Professional Documents

Culture Documents

ISO 3834 & EN 15085 Welding Standards Guide

Uploaded by

0502ravi0 ratings0% found this document useful (0 votes)

2K views10 pagesISO 3834 establishes quality requirements for welding based on the consequences of weld failure. Part 1 provides an overview. Part 2 defines comprehensive quality requirements for constructions where weld failure could lead to total product failure or major injury. Part 3 defines standard quality requirements where failure would impair intended use but poses normal safety risks. Part 4 defines elementary quality requirements where failure would not fundamentally impair use or safety, with minor financial consequences.

EN 15085 is a series of standards for welding railway vehicles. Part 1 provides an overview and scope. Part 2 defines certification and quality requirements for welding manufacturers. Part 3 establishes weld performance classes based on safety and stress factors. Part 4 specifies inspection, testing and qualifications based on performance classes. Part

Original Description:

Original Title

ISO 3834 Part-1 to 4

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentISO 3834 establishes quality requirements for welding based on the consequences of weld failure. Part 1 provides an overview. Part 2 defines comprehensive quality requirements for constructions where weld failure could lead to total product failure or major injury. Part 3 defines standard quality requirements where failure would impair intended use but poses normal safety risks. Part 4 defines elementary quality requirements where failure would not fundamentally impair use or safety, with minor financial consequences.

EN 15085 is a series of standards for welding railway vehicles. Part 1 provides an overview and scope. Part 2 defines certification and quality requirements for welding manufacturers. Part 3 establishes weld performance classes based on safety and stress factors. Part 4 specifies inspection, testing and qualifications based on performance classes. Part

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views10 pagesISO 3834 & EN 15085 Welding Standards Guide

Uploaded by

0502raviISO 3834 establishes quality requirements for welding based on the consequences of weld failure. Part 1 provides an overview. Part 2 defines comprehensive quality requirements for constructions where weld failure could lead to total product failure or major injury. Part 3 defines standard quality requirements where failure would impair intended use but poses normal safety risks. Part 4 defines elementary quality requirements where failure would not fundamentally impair use or safety, with minor financial consequences.

EN 15085 is a series of standards for welding railway vehicles. Part 1 provides an overview and scope. Part 2 defines certification and quality requirements for welding manufacturers. Part 3 establishes weld performance classes based on safety and stress factors. Part 4 specifies inspection, testing and qualifications based on performance classes. Part

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 10

ISO 3834 part-1 to 4

ISO 3834-1-General requirements

ISO 3834-2- Comprehensive quality

requirement

ISO 3834-3- Standard quality requirement

ISO 3834-4 -elementary quality requirement

ISO 3834-2- Comprehensive quality

requirement

Constructions in which the failure of welds may

lead to

total product failure

with significant financial consequences

Major injury.

The product may be subject to dynamic

loading

In addition to high static loading.

ISO 3834-3- Standard quality

requirement

Constructions in which failure of welds

impair the intended use of construction.

Normal safety risk

Financial losses not extreme.

ISO 3834-4 elementary quality

requirement

Constructions in which failure of welds

Not fundamentally impair the intended use.

No adverse effects on safety of people

Minor financial consequences.

EN 15085

Railway applications Welding of

railway vehicles and components

Part 1: General

Part 2: Quality requirements and certification

of welding manufacturer

Part 3: Design requirements

Part 4: Production requirements

Part 5: Inspection, testing and documentation

EN 15085 Part 1: General

EN 15085 Part 1 provides an overview and

scope of the 15085 series of standards and

how it applies to the welding of metallic

materials in the manufacture and

maintenance of railway vehicles and their

parts.

EN 15085 Part 2: Quality requirements and

certification of welding manufacturer

EN 15085 Part 2 of the standard defines the

certification and quality requirements for the

welding manufacturer to undertake for new

fabrication and repair work.

It then provides an essential link

between performance requirements defined

during design to achieve the appropriate

quality welds during production and the

demonstration of the required quality by

inspection

EN 15085 Part 3: Design requirements

EN 15085 Part 3 defines weld performance

class during design, which is based on safety

and stress factors relevant to railway

operation.

Quality levels of imperfections are assigned to

weld performance classes to ensure a certain

level of performance intended during design

EN 15085 Part 4: Production

requirements

Based on the weld performance classes,

certification levels for production, as well as

inspection and testing and qualifications for

welding personnel of the manufacturer are

specified.

EN 15085 Part 5: Inspection, testing and

documentation

This standard deals with inspections and

testing to be executed on the welds,

destructive as well as non-destructive tests to

be performed and necessary documentation

to issue to declare the conformity of the

products.

