Professional Documents

Culture Documents

DR FH SM

Uploaded by

camiayoungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DR FH SM

Uploaded by

camiayoungCopyright:

Available Formats

future christchurch

growing sustainably

Fritha Hobbs | 1st Semester 2012 Advanced Design 1 | School of Architecture and Planning | Camia Young & Jordon Saunders

11.3% Northland 11.3% Northland

fibreboard particleboard particleboard paperboard paperboard pulp & paper pulp & paper plywood plywood veneer/LVL veneer/LVL sawmill sawmill

3.2% Auckland 3.2% Auckland

30.3% Central North Island 30.3% Central North Island

8.9% 8.9%East Coast East Coast

7.4% Hawkes Bay 7.4% Hawkes Bay

9.5% Southern North Island 9.5% Southern North Island

9.5% Nelson/Marlborough 9.5% Nelson/Marlborough

wooD

noun: 1. The hard fibrous material that forms the main substance of the trunk or branches of a tree or shrub. 2. such material when cut and used as timber or fuel.

timber

noun: 1. wood prepared for use in building and carpentry. 2. trees grown for such wood: contracts to cut timber.

1.8% West Coast 1.8% West Coast

6.2% Canterbury 6.2% Canterbury

Christchurch

11.9%Otago 11.9% Otago/Southland

manageD timber Plantations new ZealanD

Primary wooD Processing Plants new ZealanD

With just 0.05% of the worlds forest resource, New Zealands forest industry supplies 1.1% of the world and 8.8% of Asia Pacifics forest products trade. This is proportionally a huge contribution due to a significant amount of highly productive, sustainably managed plantations across New Zealand. Covering the land is 7% plantation forest (with 24% natural forest) and due to a spike in plantation in the 90s particularly of Radiata Pine whose optimal harvest age is 30 years a significantly larger area of managed plantations will be ready for harvest in the next 5 - 20 years. In Canterbury alone there will be 1.2 million cubic metres of plantation ready for harvest in 2015, increasing to up to 3 million by 2025. The government plans to boost exports to meet this increase in supply, but I believe an increase in awareness of timbers capacity in the built industry would lead to more local demand and an increase in the sustainable use of a resource right at our feet. For these reasons Christchurch is very well resourced for an increase in timber construction, extending beyond just residential demand.

100 80 60 40 20 0 1920

1930

1940

1950

1960

1970

1980

1990

2000

2010

new forest plantation 1920-2011

forestry in new ZealanD

SAPWOOD -living cells only found in sapwood -inner region serves to transport water up and down the tree -often lighter in colour HEARTWOOD -all cells in heartwood are dead -often darker in colour than sapwood -often highly decay or insect resistand -may be difficult to penetrate with liquids -may be difficult to dry -no strength difference between heartwood and sapwood in almost all species

sapwood

heartwood

32

TAbLES AND gRAPHS

one year

earlywood latewood

SOFTWOOD - predominantly from conifers and evergreen trees - seeds uncovered - non porous structure - simple cell -ranges in density and not necessarily softer than hardwood

sawn log of douglas fir

composition of growth rings

sapwood

heartwood

fibreboard roads main particleboard railways paperboard pulp & paperforests native plywood planted forests veneer/LVL sawmill wood processing main

plants

new Zealand 1,751,000 ha plantation forests 6,500,000 ha native forests

canterbury region 113,903 ha plantation forests 264,000 ha native forests

HARDWOOD - predominantly from broad-leafed and deciduous trees - seeds within a ripening fruit - porous structure - more complexity and variety in cell structure - ranges in density and not necessarily harder than softwood

sawn log of oak

forest comPosition new ZealanD

forests anD wooD Processing canterbury

Taking a closer look at timber and its structural capacity I investigated its properties at various scales. The growth rings we see are made up of microscopic cell configurations which are responsible for the trees structure and its nutrient circulation.

