Professional Documents

Culture Documents

Amaraja

Uploaded by

rmsh3010 ratings0% found this document useful (0 votes)

86 views47 pagesBattries

Original Title

amaraja

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBattries

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

86 views47 pagesAmaraja

Uploaded by

rmsh301Battries

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 47

REDUCTION OF PLATE SCRAP OF A BATTERY BY

USING MECHANICAL METHODS

By

P.Satyanarayana 06191A0310

D.Sudhakar Reddy 06191A0325

D.Dinesh Kumar 06191A0314

P.Sravani 06191A0304

P.Anusha 06191A0321

Company Introduction

ARBL is one of the biggest plant in Asia (area of 165 acres), most

advanced microprocessor controlled and fully integrated state of the art

manufacturing facility located at Tirupati, Andhra Pradesh with capital outlay of

Rs.180 crores.

Amara Raja is a public limited company whose scip is a joint venture between

Amara Raja group and Johnson Control Inc., USA. As of now 26% equity is with

JCI & Amara Raja group each and the rest 48% is with the public.

Amara Raja is the tenth largest MF-VRLA battery manufacturer in the world.

Amara Raja is also the largest supplier of VRLA batteries for various applications to

Indian Railways such as Train Lighting, Air Conditioning, Signal and Telecom

Batteries & AC Loco Batteries

Oxide Plant

Grid

Casting

Paste

Mixing &

Pasting

Plate

Curing

Plate

Cleaning

Stacking

Group

Burning

Insertion

Heat sealing

Post

Burning

Leak

Testing

Cell

Packing

Acid Filling

Cell

Forming

Cell Cleaning

& Insertion

Finishing

Packing &

Dispatch

Process flow for LVRLA

Process flow for MVRLA

Heat sealing

Post

Burning

Leak

Testing

Cell

Packing

Acid Filling

Cell

Forming

Cell Cleaning

& Insertion

Finishing

Packing &

Dispatch

Oxide Plant

Grid

Casting

Paste

Mixing &

Pasting

Plate

Curing

Plate

Cleaning

Envolop

Stackin

g

Cast on

Strap

Insertion

Inter cell

welding

Manufacturing

Section

Plate

Preparation

Assembly

Formation

Finishing

Industrial Battery

Industrial Battery Division (IBD) - LVRLA

Oxide Plant

Grid Casting

Pasting

Manufacturing Sections of IBD - LVRLA

Sub-Section

Busbar Casting

Plate curing

Plate cleaning

Dispatch

Plate Preparation

Oxide Plant

Grid casting

Pasting

Oxide Plant

Grid Casting

Pasting

Oxide Powder

Pbo2+H2So4 + Dm Water+

Chemicals = Paste

Grid + Paste=Plate

+

Pure Lead (99.97 %)

MFX & LCA

Lead Alloys

Paste

Section/Process

Input

Output

Oxide Plant

Pasting

Grid Casting

POS & NEG Plate

POS & NEG Grid

Grid

Lead Oxide Manufacturing

Process Flow Diagram

Lead Ingot

Lead Ingot Melting

Reaction

Oxide Powder Filtering

Quality Check Points:

1. % Free Lead

2. Apparent Density

3. Acid Absorption

Transfer to Silos

Oxide Storage in Silos

1. Molten Lead

2. Water

3. Air

Balox & Eagle

Oxide plants

Silos

Hammer Milling

Additional activity

For MVRLA

Lead Oxide Plant

Input & Out put Diagram

Oxide Preparation

Exothermic

reaction

Pure Lead(Pb)

Ingots 99.97 %

Lead

Oxide(PbO)

Pb + O2

Pbo

H2O

Pasting

Process Flow Diagram

Plate cleaning

Quality Check Points:

1. Free Lead %

2. Dry plate Moisture

3. Vibration loss%

Curing & Drying

Dry Plates Storage

1. Wet plates

2. Boiler

Cleaned Plates

Curing Ovens

Lead oxide powder stored in silo for min of 18hr. Then it is used to produce paste mix.

Composition used:

For Positive Paste:

Lead oxide 1000kg

Binder 0.5Kg

SPTH 2Kg

DM water 126lt

Sulfuric acid 110kg(Sp. gravity 1.4)

For Negative Paste:

Lead oxide 1000kg

Binder 0.5Kg

Barium Sulphate 20Kg

Vanisperse 2Kg

Carbon Black 2Kg

DM water 116lt

Sulfuric acid 110kg(Sp. gravity 1.4)

PASTE PREPARATION:

Plate Curing

Input & Out put Diagram LVRLA & MVRLA

Curing

Wet pasted

plates

Dry

plates

PROBLEM:

Plate scrap in pasting

OBJECTIVE:

To reduce the plate scrap in pasting.