The EN 15085 series of standards does not

deal with product qualification

You might also like

- Assignment On Diesel Engine OverhaulingDocument19 pagesAssignment On Diesel Engine OverhaulingRuwan Susantha100% (3)

- GREAnalyticalWritingSupreme 2024 SAMPLEDocument38 pagesGREAnalyticalWritingSupreme 2024 SAMPLEVibrant PublishersNo ratings yet

- ISO 3834-1 Quality RequirenmentsDocument15 pagesISO 3834-1 Quality RequirenmentszstNo ratings yet

- Con Men ScamsDocument14 pagesCon Men ScamsTee R TaylorNo ratings yet

- ISO 3834 - Checklist-2Document6 pagesISO 3834 - Checklist-2Abhishek Anand80% (5)

- Welding procedure specification guideDocument3 pagesWelding procedure specification guideAnilNo ratings yet

- English (Step Ahead)Document33 pagesEnglish (Step Ahead)ry4nek4100% (1)

- Requirements ISO 3834Document76 pagesRequirements ISO 3834mdasifkhan2013100% (7)

- Iso 3834-4 - 2005Document8 pagesIso 3834-4 - 2005Necdet AydemirNo ratings yet

- ISO Standards On WeldingDocument22 pagesISO Standards On Weldingmoxshyde100% (1)

- TOPIC 1 - Public Speaking SkillsDocument72 pagesTOPIC 1 - Public Speaking SkillsAyan AkupNo ratings yet

- Stainless Steel DefectsDocument30 pagesStainless Steel Defects0502ravi100% (1)

- VT-2 Codes and StandardsDocument29 pagesVT-2 Codes and StandardsMirza Safeer Ahmad100% (1)

- QC Manual ISO 3834 - 2 QM-02 FinalDocument34 pagesQC Manual ISO 3834 - 2 QM-02 Finalavinash198776% (17)

- E1648-01 Aluminum Fusion WeldsDocument3 pagesE1648-01 Aluminum Fusion Welds0502raviNo ratings yet

- En 15085 Design ModuleDocument89 pagesEn 15085 Design Module0502ravi100% (1)

- Welding Defect PhotoDocument14 pagesWelding Defect Photo0502raviNo ratings yet

- ISO 3834 by SelvaDocument83 pagesISO 3834 by Selvaaravindan100% (11)

- Ss WeldingDocument12 pagesSs Welding0502ravi100% (1)

- Lloyd S Register Weld Certification GuideDocument21 pagesLloyd S Register Weld Certification GuideFaiz BokhadiNo ratings yet

- En 15085 ClassDocument63 pagesEn 15085 Class0502ravi100% (3)

- EN 15085 Part 5 - GaneshDocument36 pagesEN 15085 Part 5 - GaneshNiranjan Rajavel TigerNo ratings yet

- Iso 3834Document11 pagesIso 38340502ravi100% (1)

- Iso 3834Document11 pagesIso 38340502ravi100% (1)

- Advanced welding techniques for joining metalsDocument11 pagesAdvanced welding techniques for joining metals0502ravi100% (1)

- WELDABILITY of SteelDocument41 pagesWELDABILITY of Steel0502ravi100% (1)

- WELDABILITY of SteelDocument41 pagesWELDABILITY of Steel0502ravi100% (1)

- WELDABILITY of SteelDocument41 pagesWELDABILITY of Steel0502ravi100% (1)

- Welding Coordination Activities and ResponsibilitiesDocument7 pagesWelding Coordination Activities and ResponsibilitieseliiiiiiNo ratings yet

- Quality Requirements - Fusion Welding of Metalic MaterialDocument8 pagesQuality Requirements - Fusion Welding of Metalic MaterialStatus whatsapp status100% (2)

- Welding Coordinator Tasks and ResponsibilitiesDocument3 pagesWelding Coordinator Tasks and ResponsibilitiesShaun Holder100% (4)

- Part 01 - Review of EN ISO 9606-1Document26 pagesPart 01 - Review of EN ISO 9606-1Turbo Snail RNo ratings yet

- En 15085 - 1 & 2Document34 pagesEn 15085 - 1 & 20502ravi100% (4)

- ISO 3834-2 Compliance Check ListDocument1 pageISO 3834-2 Compliance Check ListMichael Tayactac100% (1)

- GDPR in ChartsDocument13 pagesGDPR in ChartsImageking0% (2)

- Ablutophobia Fear of Bathing and HomoeopathyDocument8 pagesAblutophobia Fear of Bathing and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (1)

- Arbitration AgreementsDocument20 pagesArbitration Agreementsmohd suhail siddiqui100% (2)

- 9 ISO 15608 Grouping of MaterialsDocument14 pages9 ISO 15608 Grouping of MaterialsTuTuy An100% (1)

- Introduction to ISO 3834Document54 pagesIntroduction to ISO 3834amit50% (2)

- ISO 9692-3-2002 Joint PreparationDocument16 pagesISO 9692-3-2002 Joint PreparationtndeshmukhNo ratings yet