forest comPosition, wooD ProDuction anD use

3D printed models of wood cellular structure

softwooD anD harDwooD

new cells formed in the cambium zone (outer layer)

test for porosity and movement within cells

radial transport via rays

vertical transport via tracheids and vessels

means of nutrient transportation in living wood

diffuse transport via cell membranes

cambium wall comprises fusiform initials ray initials which multiply to form cell structure of wood

formation of new cells

tracheid (softwood) fibre (hardwood)

water level influence on growth

fusiform initial

multiplies

separates and cell forms

cell and cell wall widens; cell type distinguished

small tracheid/fibre thick walls

large tracheid/fibre thin walls

how and when does a cell go through tranformation?

life span of wood cell transformation: initial growth of cell cell transformation : external force

cell has structural function cell has nutrient transportation function

fusiform initals

cell transformation: initial growth of cell cell shape influenced by factors at time of growth cell transformation : external force such as: wound, insects, fungus, bacteria, fire, weathering, climate death of cell [structure remains]

[fusiform initial multiplies then remains in cambium]

water level influence on growth

resin canal (softwood) vessel (hardwood)

ray initial

multiplies

separates and ray forms ray small vessel/canal large vessel/canal

deterioration of wood

ray initals

movement of nutrients through a tree macro anD micro scale

cell transformation: initial growth of cell

fungal attacK tyPe 1 walls break down cells enlarge / join

walls break down cells enlarge/join

visitor

structure 1 integrated spaces designated circulation carpark - office

fungal attacK tyPe 2 walls disconnect cells contract

carpark - manufacture

[independent of]

fungal attacK tyPe 3 walls break down cells disfigured cells dematerialise

integrated spaces free flow circulation

office - manufacture

extreme climate walls warp and split cells enlarge/shrink

separated spaces designated circulation small goods delivery/pick up

structure 2

wounD cells decay barrier forms to stop

spread of decay new cells and bark envelop decayed cells

barrier cell

new bark

large goods delivery/pick up

inDePenDent structural systems

circulation Diagrams

separated spaces free flow circulation

At the point of each cells initial growth, the trees environment informs how the cell is shaped. Factors such as temperature and water availability affect this. A second type of cell transformation will only happen if there is an external force on the cell, such as a fungal attack or a wound.

cell transformation: external force

circulation oPtions

Studies of these circulations and cell transformations formed the basis of my buildings formal concept. A structurally regular and pragmatic exterior skin envelops the space and confines an environmentally stable condition within, while an organic form permeates the structure, piercing and shrouding it at various points, similar to the way a fungus was observed to move through the cells of a tree. The two forms remain structurally separate.

circulation stuDies

work

visit

exhibition space offices storage vehicular circulation manufacture workshop/laboratory lobby/meet parking seminar/training cafe and bookshop

9540sqm total site area

14650sqm total program area

agenda of worker vs visitor

storage

manufacture offices loading bay

manufacturer

visitor

CLT manufacture loading bay storage lobby/circulation workshop/laboratory exhibition seminar/training parking offices cafe/bookshop

exhibition

workshop / laboratory

lobby / circulation

seminar / training

This organic form serves a similar purpose to a cell whereby it manages the circulation of visitors and responds to the volumes and needs of occupants moving through the space. At the entrance to the offices, for example, the form contracts, inhibiting flow into the space beyond. The exhibition space largely opens up, the walls retracting to allow a visual connection to the manufacture and research workshop space below.

manufacture program total

11200sqm

3450sqm

visit program total

cafe / bookshop parking

14650sqm

Driving formal concePt

program total

Program investigation

ground The building incorporates a range of functions. Primarily it is a space for manufacture of Cross-Laminated Timber and other laminated wood products. Space is also allocated for a research laboratory and workshop. This is a space that could be used to test products performance and develop new products. Columns extending down and two cores distinguish these spaces yet allow for flow of timber and manufacture equipment between them. The flow of production follows a practical layout, beginning at the north end (street front) of the building and moving towards the south end where a product will either be sent away or moved upstairs for exhibition or worked on in the workshop.