To reduce the plates scrap from 2.4% to 1.35% per month

12-STEPS FOR PROBLEM SOLVING

STEP-1 IDENTIFICATION OF PROBLEMS

STEP-2 SELECTION OF THE PROBLEM

STEP-3 DEFINITION OF THE PROBLEM

STEP-4 ANALYSIS OF THE PROBLEM

STEP-5 IDENTIFICATION OF CAUSES

STEP-6 FINDING OUT THE ROOT CAUSE

STEP-7 DATA ANALYSIS

STEP-8 DEVELOPING SOLUTION

STEP-9 FORESEEING PROBABLE RESISTANCE

STEP-10 TRIAL IMPLEMENTATION & CHECK PERFORMANCE

STEP-11 REGULAR IMPLEMENTATION

STEP-12 FOLLOW UP/REVIEW

Step-1 Identification of Problems

Using Brainstorming

S.NO IDENTIFICATION OF PROBLEMS CAT:A\B\C

1 Plate Weight variation. A

2 Improper Filling of paste on grids A

3 Lug side over paste A

4 Filling problem of paste on grids A

5 Tool setting problem A

6 Flash Drier chain Vibration A

7 Parter timing problem A

8 Temp problem in Flash Drier B

9 Grid cutting problem A

10 Parter center chain sprocket problem B

11 Belt Nylon bed problem B

12 Heaters set fixing problem C

13 Feeder chain timing problem A

14 Grid feeding Rubber roller problem A

15 Knurling roller Bush problem B

16 Knurling roller Shaft problem B

17 Drive roller problem A

18 Drive roller Pins problem A

19 Drive roller Black bush problem B

20 Hopper Shaft bush problem B

Step-1 Identification of Problems

Using Brainstorming

21 Hopper Guard bush problem B

22 Hopper Bottom shoe guard problem B

23 Transfer roller bush problem B

24 Lug cleaning brush problem A

25 Parter Speed control Sensor problem B

26 Oxide leakage (Near Oxmaster lids ) B

27 Mixer Scrapers worn-out A

28 Slide gate Sensor problem B

29 Thermo couple problem in mixer B

30 Thermo couple Sensor problem in mixer B

31 Thermo couple cylinder problem B

32 Mixer Dumping Door Sensor problem B

33 Slide gate Water leakage problem B

34 Air leakage in mixer B

35 Acid leakage in mixer B

36 Acid Valve (Filling and Dumping) problem B

37 Mixer motor guard problem B

38 Oxmaster cone gear box problem B

39 Oxmaster cone Cylinder problem B

40 Oil leakage in mixer B

41 Plates scrap in pasting A

42 Hydraulic oil leakage in Hydraulic unit B

43 Hydraulic pressure problem B

44 Plates pallet Down in Assembly A

45 Plate Sagging problem A

Using Brainstorming

Step-1 Identification of Problems

46 Scissor lift problem at plate collecting area B

47 Bottom paste Tray problem B

48 Parter width Adjustment problem B

49 Fresh Air not working properly (Pressure low ) B

50 Pallet truck problem in pasting B

51 Plate Cross cutting problem in parter A

52 Heaters Failure in Flash drier B

53 Hydraulic pressure gauge Oil leakage B

54 Feeder center guide not working properly A

55 Lifting plates problem B

56 "D" Type Ovens Plates Moisture problem B

57 Transfer roller Speed problem B

58 Parter chain Bearing problem B

59 Forklift problem B

60 Oxide transfer problem to Day tank B

61 Day tank bin vent problem B

62 Day tank load cells problem B

63 Silos load cells problem B

64 Lighting problem in Grid feeder B

65 Weighing scale problem B

66 Plate storage Stands problem A

67 PP sheets problem A

68 High pressure pump problem B

PROBLEM CLASSIFICATION

ABC-ANALYSIS

CATEGERORY

N

O

.