- Reflective Paper Assignment 2 Professional Practice Level 2Document3 pagesReflective Paper Assignment 2 Professional Practice Level 2api-350779667No ratings yet

- 6 Iso 03834-5-2021Document12 pages6 Iso 03834-5-2021bmqr100% (1)

- ISO 3834-5 Ver EDocument10 pagesISO 3834-5 Ver ETrung Nguyễn100% (4)

- EN 1011 welding standards for stainless steelDocument25 pagesEN 1011 welding standards for stainless steel0502ravi100% (1)

- ISO 3834 Welding Certification GuideDocument11 pagesISO 3834 Welding Certification GuideWeld Bro Sandeep100% (1)

- Iso 3834-5 - 2015Document14 pagesIso 3834-5 - 2015raghulramasamy100% (1)

- Iso 3834 2 2021Document10 pagesIso 3834 2 2021Tuan Pham Anh50% (2)

- Bs en 12072 PDFDocument12 pagesBs en 12072 PDFdzat_sudrazatNo ratings yet

- BS en 439 94 PDFDocument12 pagesBS en 439 94 PDFDario RamljakNo ratings yet

- Quest Audit 3834Document38 pagesQuest Audit 3834g33k59100% (2)

- Terms in Welding Standard en 15085Document6 pagesTerms in Welding Standard en 150850502raviNo ratings yet

- Heat TreatmentDocument29 pagesHeat TreatmentarunradNo ratings yet

- Need of ISO 3834 To Welding Fabrication IndustryDocument4 pagesNeed of ISO 3834 To Welding Fabrication IndustrySatish Keskar100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- Precode Hollywood Movies and The Case of Busby BerkeleyDocument14 pagesPrecode Hollywood Movies and The Case of Busby Berkeleystessy92No ratings yet

- Welding DefectsDocument47 pagesWelding Defects0502raviNo ratings yet

- Bs en Iso 15614 12 2014pdf PDFDocument20 pagesBs en Iso 15614 12 2014pdf PDFVasile TomsaNo ratings yet

- En 15085Document6 pagesEn 150850502ravi0% (1)

- EN15085 IntroductionDocument89 pagesEN15085 IntroductionSubramanian R33% (3)

- ISO 3834 welding certification levelsDocument9 pagesISO 3834 welding certification levelsvilukNo ratings yet

- Implement ISO 3834 welding standardsDocument34 pagesImplement ISO 3834 welding standardschowhkNo ratings yet

- Iso 3834Document52 pagesIso 3834Akshay Kumar100% (1)

- LL - Farsi IntroductionDocument13 pagesLL - Farsi IntroductionPiano Aquieu100% (1)

- BS en Iso 3834-5 2015Document18 pagesBS en Iso 3834-5 2015dan100% (2)

- Certification Guideline for Welding Manufacturers of Railway VehiclesDocument50 pagesCertification Guideline for Welding Manufacturers of Railway Vehiclesrameshqc100% (1)

- I S Eniso3834-2-2021Document28 pagesI S Eniso3834-2-2021Ngoc Bang67% (3)

- ISO 3834 Evaluation TestDocument2 pagesISO 3834 Evaluation TestSatish KeskarNo ratings yet

- DIN 6700-2 Standard for Welding of Rail VehiclesDocument27 pagesDIN 6700-2 Standard for Welding of Rail Vehicles0502ravi100% (1)

- DVS 1619Document50 pagesDVS 1619Tamási BélaNo ratings yet

- Railway Vehicle Welding inspectionEN 15085-5Document16 pagesRailway Vehicle Welding inspectionEN 15085-50502raviNo ratings yet

- Repair Dvs Supplement PDFDocument6 pagesRepair Dvs Supplement PDFGnana MoorthyNo ratings yet

- ISO 3834 IntroDocument84 pagesISO 3834 IntroUjjawal AgrawalNo ratings yet

- Iso 3834-5 2005Document14 pagesIso 3834-5 2005HARISH KUMAR B MEKINSNo ratings yet

- BS en Iso 3834-3 - 2021Document16 pagesBS en Iso 3834-3 - 2021jesonelite100% (2)

- O The Beat 1 - TBDocument164 pagesO The Beat 1 - TBJulliana SantosNo ratings yet

- ISO 3834 InterpretationDocument14 pagesISO 3834 InterpretationMako SkyNo ratings yet

- Control Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFDocument11 pagesControl Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFNenad NedeljkovicNo ratings yet

- En 15085Document3 pagesEn 15085ShowanHydraulics60% (5)

- Railway Welding Standards EN 15085 OverviewDocument6 pagesRailway Welding Standards EN 15085 Overview0502raviNo ratings yet

- Iso 3834 GuidelinesDocument3 pagesIso 3834 Guidelinesshabashakkim0% (1)

