Professional Documents

Culture Documents

Textile Restoration Report Aishah

Uploaded by

Aishah Abd RahimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Textile Restoration Report Aishah

Uploaded by

Aishah Abd RahimCopyright:

Available Formats

DEPARTMENT OF APPLIED ARTS AND DESIGN, KULIYYAH OF ARCHITECTURE AND ENVIRONMENTAL DESIGN, INTERNATIONAL ISLAMIC UNIVERSITY MALAYSIA CONSERVATION

REPORT

SERIAL NO: Textile / 1 / 10 January 2011

1. IDENTIFICATION NAME OF OBJECT : Batik Malaysia DATE OBSERVES OWNER TYPE OF OBJECT : 10 January 2011 : Mariyam binti Din @ Ariffin : Batik Sarong

2. OBJECT HISTORY DATE/ PERIOD CONCEPT 3. DESCRIPTION MATERIAL TECHNIQUES Size : Textile; Cotton : Stamp technique : 1050mm (Width) x 840mm (Height) : 1998 : Malay Traditional

4. PROBLEM IDENTIFICATION:

1. Loose Thread

2. Substandard Repair 3. Holes 4. Creases Refer to Appendix

DEPARTMENT OF APPLIED ARTS AND DESIGN, KULIYYAH OF ARCHITECTURE AND ENVIRONMENTAL DESIGN, INTERNATIONAL ISLAMIC UNIVERSITY MALAYSIA CONSERVATION REPORT

5. CONSERVATION PROPOSAL RESTORATION PROCESS

1. Observation and documentation

i) ii) iii) Recording the object description and properties Identifying problems Photo taking before, during and after restoration process

1. Material Identification i) Burning Test -This is a destructive method of identifying fibre.

ii)

Colour Bleeding Test -Testing using distilled water and cotton bud to see bleeding possibility

1. Treatment i) ii) Couching Back Stitch Colour Touch-up using colour pencils

iii)

DEPARTMENT OF APPLIED ARTS AND DESIGN, KULIYYAH OF ARCHITECTURE AND ENVIRONMENTAL DESIGN, INTERNATIONAL ISLAMIC UNIVERSITY MALAYSIA CONSERVATION REPORT

5. DESCRIPTION OF RESTORATION PROCESS

1.

Observation and documentation of object

2.

Testing colour bleeding using distilled water

3.

Conducting burning test to identify type of fibre.

4.

Place lining cloth under the part. Selection of lining cloth is according to colour and texture of textile which is closely the same.

Repairing Loose Thread Damage

5.

Stitching back stitch around the damage part

6.

Stitching using couching technique to back up the loose thread part.

7.

Touching up back the colour by referring existing motif using pencil colour.

8.

Finished repaired part.

Substandard Repair

9.

Unstitching previous repair

10. Stitching using back stitch and couching

11. Touching up back the colour Creases

12. Finished repaired part

13. Ironing using low temperature and under a layer of damp fabric

14. Finished repaired part

DEPARTMENT OF APPLIED ARTS AND DESIGN, KULIYYAH OF ARCHITECTURE AND ENVIRONMENTAL DESIGN, INTERNATIONAL ISLAMIC UNIVERSITY MALAYSIA CONSERVATION REPORT 15. RESTORATION DOCUMENTATION Problems Before During After

Loose Thread

Substandard Repair

Holes

Creases

EQUIPMENT(S) AND MATERIALS USED:

i.

Lighter (Fire Source)

ii. Scalpel iii. Distilled Water iv. Cotton Budd

v. No.12 Needle

vi. Thread

vii. Lining cloth

viii. Scissor

ix. Colour Pencils

1. RECOMMENDATION AND REMARKS: 1. Display For displaying this object, avoid it from being hung because this will create too much tension to this object. The best way is to display it in flat method where the tension of gravity is spread evenly to all part of the object. This object should also be displayed in case or within glazed frame to avoid outside pollution and dust. However, the display case must not be tight where this may lead to excess humidity. Light exposure at the display area should be kept in low level; around 50lux because light is one of the source of heat and this may cause fading and make object dry and brittle. If possible, use automatic light which only turns on as people approach the display area and turns off when people move on. The RH reading and temperature should be kept in constant at all the time. 2. Storage This textile object can be either store in flat storage or to be rolled to a tube. In using any of this method, be sure not to put any direct contact of object to the storage parts. The object must be layered with acid-free paper to keep it away from any exposure to further damages. The environment of the storage should be around 60% +/- 5% of RH, 20 degree Celsius +/- 2 degree Celsius and proper maintenance from time to time. The storage should be in total darkness, which mean to avoid any light in order to keep it in best condition. WORK CARRIED OUT BY : Aishah binti Abd Rahim STARTING DATE : 14 January 2011

