Professional Documents

Culture Documents

API 653 Daily Quizzes

Uploaded by

JoshnewfoundOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 653 Daily Quizzes

Uploaded by

JoshnewfoundCopyright:

Available Formats

<-c:

, ... u: o -. {Ju t ;oll n o CI'. IlT lrll; U (;0,1

Professional Training and Consultation

API 653

PREPARATORY COURSE

Daily Exams

26'h upto 31

st

August 2006

AI-Khobar, Saudi Arabia

MR. HASAN ATIYAH HASAN ALGHAMDI

SABle

Saudi Arabia

8

1

1. Fl oor, Al -Subeael Towers. King Abdulaziz cor. Prince Fal sal Bin Fnhd Streets, At-K hobar. Saud! Arabia

TEl (966) 3 8876633 FAX (966138876565 info@gmoitc.com www.qotcttc.com

.--;C- It-:T E GRAT ED

I l ' . \ I l. I f ' t-. N I .. It

.... . ....."

Professional Training and Consultation

API 65 3 Prepar atory

26'" upt o 31

11

Augu st 2006, AI- Khobar, KSA.

Page 1 of 13

FINAL EXAM (CLOSED)

Instructions:

Choose only one answer, which you think is most appropriate.

Use the attached answer sheet in answering the following questions.

1. The complete or partial removal and replacement of more than

12 inches of a vertical weld joining shell plates is considered a:

(a) minor alteration;

(c) major alteration;

(b) minor repair;

(d) major repair.

2. A single film technique was used to make a radiograph using a

Cobalt-50 source. The minimum permitted density in the area of

int erest is:

a.

b.

c.

d.

4 .0

1.8

2.0

1.3

3. Cathodic protection is achieved by directing the flow of current

f rom:

(

a.

b.

c.

d.

A cathode to anode

An anode to cathode

Both installations are acceptable

Neither of a and b

GS}

4. is a change f rom previous operating conditions

invol ving different properties of the stored product such as

specific gravity or corrosivity and / or different service conditions

of temperature and / or pressure:

(a) Re- rating; (b) Change in service;

(c) Repair ; (d) Reconstruction

r v-o ., ; KIll g Abdul aztz cor. Prmr e Bin Fahd Street s. AI-Khobar. Saudi Arabia

TEl (966, 3 aS7 6633 FJ\X(9661') 887 G5G5 www. qotouc.com

(

INTEGRATED

I " I : , \. I e, I l. : f. ' t:. ... T .. I t

. ... '" "Ull I :"'" , .. L In . r IU' ,- u ,

----------

Professional Tr ain ing and Consultation

API 653 Prepar atory

26"' upt o 3 1" Augu st 2006, AI- Khobar , KSA.

Page 2 of 13

FINAL EXAM (CLOSED)

5. Describe how a liquid penetrant examination should be

performed i n order to detect discontinuities which are open to

the surface.

a. Clean the part, apply the developer, apply the penetrant,

remove excess penetrant, inspect the part, clean the part

b. Clean t he part, apply penetrant, remove excess penetrant,

apply the developer, inspect the part, clean the part

c. Clean the part, apply the developer, apply the penetrant,

inspect the part, remove excess penetrant, clean the part

d. Clean the part, apply the developer, apply the penetrant,

inspect the part, clea n t he part

6. A rad iographic t echni que in wh ich radiation passed through two

walls and both t he walls are viewed on the same radiograph

(double wall , double image - ellipse) the limitation for the outside

diameter is:

a. 3-1/2"

b. 2"

c. 4"

d. Any diameter possible

7. - I nformation needed when determining the hat e of corrosion:

a. Original th ickness or last inspection thickness

b. Current thickness

c. Length of t ime i n service

d. All the above

8. The ma ximum acceptable undercutting for base metal in

reconst ruct ed tank for horizontal welds is:

(a) 1/64"; (b) 1/ 32"; (c) 1/16"; (d) 1/8"

f>. Hco- . Suneaer Lowers , KIng Abdulaziz tor . Prince r arse! Bin Fand Street s. AI- Khobar. Saudi Ara bia

"TfL ; 887 65 33 rAX{96fil 3 8&7 GSGS . mfo(!i::gotoit c,com . ......ww.gowlte.com

API 65 3 Preparatory

26

t h

uotc 3 1"l August 2006, At- k hc bar, !<SA.

Page 3 of 13

lNTEGR A TED

I I" \ I t I . ( . I'- 1 I It

. ... ,. .M " .

Profess ional Tr aining and consuttatlcn

FINAL EXAM (CLOSED)

9. Tank was inspected in 1985 and the thickness was observed to

be 0.32 inch. The thickness observed during inspection in 1995

was 0.30 inch. What is corrosion rate?

a. 2 mpy

b. 20 mpy

c. 0.2 mpy

d. 1 mpy

10. If remaining corrosion allowance (RCA) at present is 0.05 inch,

the next thickness inspecti on due for above tank shall not be

later than:

'0i;

a.

b.

c.

d.

10 years

15 years

6 years

12. 5 years

11. A corroded area of a tank bottom plate is repaired by weldi ng

overlay. There is no change in the rating and no change is made

on the nameplate. Which of the following is the correct term to

describe t his process?

(

a.

b.

c.

d.

Reconstruction

Repair

Alteration

None of t he above

12. The ma ximum i nt erval bet ween internal inspections shall not

exceed __ years when corros ion rate is known:

(a) 10; (b) 20; (c) 5; (d) 15.

13. Hot taps are not permitted under which of the following

conditions?

S'" rtc,. ..\ 1 Subeaei Towers. l\ lng Abdul aztz cor . rnnce Fai :ial Bin Fahd Street s. Al - Khobar , Saudi Arabia

TEL <966'. 3 887 66 33 FAX(966) 3 887 6565 IOfo'ri)gQ[olt c.com www.qctonc.corn

J

---sc:--- I N TEG RATED

. 1 i' , \ I 1'- f U r- t- '" T l- ...

, ,, ,. 1"'0 " '''' , "" CO;> <. I' IlT, r , . n r u ,

Professi on al Trai ni ng an d Cons ultation

API 653 Pre paratory

26

1h

up t o 3111 Augu st 2006. Al-Khobar, K$A.

Page 4 of 13

FINAL EXAM (CLOSED)

a. On plates requ iring PWHT.

b. On ultrasonically sound plate

c. On tanks with dia. more than 80 feet.

d. None of the above.

14. A tank of 160 ft diameter is to be checked for shell settlement.

Minimum number of equally spaced settlement points to be

checked will be:

a. 16

b. 20

c. 24

d. 12

15. For a tank made by reconstruction, under what circumstances

maya new shell-to-bottom weld be exempt from hydrostatic

testing?

(

a.

b.

c.

d.

When the root pass has been visually inspected and

the final weld is fully examined, visually and

radiographically.

Reconstructed tank is never exempted from

hydrostatic testing. ,

When the root pass has been visually inspected and

the final weld is fully examined, visually and by

vacuum box.

When the weldi ng method has been reviewed and

approved by an engineer experienced in tank design

in accordance with API Standard 650.

%f1.;'

-,:,. ..

16. In atmospheric conditions, bottom coatings may be applied if the

steel temperature is:

a. 2F above t he dew point

b. 5F below the dew point.

c. 10F above the dew point.

S'" Hno: . Al-Sube ee i 'towers. KlIlg Abdulaztz cor. Princ e Fatsal Bin Fahd Streets . AI- Khobar. Saudi Arabia

TEL 3 SB7 66 33 r AX 19GGl 3 86; GSG5 www.ccronc.com

.---..:;c- I NTE GRATED

' I ' I " , , < ; e- t N It / -

". ,. ."". .,,,,,,. . , ' ,r " " . c. .

------- ------

Profess ion al Tr ai ni ng and Consult ation

API 653 Prepar atory

26thuptn 311t August 2006, AI- Khobar, KSA.

