Professional Documents

Culture Documents

Gantry Girder

Uploaded by

Vishnu SamyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gantry Girder

Uploaded by

Vishnu SamyCopyright:

Available Formats

1

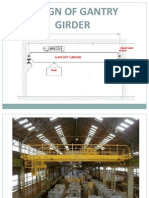

DESIGN OF GANTRY GIRDER

2

FEATURES

Design of Gantry Girder is a classic example

of laterally unsupported beam.

It is subjected to in addition to vertical loads

horizontal loads along and perpendicular to its

axis.

Loads are dynamic which produces vibration.

Compression flange requires critical attention.

3

IS:800-2007 PROVISIONS

Partial safety factor for both dead load and crane load is 1.5 (Table 4, p. no.

29).

Partial safety factor for serviceability for both dead load and crane load is

1.0 (Table 4, p. no. 29).

Deflection limitations (Table 6, p. no. 31).

Vertical loads

i) Manually operated Span/500

ii) Electric operated.... Span/750

up to 50t

iii) Electric operated Span/1000

over 50t

4

OTHER CONSIDERATIONS

Diaphragm must be provided to connect

compression flange to roof column of

industrial building to ensure restraint against

lateral torsional buckling.

Span is considered to be simply supported to

avoid bumpy effect.

5

6

7

TYPICAL GANTRY GIRDER

DETAILS

8

FORCES AND MOTIONS

9

VARIOUS TYPES OF SUPPORTS

10

11

IMPACT FACTORS

Type of load Additional load

Vertical loads

a) EOT crane 25% of static wheel load

b) HOT crane 10% of static wheel load

Horizontal forces transverse to rails

a) EOT crane 10% of wt. of

crab & wt. lifted

b) HOT crane 05% of wt of

crab & wt. lifted

Horizontal forces along the rails

For both EOT & HOT cranes 05% of static wheel load

Note: Gantry Girder & their vertical supports are designed

under the assumption that either of the horizontal

forces act at the same time as the vertical load.

12

GANTRY GIRDER DESIGN

Data

a) Wt. of crane girder/truss 180kN

b) Crane capacity 200kN

c) Wt. of crab + motor 50kN

d) Span of crane girder/truss 16m

e) Min hook approach 1.2m

f) c/c distance bet

n

gantry columns 6m

g) Wt. of rail 0.25kN/m

13

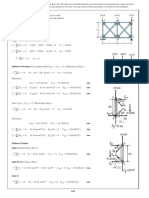

Maximum vertical static wheel load = R

A

/2

=160.625 kN

14

Wheel load with impact = 1.25 X 160.625

= 200.775 kN

Factored load = 1.5 X 200.775

= 301.16 kN

Absolute max bending moment in Gantry

Girder

This will occur under any wheel load when

distance bet

n

that load and C.G. of load system

is equidistant from the centre of the Gantry

Girder span.

15

Absolute max bending moment = 508.21 kNm

Md = Design moment for laterally unsupported beam

=

b

. Z

p

. f

bd

(Clause 8.2.2, p. no. 54)

Where

b

= 1.0 for plastic section (assumed)

Z

p

= plastic modulus of section

f

bd

= design bending compressive stress

16

Assuming f

bd

= 200 Mpa

Z

p

required = (508.21 X 10

6

) / (1.0 X 200)

= 2.54 X 10

6

mm

3

Using I and channel section and assuming 80%

of Z

p

is contributed by I section

Z

p

by I section = 2.032 X 10

6

mm

3

using shape factor of I section = 1.14

Z

e

required = 2032 / 1.14 = 1766.95 cm

3

select ISWB 500 @ 0.94 kN/m

Z

e

provided = 2091.6 > 1766.95 cm

3

. OK

17

Width of the flange of ISWB 500 = 250 mm

Select channel section having clear web depth

more than 250 mm.

