Professional Documents

Culture Documents

Hydrate and Dehydration

Uploaded by

Olvis GuillenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrate and Dehydration

Uploaded by

Olvis GuillenCopyright:

Available Formats

Gas Dehydration System

Suryas Year 2003 PMP Diversity Action Plan Agreement

ChevronTexaco Indonesian Business Unit

PT. Caltex Pacific Indonesia

Bekasap Operation GO&RT Team

August 2003

Gas Dehydration System

References: 1. John M. Cambells Gas Conditioning and Processing and Processing, Vol.2: The Equipment

Modules

2.

Maurice Stewards and Ken Arnolds Surface Production Operations Design of Gas Handling Systems and Facilities, 2nd Edition. E.Dendy Sloan, Jrs Hydrate Engineering, Monograph Volume 21 SPE Hendry L.Doherty Series

3.

August 2003

Gas Dehydration System

PT. Caltex Pacific Indonesia Bekasap GO&RT Typical Gas Plants

August 2003

Gas Dehydration System

Typical Gas Plant

METERING SKID

GLYCOL REGENERATION SYSTEM HP HEADER GLYCOL CONTACTOR HP-GAS SEPARATOR COOLER

MP HEADER

MP-GAS SEPARATOR

MP-GAS COMPRESSOR

August 2003

Gas Dehydration System

Typical Gas Plant

G/G HE INLET GAS 3 PHASE SEPARATOR CHILLER STEAM

REFRIGERANT

HC VAPOR

TO BUYER COND. FLASH TANK

RICH GLYCOL COMPRESSOR LEAN-RICH EXCHANGER REBOILER

FILTER LEAN GLYCOL

SURGE TANK

PUMP

August 2003

Gas Dehydration System

What factors influence gas quality?

Gas quality closely relates to the following parameters: 1. Saturated water content in lb/MMscfd 2. Free liquid content 3. Heat value in Btu/Scf 4. CO2 content in mol 5. Inert substance content in mol 6. H2S content in ppm 7. Oxygen content in %

August 2003

Gas Dehydration System

Hydrate and Dehydration

August 2003

Gas Dehydration System

Hydrate is solid water compound developed on a process flow

Hydrate forms in two fundamental ways:

1. 2. Slow cooling of a fluid as in a pipeline, or Rapid cooling caused by depressurization across valves or through a turbo expander

Three conditions promote hydrate formation in process:

1. 2. 3. Presence of free water from reservoir or pipeline condensation and natural gas components. Presence of sufficiently low temperature on the process stream Presence of sufficiently high pressure on the process steam

August 2003

Gas Dehydration System

Hydrate formation prevention can be accomplished through: 1. Water removal.

Separation will remove free water from gas stream.

2.

3. 4.

Maintaining of process high temperature

Pipe insulation and bundling, or steam or electrical heating process

System Pressure Decreasing

High temperature system pressure drops design through line choking.

Alcohol Inhibitors injection

Acting as antifreezes, alcohols will decrease hydrate formation temperature below operating temperature

5.

6.

Kinetic (Polymer dissolved in solvent) Inhibitors

It will bond on the hydrate surface to prevent crystal growth.

Antiagglomerants

This dispersants will cause water phase be suspended as small droplets in oil or condensate.

August 2003

Gas Dehydration System

Hydrate formation can be found on the following section of gas system: 1. Gas wells.

High reservoir temperature will prevent hydrate formation. However, abnormalities may arise during drilling, testing or shut-in/startup of a well.

2.

Gas pipelines

Pipeline maintained pressure above hydrate formation pressure and temperature below hydrate formation temperature will prevent hydration formation.

3.

Gas Processing Facilities

There are three reasons why we need gas processing facilities: 3.1. Requirement for water, gas and oil separation 3.2. Dehydrate gas into acceptable water content 3.3. Compression of gas for transportation. It is important to notice that water separation and gas dehydration are vital for hydrate prevention as they will help maintain insufficient water content on the gas for hydration formation.

August 2003

Gas Dehydration System

In gas processing facilities, Hydrate formation can be found on the following sections: 1. Low lying equipment points

such as pipeline lying under a roadway

2.

3. 4.

