Professional Documents

Culture Documents

Compressor Air

Uploaded by

Ahemad0 ratings0% found this document useful (0 votes)

43 views7 pagesOriginal Title

Compressor air.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views7 pagesCompressor Air

Uploaded by

AhemadCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 7

Compressor air necessary

during all situations whether it is

• Project activities

• Commissioning activities

• Normal operation of plant

• Overhaul & general operation of plant.

Instrument air used for most of the instruments,

valves & electrical breakers on-off operation.

Service air is used to operate many pneumatic

equipments, air operated hand tools and for other

general purpose.

classification

Dynamic type Positive displacement

Radial flow centrifugal Reciprocating

Rotory

Axial flow compressor

Mix flow compressor

1/2mv2 kinetic energy is

converted into pressure energy

• One can say that IA & SA system is life line of

power station like AC/DC electric supply

system. Non availability of air supply may lead

to shutting down of unit.

• In most of the power plant generally

1. Single or multi cylinder

2. Multistage, double acting

3. Vertical or balanced opposed reciprocating

compressors are used.

• Piston execute reciprocating motion.

• Head which contain valves.

• Piston rings are for sealing the piston.

• Piston is connected to the driving mechanism.

Following important elements are common

• Main compressor system. (Cylinder, head, air

valves & piston.)

• Driving unit.

• Cooling system. (Jacket cooling, Inter cooler, after

cooler.)

• Lubricating system.

• Regulating system

• Unloading system.

• Air dryers.

• Assuming clearance and leakage to be absent total

work done on reciprocating compressor is given

by

• W=S P2

P1 vdp

• = (r/r-1)P1V1[(P2/P1)r-1/r-1

• R = ratio of specific heats

• Ideal intercooler pressure p2 for two stage poly

tropic compression operating between pressure p1

& p3 is given by, p2 = ( p1.p3)1/2

• Volumetric efficiency of compressor considering

the clearance. =1-Vc/Vs[(p2/p1)1/n-1]

• Preventive Maintenance

• Weekly- Checking oil, Cleaning air filter.

• Monthly- Checking abnormalites and attending.

• Quarterly- Removing all SVs & DVs checking &

replacing damaged plates / parts. Replacing oil

(Enklo-150/Barat cobol-150/servo press-150) as a

general rule, the supply of lube oil to each cylinder

is arround 2-3 drops per minits.

• If knocking sound observed near the head, it is due

to less clearance betwn head & piston.

• If SVs or DVs valve plate broken, increase of vave

body temperature observe.

• If air leakage or vibration near valve cover

observed, it may cause due to damage of “O” ring

• Assem. Max

Allo.

• Diametrical clearance of the shaft main bearing 0.08-0.15 0.3

• Diametrical clearance of the connecting rod big end brg. 0.07-0.13 0.3

• Diametrical clearance of the connecting rod small end bush 0.05-0.10 0.2

• Diametrical clearance betwn cross head guide & cross head 0.18-0.26 0.6

• Side clearance of crank shaft 0.45-0.60 0.9

• Side clearance of connecting rod big end. 0.33-0.42 0.6

• End clearance piston ring per 100 mm dia. 0.3

1.0

• Diametrical clearance of betwn piston & comp. Cylinder. 0.1 0.4

• (CI piston / Aluminum piston per 100 mm)

• Piston end clearance free end. 2 mm min.

• Piston end clearance crank end 1.5 mm min.

• Tightening torque

1. Connecting rod big end bolt. ------------------ 25 mkgs

2. Main bearing stud nut ------------------- 17 mkgs

3. Blocking nut of piston rod -------------------- 25 mkgs

4. Piston rod crosshead nut ----------------------- 25 mkgs

You might also like

- Champion 700 Series Motor Grader Series I Operators Manual Revision 1 8-24-1977 PDFDocument54 pagesChampion 700 Series Motor Grader Series I Operators Manual Revision 1 8-24-1977 PDFjulianmata77% (13)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- DAVR Training ManualDocument66 pagesDAVR Training ManualAhemad100% (1)

- SMC Pneumatic HandbookDocument34 pagesSMC Pneumatic HandbookkusumodhipuroNo ratings yet

- Basic Compressor KnowledgeDocument87 pagesBasic Compressor Knowledgelrpatra100% (1)

- SM F4GE-IVECO-Telehandler EN PDFDocument117 pagesSM F4GE-IVECO-Telehandler EN PDFjulianmata71% (7)

- Eg en YlcsDocument52 pagesEg en YlcsItalo LeivaNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Hanbell Service ManualDocument80 pagesHanbell Service ManualStephen Marcus100% (2)

- 08-Force Feed Lubrication SystemDocument29 pages08-Force Feed Lubrication SystemAdrian Ropero0% (1)