Select ISLC 350 @ 0.38 kN/m

having h

1

= 291.9 mm > 250 mm .. OK

Total dead load intensity = 0.94 + 0.38 + 0.25

= 1.57 kN/m

Factored dead load intensity = 1.5 X 1.57

= 2.355 kN/m

Bending moment @ E = 9.93 kNm

Total bending moment due to DL + CL = 518.14 kNm

18

SELECTED CROSS SECTION

19

Refer Annexure E (p. no. 128)

Elastic lateral torsional buckling moment

Elastic critical moment of a section

symmetrical about minor axis yy is given

by E-1.2 of Annexure E (p. no. 128) in

which various factors and geometrical

values of Gantry Girder section are

involved.

20

These are as under

c

1

, c

2

, c

3

, = factors depending upon the

loading and end restraint

conditions, Refer table 42(p. no. 130)

K = effective length factor = 0.8

Therefore c

1

= 1.03, c

2

= 0.422 & c

3

= 1.22

K

w

= warping restraint factor = 1.0

y

g

= y distance bet

n

the point of application of

the load & shear centre of the cross section

(+ve when load acts towards Shear centre)

= 122.07 mm

21

LOCATION OF SHEAR CENTRE

22

y

j

for lipped flanges of channel section which depends

on ratio of

f

Where

f

= I

fc

/ (I

fc

+I

ft

).

= 0.7

y

j

= 94.055

Iyy = Iyy of ISWB 500 + Ixx of ISLC 350

= 2987.8 + 9312.6 = 12300.4 X 10

4

mm

4

L

LT

= K . L = 0.8 X 6000 = 4800 mm

I

w

= warping constant

= (1-

f

)

f

. I

y

. (h

y

)

2

= 6.23 X 10

12

mm

6

23

I

t

= Torsion constant

= bt

3

/3 = 10.86 X 10

5

G = 0.77 X 10

5

= 2950 kNm

To find Z

p

of Gantry Girder section we need to find

equal area axis of the section.

This axis is at a depth of 48.74 mm from the top of the

section.

Taking moments of areas about equal area axis.

A . y = Z

p

= 29.334 X 10

5

mm

3

2 2

2 2 0.5

1 2 3 2 3

2 2

( )

{[( ) ( ) ] ( )}

( )

w t LT

g j g j

LT w Y y

I GI L EIy k

Mcr c c y c y c y c y

L k I EI

t

t

= + +

24

Refering clause 8.2.2 for laterally unsupported beam

(p. no. 54)

= 0.4984

LT

= 0.21 for rolled section

= 0.655

= 0.925

Therefore f

bd

=

LT

. f

y

/

m0

= 0.925 X 250 / 1.1 = 210.22 N/mm

2

M

dZ

=

b

. Z

p

. f

bd

= 616.66 kNm > M

d

= 508.21 kNm

OK

/

LT b p y cr

Z f M | =

2

0.5[1 ( 0.2) ]

LT LT LT LT

| o = + +

2 2

1/( [ ])

LT LT LT LT

_ | | = +

25

Horizontal Action

Total horizontal force perpendicular to span of

Gantry Girder = 10 % (crane capacity + wt. of

crab and motor)

= 10% (200+50) = 25 kN.

As wheels are having double flanges

Horizontal force / wheel = 25/4 = 6.25 kN

Therefore max

m

horizontal BM in proportion to

vertical bending moment

M

y

= (6.25 /301.16) X 508.21 = 10.546 kNm

26

This is resisted by ISLC 350 with top flange of ISWB

500

Z

py1y1

= 100 X 12.5 X 337.5

2

+ (1/4) 7.4 X 325

2

+ (1/4) X 14.7 X 250

2

= 8.47 X 10

5

mm

3

27

Plastic moment capacity about y

1

y

1

axis

M

dy

=

b

. f

y

. Z

p

/

mo

= 192.5 kNm

Check for biaxial moment

Reffering clause 9.3.1.1 (p. no. 70)

(M

z

/M

dz

) + (M

y

/M

dy

)

=

(518.14 / 614.57) + (10.54 / 192.5)

= 0.897 < 1.0 .. OK

Hence select section for the gantry Girder as

I SWB 500 and I SLC 350 over it.