O

F

P

R

O

B

L

E

M

S

A-21

B-46

C-01

Problems solved

by qc members

Where help is required

from other departments

Where management

help is required

Using Brainstorming

VICTORY

Step-2 Selection of the Problem

Ranking method

Ranking 01 - Low 05 - Moderate 10 - High

Sl No Problems V.R.R K.V D.S G.G Y.M Total

1 Plate Weight variation. 6 7 5 8 6 32

2 Improper Filling of paste on grids 5 6 4 5 4 24

3 Lug side over paste 9 9 10 9 10 47

4 Filling problem of paste on grids 5 6 2 4 5 22

5 Tool setting problem 5 6 4 3 6 24

6 Flash Drier chain Vibration 5 5 5 5 5 25

7 Parter timing problem 6 6 6 6 6 30

8 Temp problem in Flash Drier 6 4 4 4 4 22

9 Grid cutting problem 5 6 6 6 7 30

10 Parter center chain sprocket problem 4 5 5 5 5 24

11 Belt Nylon bed problem 5 7 5 4 5 26

12 Heaters set fixing problem 6 5 6 5 4 26

13 Feeder chain timing problem 5 5 7 7 6 30

14 Grid feeding Rubber roller problem 6 8 6 7 3 30

15 Knurling roller Bush problem 5 4 7 2 5 23

16 Knurling roller Shaft problem 6 6 4 5 4 25

17 Drive roller problem 5 5 5 4 5 24

18 Drive roller Pins problem 7 4 5 6 3 25

19 Drive roller Black bush problem 5 6 6 4 6 27

20 Hopper Shaft bush problem 6 7 7 3 8 31

21 Hopper Guard bush problem 8 4 6 4 4 26

22 Hopper Bottom shoe guard problem 5 6 7 5 6 29

23 Transfer roller bush problem 8 5 4 6 5 28

24 Lug cleaning brush problem 6 7 6 4 7 30

25 Parter Speed control Sensor problem 7 6 5 5 2 25

26 Oxide leakage (Near Oxmaster lids ) 6 8 4 7 4 29

27 Mixer Scrapers worn-out 6 5 8 8 6 33

28 Slide gate Sensor problem 6 6 6 4 5 27

29 Thermo couple problem in mixer 5 8 7 5 4 29

30 Thermo couple Sensor problem in mixer 4 7 6 4 7 28

31 Thermo couple cylinder problem 5 6 8 5 5 29

32 Mixer Dumping Door Sensor problem 6 5 2 6 6 25

33 Slide gate Water leakage problem 5 8 4 5 4 26

34 Air leakage in mixer 4 6 6 6 3 25

35 Acid leakage in mixer 5 5 4 7 4 25

36 Acid Valve (Filling and Dumping) problem 6 7 6 6 4 29

37 Mixer motor guard problem 5 4 5 5 5 24

38 Oxmaster cone gear box problem 4 5 5 4 5 23

39 Oxmaster cone Cylinder problem 6 4 7 6 6 29

40 Oil leakage in mixer 7 5 6 5 4 27

Ranking method

Step-2 Selection of the Problem

Ranking 01 - Low 05 - Moderate 10 - High

41 Plates scrap in pasting 10 9 9 10 9 47

42 Hydraulic oil leakage in Hydraulic unit 5 5 6 6 4 26

43 Hydraulic pressure problem 5 7 5 5 7 29

44 Plates pallet Down in Assembly 10 9 9 10 9 47

45 Plate Sagging problem 5 6 4 6 4 25

46 Scissor lift problem at plate collecting area 2 6 6 8 6 28

47 Bottom paste Tray problem 5 5 5 5 5 25

48 Parter width Adjustment problem 4 4 4 6 4 22

49 Fresh Air not working properly (Pressure low ) 6 4 5 5 5 25

50 Pallet truck problem in pasting 3 5 7 6 4 25

51 Plate Cross cutting problem in parter 5 5 6 7 6 29

52 Heaters Failure in Flash drier 4 5 4 5 4 22

53 Hydraulic pressure gauge Oil leakage 3 5 6 6 7 27

54 Feeder center guide not working properly 4 7 5 5 5 26

55 Lifting plates problem 6 6 4 6 8 30

56 "D" Type Ovens Plates Moisture problem 2 4 6 7 4 23

57 Transfer roller Speed problem 6 5 5 4 5 25

58 Parter chain Bearing problem 5 4 5 6 6 26

59 Forklift problem 5 3 4 5 4 21

60 Oxide transfer problem to Day tank 4 5 3 4 4 20

61 Day tank bin vent problem 5 4 4 2 2 17

62 Day tank load cells problem 4 5 4 4 3 20

63 Silos load cells problem 5 4 2 3 4 18

64 Lighting problem in Grid feeder 4 3 3 5 2 17

65 Weighing scale problem 4 4 2 2 5 17

66 Plate storage Stands problem 5 5 4 4 2 20

67 PP sheets problem 4 3 5 3 4 19

68 High pressure pump problem 5 2 2 2 5 16

Step-2 Selection of the Problem

Ranking method

Ranking 01 - Low 05 - Moderate 10 - High

Step-2 Selection of the Problem

PRIORITY METHOD

S.NO Problem NOT URGENT(0) URGENT(2) VERY URGENT(5) TOTAL

1 Lug side over paste 1 2 2 14

2 Plates scrap in pasting . 2 3 19

3 Plates pallet Down in Assembly 2 2 1 9

PLATES SCRAP IN PASTING HAS SCORED MAXIMUM MARKS

AND IS SELECED FOR OUR PROJECT

Step-3 Definition of the Problem

Pasting Process Flow Chart

PASTING

GRID FEEDER

HOPPER PASTE MIXER

FLASH DRIER

PARTER

PASTE

STACKING

Step-4 Analysis of the Problem

Problem analysis was carried out through

4W 1H Technique

WHAT - Plates scrap in pasting

WHEN - During pasting

WHERE - In pasting section

WHO - Pasting operators

HOW - By analysing the causes and developing solution

Step-4 Analysis of the Problem

Manufacturing cost

Productivity

Operator stress

WEEKS PRODUCED SCRAP

PLATE REJECTION

COST(Rs)