Page 5 of 13

FINAL EXAM (CLOSED)

d. At the dew point.

17. Procedure qualiflcation for welding during repair of tanks is done

in accordance with:

a. AWS 01.1

b. API 1104

c. ASME Sect ion I X

d. All of the above

18. Widely scattered pits may be ignored under the following

condit ions

a.

b.

c.

d.

Where the service fluid is corrosive or hard to hold.

If sum of pit lengths along any 8" vertical line does not

exceed 2"

When no pi t has dept h which resu lts i n the minimum

thickness being less than one-half the minimum acceptable

thi ckness of the shell plate exclusive of corrosion allowance

band c

19. For verification of radiographic sensitivity and image

quali ty, which of the fol lowi ng are used:

(

a.

b.

c.

d.

Cassettes

Penetrameters

Cameras

Coll imators

20. Internal corrosion in the vapour space above liquid level occurs

due t o:

a. Hydrogen Sul phide vapour

b. Water vapour

c. Oxygen

d. Any combination of the above three

. ....1 Sneacr 1 owers. KIllq Abdul aztz cor . Pnnr e Faisal Bi n Fahd Street s. Al - Khobar , Saurf Arabia

-, sr,;, ; {, 3 3 . r .\ },' 1:1[.[.1 :; 5Ci ? G:>G) . lll f n.' :i:gowl 1C.com . www.qctouc.com

""",

0 J:;

[Si :f':,-

' ... '" I;\O U ';uu l ':'-1:I<, . r U I ' ,' " J

Professional Tra ining and Consultation

API 653 Preparato ry

261h umo 3 1JI Aug ust 2006. At -khcbar , KSA.

Page 6 of 13

FINAL EXAM (CLOSED)

21. API 650: Appendix M provides requirements for Tanks designed

to operate at the following range of temperatures:

a. Exceeding 260C

b. Above 90 - 260C

c. Below 90C

d. Below OOC

22. For a reconstructed tank as per API 653 Verticality (out-of-

plumbness) of top of the shell shall not exceed ,

a. 1/300 of total tank height

b. 1/250 of total tank height

c. 1/400 of total tank height

d. None of the above

23. When lining is applied to bottom on inside of tank, the lining

shall extend up the shell.

a. 6" min

b. 12" min

c. 18" min

d. 3" min

24. Hot tap can be performed on:

a. Vapour space in the shell

b. On the roof

c. In the shell below liquid level

d. Anywhere on the tank

25. A radiograph was having density near the penetrameter equal to

3.0. Hence the acceptable density range of the radiograph is:

a. 1.7to4

b. 2.55 to 3.9

c. 2.0 to 4.0

.. Hom. Al - Subeae: Tower s. Krng Abdul aztz COl. Prince Faisal Bin Fahd St reet s. Ai- Khob ar . Saudi Arabi a

TEL 3 8876(, 33 FAX 196Gl 3 88 7 G5G5 Itlf o'!il gOtDl tc. com www.c oto uc.com

", Cf?;.

-

INTEGRATED

r n .,. I r-: , n f : to N 1 t - It

.,.,ct' ". L" " , t " " n"

Pr ofessi onal Training and Consu ltati on

API 653 Prepa rat ory

26lh upt o 3 1" August 2006. AI- Khobar. KSA.

Page 7 of 13

FINAL EXAM (CLOSED)

d. None of the above

26. The examiner for conduct ing magnetic particle testing on the

tank welds shall be:

a. Qualified as per ASNT Level II or III

b. Able to read Jagger-2

c. Qualified as per ASME Sec. V

d. None of the above

27. I n atmospheric conditions, grit blasting can be done at

temperature of at least:

a.

b.

c.

d.

2F above the dew point.

5F below the dew point

5F above the dew point

At the dew point

28. How many equal ly spaced measurements are requi red for the

thickness averaging technique?

(a)2 (b)S (c) 4 (d)3

How many specimens must be used for impact tests f rom a

si ngle t est coupon or t est locati on?

(

29 .

(a) 1 (b) 2 (c) 3 (d) 4

30. Hydrostatic tests shall be held for

reconst ruct ed tank.

hours for the

( a) 2 (b) 8 (c) 24 (d) 72

31. In a rad iographic film of a weld, how is back scatter

checked?

(a) By use of a penetrameter

( b) By f ilm density

b 111'01. \ 1 1\.1119 (Or . pn nu, Bin Fahd Str eets, Al - Khnb ar . Saudi Ar abla

l El 3 867 (,(. 3) r, \x (9GGl 3 88 7 C':i G5 www.qot ort c. com

I j ; , I t ( ; . ... I j. II

....... I J-U ' .. ", '

Professional Trai ni ng and Consultation

API 653 Preparatory

26

1h

upt c 31"

1

August 2006. AI-Khobar, K$A.

Page 8 of 13

FINAL EXAM (CLOSED)

(c) Using lead letter "6"

(d) All of the above

32. In general, if shell thickness does not exceed __ inch, it does

not require further assessment for brittle fracture:

(a) 0.25 (b) 0.75 (c) 1.00 (d) 0.50

.<?;-,

l.igr

(

33. Potential for brittle fracture exists for tanks constructed

according to:

(a) API 650 - 7

t h

edition

(b) API 650 - latest edition

(c) API 650 - 4

t h

edition

(d) None of the above

34. Three types of external inspections are :

(a) Scheduled, routine and llquld penetrant

(b) Scheduled, routine and UT thickness

(c) Scheduled out of service, routine and UT thickness

(d) Unscheduled, routine and liquid penetrant

35. Welders qualifications shall expire as they do not weld:

(a) Within a given process for a 6 month period

(b) Using a given procedure for a 6 month period;

(c) On a tank for 6 months;

(d) For a 3 month period.

l l " [ UWt' I S, 1i.lll n Abdula ztz COf . Pn nt e Paisal Btn Eahd Str ee t s. Al - Khob.n . Sandi Ara bi a

II TEl (966) 3 gS7 6633 . fAX (96G) 3 887 GSG5 . Infof(ilgaroltc.co m . www.q oto rtc.ccm

'-X- I N T EGRATED

T 1l . \ I S I 11 r ' .... r /I

' ... ...: <' ,-,U , loU" <;.Z. "' rr u .f><- '(I I

,- --:-:--cc-- - - - - -------- - -

Professional Training and Con sultation

API 65 3 Prepar at ory

26 111 upt o 3111Aug ust 2006. Al- Khob ar, KSA.

Page90r 13

FI NAL EXAM (CLOSED)

36. What are penetrameters used for:

(a) A penetrameter is used for radiographic technique in

that it serves as an image quality indicator

(b) It indicates the magnetic properties of the materials

(c) To check penetrant quality in PT inspection

(d) To check weld penetration during welding

37. Unless otherwise agreed to by the purchaser, what is the

minimum nominal width of a shell plate?

(a) 36 inches

(c) 72 inches

(b) 48 inches

(d) 96 inches

.0;'

38. "Each vertical weld must be radiographed (either spot or full

radiography) for the bottom shell course (i.e., course no. 1) for

all tanks constructed to current API 650 Basic Standard." This

statement is:

a. False

b. True

c. Whether any radiography is requ ired or not depends

on shell thickness.

d. Depends on tank design Engineer's opinion

39. According to ASME Sec. I X, welding filler metals are grouped into

groupings (based on their usabili t y) as:

(a) P-numbers (b) F-numbers

(c) Z-numbers (d) ASTM spec.

Hn HmJI. Al - Subeae-i TOWi;>I!l. 1\1l19 Abdulazi z cor . Pnnce r eua! Bin Fahd Str eets, AI -Khobar , Saudi Arabia

a TEl 19G61 3 SS? 663 3 . FAX (966) 3 8Si G5G5 www.qotorrc.com

e

I NTE G R ATE D

- r I : ... I t : I Co.1 r - to "" 1 I I'

, ...... 1M.> "0" , l Ull" ... n ... " . \>.