28

THE END

29

DESIGN OF BEAM COLUMN

30

DESIGN OF BEAM COLUMN

Combined action of bending and axial force (tension or

compression) occurs in following situations.

Any member in a portal frame.

Beam transferring reaction load to column.

Effect of lateral load on a column due to wind,

earthquake

Effect of eccentric load by crane loading due to

bracket connection to column.

In case of principal rafter, purlins not placed exactly

over joint of roof truss.

31

IS : 800 2007 CODAL

PROVISIONS

Minimum eccentricity of load transferred by beam

to column is specified by clause 7.3.3 (p. no. 46)

Section-9, Member subjected to combined forces.

clause 9.3 for combined axial force and bending

moment (p. no. 70) recommends check for section

a) By material failure clause 9.3.1

b) By overall buckling failure clause 9.3.2

32

DESIGN OF BEAM COLUMN

DATA

A column in a building 4m in height bottom end

fixed, top end hinged.

reaction load due to beam is 500 kN at an eccentricity

of 100 mm from major axis of section.

DESIGN

Column is subjected to axial compression of 5 X 10

5

N with bending moment of 50 X 10

6

Nmm.

Taking design compressive stress for axial loading as

80 Mpa.

33

A

e

reqd = 500 X 10

3

/ 80 = 6250 mm

2

To account for additional stresses developed due to

bending compression.

Try ISHB 300 @ 0.58 kN/m

A

g

= 7485 sq.mm, r

xx

= 129.5 mm, r

yy

= 54.1 mm

f

y

= 250 Mpa

Classification of section

b/t

f

= 125 / 10.6 = 11.79 > 10.5 (limit for compact

section)

Flange is semicompact

h

1

/t

w

= 249.8 / 7.6 = 32.86 < 84

Web is plastic

Therefore overall section is semicompact.

34

a) Section strength as governed by

material failure (clause 9.3.1)

Axial stress = N/A

e

= 500 X 10

3

/ 7485

= 66.80 N/mm

2

Bending stress M

z

/Z

e

= 50 X 10

6

/ 836.3 X 10

3

= 59.78 N/mm

2

As the section is semicompact use clause 9.3.1.3 (p. no. 71)

Due to bending moment at top, horizontal shear developed V is

18.75 kN = 18750 N

Shear strength of section V

d

= ((f

y

/ 3) . h . t

w

) / 1.10

= 299 kN

35

As V/V

d

= 18750 / 299 X 10

3

= 0.062 < 0.6

Reduction in moment capacity need not be done.

As per clause 9.3.1.3 (p. no. 71)

Total longitudinal compressive stress

f

x

= 66.80 + 59.78

= 126.58 < f

y

/

mo

= 227.27 OK

Alternately

N = 500 kN

N

d

= A

g

. f

y

/

mo

= 7485 X 250 / 1.1 = 1701.136 kN

M

z

= 50 X 10

6

Nmm = 50 kNm

M

dz

= Z

e

. f

y

/

mo

= 836.3 X 10

3

X 250 /1.10

= 190.068 kN

Hence, (500 / 1701.136) + (50 / 190.068)

= 0.557 < 1 . OK

36

b) Member strength as governed by

buckling failure clause 9.3.2 (p. no. 71)

In the absence of M

y

, equations are reduced to

Where, P = 500 X 10

3

N

M

z

= 50 X 10

6

Nmm

1

z

LT

dy dz

P M

k

P M

+ s

1

mz z

z

dz dz

C M P

k

P M

+ s

37

M

dz

=

b

. Z

p

. f

bd

b

= Z

e

/ Z

p

as section is semicompact

Therefore M

dz

= Z

e

f

bd

f

bd

=

LT

f

y

/

mo

LT

= bending stress reduction factor to account

torsional buckling.