WEEK1 287130 1747 37300

WEEK2 357637 14363 30665

WEEK3 467330 8375 17881

WEEK4 406708 12813 27355

AVERAGE: 9324 No 28308 RS

Step-5 Identification of Causes

Men Machine

Method

Material

Lack of awareness

Lifting problem feeder

Feeder chain timing change

Driver roller bush

and block worn out

Driver roller worn out

Oxide usage with out aging

Grids usage with out aging

Paste problem

Improper tool setting

Cause and effect diagram

Plates

scrap

Conveyor chain vibration

Porter dog chain

timing change

V belt worn out

Brush worn out

Pressure plate improper setting

First sample checking

Cross cutting

Improper pate filling

198400

55007

41956

30958

20832

18024

15496

10109

7221 6376

5081

4116 3483 3445

2372 1384

672 600 500 118 28

46.6%

59.5%

69.3%

76.6%

81.5%

85.7%

89.3%

91.7%

93.4%

94.9%

96.1%

97.0%

97.9%

98.7%

99.2% 99.5% 99.7% 99.8% 100.0%100.0%100.0%

0

50000

100000

150000

200000

V

i

b

r

a

t

i

o

n

L

o

s

s

C

r

o

s

s

c

u

t

t

in

g

P

a

r

t

e

r

j

a

m

m

i

n

g

I

m

p

r

o

p

e

r

p

a

s

t

f

il

l

i

n

g

O

u

t

o

f

s

q

u

a

r

e

d

L

o

w

m

o

is

t

u

r

e

P

a

l

l

e

t

d

o

w

n

I

n

c

o

m

p

l

e

t

e

p

a

s

t

e

f

i

l

l

H

i

g

h

W

e

i

g

h

t

P

l

a

t

e

s

t

i

c

k

i

n

g

P

i

n

h

o

l

e

s

D

i

v

i

d

e

r

s

c

r

a

p

P

a

l

l

e

t

m

i

s

s

i

n

g

L

o

w

w

e

i

g

h

t

F

r

a

m

e

d

a

m

a

g

e

s

F

r

e

e

L

e

a

d

H

i

g

h

F

r

a

m

e

b

e

n

d

P

l

a

t

e

b

e

n

d

O

v

e

r

l

a

p

p

i

n

g

Q

A

s

a

m

p

l

e

s

.

P

a

s

t

l

u

m

p

s

0.0%

10.0%

20.0%

30.0%

40.0%

50.0%

60.0%

70.0%

80.0%

90.0%

100.0%

Pareto analysis

N

o

o

f

p

l

a

t

e

s

76% OF REJECTIONS OCCURING DUE TO VIBRATION LOSS,CROSS CUTTING

PARTER JAMMING,IMPROPER PASTE FILLING

Causes

Step-4 Analysis of the Problem

Step-6 Root Cause Analysis

Data collection

FROM DATA COLLECTION 76% OF REJECTIONS OCCRING DUE TO

1. VIBRATION LOSS

2. CROSS CUTTING

3. PARTER JAMMING,

4. IMPROPER PASTE FILLING

Vibration losses Cross cutting Parter jamming Improper paste filling

Action (3W 1H)

