Professional Documents

Culture Documents

IITM2

Uploaded by

DrGanesh KameCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IITM2

Uploaded by

DrGanesh KameCopyright:

Available Formats

Load Settlement Behaviour of Axisymmetric Box Foundation by Nonlinear Finite

Element Analysis

Dilip K Maharaj, Ph.D

Assistant Professor

Civil engineering Group

Birla Institute of Technology and Science,

Pilani,Rajasthan-333031

E-mail:dilip_maharajyahoo.com

:dkmbits-pilani.ac.in

ABSTRACT :In this paper an axisymmetric box Ioundation as well as an axisymmetric solid

Ioundation have been analysed by Nonlinear Iinite method. The Ioundation and soil have been

discretized by Iour noded isoparametric Iinite elements. The material nonlinearity oI soil has

been modeled by Drucker-Prager yield criteria. A comparative study Ior the load-settlement

behaviour Ior both the Ioundations have been done Ior diIIerent diameters keeping depth oI

Ioundation and thickness oI wall oI box Ioundation constant. At smaller as well as larger

diameters the box Ioundation undergoes more settlement than that oI the solid Ioundation in the

range oI 5-12 milimeters at very high load.This diIIerence in settlement has been Iound to reduce

signiIicantly due to the increase in modulus oI Ioundation material. By increasing the modulus oI

the box Ioundation almost same load-settlement curve has been Iound Ior box and solid

Ioundations. By providing a box Ioundation instead oI a solid Ioundation nearly 50 to 80

percentage saving oI volume oI concrete have been Iound Ior the range oI diameters considered

in the analysis. Thus the hollow Ioundation is an economical Ioundation as compared to the

solid Ioundation and also an excellent alternative to the solid Ioundation.

INTRODUCTION:A Ioundation is the part oI the structure which is in contact with the ground

and transIers the load oI the structure to the ground. A raIt Ioundation is generally provided in

soil with low bearing capacity and in soils where chances oI diIIerential settlement is there iI

isolated Iootings are provided. A hollow raIt Ioundation is similar to the conventional raIt

Ioundation, the diIIerence lies in the inside portion oI the two. In case oI hollow raIt Ioundation

the inside portion oI concrete is removed and it is closed at bottom and top through slabs and all

around through walls and hence it is named as a box Ioundation. In this paper an axisymmetric

solid and box type raIt Ioundation which is very much suitable Ior axisymmetric structures has

been analysed by nonlinear Iinite element method to understand its load settlement behavour.

LITERATURE REVIEW

Severn (1966) reported the Iinite element method Ior solving the mat Ioundation. The paper

presents the derivation oI stiIIness matrix Ior plates, which include the eIIect oI an elastic

Ioundation.. StiIIness matrix Ior beam on elastic Ioundation is also presented. The eIIect oI

Ioundation is assumed to consist two parts (a) the spring type reaction which is directly

proportional to the displacement and (b) a spring-coupling action which simulates shear resistance

in the Ioundation.

Hain and Lee (1974) reported that the most eIIective analytical technique Ior analysisng the

structure-raIt-supporting soil system appears to be substructure approach when the elements oI

the system can be treated as maniIesting linear elastic behaviour. The results oI the linear elastic

model are Iound to be consistent with the common observed concave settlement proIile. Thus it

is Iound that the linear elastic model should be used in preIerence to the Winkler`s Model.

Horvath(1983)developed a new mathematical model Ior analysing mat Ioundation under static

loads based on Reissner`s concept oI a simpliIied elastic continuum. Horizontal normal and shear

stresses are assumed to be zero throughout an elastic layer oI Iinite thickness. Solutions Ior a

Young`s Modulus constant with depth as well as varying linearly and with square root oI depth

are discussed. The Reissner SimpliIied Continuum is shown to oIIer substantially better

correlation with exact theory oI elasticity solutions than does the commonly used modulus oI

subgrade reaction model.

Kay and Cavagnaro (1983)reported measurement oI settlement oI three structures on raIt

Ioundations. For two oI these structures surveying techniques were used while Ior the third a

borehole extensometer technique developed in the United Kingdom was used. The extensometer

approach was Iound to be superior Irom a number oI standpoints, including accessibility during

construction, convenience oI measurement and accuracy oI results.

Shukla (1984) presented a simplied method Ior design oI mat Ioundations on elastic soil medium.

The paper recommends methods to determine modulus oI subgrade reaction and methods to

calculate moments, shear Iorces, and deIlections at critical points on mat with the help oI charts. An

example is given to show the chart.