- 220 KV AIS - TSDocument34 pages220 KV AIS - TSBilal AhmadNo ratings yet

- Install and Maintain Air CompressorsDocument62 pagesInstall and Maintain Air Compressorsasaturday850% (1)

- Centrifugal Compressor GuideDocument40 pagesCentrifugal Compressor Guideprabhjotbhangal67% (3)

- Introduction To The Oil Field (Drilling)Document37 pagesIntroduction To The Oil Field (Drilling)Ahmed SelmyNo ratings yet

- ValvesDocument135 pagesValvesShivang Gaur100% (4)

- Installation - Operation - Maintenance - Instructions - 30 HXC PDFDocument36 pagesInstallation - Operation - Maintenance - Instructions - 30 HXC PDFNurmansyah Dwi Cahyono100% (3)

- Air Pre HeaterDocument0 pagesAir Pre HeaterkablikhogeNo ratings yet

- Turbine Protection & EmergenciesDocument28 pagesTurbine Protection & EmergenciesAmit Chauhan96% (23)

- Multipoint Socket Profile VW 010 43: KonzernnormDocument4 pagesMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- BlowerDocument60 pagesBlowergovardhan100% (5)

- 7 Strategies For Developing Your Own Curriculum As A New TeacherDocument5 pages7 Strategies For Developing Your Own Curriculum As A New TeacherKhusnul KhotimahNo ratings yet

- Cold Start Up Procedure: - NTPC, SimhadriDocument29 pagesCold Start Up Procedure: - NTPC, SimhadriAhemadNo ratings yet

- Chilled Water System FundamentalsDocument14 pagesChilled Water System Fundamentalsjohnnybe51No ratings yet

- Circuit BreakerDocument64 pagesCircuit BreakerAshwani Dogra100% (1)

- PIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesDocument21 pagesPIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesAdil KhawajaNo ratings yet

- Media Planning BasicDocument142 pagesMedia Planning BasicHanif Lakdawala100% (1)

- Sizing and Selection of Actuators For Valves: Nidhin ManoharDocument62 pagesSizing and Selection of Actuators For Valves: Nidhin Manoharsaiful anwarNo ratings yet

- Feed Heater Performance PDFDocument32 pagesFeed Heater Performance PDFsukdev_22No ratings yet

- Relief Valves - NCCDocument26 pagesRelief Valves - NCCNour HNo ratings yet

- Optimize Reciprocating Compressor Control and MonitoringDocument2 pagesOptimize Reciprocating Compressor Control and MonitoringPedro DiazNo ratings yet

- Valves Instumentation and ControlDocument43 pagesValves Instumentation and Controlomkar khaladeNo ratings yet

- Manual de Partes Gen Set DQFADDocument272 pagesManual de Partes Gen Set DQFADJorge Calcaneo MartinezNo ratings yet

- Valve Actuator Torque CurvesDocument4 pagesValve Actuator Torque CurvesyogitatanavadeNo ratings yet

- AccuSpin Micro R 120 VDocument49 pagesAccuSpin Micro R 120 VAndrew HolmesNo ratings yet

- Air PreheaterDocument31 pagesAir PreheaterAkashKishoreNo ratings yet

- 1989 Volvo 740 Instruments and ControlsDocument107 pages1989 Volvo 740 Instruments and Controlsskyliner538No ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Pneumatic Reciprocating Powere Hacksaw Machine - Docx FinalDocument11 pagesPneumatic Reciprocating Powere Hacksaw Machine - Docx FinalARVIND DARLING100% (2)

- EHV Circuit Breaker GuideDocument40 pagesEHV Circuit Breaker Guidesandy02477No ratings yet

- 12V at 27 GLDocument4 pages12V at 27 GLMadhana GopalNo ratings yet

- Pneumatic Paper Cutting Machine CountingDocument23 pagesPneumatic Paper Cutting Machine CountingManish Shetty100% (2)

- Manual 5Document44 pagesManual 5trillas4910No ratings yet

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDocument6 pagesAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNo ratings yet

- Training Report CompressoreDocument6 pagesTraining Report CompressoreEr Raghvendra SinghNo ratings yet

- Operation Manual: Q250 Pneumatic Spinning WrenchDocument12 pagesOperation Manual: Q250 Pneumatic Spinning Wrenchmehdi HKNo ratings yet

- End Equipment Power Generation GuideDocument15 pagesEnd Equipment Power Generation Guidekumarmm1234No ratings yet

- Pneumatic Shearing MachineDocument23 pagesPneumatic Shearing MachineMani AlugoluNo ratings yet