2 2 0.5

1

1

[ ]

LT

LT LT LT

_

| |

= s

+

2

0.5[1 ( 0.2) ]

LT LT LT LT

| o = + +

38

LT

= 0.21 for rolled section

f

cr,b

depends on following factors

k

L

/ r

yy

= 0.8 X 4000 / 54.1 = 59.15

h / t

f

= 300/10.6 = 28.30

Using table 14, (p. no. 57)

f

cr,b

= 691.71 N/mm

2

= 0.060 < 0.4

,

y

LT

cr b

f

f

=

250

691.71

LT

=

39

As per clause 8.2.2 (p. no. 54)

Resistance to lateral buckling need not be checked and

member may be treated as laterally supported.

M

dz

=Z

e

. f

y

/

mo

= 190 kNm

Evaluation of P

dy

buckling load @ yy axis

Referring table 10 (p. no. 44)

h/b

f

=300/250 = 1.2

buckling @ yy axis is by class c

t

f

= 10.6 mm < 100mm

buckling @ zz axis is by class b

40

l

y

/ r

y

= 3200/54.1 = 59.15

For f

y

= 250 and using Table 9 (c), (p. no. 42)

F

cdy

= 169.275 N/mm

2

P

dy

= A

g

. f

cdy

= 1267.02 kN

Evaluation of P

dz

buckling @ zz axis

l

z

/r

z

= 3200 / 129.5 = 24.71

For f

y

= 250 and using Table 9 (b), (p. no. 41)

f

cdz

= 220.76 N/mm

2

Therefore p

dz

= A

g

. f

cdz

= 1652.38 kN

41

K

z

= 1 + (

z

0.2)n

z

Where,

l

z

/r

z

= 24.71, h/t

f

= 300 / 10.6 = 28.30

From table 14 (p. no. 57)

f

cr,z

= 4040 N/mm

2

Ratio of actual applied load to axial strength,

n

z

= 500 / 1625.38 = 0.30

n

y

= 500 / 1267.02 = 0.39

z

= 250/4040 = 0.246

,

y

z

cr z

f

f

=

42

K

z

=1 + (

z

0.2) n

z

= 1.0138 < 1+0.8 n

z

< 1.24. OK

= ratio of minimum to maximum BM

= -25 / 50 = -1 / 2

C

mz

= 0.6 + 0.4 X () = 0.4

= 0.844

0.1

1

0.25

LT y

LT

mLT

n

K

C

=

43

< 1 . OK

< 1 . OK

Hence select ISHB 300 @ 0.58 kN/m as a section for

eccentrically loaded column.

0.612

z

LT

dy dz

P M

K

P M

+ =

0.406

mz z

z

dz dz

C M P

K

P M

+ =

44

Design of Beam Column

Working Stress Method

IS : 800 - 1984

Checking section ISHB 300 @

0.58 kN/m

A = 7485 sq mm

ac,cal

= P/A = 66.80 N/mm

2

slenderness ratio = L / r

yy

= 59.15

for f

y

= 250 Mpa,

ac

=

121.15N/mm

2

from table 5.1 (p. no. 39)

45

=ratio of smaller to larger moment = 0.5

Therefore, C

mx

= 0.6 0.4 X 0.5 = 0.4 0.4 OK

bcx,cal.

= 50000 / 836.3 = 59.78 N/mm

2

f

cc

= elastic critical stress in compression

=

2

E /

2

= 563.6 N/mm

2

bcx

= Permissible bending stress in compression. As

column is laterally unsupported following ratios

are evaluated.

D/T = 28.30, L / r

yy

= 59.15

As T / L = 10.6 / 7.6 < 2

for f

y

= 250 using table 6.1 B (p. no. 58)

bcx

= 150 N/mm

2

46

< 1 .. OK

Hence requirement of section for a column under

eccentric load is same as ISHB 300 @ 0.58 kN/m

, ,

,

0.7486

1

0.6

ac cal mx bcx cal

ac cal ac

bcx

ccx

C

f

o o

o o

o

+ =

`

)

47

Thus reserve strength in a section by LSM is more than

WSM.

LSM

1) Interaction bet

n

axial &

uniaxial bending is

considered taking buckling

due to axial loading about

both axes of c/s

2) C

mx

= 0.4

3) Combined interaction is

considered for buckling @

both axes of cross section.