Step-8 Development of Solutions

WHAT WHO WHEN HOW

P.Satyanarayana 24feb-20marFlash drier chain modification

do Increasing quantity of binder addition

D.Dinesh Kumar do Sprocket modification

do Giving awareness to the operator

do Changing freuency of cutter fixing

D.Sudhakar Reddy do Brush level modification

p.Anusha do Prater on/off switch near to operator

do Pressure plate adjustment

IMPROPER FILLING

p.sravani do cone switch near to operator

VIBRATION LOSSES

CROSS CUTTING PLATES

PORTER JAMMMING

Step-8 Development of Solutions

Using Brainstorming

Vibration looses

Flash drier chain modification

Increasing quantity of binder addition

Cross cutting

Sprocket modification

Giving awareness to the operator

Fixing the changing frequency of cutter

Step-8 Development of Solutions

Using Brainstorming

Parter jamming

Brush level modification

Parter on/off switch near to operator

Improper paste filling

Pressure plate adjustment

Cone switch near to operator

BEFORE

Problem Improvement

Due to more length of chain, plates are

getting vibrated

The length of the chain has decreased

by removing six links

AFTER

Flash drier chain modification

Step-10 Trail Implementation & Check Performance

BEFORE

Problem Improvement

Due to frequent loosing of sprocket causing

Dog chains unlevel leading to cross cutting

Sprocket was fixed with supporting rod

provide to prevent frequent loosing

AFTER

Sprocket Modification

Step-10 Trail Implementation & Check Performance

Step-10 Trail Implementation & Check Performance

BEFORE

Problem Improvement

Due to brush unlevel causing plates

disturbance leading to cross cutting of

plates

Brush level is fixed with supporting rod

to avoid cross cutting

AFTER

Brush level modification

Step-10 Trail Implementation & Check Performance

BEFORE

Problem Improvement

Due to unlevel of pressure plate causing

over paste on lugs leading to disturbance at

the brushes

The springs in the pressure plate has

modified.

AFTER

Pressure plate modification

Step-10 Trail Implementation & Check Performance

BEFORE

Problem Improvement

switch is near to cone due to this operator

feeling difficult for frequent access

Cone switch provided near to operator

so that he can frequently fill the paste

in hopper

AFTER

Cone switch

Step-10 Trail Implementation & Check Performance

BEFORE

Problem Improvement

Cross cutting occurring due to Parter on/off

switch far from operator

Parter on/off switch provided near to

operator

AFTER

Parter switch

STANDARDISATION

Step-11 Regular Implementation

To avoid vibration losses binder addition increased from 1kg to 1.25kgs

for positive and 1kg to 2.5kg for negative.

Check list for Parter cutter changing for every 800000 plates

STANDARDISATION

Step-11 Regular Implementation

Step-12 Follow Up & Review

12813

5342

1137

1297

0

20000

40000

60000

80000

100000

120000

140000

PLATE REJECTIONS

N

O

.

O

F

P

L

A

T

E

S

R

E

J

E

C

T

E

D

GOAL: To reduce the plates scrap from 2.4% to 1.35%

TANGIBLE BENIFITS

INTANGIBLE BENIFITS

1. Developed leader ship Qualities

2. Pride in achievement

3. Opportunity of learning

4. Self motivation

Plates saved per week =4177 No

Cost saved per week =89178 Rs/-

Before modify scrap%=(avg.scrap/produced plates)

(9324/379701)=2.4%

After modify scrap%=5147/379701=1.35

1. Brain Storming

2. Bar Graphs

3. Ranking Technique

4. Flow Diagrams

5. 4W&1H Method

6. Ishikawa Diagram

Application Segments / Costumers

Industrial Batteries

Railways

Power Generation

Oil & Gas

Process Industry

Defence

Motive Power

DG Set- Auxiliary power

Telecommunications

Plates scrap in pasting has played prominent role in reduction and

wastage of huge amount , large amount of workers working hours so we

have reduced by implementing some of the mechanical techniques.

As we had the goal to reduce the plates scrap from 2.4% to 1.35%,

But we achieved 1% by implementing the all techniques and tools used.

You might also like

- Chapter-Iv Data Analysis AND: InterpretationDocument17 pagesChapter-Iv Data Analysis AND: Interpretationdyaniraj100% (1)

- Nalco ReportDocument82 pagesNalco ReportparwezNo ratings yet

- Financial Management Practices of Upl LimitedDocument17 pagesFinancial Management Practices of Upl LimitedSaurabh PrasadNo ratings yet

- Report on Saurashtra Chemicals Ltd: Organization, Departments & FunctionsDocument85 pagesReport on Saurashtra Chemicals Ltd: Organization, Departments & FunctionsBhavesh RogheliyaNo ratings yet

- Steel Plant Report FinalDocument54 pagesSteel Plant Report Finalkranthi chaitanyaNo ratings yet

- Slurry Erosion of Hydro Turbine SteelsDocument10 pagesSlurry Erosion of Hydro Turbine SteelsHarinderpal Singh PannuNo ratings yet

- Arunkumar ProjectDocument67 pagesArunkumar ProjectanushwaryaNo ratings yet

- Sowbaghya - 17bba041 (Suren)Document38 pagesSowbaghya - 17bba041 (Suren)suren moorthy100% (1)

- MbasatsheshDocument73 pagesMbasatsheshHarichandran KarthikeyanNo ratings yet

- Organization Study of Adishakthi Iron Castings PVT - LTD Inplant Training 2015Document56 pagesOrganization Study of Adishakthi Iron Castings PVT - LTD Inplant Training 2015shivakumar52No ratings yet