first

Receive timber, group and store

Cut timber to lengths

Apply adhesive

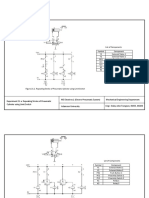

horizontal electrical servicing at roof, servicing open plan factory floor two service cores located where bathrooms are located, from roof to floor

services

Lay up panels

sheD massing stuDies ProDuct movement flow

PLAN VIEW

The secondary function is of a learning environment. The design seeks to integrate the two functions and expose visitors to the processes involved in laminated timbers manufacture whilst respecting the requirements for an operational manufacturing plant. An exhibition space and seminar rooms familiarise interested parties with the manufacture process, hovering above the factory. These spaces may also be used in conjunction with the research laboratory and workshop on the ground floor, further offering an engaging experience with the laminated timber products and their potential. The caf and bookshop pierce the glazing just above the loading dock, giving users the opportunity to view the trucks manoeuvring and goods being unloaded.

Press panels

ProDuct movement flow

SECTION vIEW

Cut and shape panels

main entry

This layout is appropriate for long-spanning glulam portal frames. The ridges are oriented in a way that daylighting can come in predominantly on the buildings southern side.

oPtimalexternal sheD form

Package and send

Program oPtions

Program DeveloPment

Program DeveloPment

DuRHAm STREET

MOORHOuSE AVENuE

Manchester St Columbo St Barbados St Madras St

DuRHAm STREET

entrance on corner of Durham street & moorhouse avenue

MOORHOuSE AVENuE

9540sqm

north

site Plan

500m

north

site Plan

500m

view of factory floor looKing into seminar/training room

DeveloPment of formal concePt

looKing over Durham street overPass

site information

glazing with timber mullions

LVL roof purlins

section B

corrugated plastic

corrugated plastic layered over

CLT panels

smooth poured concrete floor

grounD floor Plan

1:500

section A

north

glulam portal frames

first floor Plan

1:500

north

longituDinal section (a)

1:200

transverse section (b)

Plans, sections, materials

1:200

Plans, sections, materials

timber + time

common contemporary timber construction methods timber frame construction

western europe early accomplishments in wood construction have been obscured by achievements in masonry architecture, and subsequently by innovations in steel, concrete and glass

storey-by-storey form of construction primarily wood joints with mortise and tenon, oblique dado and halving joints structural members have a larger and usually square cross-section simple assembly and erection

balloon frame, platform frame

low manufacting depth, high labour input on-site building braced by planks or cladding slender- tall cross-sections close space of uprights

northern europe regional building types reflect local climate and topography four building techniques: stave construction; blockwork; frame construction with horizontal planks; half timbering

horu-ji, japan, ad 677 todai-ji, japan, ad 745

eastern europe mainly extrapolations of log construction (blockwork) NOW east asia timber framed joined by bracketsets: strength and flexibility to withstand incessant earthquakes total absence of any discernible cross-bracing members oshevnevo house, russia, 20th c

panel construction

design freedoms simple form of construction repetitive load bearing ribs of slender, standardised sections building braced by sheeting simple materials procurement storey-by-storey assembly connections achieved by direct contact and with mechanical fasteners short on-site time, different manufacting depths possible.

log construction

highly skilled labour careful selection of wood artistic corner joints rigid plan layout settling allowance high timber consumption

town hall, germnay, middle ages america since, colonization 300 years ago, wood has remained americas primary house-building material

southeast asia as many styles as local ethnic groups houses built on piles that lift the floor of the building off the ground to avoid flooding and threats posed by animals and snakes to improve ventilation and maximize use of breezes

conveyor belt, australia, ad 1910 queen anne row houses, usa, ad 1894

australia and new zealand

borgund stave church, norway, ad 1150

wat yai, thailand ad 1814

gosteli house, switzerland ad 1797

nara, ad 1195

petajavesi church, the hallenhaus, finland, ad 1765 the wehlberg, germany ad 1750 cathedral of the transfiguration, karelia, ad 1714

the norwegian loft, the forbidden city, st catherine church, after ad 1349 beijing, ad 1420 honfleur, france, ad 1466 ,