4) Interaction values are

@ yy axis 0.612

@ zz axis 0.406

WSM

1) Interaction is countered

only by taking buckling

due to axial load @ weaker

axis with bending @ major

axis.

2) C

mx

= 0.4

3) Combined interaction is

considered for buckling @

yy axis only.

4) Interaction value is

@ yy axis 0.7486

Beam Column

48

THE END

You might also like

- Design Gantry Girder Industrial Building CraneDocument28 pagesDesign Gantry Girder Industrial Building Cranes_bharathkumar75% (12)

- Balok CraneDocument31 pagesBalok CraneEzekiel Ezhe Iwawo100% (1)

- Design of Gantry Girders 1Document10 pagesDesign of Gantry Girders 1Abhishek Agarwal100% (2)

- 1984Document46 pages1984Praveen Kumar85% (13)

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Design of Gantry GirderDocument25 pagesDesign of Gantry GirderYash DhabaliaNo ratings yet

- Gantry Beam DesignDocument5 pagesGantry Beam DesignSanjeev Kumar Pillai100% (9)

- Gantry CraneDocument31 pagesGantry CraneWaheed Ahmad100% (1)

- Ravindu: VS Consulting 1Document5 pagesRavindu: VS Consulting 1Ravindu JayalathNo ratings yet

- Crane Girder DesignDocument6 pagesCrane Girder DesignAya Montes100% (3)

- Crane Girder Design-5T-5.7m SpanDocument32 pagesCrane Girder Design-5T-5.7m SpanKyatoor SantoshNo ratings yet

- Crane Girder and Channel Design DetailsDocument1 pageCrane Girder and Channel Design DetailsAnonymous RXXdbl36ANo ratings yet

- Unit 10 Gantry Girders: StructureDocument54 pagesUnit 10 Gantry Girders: StructureMahendra DewasiNo ratings yet

- Design of Gantry GirderDocument14 pagesDesign of Gantry Girdervijay10484No ratings yet

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 pagesCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Gantry GirderDocument5 pagesGantry GirderDas TadankiNo ratings yet

- Gantry GirderDocument38 pagesGantry GirderPiyush Yadav75% (4)

- Gantry ExampleDocument4 pagesGantry ExamplechrisNo ratings yet

- Crane Girder Design ProcedureDocument18 pagesCrane Girder Design ProcedureBhadresh Shah0% (1)

- Crane Runway Beam Design Using CSA S16-14 CodeDocument3 pagesCrane Runway Beam Design Using CSA S16-14 CodesergiooiNo ratings yet

- 762X267X197Crane Gantry Girder Design (BS5950)Document5 pages762X267X197Crane Gantry Girder Design (BS5950)Ravindu Jayalath100% (1)

- Design of Crane Girder for TG BayDocument31 pagesDesign of Crane Girder for TG BaygvlanushaNo ratings yet

- CraneBeam v1 1Document44 pagesCraneBeam v1 1harry_1981No ratings yet

- Single Girder EOT Cranes (SG-EOT)Document5 pagesSingle Girder EOT Cranes (SG-EOT)Nikhil PoriyaNo ratings yet

- Runway Crane GirdersDocument15 pagesRunway Crane GirdersFabio OkamotoNo ratings yet

- Design of Steel Structures IIDocument9 pagesDesign of Steel Structures IIIvan Jansen Saragih100% (2)

- Design of Gantry Girder using built-up sectionsDocument17 pagesDesign of Gantry Girder using built-up sectionsPrantik Maity100% (1)

- Load calculations for EOT crane framesDocument4 pagesLoad calculations for EOT crane framesknight1729No ratings yet

- Design Calculation of Gantry GirderDocument7 pagesDesign Calculation of Gantry GirderKushal ChhetriNo ratings yet

- Crane gantry calculation data sheetDocument7 pagesCrane gantry calculation data sheetvinit soodNo ratings yet

- Crane Girder DesignDocument1 pageCrane Girder Designmonther_alsalkhadiNo ratings yet