Professi on al Train i ng and Consultation

API 65 3 Prep ar atory

261h upt u 3 111 August 2006. Al- Khobar. KSA.

Page 10 of 13

FINAL EXAM (CLOSED)

40. When revi ewing a radiograph, a light image of the letter B can

be seen on the fil m with dark background.

(a) This is cause for rejection

(b) This is not cause for rejection

(c) This is the same as a light letter B

(d) An unusual safety hazard existed during the

exposure

41. Which of the following penetrant system is generally considered

least sensitive?

a.

b.

c.

d.

Water-washable - visible dye

Solvent removable - visible dye

Wat er-washabl e - fluorescent dye

Post-emulsification - vi si ble dye

42. The nondestructive examination method to be used for a

particul ar inspection should be determined by the:

a. Avai labil ity of certified NDE examiners

b. Length of time since the last i nspect ion

c. Age of th e component to be inspected

d. Type, location, and orientation of t he expected f laws

43 . Out of the following four options i n LPT, most sensitive results

can be obtained by :

a. Visible penet rant - wat er washabl e

b. Fluroscent penetrant - post emulsifyi ng type

c. Visible - solvent removable type

d. Visible - post emulsi fy ing type

'.;:;:;::c

6, - ! IOOl, .At - Subeaei 'r ower s. King Abdul azrz cor . Princ e Faival Bi n Fahd Streets. Al-Khcbar. Saudi Arabia

o TEl 3 887 65 33 FAX(9G6) 3 8876555 lnfo'!i':g otoltc.com . ....vww .qotoi tc. com

API 6 53 Preparatory

26

111

uptc 31

11

August 2006. AI- Khobar. KSA.

Page 11 of 13

------:;c--INT EGRATED

' .... t. ""U' ...... 'u l .. l H > r " ,

.- - --- - - - - - - --- - - -- - -

Prof essi onal Train i ng and Con sultation

,<9"

fi'i;7'

..

FINAL EXAM (CLOSED)

44. A PQR was qualified in 5G position using a new welder. But

product ion welding is to be done in 2G position. Which of the

following are applicable as a minimum?

a. Both procedure and welder shall be re-qualified in 2G

position .

b. The qualified procedure can be used ,only welder needs to

be re-qualified

c. The welder is qualified, but the procedure needs re-

qualification

d. Both procedure and welder need not be re-qualified.

45. Minimum thickness evaluation may be conducted by?

a.

b.

c.

b.

Use of an external micrometer only

Ultrasonic testing

D.P. Check

None of above

46. For procedure qualification documentation:

(

a.

b.

c.

d.

WPS gives the procedure t est data and results of

tensile/bend test

PQR gi ves ranges quali fied by procedure t est .

PQR gives procedure test data and WPS gives ranges

qualified

WPS and PQR both give test data and ranges qualified

47. Identify correct statement f rom following:

a. Tensile test for procedure qualification is passed only if base

metal failu re occurs at or above Specified Minimum Tensile

Strength (SMTS) of base metal

Hnm. 'l owers, 1\111 9 Abdulaziz tor. Pnnre Faisal Bin Fahd Al - Khobar, Saudi Arabi a

TEL ('JfJo ) } 367 65 33 . r l\ x f9GGl 3 88i G5G5 emfoc-qotortc.corn ... www.qoto rtc.corn

JNTE G RAT ED

T " , \ I :-; I ( ; e: N 1 It

' ..., . , ,.,-' ." "" . .'''''<' .. t; .. -n r ll. l> <'0 ,

-- - - ---------------- -

Professional Tr ai ning and Consultation

API 6 53 Preparatory

26'" upto 3 1

11

August 2006. Al- Khobar. !<SA.

Page 12 of 13

FI NAL EXAM (CLOSED)

b. Tensile test for procedure qualification is passed only if base

metal failure occurs above SMTS of base metal

c. Tensile test for procedure qualification is passed even if weld

metal failure occurs above 95% of SMTS of base metal

d. None of the above

48. When using radiographs to qualify welder, the acceptance

standards used are found in:

a.

b.

c.

d.

ASME Section V

ASME Section IX

ASME Section VIII

The referencing code

49. An RBI assessment can be used to alter the internal i nspect ion

strategy provided:

a) RBI is performed considering likelihood of failure and

consequence of fail ure.

b) The RBI is f ull y documented.

c) A t hird party conducts the RBI.

d) Bot h " a" and " b" above

50. You are reviewing a WPQ for a welder. The test results indicate

the fol lowing:

a. Satisfactory side bend

b. Face bend satisfactory

c. Visual satisfactory

Will th ese tests qual ify the welder?

i:;.<, Al -Snbeaei 't owei s. l\ tt1 9 Abdul azi z cor. Pnnce Faual Bin Fahd St reet s. Al -Khobar. Saudi Arabia

TEL 3 8 76(.3 3 . F\ X (9GG) 3 887 GjG S . Infof{llgoroitc.com www.qo touc.corn

....i\

(

. ' ,

('0 :

JNTEGRATED

, " ."' I :. I r- t ,.. , I 1<

' ..... ; , " ... .. " , . , . . "".L .. l l t .. .. r o ,

Professional Train i ng and Consultation

API 653 Prep aratory

261h upto 3111 Aug us t 2006. At- xhcber. KSA.

Page 13 or 13

FI NAL EXAM (CLOSED)

a. Yes

b. No, because bend tests are not correct type.

c. Not enough information given

d. No, because radiography is essential for welder

qualification

------------------ - ----- -- End --- ---------------------- ---

."l' I UJ or. 1, 111 9 Abdul aztz cor . Pnnce FCl I5i1.1Bin Fahd Str eet!' . AI -Khobar . Saudi Arabi a

. 1 Et. 3 8876633 . rAX(9GGl 3 887 GSGS Inro17) gotOlt c.cOlTI . www.qotouc.corn

I NTEGRA TED

Th . , I t- IN' )

.... j" n '" ' '' ' f "I. l' l l t l l "-' e n .

- - - - - -- - - - - - -

c'?t;;; Profess ional Trai ni ng and Consult ation

.., ..t.

API 653 Preparatory

26

th

upto 31

st

Augus t 2006, Al Khobar, KSA

Page 1 of 1

FINAL EXAM (CLOSED)

Answer Key

(

Answer

':

.< .

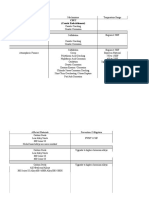

Q. Answer Reference Q. Reference, :1, .;

,-' ,., ....-

1 D API 653, 12.3.1.2 (b) 26 B API 650 6.2.3

2 C ASME V T-282.1 27 C API 652, 7.4

3 B API 65 1, 4.4.1 28 B API 653 4 .3.2. 1 (e)

4 B API 653, 3.7 29 C API 650, 2.2.8.3

-

5 B ASME V T-600 30 C API 653 12.3. 1.1

6 A ASME V, Tc271.2 (b) 31 C

ASMEV, T-284 "";1' ;' ;

7 D API 575 7.6 32 D API 653 Flo. 5-2

8 B API 653 10.4.2 .5 33 C API 653, 5.3.2 .

9 A API 653 3.8 34 B API 653 6.3

10 D API 653 6.3.3.2 (b) 35 A

ASME IX, QW 322:1 (a)

11 B API 653, 3.15 36 A ASMEV

12 B API 653, 6.4.2.1 37

C .,

API 650 . 3.6.12

13 A API 653 9. 14.1.1 38 B API 650 6.1

14 A API 653, 12.5.1.2 39 B ASME IX 431i...

15 B API 653, 12.3 .1.1 (a) 40 A ASME V, T-284

16 C API 652, -8.3 41 A ASMEV, Art. 6'i1

':"-'

..

