Professional Documents

Culture Documents

OTC 23939 LNG Barges: The Offshore Solution For Export of US Pipeline Gas

Uploaded by

totongopOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OTC 23939 LNG Barges: The Offshore Solution For Export of US Pipeline Gas

Uploaded by

totongopCopyright:

Available Formats

OTC 23939 LNG Barges: The Offshore Solution for Export of US Pipeline Gas

Javid H Talib and Brian C Price, Black & Veatch Corporation

Copyright 2013, Offshore Technology Conference This paper was prepared for presentation at the Offshore Technology Conference held in Houston, Texas, USA, 69 May 2013. This paper was selected for presentation by an OTC program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been reviewed by the Offshore Technology Conference and are subject to correction by the author(s). The material does not necessarily reflect any position of the Offshore Technology Conference, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Offshore Technology Conference is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of OTC copyright.

Abstract With the advent of increased production of Shale Gas in United States, and the continuing drop in gas prices, the possibility of exporting US gas is becoming more real. Many developers are vying to build larger capacity LNG production facilities for exporting to Free Trade Agreement (FTA) and Non-Free Trade AgreementNon-FTA) countries in Asia and Far East while smaller market exists in South America and Caribbean requiring small to midscale LNG supply volumes. The larger on-land base load LNG export production plants require significant capital and takes 4 to 5 years to bring online. A novel LNG barge concept provides a faster way to build a small to midscale LNG production facility near-shore in protected waters and/or dockside. The focus on a simple, reliable process solution and barge structure is making this concept a reality for converting US pipeline gas into LNG for export to markets which require smaller LNG volumes than are envisioned with the large scale projects. A barge mounted LNG production facility requires the application of liquefaction technology that is simple, space efficient and energy efficient. The technology of choice for these applications is the Single Mixed Refrigerant (SMR) process. The simplicity, flexibility and scalability of the SMR process can provide a wide range of liquefaction capacities in a unique single or multiple-train configuration on the barge. There are several system options from which any configuration can be built around depending up on the location, power availability, permitting constraints for use of water cooling and the LNG offloading/export strategy. The barge could be self sufficient or be integrated with onshore support systems at dockside. The barge and its topsides production facility can be built in United States or anywhere in the world competitively and towed to US locations. This paper will cover the design features of the barge configurations developed specifically for liquefying US pipeline gas between 0.5 MMTPA and 2.1 MMTPA capacities opening up a new frontier for offshore LNG production in small to mid scale range. Introduction The US went through a period of build out of LNG import terminals in the last decade. This was in anticipation of a shortage of domestic gas supply and an increasing gas prices. As can be seen in Figure 1, the gas prices in 2006 time frame were increasing from $6/MMBTU to a peak of about $12/MMBTU. At these price levels, the importation of LNG represented a strong market for gas suppliers. During the 2000-2010 decade many LNG import terminals were completed in the US, Mexico and Canada to accept new supplies of LNG. However, during the 2008-2010 time period the price fell dramatically as the US economy sagged. Also, large supplies of domestic gas have been discovered in the shale gas areas of the US. At these price levels, importation of LNG is not an economically viable option. Recently, many owners have pushed forward projects to add liquefaction capacity to exiting terminals and also to new terminals that were permitted for import but will be built out for export. Most of the terminals are slated for large scale gas supply to Asian and European markets. These larger on-land base load LNG export production plants require significant capital and take 4 to 5 years to bring online. A novel LNG barge concept provides a faster way to build a small to midscale LNG production facility near-shore in protected waters and/or dockside. The focus on a simple, reliable process solution and barge structure is making this concept a reality for converting US pipeline gas into LNG for export to markets which require smaller LNG volumes than are envisioned with the large scale projects.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pump Foundation DesignDocument18 pagesPump Foundation DesignSourav92% (12)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

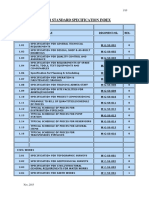

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Dna60 PDFDocument15 pagesDna60 PDFAc IdNo ratings yet

- Apocalyptic Rhetoric KritikDocument31 pagesApocalyptic Rhetoric KritikMilkdelishNo ratings yet

- Kieso - IFRS - ch11 - IfRS (Depreciation, Impairments, and Depletion)Document73 pagesKieso - IFRS - ch11 - IfRS (Depreciation, Impairments, and Depletion)Muzi RahayuNo ratings yet

- 2012 08 ReformateDocument4 pages2012 08 ReformatetotongopNo ratings yet

- Decision Tree Law Litigation 080601Document9 pagesDecision Tree Law Litigation 080601totongopNo ratings yet

- Geophysical MethodsDocument30 pagesGeophysical MethodsKhaled 2006No ratings yet

- Annex 1 - Figure A BDocument2 pagesAnnex 1 - Figure A BtotongopNo ratings yet

- National Subsidies SOE Investment: Exploration, Published in 2014Document13 pagesNational Subsidies SOE Investment: Exploration, Published in 2014totongopNo ratings yet

- Depreciation, Impairments, and DepletionDocument83 pagesDepreciation, Impairments, and DepletionfebrythiodorNo ratings yet

- Psia ºF T ºF P T Pressure Psia B RB/MCF Check DataDocument21 pagesPsia ºF T ºF P T Pressure Psia B RB/MCF Check DataArun Kumar NagarNo ratings yet

- Gas Condensate Reservoir AnalysisDocument2 pagesGas Condensate Reservoir AnalysistotongopNo ratings yet

- Lab Fire Safety ChecklistDocument2 pagesLab Fire Safety ChecklisttotongopNo ratings yet