- Crane Girder Capacity CalculationDocument4 pagesCrane Girder Capacity Calculationsatoni12No ratings yet

- Design of Gantry Girder by IS Method Limit StateDocument20 pagesDesign of Gantry Girder by IS Method Limit StateMohammed Saleem Syed Khader100% (2)

- Crane BeamDocument20 pagesCrane BeamPreyash Shah100% (1)

- Crane Runway Girder DesignDocument27 pagesCrane Runway Girder Designyeemonzolo100% (6)

- Crane Buffer ForcesDocument243 pagesCrane Buffer ForcesFourHorsemenNo ratings yet

- Design 10-Ton Crane GirderDocument13 pagesDesign 10-Ton Crane GirderDavid_PuenNo ratings yet

- Structural Steelwork ConnectionsDocument4 pagesStructural Steelwork Connectionstheunknown076No ratings yet

- Gantry Crane Beam Design3MTDocument15 pagesGantry Crane Beam Design3MTKeshav Vaity100% (1)

- Crane GirdersDocument15 pagesCrane GirdersRaduku RaduNo ratings yet

- Beam Design Calculations and SelectionDocument24 pagesBeam Design Calculations and SelectionA.K.M Shafiq MondolNo ratings yet

- Crane Girder DesignDocument6 pagesCrane Girder Designarzu50% (2)

- EOT Crane Wheel Load CalculationDocument1 pageEOT Crane Wheel Load CalculationSantosh100% (2)

- Gantry CraneDocument31 pagesGantry CraneWaheed AhmadNo ratings yet

- SteelDocument9 pagesSteelMohammedAlasaadNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- Warehouse Roof Design and AnalysisDocument51 pagesWarehouse Roof Design and AnalysisAnonymous q0irDXlWAm100% (2)

- Philosophy of Limit State Design and Classification of SectionsDocument96 pagesPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- Materials: Slab Bridge DesignDocument13 pagesMaterials: Slab Bridge DesignephremNo ratings yet

- Abutment DesignDocument10 pagesAbutment DesigndsureshcivilNo ratings yet

- Design of FootingDocument31 pagesDesign of FootingAbhinav100% (1)

- Limit State Design of Liquid Retaining SectionDocument6 pagesLimit State Design of Liquid Retaining Sectionarif_rubinNo ratings yet

- Plate Girder DesignDocument8 pagesPlate Girder Designkalpanaadhi100% (1)

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- Design of Composite Steel Girder BridgeDocument10 pagesDesign of Composite Steel Girder BridgesorowareNo ratings yet

- Strut Design SheetDocument84 pagesStrut Design SheetHafiz Kamarudin100% (2)

- Prestress Concrete (24-30)Document33 pagesPrestress Concrete (24-30)Prantik Adhar SamantaNo ratings yet

- Single Lane BridgesDocument55 pagesSingle Lane Bridgeshsword7No ratings yet

- PSC Bridge Girder Design To BS5400 by D ChildsDocument321 pagesPSC Bridge Girder Design To BS5400 by D ChildsDuke50% (2)

- Iphone Ringtone: Ca#Gc Fca#Cf Gga#Cca#Gcfca#Cf Gga#Cca#Gcfca#Cf Gga#Cca#Gcfca#CfDocument1 pageIphone Ringtone: Ca#Gc Fca#Cf Gga#Cca#Gcfca#Cf Gga#Cca#Gcfca#Cf Gga#Cca#Gcfca#CfVishnu SamyNo ratings yet

- Vinod DhamDocument7 pagesVinod DhamVishnu SamyNo ratings yet

- PALAKKAD to ALUVA TRAIN SCHEDULEDocument3 pagesPALAKKAD to ALUVA TRAIN SCHEDULEVishnu SamyNo ratings yet

- Tablature For Ilayanila - Guitar Tabs and NotesDocument2 pagesTablature For Ilayanila - Guitar Tabs and NotesVishnu SamyNo ratings yet

- Ilaya Nila - WholeNote Guitar LessonDocument4 pagesIlaya Nila - WholeNote Guitar LessonVishnu SamyNo ratings yet