17 C API 653 11.1.1 42 D General Knowledae

18 D API 653, 4. 3.2.2 43 B

ASME V, Gen. Knowledge

19 B ASMEV Art. 2 44 B

ASME IX, Table QW-461.9

20 D API 575 5.2.2 45 B General Knowledge

21 B API 650, 1.1. 17 46 C ASME IX, OW - 200.2

22 D API 653 10.5 .2.1 47 D ASMEIX OW := 153

c

r, .

23 C API 652 6.4 48 B ASME IX, OW - 191.2

24 C API653 9.14.1.2 49

D .

APL653

....

25 C ASME V Art . 2 50 B ASME IX, QW - 452

s. ' !- IOor. ,,\! - SUIh.-.H'1 TOWEr!!. Kmq Abdul aztz cor. Pnnce rats a! Bm Fahd Streets, Al -Khobar , Saudi Ar abia

I' Ll, : 9G()J 3 887 6633 F.,o, X (966) 3 as?G56 S info@'gotoi tc. com W\.......... . qot on c.com

. r T-l T E GF.P-.TE"i")

I r- -. I , ... c, : ; .;- I, I

'. "- , "<"0,_t . _.,.... . ...r ... . ' : 1,

Prcfe ssrcnal Traini ng and Consul tat ion

API 653 Preparatory

26111 uctc 31$I August 20 06, Al- Khob ar. KSA.

Page 1 of 8

FINAL EXAM (OPEN)

Instructions:

Choose only one answer, which you think is most appropriate.

Use the attached answer sheet in answering the following questions.

1. Exclusive of corrosion allowance, what is the minimum nominal

thickness for all new construction bottom plates?

a. 1/2 inch

b. 1/4 inch

c. 3/16 inch

d. 5/8 inch

2. For shell horizontal joints, how many additional radiographs shall

be taken for each 50 feet of horizontal joint, (not including those

required as per API 650) for welds made in existing plates during

t he repair?

a. 1

b. 2

c. 3

d. 4

3. The recommended minimum development time (penetrant

testing) allowed for a material made of high temperature alloy

is:

a. 5 min

b. 10 min

c. 7 min

d. 60 min

4. Select suitable hole type (source side) penetrameter for

following wel d joint:

Weld reinf. =118" thk

7/8"

thk

Backing strip = 3116" thk

3' 1= 10(;1, Al Tov.. Ki ng Abdul az tz cor . Prince Fai!>al Bin Fahd Street s, Al-Kho bar. Saudi Ara bi a

Ii TEL ! 9G6'1 3 387 GG33 CI FAX (96 6: 358, G565 e ir.f o,;:i'got oi t c.co:T: III www.q oro .rc.com

e _

I NTEG R A T E D

1 i ". '\ : t: 1 :-: G C r :: .:- I. I

.., '" ,'.'" ....... . ,'''0 ' ' {'"'"l\T lt IHP

Professio r.al Trai ni ng and Consu lt at ion

API 653 Preparatory

26th upto 31SI August 2006. Al -K hobar. KSA.

Page 2 of 8

FINAL EXAM (OPEN)

a) No. 20

b) No. 25

c) No. 30

d) None of the above

5. If type of penetrameter is Q.1 is changed to wire type what

shall be the wire designation (wire decimeter in inch)

a. 0.025 (No. 10)

b. 0.016 (No.8)

c. 0.032 (No. 11)

d. None of the above

6. For steel plates and weld to be checked LPI, what shall be the

penetration t ime for penetrant

a. 10 min for weld, 5 min for plate

b. 5 min for both

c. 10 min for both

d. 5 min for weld, 10 min for plate

7. After applying t he dry developer the examiner checked four

welds for surface defects after f oll owing period, weld A- after 5

minute, weld B after 10 minute, weld C was checked after 30

minutes and weld Dafter 65 minutes which of the weld were

checked wrongly

a. Weld A and B

b. Weld C and D

c. Weld D only

d. Weld A and D

8. Following combination of base metal and weldi ng electrode was

qualified by a certain PQR... impact testing is not required.

Base Met al =SA 285 GrC Plates, 314" th k

Welding electrode = AWS E 6015

o' i rocr. Ai r owers . KI:'1 g Abdulazr z Pnnce Fni5al Bin Eahc St reet s , At- Khober , Saudi Arabia

.. 387 G r/'.X (9GG: 3 337 0 5.5 G 0 vv-av.gOi:OI:c.cor.;

-----< I N T E G R A T ED

: t. \ J :; ; t ; : . r. :; -r I , I,

'. \ :' ,.., <.," "."", r"...r: H I',. ) Ce""

---- -------- - -- - - - - - - - - - -

?roressi on al Trai ni ng and Consult at ion

API 65 3 Preparat ory

26th up t o 3 1st August 2006. Al-Khobar. KSA.

Page 3 of 8

FINAL EXAM (OPEN)

This PQR will qualify which of the following combination of base

metal- weld ing electrodes.

a. 1" thk SA 515Gr 60 plates, E 6013 electrodes

b. 1 3f4 " rhk SA 285 GrC plates, E 6013 electrodes

c. 1 Y4 thk plates SA 516Gr70, E 7018 electrodes

d. None of the above

9. For MT examinat ion by prod techniques the spacing between

prods shall be between

a. 4 inch to 12 inch

b. 4 inch to 10 inch

c. 3 inch to 10 inch

d. 3 inch to 8 inch

10. For a tank wit h 130 ft diameter t hickness of top course worked

out was t d=5mm t t=4mm. What will be minimum nominal

t hickness provided for this course according to API 650 for a

new tan k?

a. 3/16" (5mm)

b. 1/4" (6mm)

c. 5/16" (8mm)

d. None of the above

11. For a tan k with diamet er 100ft was found to have thickness

reduction in a localized area. Minimum thickness observed (t2)

was 1 inch. What will be the critical vertical length of for the

area?

a. 40 inches

b. 37 inches

c. 45 inches

d. None of the above

Fleer. 'towers. King Abdulazrz cor. PrI'i ( E Bin Fahc Street s. Ar-x hcoar, Saudr Arabia

III TeLi9GGi 3 SS7 GG33 0 FAX (9136; 3 SSt GSf>S 0 mr o,J.'goroit c. com 0 www.qoto.t c. co rn

~ . .

.

I N TEGRAT E D

: t -. .-, : . ; : :-: c ~ . r :; -r I . I .

'.". "" " r .. . .. ' , ., ,,n . r. r RT l t' IU. C:c; .

Professional Trai ning and Consultat ion

API 653 Prepara tory

26

t h

u pto 31

1

t August 200 6, Al -K hobar . KSA.

Page 4 of 8

FINAL EXAM (OPEN)

12. On a tank roof plate two corroded areas was observed at

locations A and B for location A, average thickness = 0.085

inches, area = 105 in

2

Location B, average thickness = 0.095 inches, Area = 105 in2

your decision will be:

a. Both A and B are within limits

b. Location A i s OK, location B is art of limits

c. Both A and B are out of limits

d. Location B in OK, location A is out of limits

13. Hot tap connection is to be made on tank with following

description shell plate thickness = 314 inch. Design temperature

= 30F the plates were not tested for impact testing, (Consr.

Code API 650-1974) . What wi ll be the maximum size of tapping

connection?

a. 8 inches NPS

b. 6 inches NPS

c. 10 inches NPS

d. 4 inches NPS

14. A replacement plate to be used on a shell th ickness of 5/8 inch,

on the second course of the tank. Thickness of firs t course and

third course is also 5/8 inch . Following 3 plates are available

which one is most suitable to be used as replacement plate.

a. Plate thickness = 314 "

b. Plate thickness = 5/8"

c. Plate thickness = 1/2"

d. Plate th ickness = 1"

15. A t ank is having remaining corrosion allowance of 2.5mm and

corrosion rate of the shell is O.lmm per year. What will be

inspection int erval for next ultrasonic thickness inspection from

outside of the tank?

s' ;;IOCf , .\I - S:.; b'f2. !:J 1 0... ers. King Abdelaziz cor. Prince rersa! Bin Fahd Streets. At-Kho aar . Saudi Arabia

~ E L i ~ G G ; " S5 , 663 3 Co f AX(9GGJ 3 58; GS65 c ir.fo'.:i 'gotoit c.com 0 www.qot o.rc.c cr n

I NTEGRATED

.