Points of gas expansion

Downstream of valves, expanders and other similar equipment

Points of flow obstruction

such as screens preceding heat exchangers

Points of Change in flow direction

such as pipe elbows

As a rule of thumb, Hydrate will form in a natural gas system in free water

is available and system pressure is above 166 psig at 39 oF, which indicates: 1. Gas drying or inhibitor is required for temperature approaching 39 oF 2. A more accurate hydrate estimation procedure is required

August 2003

Gas Dehydration System

Hydrate Formation Points

PC C B Dehydrator or Inhibitor Injection D

PC GATHERING SYSTEM E F Fuel to heater or Engine

A well GAS

Dehydrator or Inhibitor Injection

J Valve

Compressor PROCESSING PLANT

Chiller Condensate

August 2003

Gas Dehydration System

When we have a pipeline partial or complete blockage, questions arisen,

among others, are (1) where is the plug? (2) is the blockage composed of hydrates, paraffin, scale, sand or some combination of these?

Indication of blockage composition can be found through combination of

separators contents and pigs returns, which can provide line solids information such as hydrates, wax, scale and sand.

How to detect pipeline blockage? 1. Pigging returns can indicate implicit hydrate as hydrate can flow with

oil/condensate.

2. 3. 4. 5.

Lack of hydrate blockage does not mean lack of hydrate! Always examine pigging returns for the best hydrate indication! Changes in fluid rates or composition at separator - Separator water arrival decline indicates separators upstream hydrate Line Differential Pressure Increase indicates Line Hydration Formation Thermo-camera Gamma-ray Densitometer with Temperature Sensor

August 2003

Gas Dehydration System

Hydrate Formation Conditions by Gas-Gravity Methods

Gas Molecule weight ratio can be used to determine hydrate formation temperature and pressure. (from page 11 of SPE book, figure 2.8)

Knowing gas gravity and the lowest temperature of the process/pipeline, we can read the hydrate formation pressure at the gas gravity and temperature. To the left of every line, hydrates form with a gas of that gravity, while for pressure and temperature to the right of the line, system is hydrate-free.

August 2003

Gas Dehydration System

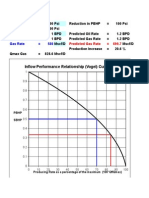

Hydrate Formation Conditions by Gas-Gravity Methods, an example

Find the pressure are which a gas composed of 92.67 mol% metahen, 5.29% ethane, 1.38% propane, 0.182% I-butane, 0.338% n-butane, and 0.14% pentane froms hydrate with free water at 50oF Solusion: Gas gravity is 0.603 = Mg (gas mole weight) / M air = 17.47/28.96 = 0.603 From the gas gravity table, gas gravity 0.603 in temperature of 50oF, hydrate pressure is around 450 psig.

Gas Gravity Chart

Molecule Mole Fraction yi 0.9267 0.0529 0.0138 0.0018 0.0034 0.0014 1.0000 Fraction Molecular Molecular Weight Weight in M Mixture yiM 16.0430 14.8670 30.0700 1.5907 44.0970 0.6085 58.1240 0.1058 58.1240 0.1965 72.1510 0.1010 Average Molecular Weight is 17.4700

Methane Ethane Prophane I-butane n-butane Pentane Total

A thing to remember is that the value is only approximation. However, it can be used to determine whether hydrate is potential to form or not in a system based on the data.

August 2003

Gas Dehydration System

Will hydrate form in my pipeline?

Knowing composition of the stream, hydrate formation temperature can be predicted using hydrate equilibrium constants in which, SUM(Yn/Kn) = 1 Where

Yn = mol fraction of hydrocarbon component n Kn = vapor solid equilibrium of component n

Kn itself can be derived from Kn = (Yn/Xn)

Xn = mol fraction of hydrocarbon component in the solid Kn value of various gas components can be taken from the charts of the following slides

Steps for determining hydrate temperature at a give pressure can be summarized; 1. Assume a hydrate formation temperature 2. Determine Kn for each component 3. Calculate Yn/Kn for each component and sum them 4. Repeat step 1-3 with other assumed temperature until getting total Yn/Kn value = 1

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

Condensation of Water Vapor

Temperature at which water condenses from natural gas is called its dew point. If a gas is saturated with water vapor, it is, then, at its dew point. Amount of water vapor saturated in a gas can be checked from the next page chart. For example, at 150 oF and 3000 psi, saturated gas will contain approximately 105 lb of water vapor per MMscf of gas. If there is less water vapor, the gas is not saturated and its temperature can be reduced without water condensing. If the gas is saturated at a higher temperature and ten cooled to 150 oF, water will condense until there are only 105 lb of water vapor left on the gas.

August 2003

Gas Dehydration System

Water content

T e m p

August 2003

pressure

Gas Dehydration System

Dehydration is the of removing water from a gas and/or liquid to

eliminate free water on the process system. Inhibition is the process of adding chemical to the condensed water to stimulate hydrate formation.

Why should water be removed from the system?