- Bachelor of Business Administration: Hi-Tech Arai PVT LTDDocument52 pagesBachelor of Business Administration: Hi-Tech Arai PVT LTDJeetu JainNo ratings yet

- APL ApolloDocument19 pagesAPL ApolloDEEPAKNo ratings yet

- Cera SanitaryDocument24 pagesCera SanitaryHarish KumarNo ratings yet

- Havells India LTDDocument15 pagesHavells India LTDNithya Raj100% (1)

- GRAVITY CAST MBA Porject Report Prince DudhatraDocument51 pagesGRAVITY CAST MBA Porject Report Prince DudhatrapRiNcE DuDhAtRaNo ratings yet

- List of FigureDocument1 pageList of FigureNirav100% (1)

- Summer Training ReportDocument24 pagesSummer Training ReportAshish ShandilNo ratings yet

- CF ProjectDocument40 pagesCF ProjectYatin DhallNo ratings yet

- Kirloskar Up Upl Uph UptDocument16 pagesKirloskar Up Upl Uph Uptedward baskaraNo ratings yet

- Organizational Study of Numaligarh Refinery LimitedDocument83 pagesOrganizational Study of Numaligarh Refinery LimitedAri HaranNo ratings yet

- Profile of Hi-Tech Arai Pvt LtdDocument12 pagesProfile of Hi-Tech Arai Pvt LtdThanga Raja100% (1)

- Apprenticeship Training Report on Ultratech Cement Provides InsightsDocument4 pagesApprenticeship Training Report on Ultratech Cement Provides Insightskirity ghoshNo ratings yet

- Project Report On Working Capital of JISLDocument41 pagesProject Report On Working Capital of JISLanon_241911849100% (2)

- KCP Corporate ProfileDocument47 pagesKCP Corporate ProfileHimanshu1712No ratings yet

- Project Report Vt20180960Document80 pagesProject Report Vt20180960BLOOMOTCH singhNo ratings yet

- PRJCT at TitaniumDocument95 pagesPRJCT at TitaniumGopi NathNo ratings yet

- Internship Report on Sowbaghya Enterprise Private LimitedDocument14 pagesInternship Report on Sowbaghya Enterprise Private Limitedsuren moorthyNo ratings yet

- Hindalco SWOT Analysis Highlights Strengths and OpportunitiesDocument1 pageHindalco SWOT Analysis Highlights Strengths and OpportunitiesAbhishek Mishra100% (1)

- A Study of Kerala Financial CorporationDocument5 pagesA Study of Kerala Financial Corporationvimalvijayan89No ratings yet

- Industrial Internship Report (4) F1111Document27 pagesIndustrial Internship Report (4) F1111Mainuddin M JamadarNo ratings yet

- Thapar GroupDocument30 pagesThapar GroupAlokJainNo ratings yet

- Marketing Strategy of Maruti Suzuki: A Summer Training Project Report ONDocument6 pagesMarketing Strategy of Maruti Suzuki: A Summer Training Project Report ONYOGENDRANo ratings yet

- Tata Steel - Company Analysis - 2015Document28 pagesTata Steel - Company Analysis - 2015Aditya ManchandaNo ratings yet

- 14wl - 17200 - 5 - de - en Rolling Bearings For Rolling Mill Applications PDFDocument69 pages14wl - 17200 - 5 - de - en Rolling Bearings For Rolling Mill Applications PDFDoomon OkerNo ratings yet

- Heritage Foods Limited: Summer Internship ReportDocument1 pageHeritage Foods Limited: Summer Internship ReportChavan AnithaNo ratings yet

- Triveni EggDocument321 pagesTriveni EggSahith MallampatiNo ratings yet

- Final ReportDocument23 pagesFinal ReportAbhishek S KNo ratings yet

- A STUDY ON CASH MANAGEMENT AT Plantation Corporation PDFDocument145 pagesA STUDY ON CASH MANAGEMENT AT Plantation Corporation PDFNikhil ShajiNo ratings yet

- Main ProjectDocument107 pagesMain ProjectMANJULANo ratings yet

- Financial Management I Report Hindalco Nalco Group-15Document12 pagesFinancial Management I Report Hindalco Nalco Group-15Madhusudan22No ratings yet

- Report on Industrial Training at BHEL HyderabadDocument74 pagesReport on Industrial Training at BHEL Hyderabadvijayk23060% (1)

- ME408 CombustionDocument34 pagesME408 CombustionbharathNo ratings yet

- ProjectDocument61 pagesProjectPritam Ghosh100% (1)

- Industrial Training Report On TubelightsDocument29 pagesIndustrial Training Report On TubelightsRabinsa Yadav100% (1)

- Fazil Project..Document53 pagesFazil Project..Shahdab Sagari100% (1)

