Professional Documents

Culture Documents

CPT Work Instruction

Uploaded by

Franklin HallCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CPT Work Instruction

Uploaded by

Franklin HallCopyright:

Available Formats

Stolt Offshore

Survey Operations

CPT Work Instruction

GR-SRV-455

Prepared by : Approved by : 1.0

Version

P.P. Syratt P.J. Jansen

Project Surveyor Chief Surveyor

P.P. Syratt P.J. Jansen

Issue for use

Reason for Issue

Jan.17.02

Issue Date Prepared by Approved by

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 2 of 8

CPT Work Instruction

GR-SRV-455

Ver. 1.0

This is an electronically generated document which has been reviewed and approved in accordance with Stolt Offshore Limiteds Management System. An audit trail of review and approval is available within the electronic system and a master approved copy is available from the HSEQ Department. The screen version of this document is the CONTROLLED COPY at all times. When printed it is considered a FOR INFORMATION ONLY copy, and it is the holders responsibility that he / she holds the latest valid version

TABLE OF CONTENTS

1. SCOPE.......................................................................................................................................................................3 2. OBJECTIVE.............................................................................................................................................................3 3. REFERENCES..........................................................................................................................................................3 4. DEFINITIONS..........................................................................................................................................................3 5. RESPONSIBILITIES...............................................................................................................................................3 6. PROCEDURES.........................................................................................................................................................4

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 3 of 8

CPT Work Instruction

GR-SRV-455

Ver 1.0

1.

SCOPE

This Work Instruction covers the description and operation of Cone Penetrometer (CPT) equipment currently available for soil investigation offshore.

2.

OBJECTIVE

The objective of this work instruction is to enable suitably qualified personnel to operate CPT equipment in the various geotechnical survey applications, such as burial assessment, pipeline route surveys, cable route surveys and site investigations. The in-situ measurements assist in determining soil type and to estimate a number of fundamental soil parameters. Results are used in corroboration with other available data, such as borehole samples or geophysical data, to facilitate the design of pipeline / cable routes and platform locations.

3.

REFERENCES

QA Practices QA Practice GR-SRV-051 GR-SRV-052 GR-SRV-066 GR-SRV-323 : : Mobilisation and Demobilisation Shipping, Handling and Packing Route / Site Survey Operations Pre-Lay Survey Operations Geotechnical Operations Soil Sampling Practice

4.

DEFINITIONS

CPT : CPTU : RUPTU : SCU : qc : fs : u : Cone Penetrometer Testing Piezo Cone Penetrometer Testing Resistivity Cone Penetration Testing Surface Control Unit Cone Resistance Sleeve Friction Pore Pressure

5.

RESPONSIBILITIES

It is the responsibility of the Senior Surveyor to ensure that all equipment mobilised is checked off the equipment manifesto. The Senior Surveyor is also responsible that any damage or loss is reported to the Project Surveyor at the earliest opportunity. It is the responsibility of the Senior Surveyor to ensure that all equipment is tested and fully operational according to the mobilisation procedures.

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 4 of 8

CPT Work Instruction

GR-SRV-455

Ver 1.0

The Senior Surveyor should ensure that deployment / recovery instructions are in place and understood by all personnel involved with the deployment, including crane or winch operators. The Senior Surveyor is responsible for carrying out the in-situ measurements in accordance with the client specifications and in line with the following procedure. It is the responsibility of all survey personnel involved in the operation of CPT equipment to comply with this procedure and provide any comments on improvements to the Project Surveyor.

6.

6.1 6.1.1

PROCEDURES

SYSTEM DESCRIPTION General The cone penetrometer and the piezo cone are the most versatile of in-situ devices currently available for soil investigation providing high resolution, continuous penetration measurements. Extensive research has proved that the results from tests, such as sleeve friction and transient pore pressure, correlate well with soil type allowing full stratigraphic profiles to be produced. The high resolution of these devices allows thin layers of sediment being identified, otherwise overseen with conventional techniques. The principal reasons for acceptance of CPT testing are the accuracy and detailed nature of geotechnical data obtained. The fact that the tests are carried out in-situ means that there is no sample disturbance or any change in stress conditions. The in-situ tests complement conventional drilling and sampling programs and are seen as a cost-effective means of collecting geotechnical data; the speed of acquiring in-situ test measurements is far superior to most conventional techniques.

