Professional Documents

Culture Documents

CCAI

Uploaded by

Vito DigeoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CCAI

Uploaded by

Vito DigeoCopyright:

Available Formats

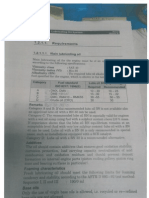

CCAI RELATED BUNKER PROBLEMS.

In these days oI burning residual Iuels in our ships, various types oI Iuel related problems

occur.

These can, while being evident, be a considerable pain in the neck` Ior the engine crew

and Ior the operator oI the vessel.

Hence, the measures to be taken Irom the owner`s side to avoid these hick-ups are to

speciIy as appropriate as possible the grade oI Iuel required Ior his` engine.

And in case oI a dispute, to be a subscriber to a recognised Iuel analysing scheme.

Sampling procedures Ior received Iuel should be accepted by all involved parties.

Let us dwell Ior a moment on the issue oI ordering bunkers and the speciIication that

normally is submitted to ensure the correct grade is received on board.

A number oI parameters are normally mentioned, such as; density max, viscosity max,

sulphur max, pour point etc.

There is however a parameter rarely being mentioned in these speciIications and that is

the CCAI, Calculated Carbon Aromaticity Index, which gives a value on the Ignition

Quality Ior residual Iuels, since these grades cannot be veriIied by methods used Ior

distillates, i.e. Diesel Index, Cetane Index and Cetane Number.

Accepted method Ior determination oI the ignition quality oI residual Iuels is currently

not available.

It has, however, been empirically established that there is a relationship between the

density, the viscosity and the ignition perIormance and the Shell-developed CCAI is the

one presently most accepted Ior indicating ignition delay, although there is also a BP-

developed Calculated Ignition Index (CII).

CCAI gives an idea oI how much the ignition is delayed, the higher the index, the longer

the delay.

The CCAI can be determined, with limited accuracy, by the enclosed nomogram AAAA

The combustion starts with a short delay already when a small amount oI the Iuel has

been injected and thereIore the remaining quantity injected burns in a controlled manner.

II, however, the delay is long, a large amount is injected beIore the combustion starts,

producing a quick and violent raise oI pressure. This produces the characteristic 'diesel

knock.

The problem is generally related to medium speed diesel engines when burning blended

Iuels less than 220 cSt. and problems seems to appear in the CCAI-span 850-890.

See enclosed diagram BBBB

II it is required (necessary) to operate the engine within this span the stresses on the

engine components might increase considerably and special attention should be paid to:

Connecting rod big-end and bearing shells.

Main bearing shells

Pistons(particularly composite pistons)

Piston rings and liners

Cylinder head with studs and gaskets

Tie bolts

Intake and exhaust valves

To alleviate the eIIect oI the ignition delay, the ambition should be to keep the engine

load within 50 - 85 and to maintain the inlet air temperature as high as practically

possible and through pre-heating prior start-up(the CCAI problems are accentuated on a

cooler engine, hence a known scenario is the vessel makes it to port but the engine can

not be restarted upon departure due to Iouled/clogged piston rings, poppet valves and

turbocharger).

With the violent increase oI combustion pressure, when operating on Iuels delaying the

ignition, the rate oI blow-by will increase and it goes without saying that the lub.oil

quality must be optimal to cope with the additional load imposed on the bearings.

So, by way oI conclusion, iI the shipowner is operating engines which are sensitive to

ignition quality he would be wise to order Iuels with a CCAI limit or to set density and

viscosity limits which will control the CCAI.

Special care to CCAI is needed when a ship is Iorced to use low viscosity Iuels (below

180 cSt), due to heating limitations. II the density oI these Iuels is high the CCAI will be

too high and ignition problems may be encountered.