, ,', '"

?iofess:ona! Training and Consul t at ion

API 653 Preparatory

26thupto 3l sI August 2006, At - Khober. KSA.

Page 5 of a

FINAL EXAM (OPEN)

a. 15 Years

b. 12.5 Years

c. 10 Years

d. 5 Years

16. Typical corroded areas on a shell plate are exhibited below in

figure 1 with measured thickness in inches indicated on the

sketch. The uri-corroded thickness of the shell plate is 0.750

inches and C.A is 0.125"

Figure 1

AREA "A"

.65

0.66

0.72

0.54

0.75

0.72

0.75

AREA "B"

AREA " C"

r. j KI:1lj Abdulaziz co-. Pn-tr.e r <: i Sil l Gin Fahc Streets . Al - Khuaa r , Saudi Ara bia

c i9GGl 3 S57 GG33 0 r/tx(9(;6J 3 58 765 65 " infO: ;?"got oltc. cO:T1 GO www.q ot o.tc.com

J. N T E GRA T E D

t II ..

Trai ni ng and Consult ati on

API 6 53 Prepar atory

26

lh

upt o 31 11 August 2006, AI-K hobar. KSA.

Page 6 of 8

FINAL EXAM (OPEN)

The total length of a arrow line drawn is 8 inches. The length of the

line in each of the corroded areas A, 6 and Care 1.5", 0.8" and 0.5

inches respectively.

Comment on t he acceptability of the corroded condition.

a. The pitting can be ignored as a case of widely scattered

pitting as both pitting depth and dimensions are within

limits

b. Not acceptable as size are not OK, total length of the pit

dimensions is more than permitted

c. The pitting can be ignored as a case of widely scattered

pitting since depth are OK

d. The pitting cannot be ignored as a case of widely scattered

pitting since depth are not OK

17. Two plates samp le A and 6 were tested for longitudinal impact

testing. Following were results observed. They belonged to

Group No. I as per API 650:

Results of impact test for sample A were 18ft Ib, 8ft Ib, 16ft lb.

Results on sample '6': 12ft Ib, 14ft Ib, 20 ft. Ib

Your assessment will be:

a. sample A and 6 both OK

b. sample A and B both to be re-test ed

c. sample 6 is OK, A shall be re-tested

d. sample a is OK, 6 shall be re-tested

18. For replacement t o an existing 0.25" t hick shell plate of an AST,

another plate of 0.25" thickness to ASTM A36 is used. What

should be the minimum clear distance between the outer edges

of the adjacent but t welds of verti cal and horizontal joints,

respect ively?

Hccr, Al -Subeae: rowers. King Abd ulazi z Pnnce Fai sal Bin Fahd Streets. Al -Khcbar , Saudi Arabi a

e 7!.. 3 8&76633 FAX (96G; 3 887 6555 wevvs,gOtOl-;: C. COr:1

~ I NTEGRATED

1 ' 0. -, , ~ . ~ I , ; C r , ~ :" i". I_

. ... N ~ . "<If),, r:rI<TI I'I"U <;{"

Profes sicnal Trai ni ng and Cons ult ation

API 653 Preparato ry

26

l h

upt o 31

01

Aug ust 2006. Al- Khobar. KSA.

Page 7 of 8

FI NAL EXAM (OPEN)

a. 10" & 6"

b. 6" & 3"

c. 8" &4 "

d. 12" & 6"

19. Repair of a 5/8" thick shell , using lapped (lap welded) patch

plate of 1/8" thick was carri ed out, without inf ormi ng t he

Owner. Such a repai r is not acceptable as per API standard

653, because:

a. Owner had not specified use of patch plate repairs

b. Lap patch plate of less than 3/16" is not permitted

c. Lap patch plate repair on shell thickness more than

above Y2" is not permitted

d. All of above

20. As per API Standard 650, the offset between vertical seams of

adjacent shells shal l be a min imum distance of:

,

\

a.

b.

c.

d.

5 t , where 't' is the plate t hickness of thicker shell

course at the offset

4t, where 't' is the plate thickness of thicker shell course

at the offset

3 t , where ' t ' is the plate t hickness of t hicker shell

course at the offset

2 t, where 't' is the plate thickness of thicker shell

course at the offset

21. When butt welded annular bottom plat es are used, in an AST

built to API Standard 650, their width from inside of the shell

shall be at least:

a. 900 mm

b. 300 mm

c. 600 mm

d. None of the above

B' " Floor , Ai -Subeae. Towers, King Abdelaz iz cor. Prince Faisal Bin Fahd Street s. Al -Khobar, Saudi Arabi a

(0 TEL (9G6"! i 8&7 66 33 6 FAX (96Gi 3 8876565 ... i nfo'J'gmoit c.com co www.qcrouc.ccm

- .,...

I_NTEGP...

r-...... J.:C"!"

Professtcnal Trai ning and Consultat ion

API 65 3 Preparatory

26

t h

upt o 31

11

August 2006 , AI-K hobar . KSA.

Page 8 of 8

FINAL EXAM (OPEN)

22. Misalignment in a completed 20 mm thick vertical seam of an

AST built to API Standard 650 shall be more than:

a. 2 mm

b. 1.5 mm

c. 0.8 mm

d. 3 mm

23. Out of roundness measured as deviation from radius

measured 1 foot above the bottom corner weld of alSO ft

diameter AST built to API Standard 650, shall not exceed:

a. 1" (25 mm)

b. V2 " (12.7 mm)

c. 3/ 4 " (19 mm)

d. 1-1/4" (32 mm)

24 . Local deviations from theoretical shape of an aboveground

storage tan k (AST), built to API Standard 650, specifically

" Peaki ng" at vertical joints or " Bandi ng" at horizontal weld

joints as measured over an appropriate sweepboard of 36" shall

not exceed:

a. 19 mm (3/4")

b. 13 mm (1/2")

c. 16 mm (5/8")

d. 1/8 mm (3")

25. An AST has remaining corrosion allowance of 3.2 mm. The

known rate of corrosion of shell is 200 microns per year. As per

API Standard 653, when should the external visual i nspect ion

by an Authorized Inspector shall be carried out at an interval

not exceeding:

a. 5 years

b. 8 years

c. 4 years

d. 15 years

---------------- --------- End -------------- -----------

S' rtcor. Suheaer To-... ers. King Abdul aztz cor. Prince Faisal E:n Fahd Streets. At-Rhobar , Saudi Arabia

;; T: !.. 3 58 7 56 33 '" F.. "\X {9G6"j 3 SS7 : 55 5 0 0 www.qcto.rc.corn

o

r::

(.";': \I."" . ........c c r....'H tll.- U ..Q 1

Prof essional Trai ni ng and Consultation

API 653 Preparatory

26

th

upto 31

st

August , AI-Kh obar, KSA

Page 1 of 1

FINAL EXAM (OPEN)

Answer Key

z; .::j ,",

Q. No. I Answer I" I L =;., .;;?.... ,::' :; ,"

1 I B I I API 650. 3.4.1

2 I

"'" A M API '653 ,,;; 'l' 2:'"

...:. ,.: ::.. . . .-' '. - . ''':' .. j

3 I c I I ASME Sec. V. Table T - 672

.. .

- .. '

I . ,.4,'. T.. '$ ,, "".: %"'",

5 I D I I ASME Sec. V. Table T - 276

, ';;! Cf'I' ASME'Sec.