Because free water can form hydrate and stimulate corrosion

Natural gas is dehydrated in one of the following methods: 1. Absorption Glycol dehydration

usually used to meet pipeline specification and field requirement

2. Adsorption

Mol Sieve, Silica Gel or Activated Alumina

used to obtain very low water content in NGL extraction and LNG plant

3. Condensation Refrigeration with Glycol or Methanol injection

usually used in transportation pipeline

August 2003

Gas Dehydration System

Four types of glycol are used for dehydration and/or inhibition

1. 2. 3. 4. Monoethilene glycol (MEG or EG) Diethylene glycol (DEG) Triethylene glycol (TEG) Tetraethylene glycol (TREG)

Glycol to be used in absorption must satisfy the following requirements:

1. 2. 3. 4. 5. 6. Hygroscopic, having an affinity to water Non corrosive Non-volatile, Easily regenerated to high concentrations, Insoluble in liquid hydrocarbons Non-reactive with hydrocarbon, CO2 and sulfur compounds

August 2003

Gas Dehydration System

Distinguishable parameters among glycol types

Ethylene Glycol

Molecular Weight Specific Gravity @ 77 F Boiling point @ 1 atm, F Freezing Point, F Viscosity, cP, @ 77 F Specific Heat @ 77 F Vapor pressure, psia @77 F Decomposition temperature, F 62.07 1.110 387.3 7.9 16.9 0.58 < 0.1 329

Diethylene Glycol

106.12 1.111 473.8 16.4 25.3 0.55 < 0.01 328

Triethylene Glycol

150.17 1.120 550.0 19 39.4 0.52 < 0.01 404

August 2003

Gas Dehydration System

Glycol Dehydration System

August 2003

Gas Dehydration System

TC DRY GAS OUT WATER VAPOR & OFF-GAS TO ATM OR INCINERATOR

TC LC

OUTLET SCRUBBER

LEAN TEG COOLER TEG PUMP TO TEG SUMP LEAN TEG SURGE TANK LEAN/RICH TEG EXCHANGER FLASHED VAPOR TO FUEL OR FLARE (LEAN TEG) REBOILER

GLYCOL CONTACTOR

PC

LC

FLASH DRUM

LC

WET GAS IN

LC

TO HC DRAIN

LC INLET SEPARATOR CARBON FILTERS SOCK FILTERS TO HC DRAIN

August 2003

Typical Glycol Regeneration System

(RICH TEG)

Gas Dehydration System

Wet gas, free of liquid water, enters bottom of contactor and flows countercurrent to glycol. Glycol-gas contacts occurs on trays or packing where glycol absorbs water from gas, leaving the dried gas flow upward to the top of the contactor while the lean glycol enriched with absorbed water leaves the contactor through the bottom line of the contactor.

Rich glycol, leaving the contractor will flow to a reflux condenser at the top of the still column and, then, to a flash tank where the entrained and soluble (volatile) components are vaporized.

Leaving the flash drum, the rich glycol will flow through glycol carbon filters before being heated in lean-rich exchanger from which it flows to still column for water distillation. The distillation process in still column and reboiler is the true glycol re-concentration media, i.e, the parts where rich glycol be turned to rich glycol.

August 2003

Gas Dehydration System

To properly absorbs gas water content in contactor (knowing how much water to absorb from incoming gas), gas system personnel needs to know:

1. Minimum concentration of lean glycol entering the contactor 2. Lean glycol rate required to pick up water from the gas

The higher glycol concentration, the higher water removal rate be The higher glycol circulation rate, the higher water removal rate be

As the concentration of lean glycol entering the contactor is a predefined value, then, things to calculate is only the lean glycol rate required to pick up water from gas. Approximation of the glycol circulation rate can be obtained by knowing (1)

lean glycol concentration, (2) entering gas water content and (3) outgoing gas water content

Combined with the use of the following approximation chart to get the circulation rate in liters TEG/kg water or in gallon TEG/ lb water.

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

Example: Find circulation rate of 98.7 wt % lean TEG required to dry 106 std m3/d (35.4 MMscfd) of gas at 7 Mpa (1000 psia) and 40 oC (104 oF) to achieve an exit gas water content of 117 kg/ 106 std m3(7 lbm/MMscf) if the incoming gas water content is 110 kg/ 106 std m3(68.5 lbm/MMscf) Solution#1 Water removal = (Win-Wout)/Win = (1100-117)/1100 = 0.894 From the chart, at 98.7 wt % TEG, the rate is around 35 liters TEG/kg

water

Solution#2 Water removal = (Win-Wout)/Win = (68.5-7)/68.5 = 0.898 From the chart, at 98.7 wt % TEG, the rate is around 4.4 gal TEG/lb water

