Professional Documents

Culture Documents

Drill Vise Mill

Uploaded by

Mike Nichlos0 ratings0% found this document useful (0 votes)

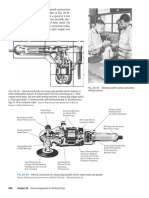

207 views2 pagesHandy milling unit for small metal-turning lathes consists simply a f a drill-press vise. Vise is a disk similar to the index disk ound rest, Figs. 1 and 2. Milling cutters should be held in a collet chuck but you can grip the cutters in a threejaw scroll or center chuck.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHandy milling unit for small metal-turning lathes consists simply a f a drill-press vise. Vise is a disk similar to the index disk ound rest, Figs. 1 and 2. Milling cutters should be held in a collet chuck but you can grip the cutters in a threejaw scroll or center chuck.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

207 views2 pagesDrill Vise Mill

Uploaded by

Mike NichlosHandy milling unit for small metal-turning lathes consists simply a f a drill-press vise. Vise is a disk similar to the index disk ound rest, Figs. 1 and 2. Milling cutters should be held in a collet chuck but you can grip the cutters in a threejaw scroll or center chuck.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

ILLING

d&. a

Just mount it on the cross slide

and do keyway cutting, end

milling and surfacing

HIS handy milling unit for small

metal-turning lathes consists simply

f a drill-press vise mounted on the

of the carriage. The vise is

a disk similar to the index disk

ound rest, Figs. 1 and 2. Thus

0th the lateral and traverse

e depth of the vise jaws gives

a considerable range of vertical adjust-

ment. Also the unit can be swiveled to any

degree desired to handle angular work.

Figs. 1 and 3 show typical operations on

parts of small models. Milling cutters

should be held in a collet chuck but if the

- lathe is not fitted with chuck and suitable

collets, you can grip the cutters in a three-

jaw scroll or center chuck and, by work-

ing carefully, get very good results on

light work.

Figs. 4 and 5 show the base or pad on

which the drill-press vise is mounted. It is

. turned from a single piece of cold-rolled

steel and all the dimensions given adapt it

to use on a well-known make of home

workshop metal-turning lathe. Notice in

Fig. 4 that the base is held in place with a

hardened pointed setscrew bearing against

the beveled projection on the underside of

the disk. The setscrew lock is regular

equipment on this particular lathe and the

beveled projection on the vise mounting

simply duplicates that on the regular com-

pound supplied with the lathe as you see

in Fig. 2, where the two parts are shown

Soldering With a Lead Pencil

For small soldering jobs, you can ef- point of the lead to the spot you wish to

fectively use an automatic lead pencil. solder and then drawing it away slowly,

Wire the metallic part of the pencil to will create a tiny arc. Use hard lead in

the negative pole of a 6-volt storage bat- the pencil, which should be a handle of

tery, and connect the positive pole to the bakelite or other heat-proof material.

work to be soldered. Then, touching the -Charles A. Younger, Somerville, N.J.

is, n o t d r i l l e d c

through and are thre

with a bottom tap.

take full advantage of

chining the base so

much louder than a sigh. The barrel is en-

cased in concrete 4 in. thick, the concrete

assuring a good mufffer long after the thin

sides of the barrel have rusted away.

am---- you want a smooth, polished finish

on w turnings such as tool handles, first

sand them carefully and then hold an oiled

strip of cloth or leather against the work ,, +

as it rotates in. the lathe.

You might also like

- ReamersDocument1 pageReamersvikash kumarNo ratings yet

- A Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialFrom EverandA Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialNo ratings yet

- PDFDocument44 pagesPDFBaSzarNo ratings yet

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningFrom EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningRating: 2.5 out of 5 stars2.5/5 (2)

- Atlas 4350 Hacksaw ManualDocument6 pagesAtlas 4350 Hacksaw Manualf4d711No ratings yet

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopFrom EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedNo ratings yet

- The Advance Metalworking LatheDocument6 pagesThe Advance Metalworking LathePronina100% (1)

- Directions for Using Bottum's Patent Improved Universal Lathe Chucks and Improved Lathes for Turning and Finishing Every Description of Watch Pivots, Pinions, Staffs, EtcFrom EverandDirections for Using Bottum's Patent Improved Universal Lathe Chucks and Improved Lathes for Turning and Finishing Every Description of Watch Pivots, Pinions, Staffs, EtcNo ratings yet

- Mill Keyways On LatheDocument1 pageMill Keyways On LatheJim100% (3)

- Lathe Parts: - Being A Brief Description of The Names and Functions of PartsDocument7 pagesLathe Parts: - Being A Brief Description of The Names and Functions of PartsDipanjana Bhowmik100% (1)

- Atlas Mill AccessoriesDocument1 pageAtlas Mill AccessoriesGary RepeshNo ratings yet

- A Rotary Sine Bar For The LatheDocument2 pagesA Rotary Sine Bar For The LatheTheodor EikeNo ratings yet

- South Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007Document16 pagesSouth Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007asdfNo ratings yet

- Tool Makers MicroscopeDocument13 pagesTool Makers MicroscopeLokesh LokiNo ratings yet