himeji castle, japan, ad 1609 the main hall of kiyomizudera, japan, ad 1635

suPPorting research: timber innovations over time

suPPorting research: contemPorary construction methoDs

engineered timber has a number of advantages over other wood-based materials:

the wood resource can be optimised by grading and selecting veneer for different parts of a cross section and making a range of products with different properties. there is an increase in strength. the strength of a single piece of timber is as strong as its weakest point, which is usually the largest knot. in laminating, the weakest point of one piece of timber is bonded to the higher strength of adjoining pieces, thus forming a homogeneous structural component of great efficiency. it therefore is possible to manufacture a beam with high strength timber in areas of high stress and utilise more economical lower grades in areas of low stress. the use of thin laminations also permits better penetration of preservative, enables better and more even drying, eliminating checking, and member size is virtually limitless. in addition the thin laminates enable the member to be finished with a curve if desired to accomplish striking architectural features. what this means? multi-storey and long span constructions from engineered timber are not only feasible but very desirable, with affordability against the equivalent in concrete and steel and the added benefit of sustainability and zero carbon construction. in post earthquake canterbury the advantages to timber buildings are numerous: timber buildings are up to a third of the weight of the equivalent concrete building giving huge advantages in difficult soil ground conditions. timber has excellent properties in seismic design, which improves and leads to damage avoidance designs. as a building material it is cost competitive due to increases in productivity and improved manufacturing methods. it is a growing resource with a beneficial value chain. engineered timber

laminated veneer lumber

laminated veneer lumber (lvl) is a structural product manufactured from thin peeled veneers of wood usually 3mm thick, glued with a durable adhesive with the grain running parallel to the main axis of the member. panels of lvl are cut into structural members which have high strength and stiffness. lvl is suited to structural applications such as beams, rafters and columns in a wide range of buildings including houses, commercial, industrial and rural structures. lvl is particularly well suited to rafters and joists, lintels, beams and framing members, truss chords, portal frames, i-beams, box-beams, scaffold planks, formwork.

Primary building material: cross - laminated timber

perpendicular layering of CLT panels

Xlam CLT factory in Nelson

murray grove, london - worlds tallest modern timber multi-storey construction. Completely built with cross-lam prefab panels.

glue - laminated timber

glue-laminated timber (glulam) is the name given to large solid wood members manufactured by gluing many smaller pieces together. glulam is an engineered structural material consisting of a number of graded, kiln dried and selected full length laminations - usually 45 mm thick - bonded with proven adhesives, to form a solid member of practically any length, shape or size.

Cross Laminated Timber is a relatively new technology to New Zealand, whereas it has been developing in Europe for some decades now, and is gaining traction in the united Kingdom and North America. It was conceived in Austria and is now receiving world-wide acclaim. Its popularity has come about in an age of growing environmental consciousness, scarce resources and the need to address our built surroundings with a sustainable vision. Its use in New Zealand is on a small scale; there is only one factory currently operating in Nelson, however there is huge room for development as it can be made using locally sourced timber from sustainably managed forests, of which we have many in New Zealand. It is a form of engineered wood, using layers of planks glued and pressed side by side, which are then stacked vertically to form solid panels of typically 3-7 layers. A CNC router cuts the panels to size and may make highly accurate cuts for windows, doors, services etc. All the panels are manufactured in factory conditions and transported to site. Panels are light enough to lift by helicopter so can be taken across difficult terrain. The adhesive used is formaldehyde and solvent free, creating a toxic-free environment for working with CLT. Commonly panels have been made from Spruce, Larch, Fir and Pine. Although 90% of our managed forests in NZ comprise Radiata Pine, domination of a single species is argued to be detrimental to the ecosystem. Cross Laminated timber panels can be made from a wide range of timbers and dont encourage this demand. Currently there are no provisions in place in the NZS3604 for cross laminated timber use. The NZS3603 for Engineered Design has provisions for solid timber which may be applicable to CLT however rigorous guidelines will need to be established for the material to be used to its potential in New Zealand and by a broad market. weekly progress of cross-lam building put up in six weeks. testing a cross- lam building on a seismic shaking table in kobe, japan. It withstood the test while contents of the building violently displaced.