- ExpressionsDocument9 pagesExpressionsdukkasrinivasflexNo ratings yet

- 7ADocument2 pages7AVishnu SamyNo ratings yet

- Zamil Steel Design ManualDocument282 pagesZamil Steel Design ManualAyubkhan289% (35)

- 7ADocument2 pages7AVishnu SamyNo ratings yet

- Etabs TutorialDocument103 pagesEtabs TutorialGlenn Rey DomingoNo ratings yet

- Analysis and Design of Multistory Building With Grid Slab Using ETABSDocument12 pagesAnalysis and Design of Multistory Building With Grid Slab Using ETABSVishnu SamyNo ratings yet

- Intro Guitar RiffDocument4 pagesIntro Guitar RiffVishnu SamyNo ratings yet

- Chennai Places To VisitDocument1 pageChennai Places To VisitVishnu SamyNo ratings yet

- Asking and Giving Directions Conversation English LessonDocument2 pagesAsking and Giving Directions Conversation English LessonVishnu SamyNo ratings yet

- Ilaya Nila - Page 3 - WholeNote Guitar LessonDocument3 pagesIlaya Nila - Page 3 - WholeNote Guitar LessonVishnu SamyNo ratings yet

- Advantages of Soilless Agriculture - PowerHouse HydroponicsDocument4 pagesAdvantages of Soilless Agriculture - PowerHouse HydroponicsVishnu SamyNo ratings yet

- Booking A Taxi Conversation at A HotelDocument2 pagesBooking A Taxi Conversation at A HotelVishnu SamyNo ratings yet

- Basic Dialogue PhrasesDocument2 pagesBasic Dialogue PhrasesVishnu SamyNo ratings yet

- Choose An Outbound Flight: FlightsDocument1 pageChoose An Outbound Flight: FlightsVishnu SamyNo ratings yet

- Al Musanna College of Technology: Academic Year: 2016 - 2017 (Semester 1 - 01-SEP-16) Attendance SheetDocument3 pagesAl Musanna College of Technology: Academic Year: 2016 - 2017 (Semester 1 - 01-SEP-16) Attendance SheetVishnu SamyNo ratings yet

- Etabs TutorialDocument103 pagesEtabs TutorialGlenn Rey DomingoNo ratings yet

- Al Musanna College of Technology: Academic Year: 2016 - 2017 (Semester 1 - 01-SEP-16) Attendance SheetDocument2 pagesAl Musanna College of Technology: Academic Year: 2016 - 2017 (Semester 1 - 01-SEP-16) Attendance SheetVishnu SamyNo ratings yet

- Divorce FAQs ExplainedDocument9 pagesDivorce FAQs ExplainedVishnu SamyNo ratings yet

- Al Musanna College of Technology: Academic Year: 2016 - 2017 (Semester 1 - 01-SEP-16) Attendance SheetDocument3 pagesAl Musanna College of Technology: Academic Year: 2016 - 2017 (Semester 1 - 01-SEP-16) Attendance SheetVishnu SamyNo ratings yet

- Gerd DietDocument2 pagesGerd DietVishnu SamyNo ratings yet

- Gmail - Your IndiGo Itinerary - M6THHV - Chennai CoimbatoreDocument3 pagesGmail - Your IndiGo Itinerary - M6THHV - Chennai CoimbatoreVishnu SamyNo ratings yet

- Mix Design - ReDocument3 pagesMix Design - ReVishnu SamyNo ratings yet

- Slab DesignDocument15 pagesSlab DesignLawrence Arellano FernandezNo ratings yet

- Foooting TotalDocument4 pagesFoooting TotalVishnu SamyNo ratings yet

- Revised Task 1 RIICWD601Document5 pagesRevised Task 1 RIICWD601jekolaf936No ratings yet

- Course Briefing Notes 2020/2021: CIVE2047 (H22POR) Portfolio of Civil Engineering Studies 2Document21 pagesCourse Briefing Notes 2020/2021: CIVE2047 (H22POR) Portfolio of Civil Engineering Studies 2Darren XuenNo ratings yet