7 1 D I 1ASME Sec. V. T-676.1

8 1 c 1, 1ASME:Sec. IXi" Table OW"- 422:"OW - ". ,., ,.

9 I D I I ASME Sec. V. T - 773.3

10 lei I API 650;'; 3.6.1.1

11 1 B I 1API 653. 4.3.2.1 (b)

:.; .-.

1'2 . I;.., ;.;, D . :l:'t01;, .oi; ., ...

,r, -"" r ..., . .. ' '''l -;_,:.0.' I: ,,," , ' .- .:>. ..

13 I D I 1API 653. 9.14.1. 1 (b)

14 1 $ 1;1API'653.r,; 92.1 \:!_, -"," C "', {'e, "

15 1 B 1 I API 653. 6.3.3.2 (b)

16 I -B I I API 653, 4.3:2.2 (b Y"" .,

17 1 ell API 650. Table 2-4. and 2.2.8.3

18 1 653;'" Rq. '\ "',,,,. -;

19 I D I 1API 653. 9.3.1. 9.3.1.3

,-

'i- " '::c :n

(

20

.Or I' , "A '" * API ' 650" "'3 1<5 2"(b)1. "'0.- .,.. <' ,'_.

,_ - I.. . , "\ " ., _ ,'._ ". _::.q. " . .... '_ .' ... ,... ,'

21 1 e l l API 650. 3.1.5.4

22 1 A

, 1 'I API' 650'" 5 2 3 .... ' "'", '.;.

c. '..0;' .'-! ' . :: """ . . . .tt r= -:'f.l '"4; .. ;.;.,:

23 I A I I API 650. 5.5.3

24 I B I 1API 650. 5.5.4

25 I c I I API 653. 6.3.2.1

g:. F!oer . Al - Subeaei Towers, King Abdulaztz cor. Pri nce Falsal Bm Fahd Streets, AI- Khobar, Saudi Arabia

TEL {9GGJ 3 887 6633 Fl\X (966) 3 887 6565 i nfo@.'gotoit c.com . .......wvv.qotoirc.com

r

-

..... .. , ..... ::. . :... , ;..' . l>... ,

Profess io nal Tra i ning and Co nsul tation

-::c--::-..-- -.- --- --- - ----

API 653 Preparatory

26" upto 31" August 2006, At- Kbober, KSA

Page 1 of 5

DAILY EXAM 5 (CLOSED)

Note: Encircle the letter of only one alternative which you think is most appropriate,

1. Guided bend test represents:

a, Ductility of weld

b. Strength of weld

c. Soundness of weld

d. Both soundness and ductility of weld

2, All positions of groove welds are qualified by

a, pipe positions lG and 5G

b. pipe positions 2G and 5G

c. pipe position 6G only

d. band c

3. According to ASME Sec, IX, A welder for SMAW can be

qualified by following minimum tests:

a. 1 tensile and 2 bend tests

b. 2 bend tests only

c. 2 tensile tests and 1 bend tests

d. 1 tensile and 1 radiography

4. Procedure Qualification Record is a document which can be

revised time to time.

a, True

b, False

Co Depends on company policy

d. Depends on client of the company

5. Use of Radiography is made f or :

a, Performance qualification only,

b. Procedure qualification only

c. Both a and b

: : (;'; i . T{:"-: t:I':>.King Abdelaz iz ( 0; . Pnn ce Fatsal Bin Fand Al -Khnbar, Saudi Arabia

TEl. (966; 3 88766 33 0 rAX (9G5) 3 887 G5G5 0 inf o-1Cgo:oltc.com 0 \\i\tvw. qotcr tc.com

r

T . \ I I :-; Co r: to N ,. I: it

. ... S I M.' " l " 1; " C U . ,

Professional Training and Consul tation

API 653 Preparatory

26t

h

upto 3 1

s1

August 2006, AI-Khobar, KSA

Page 2 of 5

DAILY EXAM 5 (CLOSED)

d. Use of Radiography is not permitted by.ASME Sec. IX.

6. Procedure Qualification is done by:

a. 1 Tensile and 2 bend tests

b. 1 tensile and 1radiography

c. 1 bend test and 1 radiography

d. 2 Tensile and 4 bend tests

7. Which of the following represent grouping of weld-metals in

ASME IX?

a. P - Nos

b. F - Nos

c. S - Nos

d. A - Nos

8. For A 516 gr 60 (SMTS = 60000 psi) material, following results

were obtained for two tensile test specimens in PQR

qualification.

Specimen T1: failed in B.M. at 57AOO psi

Specimen T2: failed in weld metal, at 59,500 psi

Your assessment is:

a. PQR test is ok since both are withi n acceptance criteria

b. PQR test is rejected as both T1 and T2 are not within

acceptance criteria

c. PQR in rejected because T1 is ok but T2 has failed

d. PQR i n rejected because T1 is fai led thoughT2 is ok

9. Based on a measured cor rosion of 0.006" annually and using a

corrosion allowance of 0.120", what is the interval for the next

UT thickness measurements on shell are required for AST?

(a) 10 years

i-IODI . Al Towe rs. King Abdulazi z cor. Prtnce Falsal Bin Fail d Streets. AI- Khobar. Saudi Ar abi a

e HI '')G6', 3 8El ? 66 3, FAX(goG) 3 887 G5G5 0 inro1' )gotQlt(. com . "' \IW\v.

,

--- - --- ---- -

I N T E G R A T E D

T '" . ... I :-.. I c. ; 1 f, It

. ... 1'0 I V,;> .. ..... , .. ... " .. <.;:. ,,- 0: .. .. 1> co ,

Professional Trai ning and Consultati on

-- ----- - - - -- -- -- - ---- -- -- - -- - - -

API 653 Preparato ry

26

th

uoco 3 August 2006, Ai-Khobsr, KSA.

Page 3 afS

DAILY EXAM 5 (CLOSED)

(b) 6.5 years

(c) 20 years

(d) 15 years

10. Per API 650, calculation of shell thickness by the 1-foot method

cannot be used for tanks:

(a) Under 200 ft. in diameter

(b) Over 200 ft. in diameter

(c) Under 150 ft. i n diameter

(d) Of any size

11. Impressed current system results i n following advantages

compared t o Galvanic System.

a. Can be used for large structures

b. Mai nt enance cost is lower

c. Installation is cheaper and easier

d. No external power supply requi red

12. Power source for impressed current system shall be checked at

i nt ervals not exceeding:

a. Annually

b. Six months

c. Two months

d. Five years

13. Thick fil m lining means thickness:

a. Greater t han 10 mils

b. Equal or greater t han 20 mils

).i ll' Flnl1f. .01 1_ "rowers. Ki ng Abdulazi z em. Prince Fai val Bin Fahd Stree t s. Al- Khobar , Saudi Arabia

Ii TFl 066'l B87 6633 . FAX (96GJ 3 887 6565 Gi nf o(!ll goroi t c,com . .....'vnv.gotOltc. corr.

~ I N TEGRATED

T i t .\. 1:": I 1"; (.: C.: i:. :-l "T " it

,.-.l" 1:-0 'm", .." ceo <::1: 11. 7 ; >" ..0 C ( , I

- --------- - - --- - - - ----:----:----- ------- - ---

Professional Training and Consultation

API 653 Preparatory

25" upto 3/" August 2005, Al- Khobsr. KSA.

Page 40f5

DAILY EXAM 5 (CLOSED)

c. Greater than 20 mils

d. Equal or greater than 10 mils

14. Sand blasting and painting operations shall not be performed if

humidity exceeds:

a. 90%

b. 80%

c. 85%

d. 95%

15. Which of the following statement is correct?

a. Soil resistivity is a measure of resistance offered by soil to

drill ing operation for oil exploration and it has no

connection with corrosivity of soil.

b. Lower soil resistivity indicates less corrosive soil.

c. Soil resistivity has nothing to do with corrosive ness of soil

because soil corrosion depends on the amount of corrosive

chemicals present in the soil .

d. Higher soil resistivity indicates less corrosive soil.