post tensioned structural components

post tensioned shear walls and post tensioned beams and columns are the latest in engineered timber technology that provide a solution for seismic performance. new generation of earthquake - resistant technology: pairs of rocking walls, joined with energy dissipators, the structure is able to absorbe seismic energy and reduce building damage in earthquake. all structural members local LvL (strength, durability, fire - resistence, equivalent of steel and concrete sustainable

panels fixed to glulam beams

nmit building, nelson

nmit building, nelson

available innovations in new ZealanD

nmit building, nelson

exterior column - floor connection

1:20

interior curveD glulam beam - column connection

1:20

material Details

You might also like

- FH Final-BoardsDocument1 pageFH Final-BoardscamiayoungNo ratings yet

- Practical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandPractical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- BEC304 TIMBER DESIGN: INTRODUCTION, LEARNING OUTCOMES, SYLLABUSDocument25 pagesBEC304 TIMBER DESIGN: INTRODUCTION, LEARNING OUTCOMES, SYLLABUSMohd Nizam ShakimonNo ratings yet

- Coconut Wood Processing PDFDocument48 pagesCoconut Wood Processing PDFZoebairNo ratings yet

- 2.1 Introduction To Timber DesignDocument66 pages2.1 Introduction To Timber DesignNazihahNo ratings yet

- Chapter1 3 NewDocument44 pagesChapter1 3 NewHailley Denson100% (1)

- Timber and Timber ProductsDocument13 pagesTimber and Timber ProductsCollins Obari AdiyeNo ratings yet

- Chapter1 3Document39 pagesChapter1 3mark100% (1)

- IJETR033282Document5 pagesIJETR033282erpublicationNo ratings yet

- CVE4002 Lecture 03Document62 pagesCVE4002 Lecture 03Keith YangNo ratings yet

- CARP02 Building Materials and Hand ToolsDocument88 pagesCARP02 Building Materials and Hand ToolsMark Lloyd-JonesNo ratings yet

- Minimising growth strain in eucalypts to transform wood processingDocument20 pagesMinimising growth strain in eucalypts to transform wood processingGeo SpatialistNo ratings yet

- Wood As A Construction Material: Tony Frank Odinga Cynthia Kethi Elvis Omondi Seth Makori John KeramaDocument49 pagesWood As A Construction Material: Tony Frank Odinga Cynthia Kethi Elvis Omondi Seth Makori John Keramatony frankNo ratings yet

- 4904 Cocowood Users Manual FINALDocument48 pages4904 Cocowood Users Manual FINALpasebanjatiNo ratings yet

- Research Paper On Bamboo As A Building MaterialDocument5 pagesResearch Paper On Bamboo As A Building Materialgvw6y2hv100% (1)

- Timber Design FundamentalsDocument49 pagesTimber Design FundamentalsAljawad14No ratings yet

- Delamination in Wood Wood Products and Wood-Based CompositesDocument416 pagesDelamination in Wood Wood Products and Wood-Based CompositesSabrina PhilippeNo ratings yet

- Application and Service Test of Coconut Fiber Cement BoardsDocument7 pagesApplication and Service Test of Coconut Fiber Cement BoardsAnonymous oNgQtJNo ratings yet

- TimberDocument53 pagesTimberCaleb Bonnet SundayNo ratings yet

- ARBE2100 Construction Technology 2: Commonwealth of AustraliaDocument96 pagesARBE2100 Construction Technology 2: Commonwealth of AustraliaGeorgia WeitenbergNo ratings yet

- Can J Chem Eng - 2023 - Germg RD - Screening of Chemical Pulp Revisiting Technology Options and The State of The ArtDocument13 pagesCan J Chem Eng - 2023 - Germg RD - Screening of Chemical Pulp Revisiting Technology Options and The State of The ArtClaudinei MayerNo ratings yet