6.1.2

Cone Penetrometer Systems The cone penetrometer probe can be equipped with a variety of sensors. In general applications, it normally contains two strain gauge load cells for independent measurements of tip and friction resistances. Electrical signals from the load cells are transmitted through the cable running through hollow push rods. The CPT is usually deployed in a specially designed seabed frame from the survey vessel using a crane or via A frame and high-speed winch. There are various seabed systems in operation that essentially differ in terms of their drive mechanism, weight and geometry, penetration capability and suitability for shallow or deepwater applications. Hydraulic ram drive systems push the CPT probe into the underlying sediment at constant rate with a continuous push action using a straight rod. Single or multi -wheel drive systems use a series of flexible push rods. Straight rod systems are used when

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 5 of 8

CPT Work Instruction

GR-SRV-455

Ver 1.0

coarser sediments are expected and the degree of cone inclination should be minimised. Owing to the finite length of straight rods, penetration is limited to 6 metre. Wheel drives do not suffer the same depth limitations; penetration depths in excess of 40 metres can be achieved using a 10 tonne single drive unit. Since the string is continuous, productivity is higher than a conventional ram drive system. However, owing to the flexible nature of the rod string, the verticality of the probe can is not guaranteed The cone is normally pushed into the sediment at a rate of 2 cm / second to depths of several metres depending on requirement. Most seabed systems are capable of achieving penetration depths of 2 metres, although penetration is limited by the presence of very course material such as cobbles and boulders. In some applications, however, the probe can be used in static mode, whereby the probe is left in place to gather data over a period of time. Power and data communications to seabed systems is provided using an umbilical cable to a Surface Control Unit (SCU) where data is recorded and processed at the computer acquisition system on the survey vessel. 6.1.2.1 Piezo Cone Penetrometer The Electrical Piezocone (CPTU) is used for determining soil stratigraphy, relative density, and strength and pore pressure. The piezocone is available with a choice of 2.5, 5.0, 10.0 and 15 ton tip capacity, variable capacity friction sleeves and pore pressure gauges. An inclinometer can be installed in the probe to measure vertical alignment. 6.1.2.2 Seismic Cone Penetrometer The seismic cone penetration test (SCPT) combines the seismic downhole method and the logging capabilities of CPT. In addition to providing geotechnical measurement, the system measures shear and compressional wave velocities using an array of built-in accelerometers. The shear wave velocity is directly proportional to the dynamic shear modulus, a fundamental parameter for the analysis of soil behaviour in response to dynamic loading from vibration. 6.1.2.3 Electrical Resistivity Cone The resistivity cone penetration test combines the downhole analysis of soil resistivity and the logging capabilities of the CPTU. In addition to providing geotechnical measurement, the system measures relative electrical resistivity. 6.1.3 Surface Control Unit The probe is initiated using the Surface Control Unit (SCU). The software allows the user to select the number of channels (or parameters) and corresponding sampling rates to be recorded. The acquisition computer collects data, usually at 0.5 cm intervals, and displays real-data enabling an accurate on-site lithological sub-surface representation. The graphical plots can be printed out for inclusion in the field report.