- Belt Sander - p1Document4 pagesBelt Sander - p1Renato PrevidelliNo ratings yet

- WB the+Awesome+MF+WorkbenchDocument72 pagesWB the+Awesome+MF+WorkbenchZé MarcoNo ratings yet

- Accu-Finish II ManualDocument8 pagesAccu-Finish II ManualOliver CollectorNo ratings yet

- 04 - Foundrywork For The AmateurDocument95 pages04 - Foundrywork For The Amateurj43951048100% (1)

- 3 Jaw Chuck RepairDocument2 pages3 Jaw Chuck RepairbrianatburleighNo ratings yet

- Mini Milldiy PDFDocument6 pagesMini Milldiy PDFCelso Ari Schlichting100% (1)

- Buying A Used Shopsmith Mark VDocument5 pagesBuying A Used Shopsmith Mark VendgameNo ratings yet

- ACIERA Milling Machine 1Document11 pagesACIERA Milling Machine 1adhencandraNo ratings yet

- Emco Star ManualDocument45 pagesEmco Star ManualGary StoltzNo ratings yet

- Christopher Jobson Clock RestorerDocument2 pagesChristopher Jobson Clock RestorerTommy JobsonNo ratings yet

- Lathebeddesign00hornrich PDFDocument56 pagesLathebeddesign00hornrich PDFLatika KashyapNo ratings yet

- Electrolysis Cleaning MethodDocument15 pagesElectrolysis Cleaning Methodtrillium_oneNo ratings yet

- Shopsmith Speed Chart Including Reducer and IncreaserDocument1 pageShopsmith Speed Chart Including Reducer and IncreaserhankgurdjieffNo ratings yet

- SphericalturninglathetoolDocument14 pagesSphericalturninglathetoolFrenchwolf420No ratings yet

- Lathes and Lathe Machining OperationsDocument11 pagesLathes and Lathe Machining OperationsJunayed HasanNo ratings yet

- Umesh Vishvakarma Sir Rahul Dev Sahu Nitesh Sahu Monendra SahuDocument10 pagesUmesh Vishvakarma Sir Rahul Dev Sahu Nitesh Sahu Monendra SahuMarina CdfmNo ratings yet

- Rotary TableDocument2 pagesRotary TableDong Dien KhaNo ratings yet

- Taig Lathe ManualDocument12 pagesTaig Lathe Manualspayt100% (1)

- Bonelle GrinderDocument11 pagesBonelle Grinderjohnjohn520% (1)

- How To Formulate Parkerizing SolutionDocument3 pagesHow To Formulate Parkerizing SolutionOtter1zNo ratings yet

- A Fine Vertical Steam Engine - Hobbies - Apr 1931Document8 pagesA Fine Vertical Steam Engine - Hobbies - Apr 1931dsdffgfgfssfdgsfgdNo ratings yet

- The Shape of The Cone of The Twist Drills Unit-2Document5 pagesThe Shape of The Cone of The Twist Drills Unit-2Akesh KakarlaNo ratings yet

- Sherline Machine CatalogDocument48 pagesSherline Machine CatalogBien MorfeNo ratings yet

- (Metalworking) Model Engineer - Gauge Making With The LatheDocument1 page(Metalworking) Model Engineer - Gauge Making With The LathekikoliverNo ratings yet

- Dapra Biax Article Art of ScrapingDocument2 pagesDapra Biax Article Art of ScrapingPedro Ernesto SilvaNo ratings yet

- Spindle NoseDocument4 pagesSpindle NoseSharad SharmaNo ratings yet

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDocument7 pagesFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioNo ratings yet

- In The Workshop: Duplex "Document6 pagesIn The Workshop: Duplex "johnboy183No ratings yet

- Sheet Metal Slotted BendingDocument28 pagesSheet Metal Slotted BendingVíctor Manuel VázquezNo ratings yet

- Drill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderDocument14 pagesDrill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderAndy L100% (1)

- Cowells Manuals PDFDocument16 pagesCowells Manuals PDFpedjaNo ratings yet

- SherlineDocument48 pagesSherlinejairomarcanoNo ratings yet

- Lathe Accessories Price List: P/N Description WT Price P/N Description WT PriceDocument2 pagesLathe Accessories Price List: P/N Description WT Price P/N Description WT PriceAnonymous hos8odNo ratings yet

- Apron: Apron To Saddle ConnectionDocument10 pagesApron: Apron To Saddle ConnectionFernando EricesNo ratings yet

- ACESORIOScatalog PDFDocument80 pagesACESORIOScatalog PDFlmelmelmeNo ratings yet

- The "How-To-Do-It" Books 1Document130 pagesThe "How-To-Do-It" Books 1Gutenberg.org100% (2)

- Instructions For Making "Home-Made" Ballistic GelatinDocument3 pagesInstructions For Making "Home-Made" Ballistic Gelatinbrowar444No ratings yet