- Qns AnsDocument37 pagesQns AnsSantosh ReddyNo ratings yet

- Gas Turbine Compressor TypesDocument36 pagesGas Turbine Compressor TypesMUHOOZI DENISNo ratings yet

- Design and Fabrication of m10 Hexagonal Nut DeburringDocument24 pagesDesign and Fabrication of m10 Hexagonal Nut DeburringGobz Christo EliezerNo ratings yet

- Pneumatic Hacksaw Machine DesignDocument10 pagesPneumatic Hacksaw Machine DesignAnoop KoshyNo ratings yet

- Bimba Air Preparation CatalogDocument48 pagesBimba Air Preparation Catalogcadillac472No ratings yet

- AEC3101 Compressors & Turbines: Dr.P.N.Kadiresh Professor/Aerospace EngineeringDocument75 pagesAEC3101 Compressors & Turbines: Dr.P.N.Kadiresh Professor/Aerospace EngineeringPraveen SundararajanNo ratings yet

- KGE1000Ti Service ManualDocument41 pagesKGE1000Ti Service Manualmarksmods100% (1)

- Turbine Control SystemDocument9 pagesTurbine Control SystemAshutosh KumarNo ratings yet

- .Para NeumáticaDocument28 pages.Para NeumáticaWilliam RomeroNo ratings yet

- 12 MARINE Air CompressorDocument13 pages12 MARINE Air CompressorTuhin HandaNo ratings yet

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoNo ratings yet

- Pruebas Yu AjustesDocument15 pagesPruebas Yu AjustesFbrzo Di GvargasNo ratings yet

- 05-Force Feed Lubrication SystemDocument34 pages05-Force Feed Lubrication SystemBookMaggotNo ratings yet

- Worcester Controls ActuatorDocument16 pagesWorcester Controls ActuatorEnrico GambiniNo ratings yet

- Workshop Small NewDocument36 pagesWorkshop Small Newesteban marinkovicNo ratings yet

- MAM I Revision Class PDFDocument19 pagesMAM I Revision Class PDFMalik ForbesNo ratings yet

- BoilerDocument18 pagesBoilerAnuj DubeyNo ratings yet

- Valve Stem ProjectionDocument2 pagesValve Stem Projectionjose luis rattiaNo ratings yet

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNo ratings yet

- The Operation ManualDocument29 pagesThe Operation ManualAdhiartha PrihanantoNo ratings yet

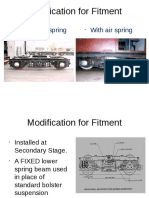

- Modification For Fitment: With Steel Spring With Air SpringDocument33 pagesModification For Fitment: With Steel Spring With Air Springiso9002No ratings yet

- CGAT Catalog0303Document2 pagesCGAT Catalog0303Chinith HengNo ratings yet

- Flowserve Actuator SizingDocument16 pagesFlowserve Actuator SizingalexmontellNo ratings yet

- P341 EN TD E33a PDFDocument62 pagesP341 EN TD E33a PDFAhemadNo ratings yet

- SINEAX VC 603, Programmable Combined Transmitter/alarm UnitDocument18 pagesSINEAX VC 603, Programmable Combined Transmitter/alarm UnitAhemadNo ratings yet

- Schematic Line Diagram of Ash Water Supply To Unit-1 To Unit-7 PDFDocument1 pageSchematic Line Diagram of Ash Water Supply To Unit-1 To Unit-7 PDFAhemadNo ratings yet

- P891 Technical ManualDocument9 pagesP891 Technical ManualAhemadNo ratings yet

- An Introduction To Controls For Steam Power Plants: Course No: D02-003 Credit: 2 PDHDocument30 pagesAn Introduction To Controls For Steam Power Plants: Course No: D02-003 Credit: 2 PDHMKE3 HEROESNo ratings yet

- Delhi Feeder All ParameterDocument16 pagesDelhi Feeder All ParameterAhemadNo ratings yet

- MBA YCNOU Project Guidlelines 2015-2016Document21 pagesMBA YCNOU Project Guidlelines 2015-2016HexaNotesNo ratings yet

- BioData PDFDocument2 pagesBioData PDFAhemadNo ratings yet

- 10 Chapter 2Document10 pages10 Chapter 2AhemadNo ratings yet

- FC360 Programming Guide MG06C202Document110 pagesFC360 Programming Guide MG06C202AhemadNo ratings yet

- ASCO Solenoid Engineering SpecsDocument26 pagesASCO Solenoid Engineering SpecsviruspoolNo ratings yet

- Micom-P13x en Brochure PDFDocument8 pagesMicom-P13x en Brochure PDFAhemadNo ratings yet

- Module 3: Programmable Logic Devices (PLDS) Introduction To Micro-Processors and Micro-ControllersDocument36 pagesModule 3: Programmable Logic Devices (PLDS) Introduction To Micro-Processors and Micro-ControllersDhanish KumarNo ratings yet