990204/KA

You might also like

- Fuel Oil PresentationDocument43 pagesFuel Oil PresentationBhupender Ramchandani100% (1)

- 2011 - Fuel Quality Guide-Ignition and CombustionDocument27 pages2011 - Fuel Quality Guide-Ignition and CombustionaleventNo ratings yet

- MEO Class 2 Misc Info PDFDocument17 pagesMEO Class 2 Misc Info PDFrajishrrrNo ratings yet

- Temperature Pressure Ls Diesel EnginesDocument8 pagesTemperature Pressure Ls Diesel EnginesCvita CvitićNo ratings yet

- THE ROLE OF TEMPERATURE AND PRESSURE IN WEAR PROCESSESDocument8 pagesTHE ROLE OF TEMPERATURE AND PRESSURE IN WEAR PROCESSESПетрNo ratings yet

- Operation On Heavy Residual Fuels 19992672Document9 pagesOperation On Heavy Residual Fuels 19992672hpss77No ratings yet

- Vacuum Hardening HssDocument6 pagesVacuum Hardening Hssharanus2000No ratings yet

- Cylinder Lubrication Timed InjectionDocument6 pagesCylinder Lubrication Timed Injectionapi-3701567No ratings yet

- Oil Tank InstallationDocument16 pagesOil Tank InstallationGabriel MontaniNo ratings yet

- TB001-MCLs For ECA Operation Feb 15-V1Document4 pagesTB001-MCLs For ECA Operation Feb 15-V1magadali7814No ratings yet

- Troubleshoot FCC Catalyst LossesDocument6 pagesTroubleshoot FCC Catalyst LossesAli IzadbakhshNo ratings yet

- Slide Fuel Valves Reduce EmissionsDocument5 pagesSlide Fuel Valves Reduce EmissionsParthiban NagarajanNo ratings yet

- Operation On Low-Sulphur Fuels-KEADocument24 pagesOperation On Low-Sulphur Fuels-KEAPaul CraciuneanuNo ratings yet

- Diesel Engines & Gas TurbinesDocument13 pagesDiesel Engines & Gas TurbinesPriscila KImNo ratings yet

- 07 Fuel Oil SystemsDocument54 pages07 Fuel Oil SystemsBabu Aravind100% (1)

- Soot Deposits and Fires in Exhaust Gas Boilers: MAN DieselDocument28 pagesSoot Deposits and Fires in Exhaust Gas Boilers: MAN Dieselvran77No ratings yet

- Volume IDocument241 pagesVolume IEduardo Casarrubias VillanuevaNo ratings yet

- Avoiding Diesel Engine Overload-1 PDFDocument3 pagesAvoiding Diesel Engine Overload-1 PDFsfekhanNo ratings yet

- Selecting The Right Cargo Containment System: Webinar Q&A SummaryDocument12 pagesSelecting The Right Cargo Containment System: Webinar Q&A Summaryengkos koswaraNo ratings yet

- sl2022 726Document13 pagessl2022 726Budi SetiawanNo ratings yet

- Crude Oil WashingDocument3 pagesCrude Oil Washingbrendanrodrigues75% (8)

- Diesel Engines and Gas Turbines in Cruise Vessel PropulsionDocument13 pagesDiesel Engines and Gas Turbines in Cruise Vessel PropulsionFuchsbauNo ratings yet

- Wear Procces DieselsDocument6 pagesWear Procces Dieselsargentum19619692No ratings yet

- GHHDocument3 pagesGHHeldiego1790No ratings yet

- GGHJKDocument8 pagesGGHJKnopibotakNo ratings yet

- Marine Fuel Oil, Its Iso Standard, Analysis and Corrective ActionDocument151 pagesMarine Fuel Oil, Its Iso Standard, Analysis and Corrective ActionMariyath Muraleedharan KiranNo ratings yet

- C20R Optimized Start Technique For C20 and C20RDocument4 pagesC20R Optimized Start Technique For C20 and C20REstevamNo ratings yet

- Stuffing Box Drain MAN B&WDocument2 pagesStuffing Box Drain MAN B&Wabhijit_11100% (5)

- Scrubber Retrofit - IMO 2020 0.5% Sulphur Limit RequirementsDocument4 pagesScrubber Retrofit - IMO 2020 0.5% Sulphur Limit RequirementsSPYROS KALOGERASNo ratings yet

- Operation On Low Sulphur FuelsDocument24 pagesOperation On Low Sulphur FuelsAlejandro Jose Malave RamosNo ratings yet

- Cylinder Liner Cold Corrosion ControlDocument8 pagesCylinder Liner Cold Corrosion ControlarunNo ratings yet