16. The preferred method for inspecting non-metallic coating is:

a. Visual inspect i on only

b. Holiday detection

c. M.P. check

d. D.P. check

b-" Hotn, Al SuueaerTcwers. "'tng Abdulaziz (or. Pri nce Fai sal Bm Fahd sneers. Al- Khobar. Saudi Arabia

Il T:: L ZJ GGi ; e ~ 7 6(;3 3 0- FAX e9G') 3 8ci G3G3 0 mfo:r'gotoitc. com 0 vrW \ v.qot ouc.com

C l;. NT i: 1I

' Al'> lH> ' , ,, ..,, ..m.. ' ,;:: 1\1" 1" ".1> (""(.0. 1

_. - --- _ ._ - - - - -- - - --_._---- - - - - -_..._- -------- - --- ------ -

Professional Traini ng and Consultation

API 653 Preparatory

26t

h

upto st Augusr 2006, AI-Khobar, KSA

Page SofS

DAILY EXAM 5 (CLOSED)

17. The accuracy of a piece of magnetizing equipment that is

equipped with an ammeter shall be verified:

a. Each year

b. Each two years

c. When possible

d. Every 6 months

18. It is decided to carryout a surface NDT for austenitic 5.5. welds.

Choose a best combination.

a. Penetrant testing with Halogen free developer

b. Penetrant testing with any aqueous developer

c. Magnetic particle testing with wet particles .

d. Magnetic particle testing with dry particles

19. In ultrasonic testing, for thickness measurement on corroded

surface, use:

a. CRT read out

b. Digital read out

c. Any of above

d. None of above

20 . For which of the following can yoke technique be used?

a. Sub-surface cracks

b. Surface cracks

c. Both a and b

d. For none of a and b

--------------------- end -----------------------

8'- tt ocr. AI St..::bf' H' :1'towers. Ri ng Abdul aziz cor. Prince Faisal Bi n Fahd Streets. Al-Khobar. Saudi Arabia

::l TEL i lJ6i BS7 6);3 It FAX 3 887 6 5G3 e e vvww.qo to rtc.com

'{;;. ffjl

.0:',,%

t .:t:::,.

(

'-:;c:--- INTEGRr"-TED

T 1\ .\ I 1'; I N U 0;: l t J T r ; t ,

, " N . <O f"> _"" " ".", ,, r.1' I' T ' t-I l.J. > ' "0 \

Prof eSSIOnal Trai ni ng and Consultat ion

, API 653 Prep a ratory

26

th

upto 31

st

August 2006, AI- Khobar, KSA.

Page1 of 1

DAILY EXAM 5 (CLOSED)

Answer Key

'"* ";:, .. .1'";:11 fi/

,;

Q. No. Answer

-

Reference: ', . _;:: - ,

' .:-111 Ii:: ,..c: ;".,..,..."

1 D ASME Sec. IX, QW - 141.2

2 D ASME Sec. IX, Table QW - 461.9

- ",' ...

,,,

3 B ASME Sec. IX Table OW - 452.1

4 B ASME Sec. IX OW - 200:2 (c)

".uf.

5 A ASME Sec. IX, QW - 142

6 D ASME Sec. IX OW - 451.1

,'- :./ '. r:

..

7 D ASME Sec. IX, Table QW - 442

8 C ASME Sec. IX OW - 153

'"

9 A API 653 6.3.3 .2 (b)

10 B API 650, 3.6.3 .1

-

_.

....

11 A API 651 6.3.3

12 C API 651 11.3.3.1

':--.

13 C API 652 6.1

14 B API 652 7.4 and 8.3

-"

,

-

15 D API 651 Table 1

16 B API 575. 7.4.7

-

'" "

,

17 A ASME Sec. V T-761

18 A ASME Sec. V, T-641

-

-,

19 A ASME Sec. V SE - 797 Para. 8

20 B ASME Sec. V T - 776.1

ito"'! .-

-

21 ---------

,

---------------------------------------------------------

22

23

24

25

t rn I T\. U: Ano J \ 3_FdH \,:?nO( - 26 - 3 I - Auqus t - 2006 ,APC6 53. PC 26- 3 I -Augus t

,\ PI.ii 'i 3. F' C2{j -31 - ALl g us t- 200i_[).1IlY_[ ,(,lrr,s , .. \ F'I. (i53_PC__ . Jc e v. doc

I If) 245:' AII. ', I NCO

! r "':'TE(";R i'J' .;,:T"E. D

_ \ . :. . , ; I , ..

.'. ... ",L'. .'... ::t ::. ... I. ,f. ,

__.0 . . _

Fr of::;ssiona. ! Training and Consultat io n

API 653 Preparatory

2 6

th

upto 3 1

st

Aug ust AJ-Khoba r, KSA.

Page 1 of 5

DAILY EXAM 4 (CLOSED)

Note : Encircl e th e letter of only one alternati ve which you think is most appropriate.

1. A hydrostatic test for a relocated tank:

Ldi!' May be wai ved by the Owner/Operator

Is required

c. May be wai ved by the Inspector

d. I s not necessary

2. Minimum thickness of tank bottom in critical zone shall be at

least 0.1 inch but also it shall be:

- -

a. Greater of: V2 t

min

for lowest shell course and half of

original thickness in critical zone

LA>. Smal ler of: 112 t min for lowest shell course and half of

original thickness in cr itical zone

c. 0.1" only

d. 0.05" as from Table 6-1, if leak detection system . is

provided

3 . During the hydrostatic test, no less than

measurement points shal l be surveyed.

-0. 8

b. 10

c. 15

d. 5

settlement

4. For vacuum box test, a partial vacuum of at least shall

be used using to check the cracks.

/'a. 3 psi, penetrating oil

b. 5 psi, water immersion

-.....cc.- 3 psi , film sol ution

d. 5 psi, li qui d penetrant

L' noo- . i;, l St.neavt Towe r s. King Abdut nztz Prince F21 521Bin Fa-td Streets, Al -Khobar , Sauer Arabta

e TFi. :'9(.0) :; 387 663 3 It FA.X as:" 65 65 0 vrv...... .

--y:::

. ...: . '-'V '' ..." . . ut:.. '. :, ' n l" " n CO,

API 653 Preparat ory

26

th

upto 31

sl

August 2006

1

AI-Khobar, KSA.

Page 2 of 5

:--- ---- --- - -

?iores s; onal Trai nf ng and Consul tation

DAILY EXAM 4 (CLOSED)

5. Which tests are usually conducted to verify acceptability of shell

to bottom plate welds! .

a. Penetrating oil .

b. RT

c. Vacuum box test

\...,/""' d . "a" and "c"

6. Except for cast iron parts, internal coils and supports may be:

,

a Dye penetrant tested

b. Leak tested

.,..-c Hammer tested

d. Magnetic particle tested

7. At the next out-of-service inspection on a tank that has had a

hot tap performed, the visual inspection should include:

a. Size of t he hot tap nozzle holes

b. Thickness of the plate at the hot tap

c. Height of the hot tap from the tank bottom

t...d-:' Trimming of the hot tap nozzle holes

8. The term "roof drain" is applicable for which type of tanks?

a. Tanks with a breather device inst all ed on the roof

b. High octane fuel tanks (Dome roof tanks)

Tanks with floating roofs (open top-tanks)

d. Tanks with internal floating roof

9. Industry experience and laborat ory test have shown that a

membrane stress in tank shell plates of at least is

requi red to cause failure due to brittle fracture?

a. 500 psi

b. 100 Mpa

c. 7 ksi

d. 18 kg/ mm

2

0' <Iocr . Al - Subeaet Towers. King Abdel aziz co-. Pri nce Fatsal Sin Fahd St reets, AI-Khobar, Saudi Arabia

' Sr.(;i S ::; S? CG 33 a F,' \.. x {gGb:: 3 SS7 6565 2 i nf c,':::' got ci rc. com SI ,:.'WW.90i0l : c.r om

.--;---

I ........... e s \;s ::-. n

... . '.'I....... ..."" ..:.. ... J " , . ,

--- -- - --- -- ----_._ - ------- - - - - -

:=- -:.'f essior:a i Tra in [ng and Consultati on

API 653 Pr epsret orv

26t/1 upt o 31

st

August 20 06, KSA.

