Circuit Current Making and Breaking TestsFelipe Mafioletti Schuartz100% (1)

- Samsung 2400mah ICR18650-24EDocument15 pagesSamsung 2400mah ICR18650-24EStreet_skNo ratings yet

- Samsung 2600mah ICR18650-26ADocument16 pagesSamsung 2600mah ICR18650-26AStreet_skNo ratings yet

- Samsung 3000mah ICR18650-30ADocument14 pagesSamsung 3000mah ICR18650-30AStreet_skNo ratings yet

- Samsung ICR18650 22EDocument12 pagesSamsung ICR18650 22ENicolae PopNo ratings yet

- Samsung 2800mah ICR18650-28ADocument17 pagesSamsung 2800mah ICR18650-28AStreet_skNo ratings yet

- Specification of Product Specification of Product Specification of Product Specification of ProductDocument18 pagesSpecification of Product Specification of Product Specification of Product Specification of ProductferrumoxideNo ratings yet

- ICR18650 26H SamsungDocument17 pagesICR18650 26H SamsungVasil MilchevNo ratings yet

- 2200mAh_Li-Ion_Cell_SpecificationDocument9 pages2200mAh_Li-Ion_Cell_Specificationreihane m rezaeeNo ratings yet

- Samsung 2200mah ICR18650-22FDocument17 pagesSamsung 2200mah ICR18650-22FStreet_skNo ratings yet

- Samsung SDI Lithium-Ion Cell SpecificationDocument16 pagesSamsung SDI Lithium-Ion Cell SpecificationNajumNo ratings yet

- Inr18650 20RDocument17 pagesInr18650 20RAli PadaryamNo ratings yet

- Samsung SDI 2800mAh Lithium-Ion Cell SpecificationDocument6 pagesSamsung SDI 2800mAh Lithium-Ion Cell SpecificationSean CanoNo ratings yet

- Specification of Product Specification of Product Specification of Product Specification of ProductDocument17 pagesSpecification of Product Specification of Product Specification of Product Specification of Productzuffflor_925748656No ratings yet

- Samsung ICR18650 26FM Spec SheetDocument16 pagesSamsung ICR18650 26FM Spec SheetMargus SiilakNo ratings yet

- Samsung ICR18650-26J Lithium Ion CellDocument6 pagesSamsung ICR18650-26J Lithium Ion CellrabyteNo ratings yet

- INR18650-30Q SamsungDocument20 pagesINR18650-30Q SamsungJamilson Oliveira de AraujoNo ratings yet

- Specification of Li-Polymer Rechargeable Battery: Model No.: LP-573442-1S-3Document10 pagesSpecification of Li-Polymer Rechargeable Battery: Model No.: LP-573442-1S-3Petre GeorgescuNo ratings yet

- Samsung Icr18650 22fmDocument17 pagesSamsung Icr18650 22fmmdrizwanuddinNo ratings yet

- Li-Ion CellDocument17 pagesLi-Ion CellDavid CondoviciNo ratings yet

- Samsung 22PDocument18 pagesSamsung 22PNguyen DuyNo ratings yet

- SAMSUNG SDI Confidential Proprietary. Spec. No. ICR18650-22P Version No. 1.0Document18 pagesSAMSUNG SDI Confidential Proprietary. Spec. No. ICR18650-22P Version No. 1.0Tecnico ID LedNo ratings yet

- Samsung 15qDocument15 pagesSamsung 15qАлександр КрюковNo ratings yet

- Samsung SDI Confidential Specification for ICR18650-30B Lithium-ion Rechargeable CellDocument17 pagesSamsung SDI Confidential Specification for ICR18650-30B Lithium-ion Rechargeable CellPedro Militao CoboNo ratings yet

- Specification of Product: For Lithium-Ion Rechargeable Cell ModelDocument18 pagesSpecification of Product: For Lithium-Ion Rechargeable Cell ModelejdiggerNo ratings yet

- 野村商会 7043125SH1-SP1-R&D-77G Ver0Document9 pages野村商会 7043125SH1-SP1-R&D-77G Ver0Anonymous RgLs9INo ratings yet

- Specification of Product: For Lithium-Ion Rechargeable Cell ModelDocument18 pagesSpecification of Product: For Lithium-Ion Rechargeable Cell ModelFrancisco Daniel ColimbaNo ratings yet

- 26JM SamsungDocument20 pages26JM SamsungMartin FernandezNo ratings yet

- CFL Home Lighting System Test ReportDocument4 pagesCFL Home Lighting System Test ReportgavinilaaNo ratings yet

- 12v 40ah Lifepo4 Lithium Ion BatteryDocument10 pages12v 40ah Lifepo4 Lithium Ion BatteryBenjamín Andres Lagos BerriosNo ratings yet