August 2003

Gas Dehydration System

TEG Regeneration

August 2003

Gas Dehydration System

TC DRY GAS OUT WATER VAPOR & OFF-GAS TO ATM OR INCINERATOR

TC LC

OUTLET SCRUBBER

LEAN TEG COOLER TEG PUMP TO TEG SUMP LEAN TEG SURGE TANK LEAN/RICH TEG EXCHANGER FLASHED VAPOR TO FUEL OR FLARE (LEAN TEG) REBOILER

GLYCOL CONTACTOR

PC

LC

FLASH DRUM

LC

WET GAS IN

LC

TO HC DRAIN

LC INLET SEPARATOR CARBON FILTERS SOCK FILTERS TO HC DRAIN

August 2003

Typical Glycol Regeneration System

(RICH TEG)

Gas Dehydration System

Regeneration system consists of a reboiler, still column and a gas stripping column. Lean glycol concentration is controlled with adjustment of reboiler temperature, pressure and possible use of a stripping gas, while Concentration of rich glycol leaving a contactor can be calculated with : %wt of rich TEG = (j.(%wt of lean TEG))/(j + (1/CR))

Where is equal to 1.12 kg/lt or 9.3 lb/gal

One thing to notice is that, whatever rich glycol concentration flown to an atmospheric pressure glycol regeneration system, in no stripping gas, the lean glycol concentration will be: * 98.1 wt % if the reboiler temperature is maintained 128 oC or 360 oF * 98.4 wt % if the reboiler temperature is maintained 193 oC or 380 oF * 98.7 wt % if the reboiler temperature is maintained 204 oC or 400 oF. One other thing to notice is than 20 oF reboiler increase of decrease will cause the lean glycol wt % increase or decrease by 0.3 wt %, however NEVER let temperature exceeds 400 oF.

For stripping gas usage, the lean glycol wt % can be approximated with the following chart (figure 18.12 JMC page 359)

August 2003

Gas Dehydration System

August 2003

Gas Dehydration System

Still column is the fractionator portion of the regenerator in which rich glycol is fractionated to some portions of water vapour, and lean glycol fractions. Flash Drum is used to remove light hydrocarbons, CO2 and/or H2S absorbed or entrained with glycol, and to separate liquid hydrocarbons from glycol to prevent it from entering the reboiler and causing fouling and foaming. Notwithstanding that flash drum should not contain liquid hydrocarbon, sometimes, we may find it there. Consequently, it is wise to have some kinds of skimmer to separate liquid condensate from rich glycol. Filters in the regeneration system is used to reduce solids from rich glycol

to about 100 ppm which will reduce corrosion, plugging and solid deposits in the reboiler and may reduce foaming losses.

Filters effectiveness can be checked through differential pressure inspection. As it reaches 25 psi, it needs replacement.

August 2003

Gas Dehydration System

Lean-Rich Glycol Heat Exchanger is designed to have lean glycol exchanger outgoing temperature of around 60 65 oC. Reboiler is the actual location of regeneration kitchen in which heat source, such as hot oil, steam or electrical resistance heater, is usually direct fired with fire tubes immersed in a glycol bath. Surge tank is installed in regeneration system to give at least 20 minutes retention times between pumpings with sufficient volume to accept glycol drained from the reboiler to allow repair or inspection of fire tube or heating coil. Glycol Circulating Pump is installed to provide flexibility to increase glycol circulation rate to meet dew-point requirements Types of pumps to use in this function can be reciprocating multiplex type with conservative slow piston speed. Lean Glycol Cooler is designed to have temperature of the lean glycol entering the top of contactor be within 5-10 oC.

August 2003

Gas Dehydration System

One thing that must be made sure in glycol dehydration system is that whatever gas fed to the contactor should have been free of liquid hydrocarbons, liquid water, solids, corrosion inhibitor, etc, i.e, gas must be sufficiently clean and free of liquid before dehydrated. It is wise to make sure that gas planned to be glycol dehydrated be flown to a separator or to a slug catcher before being flown to contactor.

Other important thing to remember is that glycol must be free of nonvolatile contaminant such as salt or hydrocarbon. Salt can cause plugging which increases pressure drops and flow rate in regeneration parts such as reboiler, still column and exchangers. In addition to causing things caused by salt, hydrocarbon can stimulate foaming in contactor and cause filters damage.

August 2003

Gas Dehydration System

How much glycol is required?