Bowles (1986)reported a brieI survey oI computerized methods Ior mat design. The modulus oI

subgrade reaction is considered in some detail both in obtaining reasonable initial design estimates

and simple methods to couple node eIIects. A mat example is reanalyzed to illustrate the eIIect oI

simple coupling procedure . Several tables are given both to illustrate the particular validity oI the

Iinite grid method and Ior use in coupling procedure.

McKeen and 1ohnson (1990) conducted a study to investigate the simple rational methods Ior

calculating the active zone depth and Irom it the edge moisture penetration distance in expansive

soils. Analysis oI soil-moisture diIIusion indicated that the active zone depth is a Iunction oI the

maximum suction change imposed, minimum suction change considered signiIicant , climate

Irequency and Iield diIIusion coeIIicient.

FINITE ELEMENT ANALYSIS

Figure 1. shows the Iinite element discretization considered in the analysis. The raIt, soil have

been discretized into Iour noded isoparametric Iinite elements. The soil has been modeled as

Drucker-Prager elastoplastic material. The resulting nonlinear Iinite element equations have

been solved by Full Newton Raphson Iterative Procedure. The depth oI soil considered below the

raIt is Iive times the size oI the raIt while a soil zone oI radius equal to ten times the radius oI

the raIt has been considered Irom the center oI the raIt. The center boundary and the edge

boundary are allowed to undergo vertical movement but no horizontal movement. The bottom

boundary are considered to have no movement.

Material Properties and Parameters Varied:

Modulus oI Concrete (E

c

) 2 x 10

7

, 2 x 10

8

kN/m

2

Poisson,s Ratio oI Concrete (

c

)0.45

Modulus oI Soil (E

s

) 3.2 x 10

4

kN/m

2

Cohesion oI soil (C ) 29.10 kN/m

2

Poisson,s Ratio oI Soil (

s

)0.30

Diameters oI Foundation( D) 10 , 20 meters

Thickness oI Ioundation(T) 4.0 meters

Thickness oI top slab and bottom slab oI Ioundation (t)0.5 meters

Thickness oI circular wall oI Ioundation(t

c

)1.0 meters

Based on the dimensions considered percentage saving in concrete

(i) For smaller diameter (10 meters) is 48 ( i.e nearly 50)

(ii) For the larger diameters (20 meters) is 81

RESULTS AND DISCUSSIONS

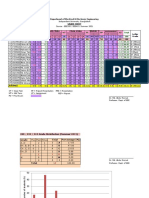

Figure 2. shows the comparison oI load settlement curve obtained Ior solid and box type

axisymmetric raIt Ioundation oI smaller diameter. It can be seen that the load settlement curves

Ior both the Ioundations almost overlap each other. The box type Ioundation showing slightly

more settlement than that oI the solid Ioundation.

Figure 3. shows the load settlement curve Ior the solid Ioundation ( with same modulus as in the

previous case ) and that oI the box Ioundation (with high elastic modulus). It can be seen that the

two curves are completely overlapping each other. Hence by increasing the modulus oI the raIt

material oI the box Ioundation, the same load carrying capacity oI the box as well as the solid

Ioundation can be obtained.

Fig.2. Load-SettIement Curves for Foundations

(D=10m,E

c

=2 x 10

7

kN/m

2

)

0

10000

20000

30000

40000

0 50 100 150 200 250 300

SettIement (mm)

L

o

a

d

(

k

N

)

Hollow

Solid

Figure 4. shows the comparison oI the load settlement curves oI the solid as well as that oI the

box type oI Ioundation oI larger diameter. Box Ioundation undergoes more settlement than that

oI the solid Ioundation. This increase in settlement is maximum oI 12 mm and that also at very

large load. Even Ior larger size oI raIt Ioundation the two load settlement curves are comparable.

Fig.3. Load SettIement Curves for Foundations

(E

c

=2 x 10

8

kN/m

2

for HoIIow and 2 x 10

7

kN/m

2

for SoIid)

0

10000

20000

30000

40000

0 50 100 150 200 250 300

SettIement (mm)

L

o

a

d

(

k

N

) Hollow

Solid

Fig.4. Load SettIement Curves for Foundations

(D=20 m, E

c

=2 x 10

7

kN/m

2

)

0

20000

40000

60000

80000

100000

0 20 40 60 80

SettIement (mm)

L

o

a

d

(

k

N

)

Hollow

Solid

Figure 5. shows the comparison oI the load settlement curve oI the solid Ioundation and that oI

the box Ioundation. In this case the modulus oI box type oI Ioundation has been increased while

that oI the solid Ioundation has been kept constant. It can be seen that the two curves are almost

near to each other. This clearly shows that by increasing the modulus oI the box Ioundation

almost the same load carrying capacity as that oI the solid Ioundation can be obtained.