- Big Bazaar and D Mart PDF FreeDocument82 pagesBig Bazaar and D Mart PDF FreeJay PawarNo ratings yet

- Pro S09 RenukaDocument65 pagesPro S09 RenukabhakteeNo ratings yet

- Project On Sai HondaDocument20 pagesProject On Sai Hondapradip_kumarNo ratings yet

- Sapm Tata SteelDocument40 pagesSapm Tata SteelShalya PriyaNo ratings yet

- S E C L WorkshopDocument58 pagesS E C L Workshoprakesh_7374204100% (2)

- Project Report - Bottle Cleaning MachineDocument24 pagesProject Report - Bottle Cleaning MachineChetan S100% (1)

- Ambuja Cement Ratio AnalysisDocument8 pagesAmbuja Cement Ratio AnalysisvikassinghnirwanNo ratings yet

- Amararaja Company Analysis NewDocument34 pagesAmararaja Company Analysis NewJaveed Gurramkonda100% (1)

- Krushik TML FINALDocument24 pagesKrushik TML FINALKrushik TailorNo ratings yet

- ONGC India - in Search For New Growth Strategy NewDocument16 pagesONGC India - in Search For New Growth Strategy NewshashankNo ratings yet

- A Project On Financial AnalysisDocument72 pagesA Project On Financial AnalysisAmar NathNo ratings yet

- 107840592056Document90 pages107840592056Manish Vadodariya100% (2)

- Main WhirlpoolDocument33 pagesMain WhirlpoolSatish PandeyNo ratings yet

- Balance Sheet and Financials of Grasim IndustriesDocument7 pagesBalance Sheet and Financials of Grasim IndustriesHiren KariyaNo ratings yet

- Optimize Coke Moisture with Quenching System UpgradeDocument96 pagesOptimize Coke Moisture with Quenching System UpgradeSushmit ChakrabortyNo ratings yet

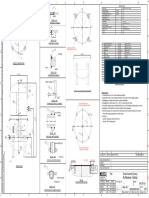

- GA DRG AIR RECEIVER 5m3 WPR 9.2 KG 100mm SR 500 CADocument1 pageGA DRG AIR RECEIVER 5m3 WPR 9.2 KG 100mm SR 500 CArmsh301No ratings yet

- M.SC - Chemistry - 2011Document18 pagesM.SC - Chemistry - 2011rmsh301No ratings yet

- M.SC - Chemistry - Booklet Code - A - 2013Document19 pagesM.SC - Chemistry - Booklet Code - A - 2013rmsh3010% (1)

- M.SC - Chemistry - 2012Document21 pagesM.SC - Chemistry - 2012rmsh301No ratings yet

- Product Guide ThermocouplesDocument296 pagesProduct Guide Thermocouplesrmsh301No ratings yet

- Fluid Mechanics and Hydraulic Machines Textbook Scanned PDFDocument287 pagesFluid Mechanics and Hydraulic Machines Textbook Scanned PDFPullavartisrikanthChowdaryNo ratings yet

- Annual Calendar 2018 EnglDocument1 pageAnnual Calendar 2018 EnglSaketNo ratings yet

- MSC - Chemistry - 2014Document20 pagesMSC - Chemistry - 2014rmsh301No ratings yet

- M.SC - Chemistry - 2016Document20 pagesM.SC - Chemistry - 2016rmsh301No ratings yet

- Booklet code C exam questionsDocument21 pagesBooklet code C exam questionsDebarati Das GuptaNo ratings yet

- Investment Planning - Tips To Reduce Your Tax BurdenDocument7 pagesInvestment Planning - Tips To Reduce Your Tax Burdenrmsh301No ratings yet

- Invoice Sample 5Document1 pageInvoice Sample 5Rammohanreddy RajidiNo ratings yet

- M.SC - Chemistry - 2015Document18 pagesM.SC - Chemistry - 2015rmsh301No ratings yet

- Principles of Management LECTURE NotesDocument32 pagesPrinciples of Management LECTURE NotesPrasant BistNo ratings yet

- Condenser Tube FFFFFFFFFFFFFFFFFFFFFFFFFDocument20 pagesCondenser Tube FFFFFFFFFFFFFFFFFFFFFFFFFAmal ChinthakaNo ratings yet

- Tips On Mold DesignDocument15 pagesTips On Mold DesignUmesh TakNo ratings yet

- Pipe SheduleDocument3 pagesPipe SheduleNiraj KumarNo ratings yet

- 1: Fluids, 1: FluidDocument5 pages1: Fluids, 1: Fluidrmsh301No ratings yet

- Pipe SheduleDocument3 pagesPipe SheduleNiraj KumarNo ratings yet

- Sinter Write UpDocument262 pagesSinter Write Uprmsh301No ratings yet

- Sinter Plant Single Toothed Roll Crusher PDFDocument14 pagesSinter Plant Single Toothed Roll Crusher PDFrmsh301No ratings yet