August 2003

Gas Dehydration System

Estimation of Hydrate Inhibitors Needed in Free-Water phase

Gas gravity chart described before may be combined with Hammerschmidth equation to estimate hydrate depression temperature for several inhibitors: dT = CIWI /(MI (100-WI)) Where dT = hydrate depression, (Teq Top), oF at the pressure CI = constant for particular inhibitor (2 for MEG) WI = weight % of inhibitor in the liquid MI = molecular weight of inhibitor (62 for MEG)

This equation is usable to determine amount of inhibitor to prevent hydrate formation with great accuracy

August 2003

Gas Dehydration System

Estimation of Hydrate Inhibitors Needed in Pipeline

Three considerations must be analyzed before injecting inhibitors to pipelines 1. Amount of inhibitors in free-water phase 2. Amount of inhibitor lost to gas phase 3. Amount of inhibitor lost to condensate phase Rule of thumb : For long pipelines approaching ocean, bottom temperature of 39 oF, the lowest water content can be tabulated

Gas Water Content at 39 oF

Pipe pressure, psia water content, lbm/MMscfd 500 15 1000 9 1500 7 2000 5.5

Rule of thumb : At 39 oF, and pressure greater than 1000 psia, the maximum amount of MEG lost to the gas is 0.02 lbm/MMscfd.

August 2003

Gas Dehydration System

Rules of Thumb

August 2003

Gas Dehydration System

1. At 39 oF, hydrates will form in anural gas system if free water is available and the pressure is greater than 166 psig.

2.

3.

It is always better to expand a dehydrated gas than a moist gas to prevent hydrate formation

Where drying is not a possibility, it is always better to take a large pressure drop at a process condition where the inlet temperature is high. Hydrate blockages occur owing to abnormal operating conditions such as well tests with water, loss of inhibitor injection, dehydration malfunction, startup and shut-in.

4.

5.

In gas/water systems, hydrates tend to form on the pie wall. In gas.condensate or gas/oil systems, hydrates frequently form from free water as particles that agglomerate and bridge as larger masses in the bulk stream.

August 2003

Gas Dehydration System

6. A lack of hydrate blockages does not indicate a lack of hydrates. Frequently, hydrates form but flow with an oil/condensate (e.g., in an oil with a natural dispersant present) so they can be detected in pigging returns. Attempts to blow the plug out of the line by increasing pressure differentials result in more hydrate formation because higher pressure place the system farther into the hydrate-formation region. When a hydrate blockage is experienced, for safety reason, the first step is to inject inhibitor from any access point. As gas is cooled from reservoir temperature, the amount of water vapor contained in the gas will decrease. That is water will condense

7.

8.

August 2003

Thank you very much Your support is very appreciated

See you in other presentation

August 2003

You might also like

- Gas DehydrationDocument48 pagesGas DehydrationAljan AbetoNo ratings yet

- A Systemic Optimization Approach For The Design of Natural Gas Dehydration PlantDocument9 pagesA Systemic Optimization Approach For The Design of Natural Gas Dehydration PlantInternational Journal of Research in Engineering and ScienceNo ratings yet

- Teg PDFDocument5 pagesTeg PDFElena RicciNo ratings yet

- Natural Gas ProcessingDocument6 pagesNatural Gas ProcessingsgrsthNo ratings yet

- Natural Gas PropertiesDocument18 pagesNatural Gas PropertiesMUHAMMED FUADNo ratings yet

- Acid Gas Removal Flow PDFDocument1 pageAcid Gas Removal Flow PDFHIPAPNo ratings yet

- Joule Thomson ExpansionDocument2 pagesJoule Thomson ExpansiondndudcNo ratings yet

- Natural Gas Processing - Summary & IntroductionDocument7 pagesNatural Gas Processing - Summary & IntroductiondndudcNo ratings yet

- Chapter 2 HydrateDocument38 pagesChapter 2 HydrateTaha Azab MouridNo ratings yet

- NG Engineering by Engr DR CIC AnyadiegwuDocument31 pagesNG Engineering by Engr DR CIC Anyadiegwudavidchinedu008No ratings yet

- Multiphase - Pumps - Axel CalgaryDocument45 pagesMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáNo ratings yet

- Compressors: Presented By: Andrith Fabian Güiza Zambrano 2134124 Presented To: Ing. Nicolas Santos SantosDocument50 pagesCompressors: Presented By: Andrith Fabian Güiza Zambrano 2134124 Presented To: Ing. Nicolas Santos SantosbrandonNo ratings yet

- Liquid Seal Drums: AdvantagesDocument1 pageLiquid Seal Drums: Advantagesbinapaniki6520No ratings yet