- 53C9EBF806C20CF8AE387D5CA3369D2EDocument12 pages53C9EBF806C20CF8AE387D5CA3369D2EAhemadNo ratings yet

- Det Civil Direct Select List PDFDocument1 pageDet Civil Direct Select List PDFAhemadNo ratings yet

- Servo Valves TechnicalDocument24 pagesServo Valves Technicalobvert100% (2)

- Centre Accreditation & Affiliation Guidelines Version 1.0Document15 pagesCentre Accreditation & Affiliation Guidelines Version 1.0Saravanakumar NNo ratings yet

- Chart of Accounts for Electricity SalesDocument406 pagesChart of Accounts for Electricity SalesAhemadNo ratings yet

- IBPS Diploma Engineer Trainee Final Selection ListDocument1 pageIBPS Diploma Engineer Trainee Final Selection ListAhemadNo ratings yet

- Open - Workflow For Vendor Registartion PDFDocument1 pageOpen - Workflow For Vendor Registartion PDFAhemadNo ratings yet

- Ijaerv13n5 29Document28 pagesIjaerv13n5 29AhemadNo ratings yet

- Sbi Final Jan 2020 - CMP00000000209399653 PDFDocument1 pageSbi Final Jan 2020 - CMP00000000209399653 PDFAhemadNo ratings yet

- Det Civil Direct Wait ListDocument1 pageDet Civil Direct Wait ListAhemadNo ratings yet

- Table of ContentsDocument1 pageTable of ContentsAhemadNo ratings yet

- DET DIST INTERNAL Select ListDocument3 pagesDET DIST INTERNAL Select ListAhemadNo ratings yet

- 1102112Document8 pages1102112AhemadNo ratings yet

- Civil & Environmental Engineering Lab Consolidation TestDocument14 pagesCivil & Environmental Engineering Lab Consolidation TestSapria AdiNo ratings yet

- Side Wall SprinklerDocument6 pagesSide Wall SprinklerLasandu WanniarachchiNo ratings yet

- Definitions of CEC2017 Benchmark Suite Final Version UpdatedDocument34 pagesDefinitions of CEC2017 Benchmark Suite Final Version Updatedpc100% (1)

- Manual em Portugues DGX230Document120 pagesManual em Portugues DGX230Agosthis0% (1)

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDocument6 pagesMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaNo ratings yet

- Philippines - Media LandscapesDocument38 pagesPhilippines - Media LandscapesGuillian Mae PalconeNo ratings yet

- Specialized Epic EVO 2021Document3 pagesSpecialized Epic EVO 2021MTB-VCONo ratings yet

- How To Build A 43 Note CalliopeDocument14 pagesHow To Build A 43 Note CalliopeBrad SommersNo ratings yet

- Adding Value To Corporate Recruitment: Carlos Jordán de Urries Talent Search ConsultantDocument8 pagesAdding Value To Corporate Recruitment: Carlos Jordán de Urries Talent Search ConsultantCarlos Jordan de UrriesNo ratings yet

- FinePrint pdfFactory Pro Trial Version PDF CreationDocument40 pagesFinePrint pdfFactory Pro Trial Version PDF CreationTUAN NGUYEN VANNo ratings yet

- Export Promotion Councils - Final UpdatedDocument14 pagesExport Promotion Councils - Final UpdatedUtkarsh SaxenaNo ratings yet

- Range and Angle Tracking Techniques for Moving Target EstimationDocument34 pagesRange and Angle Tracking Techniques for Moving Target Estimationmykingboody2156No ratings yet

- Open-Ended CG Experiments Spark CreativityDocument9 pagesOpen-Ended CG Experiments Spark CreativityArjun ShettyNo ratings yet

- BS en 50160 2007Document24 pagesBS en 50160 2007Pepe Eulogio OrtízNo ratings yet

- Sabri Toyyab Resume Spring 2019Document2 pagesSabri Toyyab Resume Spring 2019api-457400663No ratings yet

- Guide to Rubber Expansion JointsDocument7 pagesGuide to Rubber Expansion JointsHu HenryNo ratings yet

- HDDTB 15 PDFDocument4 pagesHDDTB 15 PDFdakidofdaboomNo ratings yet

- Object-Oriented Programming Lab Manual RDocument63 pagesObject-Oriented Programming Lab Manual RKLR CETNo ratings yet

- Formalin MsdsDocument10 pagesFormalin MsdsMank WidhieNo ratings yet

- Stock PartDocument20 pagesStock PartGReyNo ratings yet

- New Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)Document3 pagesNew Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)TASHKEELNo ratings yet