- Guidelines For Fuels and Lubes PurchasingDocument24 pagesGuidelines For Fuels and Lubes PurchasingFuchsbauNo ratings yet

- Siemens Gas Turbine SGT 500 Crude OilDocument10 pagesSiemens Gas Turbine SGT 500 Crude Oilgeverett2765No ratings yet

- Feature: Vlsfos - The Concerning Fuel Management Issues So Far...Document6 pagesFeature: Vlsfos - The Concerning Fuel Management Issues So Far...romeo del rosarioNo ratings yet

- SL2005 452Document5 pagesSL2005 452Nick VoulgarisNo ratings yet

- Marine Operations Notes Part 2Document32 pagesMarine Operations Notes Part 2Ekiyo PiusNo ratings yet

- Article - Delayed Coker RevampsDocument13 pagesArticle - Delayed Coker RevampsPlatinium1002No ratings yet

- CIMAC WG7 2015 01 Guideline Cold Flow Properties Marine Fuel Oils FinalDocument9 pagesCIMAC WG7 2015 01 Guideline Cold Flow Properties Marine Fuel Oils FinalKowalski KrzysztofNo ratings yet

- Fuel Oil Quality Testing with API Gravity, BSW, and ColorDocument3 pagesFuel Oil Quality Testing with API Gravity, BSW, and ColorThomas KerlNo ratings yet

- Understanding in Situ Combustion: Schlumberger: Heavy OilDocument2 pagesUnderstanding in Situ Combustion: Schlumberger: Heavy OilRaviAnandNo ratings yet

- Crude Oil Washing and Heating PolicyDocument6 pagesCrude Oil Washing and Heating PolicyGuss Kontarakis100% (1)

- CCAIDocument0 pagesCCAIshishir4870No ratings yet

- Answer:-Repeat QuestionDocument13 pagesAnswer:-Repeat Questionsumitsinha89No ratings yet

- Distillation Characteristics of Petroleum DieselDocument30 pagesDistillation Characteristics of Petroleum DieselT Richie100% (2)

- MAN Diesel and Turbo SL2014-571 PDFDocument20 pagesMAN Diesel and Turbo SL2014-571 PDFparamjyot_sabharwal0% (1)

- tsb10 20 02Document2 pagestsb10 20 02guillermo1serranoNo ratings yet

- Bop Closure TimeDocument2 pagesBop Closure TimeJuanNo ratings yet

- Bunkering Operation CriticalDocument29 pagesBunkering Operation CriticalVikasYadavNo ratings yet

- Flash Points and Volatility Characteristics of Gasoline/diesel BlendsDocument10 pagesFlash Points and Volatility Characteristics of Gasoline/diesel BlendskhalidNo ratings yet

- SPE 150495 Worldwide Drill-Stem-Testing Experiences in Heavy and Viscous-Oil Offshore Environments That Improve Operational EfficiencyDocument9 pagesSPE 150495 Worldwide Drill-Stem-Testing Experiences in Heavy and Viscous-Oil Offshore Environments That Improve Operational Efficiencychris_glezzNo ratings yet

- B&W Cylinder Oil Feed RateDocument12 pagesB&W Cylinder Oil Feed Rateig_yo67% (3)

- Motor 1Document46 pagesMotor 1Ganesh Anand100% (1)

- Low Sulfur Fuel Impacts Marine IndustryDocument5 pagesLow Sulfur Fuel Impacts Marine IndustryHendrik ATsmaNo ratings yet

- Operation On Low-Sulphur FuelsDocument14 pagesOperation On Low-Sulphur Fuelsgiannis2No ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- CNSK - Pocket Fits06-Fits and ClearancesDocument15 pagesCNSK - Pocket Fits06-Fits and Clearancesswamymk100% (1)

- NRF Boxcooler Installation Manual PDFDocument22 pagesNRF Boxcooler Installation Manual PDFVito DigeoNo ratings yet

- Challenge of Stern Tube Bearings and Seals)Document6 pagesChallenge of Stern Tube Bearings and Seals)Vito DigeoNo ratings yet