- Refinery Amine, Sour Water & Sulphur Recovery Unit (SRU) HYSYS SimulationDocument58 pagesRefinery Amine, Sour Water & Sulphur Recovery Unit (SRU) HYSYS Simulationyou kackNo ratings yet

- Glycol DehydrationDocument3 pagesGlycol DehydrationDharam RajgorNo ratings yet

- Dehydration of natural gas using solid desiccantsDocument9 pagesDehydration of natural gas using solid desiccantsAjay BharaneNo ratings yet

- Fractionation OnlyDocument27 pagesFractionation OnlymohamedNo ratings yet

- 2 Phase Seperator PDFDocument66 pages2 Phase Seperator PDFKanthan DevanNo ratings yet

- Flare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaDocument10 pagesFlare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaJR RomanNo ratings yet

- 6.2. Natural Gas (Treatment)Document45 pages6.2. Natural Gas (Treatment)MaisarahNo ratings yet

- Vapor Absorption Refrigeration SystemsDocument12 pagesVapor Absorption Refrigeration SystemstbijnresdcNo ratings yet

- RG Integrally Geared Compressors PDFDocument6 pagesRG Integrally Geared Compressors PDFJaswindersingh BhatiaNo ratings yet

- Properties of Oils and Natural GasesDocument132 pagesProperties of Oils and Natural GasesAtul Khatri100% (2)

- Technical PaperDocument6 pagesTechnical PaperCJ CHNo ratings yet

- Optimization and Design of Dehydration Unit and NGL ProcessDocument51 pagesOptimization and Design of Dehydration Unit and NGL ProcessHoracio RodriguezNo ratings yet

- Natural Gas Engineering: An SEO-Optimized TitleDocument79 pagesNatural Gas Engineering: An SEO-Optimized TitleSamNo ratings yet

- E1.0 - Crude Stab - Foaming PDFDocument32 pagesE1.0 - Crude Stab - Foaming PDFRégis Ongollo100% (2)

- VSD Affinity Laws and ApplicationsDocument32 pagesVSD Affinity Laws and Applicationsram_river808100% (2)

- Compressor SurgeDocument3 pagesCompressor SurgeajaysapruNo ratings yet

- NGL Recovery Technologies: Irfan HussainDocument23 pagesNGL Recovery Technologies: Irfan HussainFarhad Ashraghi100% (1)

- What Is DistillationDocument25 pagesWhat Is DistillationashirNo ratings yet

- Restriction Orifice RO Flow Control Instrument PDFDocument8 pagesRestriction Orifice RO Flow Control Instrument PDFRaphael212219No ratings yet

- SRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFDocument26 pagesSRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFJunghietu DorinNo ratings yet

- Furnace Internal PressureDocument3 pagesFurnace Internal PressureskluxNo ratings yet

- Petroleum Gas Compression Centrifugal CompressorsDocument59 pagesPetroleum Gas Compression Centrifugal CompressorsEngr TheyjiNo ratings yet

- Furnace Flooding, 011107Document11 pagesFurnace Flooding, 011107Arief HidayatNo ratings yet

- Offshore Sump Caisson Treats Drain & Produced WaterDocument2 pagesOffshore Sump Caisson Treats Drain & Produced WaterEddy RochmadiNo ratings yet

- What Are The Types of HRSGDocument2 pagesWhat Are The Types of HRSGThiruvengadamNo ratings yet

- Antisurge Control SystemDocument10 pagesAntisurge Control Systemlac1981No ratings yet

- Teg ContactorDocument4 pagesTeg ContactorrepentinezNo ratings yet

- LPG (Gas) Pipe Sizing Notes: Properties Natural Gas Liquid Petroleum Gas (LPG) PropaneDocument4 pagesLPG (Gas) Pipe Sizing Notes: Properties Natural Gas Liquid Petroleum Gas (LPG) PropaneSarah DeanNo ratings yet

- FlareDocument39 pagesFlareMuhammad Tahir RazaNo ratings yet

- 245 NGL Deethanizer Capacity ExpansionDocument1 page245 NGL Deethanizer Capacity ExpansionRafeek Emad AbdElkader0% (1)

- Putting It All Together: OperationsDocument34 pagesPutting It All Together: OperationsIbrahim FaqaihNo ratings yet

- Refining Processes PDFDocument60 pagesRefining Processes PDFbilalaimsNo ratings yet

- DesalterDocument2 pagesDesalterHimanshu SharmaNo ratings yet

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73No ratings yet

- PP Pad and Knit Mesh Demisters: Comparing Demisting Technologies Under 40 CharactersDocument4 pagesPP Pad and Knit Mesh Demisters: Comparing Demisting Technologies Under 40 CharactersmariniabrahanNo ratings yet