- Chapter 1-3 (A)Document26 pagesChapter 1-3 (A)Ram Vincent EvioNo ratings yet

- 1 TimberDocument86 pages1 TimberNur Adham Shah100% (1)

- Determine Wood Moisture ContentDocument3 pagesDetermine Wood Moisture Contentاسد علیNo ratings yet

- Azobe Class1 Against Marine BorerDocument3 pagesAzobe Class1 Against Marine BorerEgemen AkbulutNo ratings yet

- Aircraft Wood InformationDocument52 pagesAircraft Wood Informationjmercano100% (1)

- Dry Kiln Operator's Manual: Forest Service Forest Products Laboratory Madison, Wisconsin Agriculture Handbook No. 188Document273 pagesDry Kiln Operator's Manual: Forest Service Forest Products Laboratory Madison, Wisconsin Agriculture Handbook No. 188Diego Calero100% (1)

- Bamboo DissertationDocument7 pagesBamboo DissertationCollegePapersWritingServiceCanada100% (1)

- Bamboo EssayDocument22 pagesBamboo EssayJodie SmithNo ratings yet

- TimberDocument22 pagesTimberMrr KuxNo ratings yet

- Group 1 Thesis CH 1Document7 pagesGroup 1 Thesis CH 1BSCE 5BNo ratings yet

- Module 10 WoodDocument9 pagesModule 10 WoodMinari ChaengNo ratings yet

- Research Paper On BambooDocument5 pagesResearch Paper On Bamboogvzh54d3100% (1)

- Some Technological Properties of Laminated Veneer Lumber Produced With Fast-Growing Poplar and EucalyptusDocument13 pagesSome Technological Properties of Laminated Veneer Lumber Produced With Fast-Growing Poplar and Eucalyptusclaudio06111983No ratings yet

- Research Paper On WoodDocument6 pagesResearch Paper On Woodm1dyhuh1jud2100% (1)

- Chemistry in the Utilization of Wood: Pergamon Series of Monographs on Furniture and TimberFrom EverandChemistry in the Utilization of Wood: Pergamon Series of Monographs on Furniture and TimberNo ratings yet

- Plywood ManufacturingDocument11 pagesPlywood ManufacturingNeeraj Kamboj100% (2)

- The basics of biomass roofing materialsDocument35 pagesThe basics of biomass roofing materialsLakshmi PillaiNo ratings yet

- Innovative Building Materials Final Report PDFDocument38 pagesInnovative Building Materials Final Report PDFMark Anthony Liwag Nama100% (1)

- Growth of TreeDocument16 pagesGrowth of TreeJohn EgbongNo ratings yet

- Wastewater Management in Lumber and Wood Products Industry-ProgressDocument23 pagesWastewater Management in Lumber and Wood Products Industry-ProgressÖzgüll ClNo ratings yet

- Green Building Materials Guide: Characteristics, Selection & CategoriesDocument23 pagesGreen Building Materials Guide: Characteristics, Selection & Categoriessusmita sethiNo ratings yet

- Feasibility Study of Establishing A Coconut Lumber Processing Plant in The Pomio District of East Britain2Document19 pagesFeasibility Study of Establishing A Coconut Lumber Processing Plant in The Pomio District of East Britain2rooker77No ratings yet

- Test 2Document14 pagesTest 2Thanh Tú VũNo ratings yet

- Timber: 7.1 Growth of WoodDocument7 pagesTimber: 7.1 Growth of WoodeyobNo ratings yet

- Material ReportDocument20 pagesMaterial Reportfirstman31100% (1)

- Presentation of Materials finalFINALDocument10 pagesPresentation of Materials finalFINALShahil SadoolNo ratings yet

- Timber A Wood Prepared For The Engineering Purpose Is A TimberDocument21 pagesTimber A Wood Prepared For The Engineering Purpose Is A TimberMohit VermaNo ratings yet

- Bamboo Preservation BookDocument60 pagesBamboo Preservation Bookchub22No ratings yet