FINISHING DATE LECTURER SIGNATURE DATE

: 16 January 2011 : :

Appendix

Problems Identification

Holes Substandard Repair

Loose Thread

Size: 1050mm (Width) x 840mm (Height)

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Boiler Operator Exam Prep Guide PDFDocument3 pagesBoiler Operator Exam Prep Guide PDFJawad HussainNo ratings yet

- McGrath - The Black AndromedaDocument23 pagesMcGrath - The Black Andromedaܕܢܝܐܝܠ ܕܢܝܐܝܠNo ratings yet

- DTC Compilation 2Document33 pagesDTC Compilation 2api-302089668No ratings yet

- Bluebeards Bride Book of Rooms PDFDocument98 pagesBluebeards Bride Book of Rooms PDFBrian Gallego Londoño100% (1)

- A020 PDFDocument32 pagesA020 PDFsolrac4371No ratings yet

- Philips Industry Lighting BrochureDocument39 pagesPhilips Industry Lighting Brochureuriquil006No ratings yet

- Tecnicas Estendidas para GuitarraDocument257 pagesTecnicas Estendidas para Guitarraricardo_thomasiNo ratings yet

- Dreams Really Do Come TrueDocument30 pagesDreams Really Do Come Trueantou74No ratings yet

- Wagner Otto-Modern Arch 198Document202 pagesWagner Otto-Modern Arch 198Marta Donoso Llanos100% (2)

- English For Academic and Professional Purposes: Quarter 1 - Module 2 Reaction Paper and Concept PaperDocument74 pagesEnglish For Academic and Professional Purposes: Quarter 1 - Module 2 Reaction Paper and Concept PaperJieza May Marquez72% (39)

- The Last Judgment (Michelangelo)Document4 pagesThe Last Judgment (Michelangelo)Jason Tiongco100% (1)

- Prenos Slike Na DrvoDocument9 pagesPrenos Slike Na DrvorajwosaNo ratings yet

- Technical LetteringDocument3 pagesTechnical LetteringAdair LopezNo ratings yet

- Rose's Garden by Peter H. Reynolds Press KitDocument4 pagesRose's Garden by Peter H. Reynolds Press KitCandlewick Press100% (2)

- Alfred TennysonDocument12 pagesAlfred TennysonAnonymous IogovJWNo ratings yet

- Elizabeth MulhollandDocument17 pagesElizabeth MulhollandJOHN A WALKERNo ratings yet

- Resume Iryne RohDocument2 pagesResume Iryne RohIryne RohNo ratings yet

- Artist and ArtisanDocument17 pagesArtist and ArtisanNAMERAH GOTENo ratings yet

- Regis Windows Book 1Document11 pagesRegis Windows Book 1shstudioNo ratings yet

- Uses of Synthetic Fibre in ConcreteDocument10 pagesUses of Synthetic Fibre in ConcreteRama Lakshmi Velusamy100% (1)

- Beethoven's Piano Sonata in C MinorDocument2 pagesBeethoven's Piano Sonata in C MinorSarah Lade100% (1)

- Common Assessment 2Document2 pagesCommon Assessment 2api-269655541No ratings yet

- SAT Essay TopicsDocument23 pagesSAT Essay TopicsKhaled Atef AbulfadlNo ratings yet

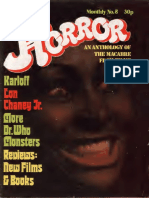

- World of Horror 008 (1972)Document27 pagesWorld of Horror 008 (1972)MindSpaceApocalypse100% (1)

- Belfiore - CarmidesDocument11 pagesBelfiore - CarmidesNatalia PerrottiNo ratings yet

- 2016 Year 7 Half Yearly English 2Document16 pages2016 Year 7 Half Yearly English 2api-322242426No ratings yet

- The Interpretation of Early MusicDocument740 pagesThe Interpretation of Early Musicpaulreedsmith100% (2)

- 'Killing The Author' With Reference To Moulin RougeDocument13 pages'Killing The Author' With Reference To Moulin RougeCharlotte BuchanNo ratings yet

- Key 10 de HSGQGDocument256 pagesKey 10 de HSGQGK60 TRẦN MINH QUANGNo ratings yet

- 120221-Drawing Numbering System - RevaDocument2 pages120221-Drawing Numbering System - RevaJohn Paul UmaliNo ratings yet