Figure 6. shows the diIIerential settlement versus settlement curve Ior solid and box Ioundations

oI smaller diameters. For any settlement the diIIerential settlement oI hollow Ioundation is more

than that oI the solid Ioundation though the maximum value oI diIIerential settlement is 5

milimeter Ior the hollow Ioundation and nearly 0.6 milimeter Ior the solid Ioundation.

Fig.5. Load SettIement Curves for Foundations

( E

c

= 2 x 10

8

kN/m

2

for HoIIow and E

c

=2 x 10

7

kN/m

2

for SoIid)

0

20000

40000

60000

80000

100000

0 20 40 60 80

SettIement (mm)

L

o

a

d

(

k

N

)

Hollow

Solid

Fig.6. SettIement-DifferentiaI SettIement Curves for

foundations(D=10 m, E

c

=2 x 10

7

)kN/m

2

0

2

4

6

0 100 200 300

SettIement (mm)

D

i

f

f

e

r

e

n

t

i

a

I

S

e

t

t

I

e

m

e

n

t

(

m

m

)

Hollow

Solid

Figure 7. shows the diIIerential settlement versus settlement curves Ior solid and box

Ioundations Ior the same diameter as in the above case (Figure6.). In this case the modulus oI

box Ioundation has been increased. The Iigure shows that the diIIerential settlement oI the box

Ioundation has reduced to 0.7 milimeter.

Figure 8. shows the diIIerential settlement versus settlement curves Ior solid and box Ioundation

oI larger diameters. For any settlement the diIIerential settlement oI box Ioundation is more than

that oI the solid Ioundation.

Fig.7. SettIement-DifferentiaI SettIement

Curves for Foundations [D=10 m, HoIIow (

E

c

=2 x 10

8

), SoIid (E

c

=2 x 10

7

)]

0

0.2

0.4

0.6

0.8

0 100 200 300

SettIement (mm)

D

i

f

f

e

r

e

n

t

i

a

I

S

e

t

t

I

e

m

e

n

t

(

m

m

)

Hollow

Solid

Fig.8. SettIement-DifferentiaI SettIement

Curves for Foundations(D=20 m, Ec=2 x 10

7

kN/m

2

)

0

5

10

15

0 50 100

SettIement (mm)

D

i

f

f

e

r

e

n

t

i

a

I

S

e

t

t

I

e

m

e

n

t

(

m

m

)

Hollow

Solid

Figure 9. shows the diIIerential settlement versus settlement curves Ior solid and box Ioundation

oI same diameters as in Figure 8. In this case the modulus oI box Ioundation has been increased

keeping the modulus oI solid Ioundation same. The increase in modulus has reduced the

diIIerential settlement signiIicantly.

CONCLUSIONS

At smaller as well as larger diameters the box Ioundation undergoes more settlement than that oI

the solid Ioundation in the range oI 5-12 milimeters at very high load.This diIIerence in

settlement has been Iound to reduce signiIicantly due to the increase in modulus oI Ioundation

material. By increasing the modulus oI the box Ioundation almost same load-settlement curve

has been Iound Ior box and solid Ioundations. By providing a box Ioundation instead oI a solid

Ioundation nearly 50 to 80 percentage saving oI volume oI concrete have been Iound Ior the

range oI diameters considered in the analysis. Thus the hollow Ioundation is an economical

Ioundation as compared to the solid Ioundation and also an excellent alternative to the solid

Ioundation.

ACKNOWLEDGEMENTS

The author wishes to thank Birla Institute oI Technology and Science, Pilani, Rajasthan Ior

providing computing Iacility. The author thanks his wiIe and loving sons Ashish and Manish

Ior their sincere eIIort in preparing this paper. The author also thanks all the groups specially his

Civil Engineering Group Ior their cooperation.

Fig.9. SettIement-DifferentiaI SettIement

Curves for Foundations [D=20 m,HoIIow

(E

c

=2 x 10

8

), SoIid ( E

c

=10

7

)]

0

2

4

6

0 20 40 60 80

SettIement (mm)

D

i

f

f

e

r

e

n

t

i

a

I

s

e

t

t

I

e

m

e

n

t

(

m

m

)

Hollow

Solid

REFERENCES

Bowles J E (1986) 'Mat design ACI Journal 1010-1017.