- Icr18650 26J3Document22 pagesIcr18650 26J3Mustapha BELARBINo ratings yet

- Operation Instruction: For BK-300 Internal Resistance MeterDocument7 pagesOperation Instruction: For BK-300 Internal Resistance MetercannjohnNo ratings yet

- UnionBattery 2000mahDocument6 pagesUnionBattery 2000mahOprita Cristescu AlinaNo ratings yet

- Type SSM 1kV - Manual - Rev1Document60 pagesType SSM 1kV - Manual - Rev1Carlos AnibalNo ratings yet

- PB-1180-1M01 Spec RevADocument14 pagesPB-1180-1M01 Spec RevAgabrielNo ratings yet

- YP32DVR Power SpecificationDocument8 pagesYP32DVR Power SpecificationMarcio Antonio Machado0% (1)

- Samsung Inr21700 40t DatasheetDocument23 pagesSamsung Inr21700 40t DatasheetjsanjaiNo ratings yet

- Samsung 33GDocument18 pagesSamsung 33GMustapha BELARBINo ratings yet

- jf5061-00 - SpecificationDocument14 pagesjf5061-00 - Specificationoscar gonzalo mondalgo ortizNo ratings yet

- SAMSUNG SDI Confidential Proprietary Spec. No. INR18650-32E Version No. 2.0Document19 pagesSAMSUNG SDI Confidential Proprietary Spec. No. INR18650-32E Version No. 2.0Andrei DanNo ratings yet

- LG 42PC55 Service ManualDocument54 pagesLG 42PC55 Service ManualThomas Oldbury100% (1)

- Polymer battery spec sheetDocument9 pagesPolymer battery spec sheetJean Paul Herrera MoncayoNo ratings yet

- Energing Power - Bateria para OTDR, (NM35S-38)Document10 pagesEnerging Power - Bateria para OTDR, (NM35S-38)mnolasco2009No ratings yet

- Cbi2410a PDFDocument2 pagesCbi2410a PDFdinhvuNo ratings yet

- Schaffler Battery ChargersDocument4 pagesSchaffler Battery ChargersRudy IndrawanNo ratings yet

- CBI ManualDocument12 pagesCBI ManualIdiks OtnaythreeNo ratings yet

- CB2410AC Manual PDFDocument4 pagesCB2410AC Manual PDFdinhvuNo ratings yet

- CT720g S774AAR5S2NCDocument45 pagesCT720g S774AAR5S2NCAnonymous CJnGHNNo ratings yet

- Lithium-Ion Rechargeable Battery Specification: Electric Vehicle Power System Technology Co. LTDDocument7 pagesLithium-Ion Rechargeable Battery Specification: Electric Vehicle Power System Technology Co. LTDDmitry LeyzerovichNo ratings yet

- Introduction To Preventive MaintenanceDocument11 pagesIntroduction To Preventive MaintenanceTEMIDAYONo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Maxxis Catalogue 2013/2014Document72 pagesMaxxis Catalogue 2013/2014Street_skNo ratings yet

- Panasonic 2900mah NCR18650Document1 pagePanasonic 2900mah NCR18650Street_skNo ratings yet

- Panasonic 3100mah NCR-18650ADocument1 pagePanasonic 3100mah NCR-18650AStreet_skNo ratings yet

- Sanyo 2800mah UR18650ZTDocument1 pageSanyo 2800mah UR18650ZTStreet_skNo ratings yet

- Panasonic 2250mah CGR18650CGDocument1 pagePanasonic 2250mah CGR18650CGStreet_skNo ratings yet

- Panasonic 2450mah CGR18650DADocument1 pagePanasonic 2450mah CGR18650DAStreet_skNo ratings yet

- Panasonic 2250mah CGR-18650CHDocument1 pagePanasonic 2250mah CGR-18650CHStreet_skNo ratings yet

- Sanyo 2250mah UR18650ADocument1 pageSanyo 2250mah UR18650AStreet_skNo ratings yet

- LG 2800mah ICR18650 C1Document8 pagesLG 2800mah ICR18650 C1Street_skNo ratings yet

- Sanyo 2000mah UR18650YDocument1 pageSanyo 2000mah UR18650YStreet_skNo ratings yet

- Sanyo 2600mah UR18650FDocument1 pageSanyo 2600mah UR18650FStreet_skNo ratings yet

- LG 2600mah ICR18650 B3Document8 pagesLG 2600mah ICR18650 B3Street_skNo ratings yet

- Sanyo 1600mah UR18650WDocument1 pageSanyo 1600mah UR18650WStreet_skNo ratings yet

- Sanyo 2150mah UR18650EDocument1 pageSanyo 2150mah UR18650EStreet_skNo ratings yet