- Further ResearchDocument27 pagesFurther ResearchBeckie RyanNo ratings yet

- Coir Boards: Sem, Mbem, SpaDocument57 pagesCoir Boards: Sem, Mbem, SpaTarishi JainNo ratings yet

- Component in Making Fiber Board As Substitute For HardiflexDocument9 pagesComponent in Making Fiber Board As Substitute For Hardiflexxiniac_1No ratings yet

- Timber As A Structural MaterialDocument13 pagesTimber As A Structural MaterialAbba-Gana Mohammed100% (1)

- BMC - Research Block 3Document31 pagesBMC - Research Block 3Lesther Roblo100% (1)

- Materials and Construction - I: Lecture O1 Dated: 13/02/2020Document14 pagesMaterials and Construction - I: Lecture O1 Dated: 13/02/2020awais anjumNo ratings yet

- Utilizing Agricultural Wastes as Cement-Bonded Particle BoardDocument7 pagesUtilizing Agricultural Wastes as Cement-Bonded Particle BoardELMER0% (1)

- Chapter 1 TIMBER IntroductionDocument23 pagesChapter 1 TIMBER IntroductionResearcher BrianNo ratings yet

- Recycling of Wood PolymereDocument5 pagesRecycling of Wood PolymereKenza SADOUKINo ratings yet

- RPRGRMMNG SydmDocument13 pagesRPRGRMMNG SydmcamiayoungNo ratings yet

- Linwood BookDocument39 pagesLinwood BookcamiayoungNo ratings yet

- Junc FactoryDocument17 pagesJunc Factorycamiayoung100% (1)

- DENCITYDocument26 pagesDENCITYcamiayoung100% (1)

- Halswell-Book VyDocument26 pagesHalswell-Book VycamiayoungNo ratings yet

- Sydm BoardDocument4 pagesSydm BoardcamiayoungNo ratings yet

- Halswell-Board ZHDocument1 pageHalswell-Board ZHcamiayoungNo ratings yet

- Tower Junction Board yDocument1 pageTower Junction Board ycamiayoungNo ratings yet

- Tower Junction Board LDocument1 pageTower Junction Board LcamiayoungNo ratings yet

- Ferrymead BoardDocument2 pagesFerrymead BoardcamiayoungNo ratings yet

- Halswell-Board VyDocument1 pageHalswell-Board VycamiayoungNo ratings yet

- Tower Junction BookDocument16 pagesTower Junction BookcamiayoungNo ratings yet

- Tower Junction BoardDocument1 pageTower Junction BoardcamiayoungNo ratings yet

- Linwood BoardDocument2 pagesLinwood BoardcamiayoungNo ratings yet

- Airport BoardDocument2 pagesAirport BoardcamiayoungNo ratings yet

- Halswell-Board DLDocument1 pageHalswell-Board DLcamiayoungNo ratings yet

- Sydm-BookDocument49 pagesSydm-BookcamiayoungNo ratings yet

- Tower Junction BookDocument40 pagesTower Junction BookcamiayoungNo ratings yet

- Micro UrbanismDocument17 pagesMicro UrbanismcamiayoungNo ratings yet

- Airport BookDocument53 pagesAirport BookcamiayoungNo ratings yet

- Ferrymead BookDocument76 pagesFerrymead BookcamiayoungNo ratings yet

- Halswell-Book ZHDocument13 pagesHalswell-Book ZHcamiayoungNo ratings yet

- Halswell-Book DLDocument20 pagesHalswell-Book DLcamiayoungNo ratings yet

- Retail PrecinctDocument38 pagesRetail PrecinctcamiayoungNo ratings yet

- Green StitchDocument110 pagesGreen StitchcamiayoungNo ratings yet

- Urban ArchipelagoDocument58 pagesUrban ArchipelagocamiayoungNo ratings yet

- Linear CorridorDocument43 pagesLinear CorridorcamiayoungNo ratings yet

- Urban ArchipelagoDocument58 pagesUrban ArchipelagocamiayoungNo ratings yet

- The Green BufferDocument72 pagesThe Green BuffercamiayoungNo ratings yet

- Southwest Presentation PDFDocument27 pagesSouthwest Presentation PDFcamiayoungNo ratings yet