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 6 of 8

CPT Work Instruction

GR-SRV-455

Ver 1.0

The continuous profiles obtained with the CPT allow the user to visualise the underlying stratigraphy, to evaluate soil type, to estimate a number of fundamental soil parameters and to directly design shallow foundations subjected to vertical load. Some CPT systems have self-recording capabilities, logging pre-set configurable routines to internal memory. 6.2 6.2.1 SYSTEM INSTALLATION AND OPERATION Mobilisation During mobilisation the equipment should be inspected to ensure it has not suffered any damage. Any loss, omission or damage, particularly to hoses, cables and rods, should be reported to the Project Surveyor at the earliest opportunity to arrange replacement. Any repairs that can be undertaken on board should be carried out before commencement of the survey. Sufficient sensors and CPT cone tips should be available to replace faulty or damaged units during fieldwork. The CPT probe should be attached to the push rod in the seabed frame. Power and data communications should be tested. The Senior Surveyor should set up the correct logging routines in the SCU and provide a sample data set to test the complete system is operating per client specification. The Survey Engineer should ensure that compressors used are serviced and in full working order, and that all cables and hoses are checked for breaks. All winch cabling should be greased and in good order. Tag lines should be attached to the frame to maintain stability during deployment, particularly during periods of excessive sea state. Prior to commencement of CPT operations the Senior Surveyor should review the full workscope. The requirements and specifications should be addressed and approved by the Client Representative onboard. The position of required CPT locations should also be confirmed with the onboard geophysicist in consultation with survey data available. A list of the proposed locations should be given to the on-line surveyor. 6.2.2 Deployment The Senior Surveyor should ensure that deployment instructions are in place and understood by all personnel involved with CPT operations including the winch operator. The seabed frame is should be deployed over the side by crane or over the stern using a pivotal A frame and winch. Prior to deployment the vessel should be positioned stationary at the proposed CPT location. The seabed frame should then be released and lowered to the seabed in a controlled manner. 6.2.3 Operation

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 7 of 8

CPT Work Instruction

GR-SRV-455

Ver 1.0

When the CPT frame reaches the seabed (when the winch cable goes slack) a position fix should be logged on the navigation software by the on-line surveyor and recorded in the field logbook. Once the seabed frame is in place the drive should be activated using the compressor or electrical switch. The rate of penetration will vary with each drive system but rates of 2 cm per second in good ground conditions are achievable. The drive force should be adjusted to ensure that penetration rates remain constant. Care should be taken not to overdrive the rods as this will lead to damage. The vessel should maintain station at the location until CPT measurements are complete at the site and the push rods and probe have been recovered. To avoid unnecessary tension on cables or hoses, conditions may dictate that the vessel position itself on anchor. This will obviously reduce productivity over a number of sites. Care should also be taken to ensure that all cables are keep clear of the vessel to prevent snagging especially in the vessel propellers. The Senior Surveyor should evaluate the data acquired and confirm the system is operating effectively. Any significant results, such as anomalies or depth of refusal, should be recorded in the field log and marked on the graphic record. The Senior Surveyor will give confirmation that testing is complete. The Senior Surveyor should provide a complete summary of results for each CPT location to the client representative for approval. 6.2.4 Recovery On completion of CPT tests the push rods, or string, should be fully retracted using the drive unit and the seabed frame hoisted steadily to the surface. The seabed frame should be on deck and secure before the vessel moves to the next location. 6.2.5 Data Processing The geotechnical data is processed and reviewed with available geophysical data, or borehole information, by the Senior Surveyor in consultation with the onboard Geophysicist / Geologist to allow a total integration of data onboard the vessel. The most common geotechnical properties that can be evaluated from cone data include: Horizontal stress Relative density Friction angle Constrained Modulus Youngs Modulus Stress history Sensitivity

Stolt Offshore Division

Process

Date of Issue

Stolt Offshore Survey Services

Document Title:

Survey Operations

Document No & Revision

Jan.17.02 Page 8 of 8

CPT Work Instruction

GR-SRV-455

Ver 1.0

Undrained shear strength Coefficient of consolidation Permeability Liquefaction potential.

The analysis of the CPT data should be undertaken in line with specific geotechnical procedures outlined in the project briefing and the associated reporting guidelines.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Light Combat AircraftDocument5 pagesLight Combat AircraftUtsav NiroulaNo ratings yet

- LBL Acoustic Work InstructionDocument13 pagesLBL Acoustic Work InstructionFranklin HallNo ratings yet

- Velocity Probe Work InstructionDocument9 pagesVelocity Probe Work InstructionFranklin HallNo ratings yet

- Rs 232 Prog ManualDocument43 pagesRs 232 Prog ManualFranklin HallNo ratings yet