- Gas Hydrates - PCDocument8 pagesGas Hydrates - PCAashish DwivediNo ratings yet

- Gas Treating Systems and ProcessesDocument26 pagesGas Treating Systems and Processesdinesh_hsenidNo ratings yet

- Valves & Flare StackDocument9 pagesValves & Flare Stackrezad100% (1)

- Optimize Crude Oil Desalting with Membrane FiltrationDocument14 pagesOptimize Crude Oil Desalting with Membrane FiltrationDucViking100% (1)

- ScoreDocument2 pagesScoreEdgar HuancaNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationotis-a6866No ratings yet

- Molecular Sieve Dehydration Optimization PDFDocument24 pagesMolecular Sieve Dehydration Optimization PDFمصطفى العباديNo ratings yet

- Overview of Gas-Handling FacilitiesDocument6 pagesOverview of Gas-Handling FacilitiesMatthew AdeyinkaNo ratings yet

- Gas Plant - 2Document63 pagesGas Plant - 2viettanctNo ratings yet

- Natural Gas Dehydration Using Glycol AbsorptionDocument4 pagesNatural Gas Dehydration Using Glycol AbsorptionPorkkodi SugumaranNo ratings yet

- McCabe Thiele DiagramDocument8 pagesMcCabe Thiele DiagramDaniel Ippolito PelufoNo ratings yet

- Pneumatic Control ValvesDocument59 pagesPneumatic Control ValvesArvind97No ratings yet

- IPR For Gas WellsDocument2 pagesIPR For Gas WellsOlvis GuillenNo ratings yet

- Flare System OptimizationDocument4 pagesFlare System OptimizationOlvis GuillenNo ratings yet

- ION7300 Instl Guide 70002-0198-08Document28 pagesION7300 Instl Guide 70002-0198-08Olvis GuillenNo ratings yet

- Project Component Type Item Information ValueDocument14 pagesProject Component Type Item Information ValueOlvis GuillenNo ratings yet

- Netopt UGDocument105 pagesNetopt UGMarcosGonzalezNo ratings yet

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDocument106 pagesHazard and Operability (HAZOP) & Hazard Analysis TrainingShainu Govindankutty100% (8)

- LOPADocument125 pagesLOPAOlvis Guillen100% (1)

- Brill Beggs ZDocument3 pagesBrill Beggs ZtechbhaskarNo ratings yet

- Flare System OptimizationDocument4 pagesFlare System OptimizationOlvis GuillenNo ratings yet

- Student Registry ListingDocument1 pageStudent Registry ListingOlvis GuillenNo ratings yet

- Pump With Connection Streams, Matl&Manhouradjustments, and Pipe Item DetailsDocument16 pagesPump With Connection Streams, Matl&Manhouradjustments, and Pipe Item DetailsOlvis GuillenNo ratings yet

- Adsorcion GasDocument6 pagesAdsorcion GasOlvis GuillenNo ratings yet

- Pump - Efficiency For CentrifugalDocument10 pagesPump - Efficiency For CentrifugalFrankhil ContrerasNo ratings yet

- Vessel - Vertical Sizing - IPunitsDocument25 pagesVessel - Vertical Sizing - IPunitsAnders FTNo ratings yet

- Pump - Efficiency For CentrifugalDocument10 pagesPump - Efficiency For CentrifugalFrankhil ContrerasNo ratings yet

- Well Testing SpeDocument5 pagesWell Testing Speiqbalpec12345No ratings yet

- Floating Roof Tank - Design PDFDocument2 pagesFloating Roof Tank - Design PDFlinustec100% (5)

- PWC - Financial Reporting in The Oil and Gas IndustryDocument156 pagesPWC - Financial Reporting in The Oil and Gas Industryahsan57100% (2)

- Pipeline Design and ConstructionDocument47 pagesPipeline Design and ConstructionSaber Abdel Moreid100% (5)

- Determination of Permeability Using Well Test AnalysisDocument216 pagesDetermination of Permeability Using Well Test AnalysisAditya AriewijayaNo ratings yet

- Spreadsheet Line PackDocument3 pagesSpreadsheet Line PackOlvis GuillenNo ratings yet

- Basic Anti-Surge Control System ReferenceDocument6 pagesBasic Anti-Surge Control System ReferenceOlvis GuillenNo ratings yet

- A Snapshot of A TripDocument2 pagesA Snapshot of A TripOlvis GuillenNo ratings yet

- AdvancesNaturalGasTechnologyITO12 PDFDocument553 pagesAdvancesNaturalGasTechnologyITO12 PDFgion_ro401No ratings yet