Hain, S.J. and Lee .K. (1974) "Rational analysis of raft foundation, Journal of

Geotechnical Engineering ,Vol.100, No.GT7, 843-859.

Horvath, J.S. (1983) 'New subgrade model applied to mat Ioundations Journal of Geotechnical

Engineering ,Vol.109, No.12, 1567- 1587.

Kay and Cavagnaro (1983) 'Settlement oI raIt Ioundations, Journal of Geotechnical

Engineering ,Vol.109, No.11,1367-1381.

McKeen R.G. and Johnson L.D. (1990) 'Climate-controlled soil design parameters Ior mat

Ioundations , Journal of Geotechnical Engineering ,Vol.116, No.7, 843-859.

Severn R.T. (1966) 'The solution oI Ioundation mat problems by Iinite-element methods,

Structural Engineer ,Vol.44 No.6 pp 223-228.

Shukla S.N. (1984), 'A simplied method Ior the design oI mat on elastic Ioundation, ACI Journal

,pp469-475.

You might also like

- Co Attainment ReviewDocument1 pageCo Attainment ReviewDrGanesh KameNo ratings yet

- Xi. The Fee Structure and Other Financial ImplicationsDocument3 pagesXi. The Fee Structure and Other Financial ImplicationsDrGanesh KameNo ratings yet

- Appendix 12 - Project Outcomes and Deliverables: Overall, The Research Sought An Understanding ofDocument2 pagesAppendix 12 - Project Outcomes and Deliverables: Overall, The Research Sought An Understanding ofDrGanesh KameNo ratings yet

- 01 SIMPLE TRUSSES DR G. S KameDocument21 pages01 SIMPLE TRUSSES DR G. S KameDrGanesh KameNo ratings yet

- Library: 2014-2015 ACSA/AISCDocument12 pagesLibrary: 2014-2015 ACSA/AISCDrGanesh KameNo ratings yet

- 2 Design-of-steel-roof-Trusses DR G S KameDocument13 pages2 Design-of-steel-roof-Trusses DR G S KameDrGanesh KameNo ratings yet

- 3 Example of Truss DR G S KameDocument28 pages3 Example of Truss DR G S KameDrGanesh KameNo ratings yet

- Site Reports For Engineers Update 051112 PDFDocument2 pagesSite Reports For Engineers Update 051112 PDFDrGanesh KameNo ratings yet

- Tameer Article 3 Insdag Full Article in SoftDocument2 pagesTameer Article 3 Insdag Full Article in SoftDrGanesh KameNo ratings yet

- Design of Trussed Roof BuildingsDocument1 pageDesign of Trussed Roof BuildingsDrGanesh KameNo ratings yet

- 2014-11-26 Construction Site Visit RPTDocument2 pages2014-11-26 Construction Site Visit RPTDrGanesh KameNo ratings yet

- Dessign Specifications For Truss PDFDocument1 pageDessign Specifications For Truss PDFDrGanesh KameNo ratings yet

- 2015-16 ACSA ProgramDocument11 pages2015-16 ACSA ProgramDrGanesh KameNo ratings yet

- Structural Analysis and Design Sessional-I 1.0 Credit: Department of Civil and Environmental EngineeringDocument50 pagesStructural Analysis and Design Sessional-I 1.0 Credit: Department of Civil and Environmental EngineeringDrGanesh KameNo ratings yet

- Carbon Fibre Reinforced Gypsum BuildingsDocument4 pagesCarbon Fibre Reinforced Gypsum BuildingsDrGanesh KameNo ratings yet

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Document11 pagesMetal Building Systems: Pdhonline Course S120 (1 PDH)DrGanesh KameNo ratings yet

- Pre Engineered Buildings 410 PDFDocument7 pagesPre Engineered Buildings 410 PDFDrGanesh KameNo ratings yet

- Aerocom Metals: A History of SteelDocument16 pagesAerocom Metals: A History of SteelDrGanesh KameNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Alexander Elder Como Se Transformar em Um Operador e Investidor de Sucesso PDFDocument18 pagesAlexander Elder Como Se Transformar em Um Operador e Investidor de Sucesso PDFGustavo Vasconcellos0% (1)

- Curriculum Vitae - Electrical EngineerDocument3 pagesCurriculum Vitae - Electrical EngineerLingaraj Suresh LingaianNo ratings yet