- Marine Bearing Installation Manual A4Document64 pagesMarine Bearing Installation Manual A4mkm123100% (1)

- Hatz 1D Operators ManualDocument120 pagesHatz 1D Operators ManualVito DigeoNo ratings yet

- L16-24 Gen Sets 2008 UpgradeDocument4 pagesL16-24 Gen Sets 2008 UpgradeVito DigeoNo ratings yet

- Hatz 1D Repair ManualDocument193 pagesHatz 1D Repair ManualVito Digeo91% (22)

- NRF Boxcooler Installation Manual PDFDocument22 pagesNRF Boxcooler Installation Manual PDFVito DigeoNo ratings yet

- HZTL455311P0020 enDocument20 pagesHZTL455311P0020 enVito DigeoNo ratings yet

- Coops Nieborg Gantry Crane ManualDocument26 pagesCoops Nieborg Gantry Crane ManualVito Digeo0% (1)

- Guidelines For Inspection of Hull WeldsDocument110 pagesGuidelines For Inspection of Hull WeldsVito DigeoNo ratings yet

- Coatings Industrial Maintenance GuideDocument11 pagesCoatings Industrial Maintenance GuideVito DigeoNo ratings yet

- Dnvps Line Sampler: (Marpol Annex Vi-Compliant)Document6 pagesDnvps Line Sampler: (Marpol Annex Vi-Compliant)dassi99No ratings yet

- Shaft Alignment GN E-Feb14Document122 pagesShaft Alignment GN E-Feb14supriadi90315No ratings yet

- Handbook Conical MountingsDocument28 pagesHandbook Conical MountingsVito DigeoNo ratings yet

- Damen ASD Tug 2810Document36 pagesDamen ASD Tug 2810Vito Digeo100% (2)

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- AvK Project GuideDocument12 pagesAvK Project GuideVito DigeoNo ratings yet

- Wartsila 26 Lubricating SystemDocument25 pagesWartsila 26 Lubricating SystemVito DigeoNo ratings yet

- Wartsila SR RT82 Distillate Fuel UseDocument11 pagesWartsila SR RT82 Distillate Fuel UseVito DigeoNo ratings yet

- Towage Guidance NotesDocument8 pagesTowage Guidance NotesVito DigeoNo ratings yet

- Fuel Oil QualityDocument2 pagesFuel Oil QualityAmit BaruaNo ratings yet

- Bearings For Longer Shaft LifeDocument3 pagesBearings For Longer Shaft LifeVito Digeo100% (1)

- Anchor Handling Manual MSFDocument45 pagesAnchor Handling Manual MSFfeghuolhakim100% (4)

- Wartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesWartsila TB 2stroke Troubleshooting & Maintenance On Injection Control UnitVito Digeo100% (2)

- MaK M 32 C Low Emission EngineDocument12 pagesMaK M 32 C Low Emission EngineJenniferValleNo ratings yet

- Regulations KIEL CANALDocument76 pagesRegulations KIEL CANALdivermarinerNo ratings yet

- 5 Towing Techniques: CRV Crew Training Manual 66 January 2010Document40 pages5 Towing Techniques: CRV Crew Training Manual 66 January 2010Irdam Jono100% (5)

- Important info for Heliodyssey 2019 solar eclipse expeditionDocument8 pagesImportant info for Heliodyssey 2019 solar eclipse expeditionTusshar SharmaNo ratings yet

- Soft Ground NATM Methods ExplainedDocument9 pagesSoft Ground NATM Methods Explainedmilan_popovic_2No ratings yet

- Numerical Analysis of Nonlinear Pulse Propagation in Optical Fiber (35Document107 pagesNumerical Analysis of Nonlinear Pulse Propagation in Optical Fiber (35MuhammadMazidNo ratings yet

- Vacuum Coating of Plastic OpticsDocument15 pagesVacuum Coating of Plastic OpticsSasiKumar PetchiappanNo ratings yet

- Fase 4 Edgar DiazDocument9 pagesFase 4 Edgar DiazedgarNo ratings yet

- Class 12 Chapterwise PYQs Shobhit NirwanDocument65 pagesClass 12 Chapterwise PYQs Shobhit NirwanHimanshu92% (13)