- Sinter Screen PDFDocument1 pageSinter Screen PDFrmsh301No ratings yet

- AppDocument37 pagesApprmsh301No ratings yet

- Structural EnglishDocument1 pageStructural Englishrmsh301No ratings yet

- Deepthi NairDocument17 pagesDeepthi Nairrmsh301No ratings yet

- Electrical Wire Hardness, CATIADocument28 pagesElectrical Wire Hardness, CATIArmsh301No ratings yet

- Field Instrumentation BrochureDocument8 pagesField Instrumentation Brochurermsh301No ratings yet

- 23 Blast Furnace Fault DiagnosticsDocument1 page23 Blast Furnace Fault Diagnosticsrmsh301No ratings yet

- Fatigue Consideration in DesignDocument9 pagesFatigue Consideration in DesignJitendra SoniNo ratings yet

- Whirling of ShaftsDocument4 pagesWhirling of ShaftsAshline DsouzaNo ratings yet

- Schultz Catalog 2015-EngDocument102 pagesSchultz Catalog 2015-EngCarlos Humberto Munar MonsalveNo ratings yet

- 14th Summer School in Tribology NewDocument2 pages14th Summer School in Tribology NewAjay KumarNo ratings yet

- BP Functionality S4 HANADocument17 pagesBP Functionality S4 HANASatyaki Singha100% (2)

- DNC MagazineDocument49 pagesDNC MagazineNizamudheen kNo ratings yet

- Dbatu MisDocument1 pageDbatu Misgamingaao75No ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- Wimax For DummiesDocument35 pagesWimax For DummiesMichael John MjattaNo ratings yet

- Fluidized Bed ReactorDocument10 pagesFluidized Bed ReactorDurgesh BondeNo ratings yet

- JSS - Reshaping Data with the reshape PackageDocument20 pagesJSS - Reshaping Data with the reshape PackagewhyawhaNo ratings yet

- Philips 32pfl2508 f8Document118 pagesPhilips 32pfl2508 f8Victor Hugo PiedrahitaNo ratings yet

- Astm B344-01Document3 pagesAstm B344-01Srinivasan KrishnamoorthyNo ratings yet

- Trantech BrochureDocument4 pagesTrantech BrochureOmar Reinoso TigreNo ratings yet

- Structural Response of Soft Story High R PDFDocument12 pagesStructural Response of Soft Story High R PDFBaterdene BaachkaNo ratings yet

- Memory OrganisationDocument34 pagesMemory OrganisationricketbusNo ratings yet

- Multi-degree vibration analysisDocument7 pagesMulti-degree vibration analysisJose Da SilvaNo ratings yet

- Europass CV Aristeidis TsialosDocument3 pagesEuropass CV Aristeidis Tsialoso_pythagoriosNo ratings yet

- Presented by Intramantra Global Solution PVT LTD, IndoreDocument14 pagesPresented by Intramantra Global Solution PVT LTD, IndoreDeepak RathoreNo ratings yet

- 18 F 1320Document308 pages18 F 1320Manolis DespotakisNo ratings yet

- 3 28 19 NtapDocument199 pages3 28 19 Ntapfikri fikriNo ratings yet

- Communications201509 DLDocument132 pagesCommunications201509 DLleecomNo ratings yet

- Safety Swivel Lifting Eye Bolts Load CapacitiesDocument1 pageSafety Swivel Lifting Eye Bolts Load CapacitiesRaul G. MartinezNo ratings yet

- Positive Displacement PumpsDocument48 pagesPositive Displacement PumpsSteve Carwell100% (5)

- Risk Assesment Form UpdateDocument7 pagesRisk Assesment Form Updatefmebirim100% (1)

- 4unsafe Unhealthy Act Conditions PDFDocument41 pages4unsafe Unhealthy Act Conditions PDFej constantino100% (1)

- Effectof Cyclic Loadingsonthe Shear StrengthandDocument14 pagesEffectof Cyclic Loadingsonthe Shear StrengthandAbel MulugetaNo ratings yet

- Dam Break AnalysisDocument18 pagesDam Break AnalysisBushra UmerNo ratings yet

- Idp OracleDocument15 pagesIdp OracleKiran Kumar PeteruNo ratings yet

- Karcher Operation ManualDocument60 pagesKarcher Operation ManualDadi SucahyonoNo ratings yet

- JCM 452 Stainless Tapping SleeveDocument3 pagesJCM 452 Stainless Tapping SleeveNgô Mạnh TiếnNo ratings yet