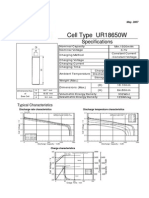

- Sanyo 1300mah UR18650SADocument1 pageSanyo 1300mah UR18650SAStreet_skNo ratings yet

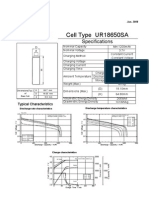

- Sanyo 1200mah UR18650UDocument1 pageSanyo 1200mah UR18650UStreet_skNo ratings yet

- LG 2400mah ICR18650 A3Document8 pagesLG 2400mah ICR18650 A3Street_skNo ratings yet

- Samsung 2600mah ICR18650-26FDocument8 pagesSamsung 2600mah ICR18650-26FStreet_skNo ratings yet

- LG 2350mah ICR18650 A2Document8 pagesLG 2350mah ICR18650 A2Street_skNo ratings yet

- LG 2200mah ICR18650 S3Document8 pagesLG 2200mah ICR18650 S3Street_skNo ratings yet

- Samsung 2200mah ICR18650-22FDocument17 pagesSamsung 2200mah ICR18650-22FStreet_skNo ratings yet

- LG 2000mah ICR18650 P2Document10 pagesLG 2000mah ICR18650 P2Street_skNo ratings yet

- FMS 1Document27 pagesFMS 1bishal dattaNo ratings yet

- Tiotropium Bromide: Spiriva Handihaler, Spiriva RespimatDocument9 pagesTiotropium Bromide: Spiriva Handihaler, Spiriva RespimatAssem Ashraf KhidhrNo ratings yet

- Yealink Device Management Platform: Key FeaturesDocument3 pagesYealink Device Management Platform: Key FeaturesEliezer MartinsNo ratings yet

- Alcatel 350 User Guide FeaturesDocument4 pagesAlcatel 350 User Guide FeaturesFilipe CardosoNo ratings yet

- Chapter 7Document22 pagesChapter 7one loveNo ratings yet

- FDocument109 pagesFssissaaNo ratings yet

- CGE Quester Spec Sheet E29Document2 pagesCGE Quester Spec Sheet E29Ruveen Jeetun100% (1)

- Handouts For Semantics GradDocument8 pagesHandouts For Semantics GradPhuong Thao DangNo ratings yet

- Technical Data Sheet 01DT-1L..: Type OverviewDocument4 pagesTechnical Data Sheet 01DT-1L..: Type OverviewJNo ratings yet

- Useful List of Responsive Navigation and Menu Patterns - UI Patterns - GibbonDocument16 pagesUseful List of Responsive Navigation and Menu Patterns - UI Patterns - Gibbonevandrix0% (1)

- Essay #01 (First Draft)Document2 pagesEssay #01 (First Draft)thanhtam3819No ratings yet

- Calculation of Moments and Shear: Input DataDocument3 pagesCalculation of Moments and Shear: Input DataARSENo ratings yet

- Cable Drag ChainDocument44 pagesCable Drag ChainsunhuynhNo ratings yet

- Symbolic Calculus Sage ReferenceDocument25 pagesSymbolic Calculus Sage ReferenceLn Amitav BiswasNo ratings yet

- Tauros TBM Guidance SystemDocument3 pagesTauros TBM Guidance SystemMiloš StanimirovićNo ratings yet

- Handout Week10.1Document7 pagesHandout Week10.1Antoniette Niña YusonNo ratings yet

- QUARMEN Prerequisites - SEM1Document12 pagesQUARMEN Prerequisites - SEM1Valérie NguyenNo ratings yet

- Comparing Means of Two GroupsDocument8 pagesComparing Means of Two GroupsRobert Kier Tanquerido TomaroNo ratings yet

- Production of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyDocument7 pagesProduction of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyEspinosa Balderas GenaroNo ratings yet

- 3: Batteries: I Ne NR+RDocument3 pages3: Batteries: I Ne NR+RIsrael EdeagheNo ratings yet

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BDocument11 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BJignesh TrivediNo ratings yet

- The Photoconductive CellDocument4 pagesThe Photoconductive Cellfasdasd123No ratings yet

- AmpConectorsExtracto PDFDocument5 pagesAmpConectorsExtracto PDFAdrian AvilesNo ratings yet

- Urea CycleDocument2 pagesUrea CycleyoungdandareNo ratings yet

- Performance of Filler Material in GabionsDocument4 pagesPerformance of Filler Material in GabionsPreetham N KumarNo ratings yet

- Vision CSP22 Abhyaas Test 3SDocument44 pagesVision CSP22 Abhyaas Test 3SManasa DevarakondaNo ratings yet