- Glass Evidence: by The End of This Chapter You Will Be Able ToDocument15 pagesGlass Evidence: by The End of This Chapter You Will Be Able ToArundeep Singh100% (1)

- Chapter 10 Light Refraction Part 2Document18 pagesChapter 10 Light Refraction Part 2The ProgenitorNo ratings yet

- Physical and Chemical Properties of Dental MaterialsDocument50 pagesPhysical and Chemical Properties of Dental MaterialsGyan AbhishekNo ratings yet

- Testing Fso WDM Communication System in Simulation Software Optiwave Optisystem in Different Atmospheric EnvironmentsDocument12 pagesTesting Fso WDM Communication System in Simulation Software Optiwave Optisystem in Different Atmospheric EnvironmentsNguyễn NhungNo ratings yet

- High-Contrast and Compact Integrated Wavelength Diplexer Based On Subwavelength Grating Anisotropic Metamaterial For 1550-2000-nmDocument11 pagesHigh-Contrast and Compact Integrated Wavelength Diplexer Based On Subwavelength Grating Anisotropic Metamaterial For 1550-2000-nmPaola GongoraNo ratings yet

- 2.9.31. Particle Size Analysis by Laser Light DiffractionDocument5 pages2.9.31. Particle Size Analysis by Laser Light DiffractionPablo ParraNo ratings yet

- BERE1013 Lab 5 - Snell's Law 1.0Document10 pagesBERE1013 Lab 5 - Snell's Law 1.0Aina BalqisNo ratings yet

- Mark Scheme (Results) January 2012: International GCSE Physics (4PH0) Paper 1P Science Double Award (4SC0) Paper 1PDocument20 pagesMark Scheme (Results) January 2012: International GCSE Physics (4PH0) Paper 1P Science Double Award (4SC0) Paper 1PSusskindNo ratings yet

- Verification of Snell's LawDocument2 pagesVerification of Snell's Lawphydotsi100% (4)

- Prisms A Level PDFDocument28 pagesPrisms A Level PDFJeremiah NakibingeNo ratings yet

- Analysis of Glass - Glass EvidenceDocument40 pagesAnalysis of Glass - Glass EvidenceCebotarenco TamaraNo ratings yet

- Ray Optics and Optical Instruments: Very Short Answer Type QuestionsDocument5 pagesRay Optics and Optical Instruments: Very Short Answer Type QuestionsAvni RaghavNo ratings yet

- Bending Light Remote Lab: Understand Refraction & DispersionDocument3 pagesBending Light Remote Lab: Understand Refraction & DispersionLovefrin sijabatNo ratings yet

- Refraction of Light Refractive Index: W.R.T. Medium (1) Is Called It's Relative Refractive Index I.EDocument18 pagesRefraction of Light Refractive Index: W.R.T. Medium (1) Is Called It's Relative Refractive Index I.ES YashaswiniNo ratings yet

- 05.optical Properties 1Document11 pages05.optical Properties 1Salman TareqNo ratings yet

- Sound Light Heat and TempDocument40 pagesSound Light Heat and TempJ3sterNo ratings yet

- Beee201l Electronic-Materials TH 1.0 65 Beee201lDocument3 pagesBeee201l Electronic-Materials TH 1.0 65 Beee201lwgjsesotxjxzosyxjpNo ratings yet

- Ray Optics and Optical InstrumentsDocument51 pagesRay Optics and Optical Instrumentsrajputrishi1982No ratings yet

- Totorials Unit1,2Document6 pagesTotorials Unit1,2Tharun RagavNo ratings yet

- D1747 PDFDocument4 pagesD1747 PDFMahmoud FlefilNo ratings yet

- Chapter 10 - LightDocument35 pagesChapter 10 - LightMadhanNo ratings yet

- Polymer Optical PropertiesDocument179 pagesPolymer Optical PropertiesScot FrankNo ratings yet

- 12 Phy. N Ch. 9Document5 pages12 Phy. N Ch. 9Serious LearningNo ratings yet

- Two Types of Light ReflectionDocument48 pagesTwo Types of Light ReflectiondarwishmajidNo ratings yet