- Pneumatic Valves: For Precision and ControlDocument45 pagesPneumatic Valves: For Precision and Controlm_alodat6144No ratings yet

- Thin Walled Pressure Vessels 1Document21 pagesThin Walled Pressure Vessels 1shangovinna_10781090No ratings yet

- Oil and Gas Pipeline Pigging OperationsDocument60 pagesOil and Gas Pipeline Pigging OperationsOlvis Guillen100% (1)

- Chap 6-Chemical Energetics IGCSE Chemistry NotesDocument9 pagesChap 6-Chemical Energetics IGCSE Chemistry NotesMisbah Kamran100% (1)

- IECDocument1 pageIECJay Jay100% (1)

- A Small List of Operating Oil and Gas Fields in Myanmar by Production LevelDocument6 pagesA Small List of Operating Oil and Gas Fields in Myanmar by Production LevelNickAronNo ratings yet

- FYDP 2 Students Briefing PDFDocument15 pagesFYDP 2 Students Briefing PDFCai ZiminNo ratings yet

- Optimizing DRI Production Using Natural Gas: Designed For TodayDocument8 pagesOptimizing DRI Production Using Natural Gas: Designed For Today5284erNo ratings yet

- Assignment Clo1 EnergyDocument3 pagesAssignment Clo1 EnergyaNo ratings yet

- RAC Lecture 13Document25 pagesRAC Lecture 13Mohammed SiddiqueNo ratings yet

- Astm D 1835-2018 - LPGDocument6 pagesAstm D 1835-2018 - LPGsoledad luerNo ratings yet

- 4-L2-Heuristics For Process DesignDocument13 pages4-L2-Heuristics For Process DesignCamilo SernaNo ratings yet

- Redox and DisinfectionDocument41 pagesRedox and DisinfectionKanchanNo ratings yet

- Mig Welding GuideDocument30 pagesMig Welding GuideFer MinNo ratings yet

- TECH 707 Separating A Mixture of Biphenyl, Benzhydrol, and Benzophenone by TLCDocument3 pagesTECH 707 Separating A Mixture of Biphenyl, Benzhydrol, and Benzophenone by TLCsadaf_5No ratings yet

- TB1-019 Off-Line Boiler Protection OptionsDocument1 pageTB1-019 Off-Line Boiler Protection Optionsjesus_manrique2753No ratings yet

- Refinery OverviewDocument79 pagesRefinery Overviewchikukotwal100% (1)

- Highly Stable M/Nioemgo (M Co, Cu and Fe) Catalysts Towards Co MethanationDocument16 pagesHighly Stable M/Nioemgo (M Co, Cu and Fe) Catalysts Towards Co Methanationfarah al-sudaniNo ratings yet

- CRDocument104 pagesCRRoberto SanchezNo ratings yet

- Lab Petchem (Exp 4)Document13 pagesLab Petchem (Exp 4)Hafiz ImranNo ratings yet

- Gas Lift2021Document110 pagesGas Lift2021Malek r.i.pNo ratings yet

- Peb-Gas Absorption PDFDocument29 pagesPeb-Gas Absorption PDFEJ TanNo ratings yet

- Boilers BasicsDocument19 pagesBoilers BasicsShayan Hasan KhanNo ratings yet

- Medical GasesDocument26 pagesMedical Gaseskanika100% (1)

- Chiller Plant 1Document20 pagesChiller Plant 1Krishna Kanchi100% (1)

- Ignition Characteristics of Cracked JP-7 FuelDocument4 pagesIgnition Characteristics of Cracked JP-7 Fuelfahrul3xNo ratings yet

- Lurgi ProcessDocument8 pagesLurgi ProcessKellyCristinaNo ratings yet

- IOCLDocument13 pagesIOCLNingSeng SingphoNo ratings yet

- Mike-Banach-UOP-2016 Presentation On Oleflex Operating UnitsDocument20 pagesMike-Banach-UOP-2016 Presentation On Oleflex Operating Unitsagarwalashwin32100% (1)

- Improving Aromatic Hydrocarbons Yield From Coal Pyrolysis VolatileDocument6 pagesImproving Aromatic Hydrocarbons Yield From Coal Pyrolysis Volatilebambang_teknikkimiaNo ratings yet

- Reaction of Metals With OxygenDocument9 pagesReaction of Metals With Oxygenmanery23No ratings yet

- Oil Weathering Final 11-04-07Document129 pagesOil Weathering Final 11-04-07sirlancelotksaNo ratings yet

- Mid Unit Science TestDocument5 pagesMid Unit Science Testapi-535378803No ratings yet