- 2012 11 LPG Chem Gas QuantityDocument4 pages2012 11 LPG Chem Gas QuantitytotongopNo ratings yet

- Pipe Hanging and Supports SpecificationDocument5 pagesPipe Hanging and Supports SpecificationhiyeonNo ratings yet

- Solar Group Case StudyDocument3 pagesSolar Group Case StudytotongopNo ratings yet

- BDocument3 pagesBtotongopNo ratings yet

- OTC 23939 LNG Barges: The Offshore Solution For Export of US Pipeline GasDocument1 pageOTC 23939 LNG Barges: The Offshore Solution For Export of US Pipeline GastotongopNo ratings yet

- BDocument3 pagesBtotongopNo ratings yet

- Project Standards and Specifications LPG Recovery and Splitter Systems Rev01Document5 pagesProject Standards and Specifications LPG Recovery and Splitter Systems Rev01hiyeonNo ratings yet

- Project Standards and Specifications Crude Desalter Systems Rev01Document6 pagesProject Standards and Specifications Crude Desalter Systems Rev01muhammad_asim_10No ratings yet

- Heat Exchanger Datasheet SampleDocument1 pageHeat Exchanger Datasheet SampleMuhd Fadzlee ZNo ratings yet

- 9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantsDocument2 pages9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantstotongopNo ratings yet

- RG FlowchartDocument1 pageRG FlowcharttotongopNo ratings yet

- Sample Invoice Schedule FormatsDocument6 pagesSample Invoice Schedule FormatstotongopNo ratings yet

- 9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantsDocument2 pages9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantstotongopNo ratings yet

- Pressure Relief Valve Data Sheet-Rev01Document1 pagePressure Relief Valve Data Sheet-Rev01thawdarNo ratings yet

- Project Standards and Specifications Pipeline Leak Detection Systems Rev01Document6 pagesProject Standards and Specifications Pipeline Leak Detection Systems Rev01hiyeonNo ratings yet

- RG FlowchartDocument1 pageRG FlowcharttotongopNo ratings yet

- 9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantsDocument2 pages9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantstotongopNo ratings yet

- Pressure Relief Valve Data Sheet-Rev01Document1 pagePressure Relief Valve Data Sheet-Rev01thawdarNo ratings yet

- 9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantsDocument2 pages9697s2 - Abs Major Liquefaction Processes For Base Load LNG PlantstotongopNo ratings yet

- Fundamix Brochure EN WebDocument9 pagesFundamix Brochure EN Webjgjb4csrj7No ratings yet

- rt8205b Datasheet-06Document28 pagesrt8205b Datasheet-06André Hipnotista100% (1)

- IPM 200 Series: Internal Permanent Magnet MotorsDocument7 pagesIPM 200 Series: Internal Permanent Magnet MotorsLuu JosNo ratings yet

- Microcontroller-Based Power Monitoring for COE RoomsDocument8 pagesMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475No ratings yet

- Matter-Energy Transformations ExploredDocument22 pagesMatter-Energy Transformations ExploredAmit BidlanNo ratings yet

- ELECTRONICDocument13 pagesELECTRONICMahmoued YasinNo ratings yet

- Kalina Cycle and Cement IndustryDocument8 pagesKalina Cycle and Cement IndustryEhab SabryNo ratings yet

- Annual Syllabus 9 & 10Document6 pagesAnnual Syllabus 9 & 10Kumar SiddhantNo ratings yet

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסNo ratings yet

- Medium Power Substation Instruction ManualDocument24 pagesMedium Power Substation Instruction ManualOmar GraterolNo ratings yet

- Galcon ProductDocument69 pagesGalcon Productapi-36492444No ratings yet

- Current Transformer - Electrical Notes & ArticlesDocument47 pagesCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Halogen Linear - 76534 - Tu k12 c100w 240v r7s 78mm Ge tbl1 10mih - 0 - EmeaDocument3 pagesHalogen Linear - 76534 - Tu k12 c100w 240v r7s 78mm Ge tbl1 10mih - 0 - EmeaMarcos AfonsoNo ratings yet

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 pagesDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.No ratings yet

- Cylinder Cutout Cylinder CutoutDocument12 pagesCylinder Cutout Cylinder CutoutIsrael Miranda ZamarcaNo ratings yet

- Electrical Machines DC MotorDocument5 pagesElectrical Machines DC MotorKitkay NivramNo ratings yet

- Fabric Expansion JointsDocument28 pagesFabric Expansion Jointswarmachine269889No ratings yet

- Enclosed Control Product Guide: April 2008Document456 pagesEnclosed Control Product Guide: April 2008MED-ROBIN2000No ratings yet

- 2013 Renault ZOE PresskitDocument34 pages2013 Renault ZOE PresskitDidelisNo ratings yet

- U3 Oxidation and Reduction PPT WatermarkDocument45 pagesU3 Oxidation and Reduction PPT Watermarkapi-125934329No ratings yet

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDocument2 pagesKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareNo ratings yet

- APFC Epcos 6Document8 pagesAPFC Epcos 6Sriman ChinnaduraiNo ratings yet

- Industrial ReactorsDocument10 pagesIndustrial ReactorssarahNo ratings yet

- Atmospheric Water Generator DesignDocument9 pagesAtmospheric Water Generator Designscribd2No ratings yet

- Dual Nature of Radiation and MatterDocument6 pagesDual Nature of Radiation and Mattersub100% (1)

- Mechanics - Fluid Dynamics: K. Suresh Senanayake 1Document2 pagesMechanics - Fluid Dynamics: K. Suresh Senanayake 1mangsureshNo ratings yet