- Arc Length MethodDocument22 pagesArc Length MethodJoe Satch100% (1)

- Salt Barn SpecificationsDocument24 pagesSalt Barn SpecificationsRomoex R RockNo ratings yet

- Truss Terminology PDFDocument3 pagesTruss Terminology PDFNerinel CoronadoNo ratings yet

- Rock BoltingDocument15 pagesRock BoltingDanang Ardianto100% (1)

- Ms. Shraddha Sunil Kadam (REG NO. C1652005) : DR A.A.BageDocument43 pagesMs. Shraddha Sunil Kadam (REG NO. C1652005) : DR A.A.BageSHRADDHA KADAMNo ratings yet

- Building Technology FundamentalsDocument46 pagesBuilding Technology Fundamentalshans abesamis100% (2)

- Analysis of the Acoustic Response of a Rail Road Bridge Presented at the COMSOL Conference 2009 BostonDocument13 pagesAnalysis of the Acoustic Response of a Rail Road Bridge Presented at the COMSOL Conference 2009 BostonferelvishalNo ratings yet

- Villaboard Lining Installation Manual Jan 12Document20 pagesVillaboard Lining Installation Manual Jan 12charlie20377240No ratings yet

- Statics Problems PDFDocument21 pagesStatics Problems PDFClarence Jay AcaylarNo ratings yet

- Truss bridge simulationDocument5 pagesTruss bridge simulationOri SeinNo ratings yet

- High-Strength Steel RoofDocument9 pagesHigh-Strength Steel RoofalbertofgvNo ratings yet

- SeaStar Mini TLP PaperDocument8 pagesSeaStar Mini TLP PaperSean MiddletonNo ratings yet

- Chapter 2 Pin Jointed FrameDocument29 pagesChapter 2 Pin Jointed FrameShahul14No ratings yet

- CE 3010 Syllabus - Summer 2022Document6 pagesCE 3010 Syllabus - Summer 2022Engr. Waqas AhmedNo ratings yet

- Wooden Stick Bridge Calculation ProcedureDocument9 pagesWooden Stick Bridge Calculation ProcedureScribdTranslationsNo ratings yet

- Sandwich 3D Panel System: Construction Practices and Experimental InvestigationsDocument11 pagesSandwich 3D Panel System: Construction Practices and Experimental InvestigationsVirat DesaiNo ratings yet

- Chapter 7 PDFDocument67 pagesChapter 7 PDFNathalhyn ArmijoNo ratings yet

- Mitchell TrussDocument16 pagesMitchell TrussvishalnalwarNo ratings yet

- JAGADEESHDocument139 pagesJAGADEESHMannam Sarath Sarath0% (1)

- CRN Cs 300 v1 1Document30 pagesCRN Cs 300 v1 1kaushik960No ratings yet

- Element 45 - 1538-NOTE 2Document35 pagesElement 45 - 1538-NOTE 2hadeer youns100% (1)

- Dss - SyllabusDocument2 pagesDss - Syllabusapi-306484475No ratings yet

- Industrial Construction Consist of The Buildings IncludingDocument10 pagesIndustrial Construction Consist of The Buildings IncludingShruti SaxenaNo ratings yet

- Comparing Structural Systems in Contemporary High-Rise BuildingsDocument19 pagesComparing Structural Systems in Contemporary High-Rise BuildingsBagoes Rama Al AriefqiNo ratings yet

- CE8502 Structural Analysis 1 MCQ PadeepzDocument22 pagesCE8502 Structural Analysis 1 MCQ Padeepzpriya dharshini100% (1)

- Steel Trusses Notes-1Document9 pagesSteel Trusses Notes-1Nicholas ThompsonNo ratings yet

- Connection: EN 1993-1-8 DefinitionsDocument49 pagesConnection: EN 1993-1-8 DefinitionsZeiwa Rex100% (1)

- PROBLEM 6.39: SolutionDocument10 pagesPROBLEM 6.39: SolutionWilliam HendersonNo ratings yet