- Electrode Placement ChartDocument34 pagesElectrode Placement ChartFranklin Hall86% (7)

- Sensibo Sky User ManualDocument34 pagesSensibo Sky User ManualMauMadie FuntanarNo ratings yet

- REERTRDocument4 pagesREERTRvgteeNo ratings yet

- Lista Preturi Linhai 300 2014 PDFDocument25 pagesLista Preturi Linhai 300 2014 PDFSimonaVătafuNo ratings yet

- D-1967 (Clean) Quilting Machine ManualDocument33 pagesD-1967 (Clean) Quilting Machine Manualvalter craccoNo ratings yet

- RAEX 300 DatasheetDocument2 pagesRAEX 300 Datasheetabdulloh_99No ratings yet

- Dism Repair Tools PDFDocument21 pagesDism Repair Tools PDFprashant4455No ratings yet

- Make A Project of Calculator in Visual BasicDocument9 pagesMake A Project of Calculator in Visual BasicCHITRA MINI96% (23)

- Railway-4 Permanent Way & Alignment (Lecture-4)Document17 pagesRailway-4 Permanent Way & Alignment (Lecture-4)OBIDUR RAHMAN 1701085No ratings yet

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Document4 pages7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallNo ratings yet

- Tesys T Ltmr100pbdDocument3 pagesTesys T Ltmr100pbdsimbamikeNo ratings yet

- Basic ProbabilityDocument53 pagesBasic ProbabilityGhada SheashaNo ratings yet

- GRT655 GRT655L Product Guide ImperialDocument20 pagesGRT655 GRT655L Product Guide ImperialDanilo UrruchurtoNo ratings yet

- Contactor HassDocument1 pageContactor Hassecaldera10No ratings yet

- Occupational Health and Safety of Hydrogen Sulphide (H2S)Document20 pagesOccupational Health and Safety of Hydrogen Sulphide (H2S)hitm357100% (1)

- GANTREX® MK6 Rail PadDocument4 pagesGANTREX® MK6 Rail PadwickremasingheNo ratings yet

- Technology and Culture - ReadingDocument3 pagesTechnology and Culture - ReadingBraulio Pezantes100% (1)

- Resume For FaisalDocument3 pagesResume For FaisalFaisal Zeineddine100% (1)

- PC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensDocument2 pagesPC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensSarah JenkinsNo ratings yet

- DE GUZMAN - Module 2 Activity No. 2Document4 pagesDE GUZMAN - Module 2 Activity No. 2Alvin De GuzmanNo ratings yet

- Uniport Data Capture PortalDocument1 pageUniport Data Capture PortalPrince AdieNo ratings yet

- Solar Storage System Comp GUIDEGTM 2 1Document10 pagesSolar Storage System Comp GUIDEGTM 2 1harosalesvNo ratings yet

- Revised Runway Length Discussion (20171206) - 201712211212022318Document3 pagesRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiNo ratings yet

- Thesis Report Vishal Part 1Document9 pagesThesis Report Vishal Part 1vishal infantrajNo ratings yet

- ABB - AppNotes - 2.2 - 1HC0138868 EN AADocument8 pagesABB - AppNotes - 2.2 - 1HC0138868 EN AADeoudrafNo ratings yet

- ORF Issue Brief 309 SpaceLawDocument12 pagesORF Issue Brief 309 SpaceLawNitish KumarNo ratings yet

- Abu Dhabi Certification Scheme For Assistant EngineerDocument12 pagesAbu Dhabi Certification Scheme For Assistant EngineersureshNo ratings yet

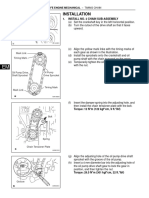

- Sincronizacion de Motor Toyota 2az-FeDocument12 pagesSincronizacion de Motor Toyota 2az-FeWilliams NavasNo ratings yet

- Em 59717521644Document68 pagesEm 59717521644Mostafa MirbaghriNo ratings yet

- Dilg-Mbcrpp Isf Q2 2023Document2 pagesDilg-Mbcrpp Isf Q2 2023Mallari GabrielNo ratings yet