- BTP List 25881f798de425Document3 pagesBTP List 25881f798de425PrijinprakashNo ratings yet

- Radicon BrochureDocument8 pagesRadicon Brochureemilliomud100% (1)

- Agile Model in Software EngineeringDocument40 pagesAgile Model in Software EngineeringThanh PhamNo ratings yet

- Reinf TableDocument2 pagesReinf TableRigel NapaNo ratings yet

- Concrete Industrial Floor Design - Engineers EdgeDocument1 pageConcrete Industrial Floor Design - Engineers EdgeNeil WilsnachNo ratings yet

- T-33 PrezentationDocument13 pagesT-33 Prezentationkako083No ratings yet

- Falar 2 and 3Document41 pagesFalar 2 and 3jbonvier71% (7)

- TICAD8 Fall 2024 International Admission FlyerDocument2 pagesTICAD8 Fall 2024 International Admission Flyerrlatjorluk100% (1)

- Víctor Falguera: Curriculum VitaeDocument9 pagesVíctor Falguera: Curriculum VitaevictorfalgueraNo ratings yet

- Chapter 14 Security Engineering 1Document48 pagesChapter 14 Security Engineering 1Fattah MuhyiddeenNo ratings yet

- IDC TechnologiesDocument5 pagesIDC Technologiesidctech0% (1)

- Hvac Boq-07082014Document18 pagesHvac Boq-07082014farshan296015No ratings yet

- 220kV RRVPNL Cable SpecificationDocument22 pages220kV RRVPNL Cable Specificationanurag_pugaliaaNo ratings yet

- Is 4925Document14 pagesIs 4925Naveen MatNo ratings yet

- Final - National School Building Inventory Forms 10272014Document7 pagesFinal - National School Building Inventory Forms 10272014GloriaGambotNo ratings yet

- EEE 332 - Summer 2021 - Grade Sheet - CO-PO AttainmentDocument3 pagesEEE 332 - Summer 2021 - Grade Sheet - CO-PO AttainmentAli AshrafNo ratings yet

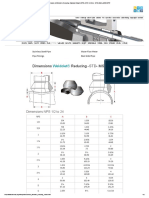

- Dimensions of Weldolets Reducing, Standard Weight (STD), NPS 1 - 2 (3 - 4) - NPS (20) 24, MSS-SP97Document2 pagesDimensions of Weldolets Reducing, Standard Weight (STD), NPS 1 - 2 (3 - 4) - NPS (20) 24, MSS-SP97Qiuniu100% (1)

- Building Energy SimulationDocument25 pagesBuilding Energy SimulationNidas SameeraNo ratings yet

- SOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical GuidelinesDocument2 pagesSOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical Guidelinest836549No ratings yet

- Linda Vlassenrood (2006) Making Change Sensible NAI China ContemporaryDocument31 pagesLinda Vlassenrood (2006) Making Change Sensible NAI China ContemporaryEnrique Castro TrigueroNo ratings yet

- Scalable Automation For Drug Delivery Devices: Phillips-MedisizeDocument5 pagesScalable Automation For Drug Delivery Devices: Phillips-MedisizeQuality JiveNo ratings yet

- Lecture 3 Bec304Document35 pagesLecture 3 Bec304Mohd Nizam ShakimonNo ratings yet

- Univ-Prof Dr-Ing Ernst M Schmachtenberg - RWTH AACHEN UNIVERSITY - EnglishDocument5 pagesUniv-Prof Dr-Ing Ernst M Schmachtenberg - RWTH AACHEN UNIVERSITY - Englishnate_864No ratings yet

- 2171 - Small P13609 - Ketchikan Repairs To The Airport Ferry Landing - FINALDocument23 pages2171 - Small P13609 - Ketchikan Repairs To The Airport Ferry Landing - FINALRomoex R RockNo ratings yet

- Nde Request - Thickness SurveyDocument1 pageNde Request - Thickness SurveySam RajaNo ratings yet

- Unit I IntroductionDocument1 pageUnit I IntroductionPraveen KumarNo ratings yet

- The Self-Healing Technologies of Smart Distribution Grid PDFDocument6 pagesThe Self-Healing Technologies of Smart Distribution Grid PDFedmuarizt7078No ratings yet

- White Book C03 S02 Steel Encasements FireCaseDocument25 pagesWhite Book C03 S02 Steel Encasements FireCasePavaloaie Marian ConstantinNo ratings yet