- Unix For Beginners - SLDocument220 pagesUnix For Beginners - SLPavan VasanthamNo ratings yet

- Stock PartDocument20 pagesStock PartGReyNo ratings yet

- Qtiplot Manual enDocument390 pagesQtiplot Manual enjovita georgeNo ratings yet

- BS Basics Boundary Scan PDFDocument2 pagesBS Basics Boundary Scan PDFShankar ArunmozhiNo ratings yet

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDocument3 pagesBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaNo ratings yet

- DBX DriveRack PA 2 BrochureDocument2 pagesDBX DriveRack PA 2 BrochureSound Technology LtdNo ratings yet

- List of ComponentsDocument2 pagesList of ComponentsRainwin TamayoNo ratings yet

- Hitachi SetFree MiniVRF 0120LRDocument52 pagesHitachi SetFree MiniVRF 0120LRAhmed AzadNo ratings yet

- Air Car SeminarDocument24 pagesAir Car SeminarSatyajit MenonNo ratings yet

- How To Setup CM Notify SyncDocument2 pagesHow To Setup CM Notify SyncascfsfNo ratings yet

- Solar Powered Automatic Toilet LightDocument10 pagesSolar Powered Automatic Toilet LightarwinNo ratings yet

- Dekut Teaching Practice ManualDocument20 pagesDekut Teaching Practice Manualstephen njorogeNo ratings yet

- Blackberry Enterprise Server For Microsoft Exchange: Troubleshooting GuideDocument48 pagesBlackberry Enterprise Server For Microsoft Exchange: Troubleshooting GuideKhaled AjouzNo ratings yet

- Installation Guide: For Packetfence Version 8.3.0Document270 pagesInstallation Guide: For Packetfence Version 8.3.0Ferjani TarekNo ratings yet

- Riveting vs. WeldingDocument5 pagesRiveting vs. WeldingNikhilVinay100% (1)

- Dual-Band Band Pass Filters Using Stub-Loaded ResonatorsDocument3 pagesDual-Band Band Pass Filters Using Stub-Loaded ResonatorsfracosoeNo ratings yet

- Ticketreissue PDFDocument61 pagesTicketreissue PDFnicoNicoletaNo ratings yet

- HRIS1Document24 pagesHRIS1UMESH VINAYAK ARVINDEKARNo ratings yet

- Feature Setup Description: Software Basic Data Mcs - TCBCDocument77 pagesFeature Setup Description: Software Basic Data Mcs - TCBCAlexis MauricioNo ratings yet

- Tube Upsetting Machines BrochureDocument10 pagesTube Upsetting Machines BrochuredemirilkNo ratings yet

- Complete Checklist for Manual Upgrades to Oracle Database 12c R1Document27 pagesComplete Checklist for Manual Upgrades to Oracle Database 12c R1Augustine OderoNo ratings yet

- (Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerDocument332 pages(Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerFuadAshadLNo ratings yet

- Perkins T6.354 WorkshopDocument130 pagesPerkins T6.354 WorkshopAlexis SocarrósNo ratings yet

- Transistor InfoDocument3 pagesTransistor InfoErantha SampathNo ratings yet

- Sound level meter covers noise applicationsDocument2 pagesSound level meter covers noise applicationsAbigail DextreNo ratings yet

- KSSR - MatematikDocument6 pagesKSSR - MatematikFaris FarhanNo ratings yet

- Chiller Selection Made Easier With myPLV™Document12 pagesChiller Selection Made Easier With myPLV™Omair FarooqNo ratings yet

- Multipoint Socket Profile VW 010 43: KonzernnormDocument4 pagesMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- JVC TH-M606 - 603 - SMDocument101 pagesJVC TH-M606 - 603 - SMCaillouxNo ratings yet