- ISO 3834-Part-1-To-4Document10 pagesISO 3834-Part-1-To-4ken silkNo ratings yet

- 1 CE Marking in A Brexit WorldDocument65 pages1 CE Marking in A Brexit WorldScott TrainorNo ratings yet

- Iso 3834aDocument8 pagesIso 3834aCentre For Total Quality ManagementNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Icf-Pioneering in A Changing Economic EnvironmentDocument18 pagesIcf-Pioneering in A Changing Economic Environment0502raviNo ratings yet

- CANFAN Airzon BLDC Super Efficient Fans - ICF PeramburDocument13 pagesCANFAN Airzon BLDC Super Efficient Fans - ICF Perambur0502raviNo ratings yet

- Welding VisualDocument25 pagesWelding Visual0502ravi100% (1)

- 7310 - 1 - 1974Document12 pages7310 - 1 - 19740502raviNo ratings yet

- Weld DefectsDocument6 pagesWeld Defects0502raviNo ratings yet

- Is-16003-2012-Specification and Qualification of WeldingDocument23 pagesIs-16003-2012-Specification and Qualification of WeldingvijaykumarnNo ratings yet

- To CNC Machines & RobotsDocument29 pagesTo CNC Machines & Robots0502raviNo ratings yet

- GR ExercisesDocument10 pagesGR Exercises0502raviNo ratings yet

- I So AwarenessDocument32 pagesI So Awareness0502raviNo ratings yet

- Time StudyDocument28 pagesTime Study0502raviNo ratings yet

- Fmea 1Document22 pagesFmea 10502raviNo ratings yet

- Wps 15614 TemplateDocument2 pagesWps 15614 Template0502raviNo ratings yet

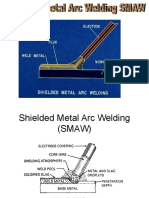

- SmawDocument11 pagesSmaw0502raviNo ratings yet

- Welding ConsumablesDocument31 pagesWelding Consumables0502raviNo ratings yet

- Welding ElectrodesDocument19 pagesWelding ElectrodesVijayan MunuswamyNo ratings yet

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- Welding of Stainless SteelsDocument11 pagesWelding of Stainless Steels0502raviNo ratings yet

- Irish Blessings and PrayersDocument17 pagesIrish Blessings and PrayersvivesurNo ratings yet

- Ziarat e NahiyaDocument48 pagesZiarat e Nahiyazaighama_1100% (7)

- MKTG10001Document38 pagesMKTG10001Jessica KokNo ratings yet

- Parle Sales DistributionDocument21 pagesParle Sales Distributionkakki1088No ratings yet

- A Legacy of Female Autonomy During The Crusades: Queen Melisende of Jerusalem by Danielle MikaelianDocument25 pagesA Legacy of Female Autonomy During The Crusades: Queen Melisende of Jerusalem by Danielle MikaelianDanielle MikaelianNo ratings yet

- Depository Receipts: Presented By-Vikash Sharma (51) Ruchi BangaDocument12 pagesDepository Receipts: Presented By-Vikash Sharma (51) Ruchi Bangasuraj kumar0% (1)

- Sidak 2008 FAQsDocument3 pagesSidak 2008 FAQssikhswimNo ratings yet

- Agganna Sutta - Theory of KingshipDocument8 pagesAgganna Sutta - Theory of KingshipTanya ChopraNo ratings yet

- Confidential: Turn in Exam Question PaperDocument20 pagesConfidential: Turn in Exam Question PaperRifat ManzoorNo ratings yet

- Initial Evaluation in The 11th Form B1 LevelDocument2 pagesInitial Evaluation in The 11th Form B1 LevelDumitru GruscaNo ratings yet

- MERLINDA CIPRIANO MONTAÑES v. LOURDES TAJOLOSA CIPRIANODocument1 pageMERLINDA CIPRIANO MONTAÑES v. LOURDES TAJOLOSA CIPRIANOKaiserNo ratings yet

- MC Data Dig Graphic Organizer 1Document5 pagesMC Data Dig Graphic Organizer 1api-461486414No ratings yet

- Low Advanced Analogies 4Document2 pagesLow Advanced Analogies 4marc leacockNo ratings yet

- French demonstrative pronouns guideDocument8 pagesFrench demonstrative pronouns guidedfñoiiuglkjs.No ratings yet

- 일반동사 부정문 PDFDocument5 pages일반동사 부정문 PDF엄태호No ratings yet

- Present Tense Review for Motorcycle RepairDocument2 pagesPresent Tense Review for Motorcycle RepairFaheemuddin Veterans50% (2)

- A History Analysis and Performance Guide To Samuel Barber?Document117 pagesA History Analysis and Performance Guide To Samuel Barber?giorgio planesioNo ratings yet

- Advocacy Plan Final Edec 435Document11 pagesAdvocacy Plan Final Edec 435api-375034422No ratings yet