- 04 80 PDFDocument272 pages04 80 PDFRahmat Budi PermanaNo ratings yet

- A Few Project Images: Tool Posts Lathe Cutting ToolsDocument4 pagesA Few Project Images: Tool Posts Lathe Cutting ToolsAnonymous mKdAfWifNo ratings yet

- Auto-Powered Arc Welder: by Norman E. SchuttzDocument60 pagesAuto-Powered Arc Welder: by Norman E. SchuttzPierre799es100% (1)

- Tool Makers Micro ScopeDocument7 pagesTool Makers Micro ScopeskumarNo ratings yet

- Tool Makers MicroscopeDocument11 pagesTool Makers Microscopeirfanajai100% (1)

- Spot Welder PlansDocument4 pagesSpot Welder Planscesargramcko100% (2)

- Sailing SurfboardDocument4 pagesSailing SurfboardFrenchwolf420100% (3)

- Corky 18 FT Sloop Diy PlansDocument7 pagesCorky 18 FT Sloop Diy PlansFrenchwolf420100% (4)

- Happy Clam SkiffDocument11 pagesHappy Clam SkifffccfNo ratings yet

- Multi SkiffDocument6 pagesMulti SkiffScaramagnao Miao BauNo ratings yet

- 8 FT SkiffDocument3 pages8 FT SkiffFrenchwolf420100% (3)

- Sea SkiffDocument5 pagesSea SkiffFrenchwolf420100% (3)

- 16 Foot Apache Outboard - PlansDocument8 pages16 Foot Apache Outboard - PlansRolando DaclanNo ratings yet

- 15 Foot SailboatDocument4 pages15 Foot SailboatAntónio OliveiraNo ratings yet

- Rowboat Sail ConversionDocument2 pagesRowboat Sail Conversionleather_nunNo ratings yet

- Jump N JackDocument5 pagesJump N JackFrenchwolf420100% (2)

- Merry MaidDocument6 pagesMerry MaidFrenchwolf420100% (3)

- Paddle TurtleDocument4 pagesPaddle TurtleFrenchwolf420No ratings yet

- 16 FT Sailing ScowDocument7 pages16 FT Sailing ScowFrenchwolf420100% (2)

- Arrow Outboard RunaboutDocument4 pagesArrow Outboard RunaboutFrenchwolf420No ratings yet

- Water Bug Tiny Paddle BoatDocument5 pagesWater Bug Tiny Paddle BoatFrenchwolf420No ratings yet

- Plywood RowboatDocument7 pagesPlywood RowboatAlphamatrix01No ratings yet

- Rowboat 3 PieceDocument3 pagesRowboat 3 PieceFrenchwolf420100% (1)

- Nereia PramDocument2 pagesNereia PramFrenchwolf420100% (1)

- Sabot 8 FT Pram DinghyDocument6 pagesSabot 8 FT Pram DinghyFrenchwolf420100% (2)

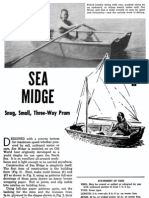

- Sea MidgeDocument5 pagesSea MidgeFrenchwolf420No ratings yet

- Pedal CatDocument8 pagesPedal CatFrenchwolf420No ratings yet

- Pedal BoatDocument4 pagesPedal BoatFrenchwolf420No ratings yet

- Paddle WheelDocument4 pagesPaddle WheelFrenchwolf420No ratings yet

- Row BoatDocument2 pagesRow BoatBenjamin GoyaNo ratings yet

- Car Top BoatDocument4 pagesCar Top BoatFrenchwolf420No ratings yet

- Paddle Bass BoatDocument3 pagesPaddle Bass BoatFrenchwolf420No ratings yet

- Paddle BoatDocument4 pagesPaddle BoatFrenchwolf420No ratings yet

- 3 Piece BoatDocument4 pages3 Piece BoatFrenchwolf420No ratings yet

- Motor Driven PaddleboardDocument5 pagesMotor Driven PaddleboardFrenchwolf420100% (1)

- Bicycle BoatDocument3 pagesBicycle BoatFrenchwolf420No ratings yet

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeFrom EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeRating: 5 out of 5 stars5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesFrom EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Timeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersFrom EverandTimeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersNo ratings yet

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysFrom EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysRating: 4.5 out of 5 stars4.5/5 (7)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallFrom EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallRating: 4 out of 5 stars4/5 (24)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsFrom EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsRating: 5 out of 5 stars5/5 (1)

- Celtic Line Drawing - Simplified InstructionsFrom EverandCeltic Line Drawing - Simplified InstructionsRating: 5 out of 5 stars5/5 (4)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestFrom EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestRating: 5 out of 5 stars5/5 (2)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Tunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!From EverandTunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Rating: 5 out of 5 stars5/5 (3)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!From EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Rating: 3 out of 5 stars3/5 (2)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreFrom EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreRating: 4.5 out of 5 stars4.5/5 (3)

- Creative Watercolor: A Step-by-Step Guide for BeginnersFrom EverandCreative Watercolor: A Step-by-Step Guide for BeginnersRating: 4 out of 5 stars4/5 (8)

- Knit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyFrom EverandKnit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyRating: 4.5 out of 5 stars4.5/5 (2)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)