Page 3 of 5

DAILY EXAM 4 (CLOSED)

10. Which of the following is an advantage of magnetic particle

testing over penetrant testing?

a. it can detect surface discontinuities with foreign material

imbedded in them

b. It is faster on i ndividual parts

c. It can detect near-surface discontinuities

d. All of the above

11. Which of the following types of discontinuities is not normally

detected by radiography?

a. Cracks

b. Incomplete penetration

L-C Laminations

d. Slag

12. The reason for periodical inspection of ASTs is to:

a. Determine their physical condition

, J b. Determine the rate of deterioration

c. Mai nt ai n safe operating conditions

All of the above

13. Resistance of grounding connection shall not be,

t.z:" more than 25 Ohms

b. less than 1 Meg-Ohm

c. less than 25 Ohms

d. more than 5 Ohms

';; " Hoot . ;' ,1 t ower s. King Abdula ztz cor. Prince Faisal Bin Fa.. hd Streets . Al -Khobar. Saucl Arabia

c: T::: L ('JGG} 3 88 760333 0 FAX t9 G6J 3 887 6565 " i :'r Cl v..w w.qotoi tc.ccm

-r ... I (; S T I . 1

.... s .. .... , ... , :; ..., ' :O' LI ' .- " l

P:Gfessional I ra i ning and Consultat io n

API 653 Preparatory

26

th

upto 31$1 August 2006, KSA.

Page 4 of 5

DAILY EXAM4 (CLOSED)

14. Internal inspection is primarily to:

va. All of the below

b. Ensure that the bottom is not corroded and leaking;

c. Gather data for shell assessment

d. Identify and evaluate bottom settlement.

15. Repairs on butt welds shall be radiographically examined by:

b.

c.

:.<- CEY.

Full radiography over entire repaired lengt h of weld

1 spot on repair portion for each vertical weld

1 spot on each 50' for horizontal weld

"b" and "c"

16. The API 653 standard covers the maintenance inspection,

repairs, alteration, relocation and reconstruction of tanks

constructed to as basic standards though it

may be adopted for other tanks also.

a. ASME

b. API 651

c. API 652

c/d. API 650

17. The complete or partial removal and replacement of more

than 12, inches of a vertical weld joini ng shell plates is

considered a: . '

a. minor alteration

b. minor repair

v c. major alteration

'" d. major,repair

(i ' 1'\ l1J! ,\I Tower S. K,ng Ahdul az tz cor. Pi mc e r euer Ern Fall d Street s. ... \1- Salle! Arab ia

"l Fj, 3 6633 0 FAX 1966J 3 ga7 655 5 0 0 wv....w.qoro- rc. corn

o "

- ..,- :" \ 1S t U N I It iI

d . ' , ..., .. :; .. -; ,,.,, 1> ..... .

Fi07eS.s;o na f l i Zirtl ;l g and Consultat io n

API 653 Pr eparat ory

26

1

/1 uoto 31

st

Augus t 2006

1

At- Khobsr, KSA.

Page 5 of 5

ee.", /c....; I'v5 0 cc u."rU

I i'\. \JV .(,. i c c.( C/ LJ. "

o....-J -::. OC'::: \.W'"

i '\.. RoyP:;.(I.- ? "J'

OJ t-L...L

DAILY EXAM 4 (CLOSED)

The difference between peaking and banding is:

a. peaking pertains to the roof;

b. banding is external t o the tank;

t- ". peaking pertains to vertical weld seams, banding

pertains to horizontal weld seams;

Cl-:" peaking pertains to horizontal weld seams, banding

pertains to vertical weld seams.

18.

19. The minimum interval for external inspection by a qualified

inspector is __ years or at the quarter corrosion-rate life of

the shell, whi chever is less:

a. Twenty

<-1J. Five

c. Ten

d. Fifteen

20. The minimum retirement th ickness of an annular plate ring is

usually greater than:

0.10 inch

b. 0.25 inch

c. 0.0625 inch

d. 0.1875 i nch

-- - - - - -------------- end - - - -- - - - - -- - - - -- --- -

1" 1 ,':.' Sub" ,:" Y.i :'II] ..... bdt.laziz CQ ' Prince Fa:s;:181:1 FJ. l1d Str eets . Al -Khcbar, $iwdl Arabia

o l l.t. S8 ? i.iG :3 tI FAXr.9 ()6i 3 587 6565 It C we....w.coronc.corn

l

-------:;c-- 1NTEGRATED

'. r " " 1 '" I Cl t : I : .... -r It

..,,, ,, 'U''''' , <. 1 lUI)' '' 0 , : .. "

Prol essional Trai ni ng and Consultation

API 653 Preparatory

26"' upto 31" August 2006, AI-Khobar, KSA

Page 1 of 1

DAI LY EXAM 4 (CLOSED)

Answer Key

,

Q. No. Answer

,

1 B API 653, 12.3.1.1 (a)

2 B API 653 4':4.7.4

.....st.i'. .,

3 A API 653, 12.5.1.2

4 C API 650. 6.6.3

"

'... 2. u

5 D API 653 12.1.6. 1

6 C API 574. 7.4:9

":-= 'i.

7 D API 653 9.14. + General Knowledqe

8 C Ge neral Knowledoe for Tank Insoector;;:''?1!),';''''\' '>'2iFrr."",

9 c API 653 5.3.6

10 D General Knowledne for Anv Insoector

. _;'

11 C ASMEV. Art. 2 + General Knowledqe

12 D API 575. 5.1

" .:.-

. i:' ... "',..;\,C -r -

13 A API 575, 7.2.6

14 A

,

API 653. 6.4.1.1-

"

.. -

,'{' '''' ;l?:':

15 A API 653 12.1.3.20

16 D API 653. ' 1. 1. 1

;>j; -" ,

17 D API 653. 12.3.1.2 (c)

1718 .eD API 653. 10.5.4

, ;.;i

i l ,,';c

19 B API 653. 6.3.2

. 20

A API 653 4.4.8.1 i ' ', .t'

:-ii-:J '.....'.<dO;

21 ----- ----

-------------------------------------------------------. -

22

23

24

25

-r; ,'. -.c-actoz.z cor. ?r,n::e Fo!!:::: bn -ono . . ':; ouoi Arobio

':: .. ::.:':. 196 61: 5.3:> !;S6S - l'i :-:; s.;: :,.:.:;itc..c o m _ w..........,'.gqtoitC.COrr.

I . ', ! h ,: 1_ T 1:;4

, . :;.<.>. .. " . . ." ., ,, . .. 7n " ,. CO. ,

Profes sto nal Tra ini ng and Consultation

AP/653 Preparatory

26t

h

upto s t August 2006, AI-Khobar, KS"A.

Page lofS

DAILY EXAM 3 (OPEN)

Note: Tick only one alternative which you think is most appropriate.

1. Typical corroded areas on a shell plate are exhibited below in Figure

1 with measured thickness in inches indicated on the sketch. The

minimum required thickness of the shell plate is 0.750" and C.A.

required is 0.15".

Figure 1

0.65 X

0.66 x

x 0.72

xO.54

x 0.75

x 0.72

x 0.66

x 0.75

0.72

AREA "A"

AREA "S"

AREA "C"

:. .

The t ot al length of arrow line drawn is 8 inches. The length of

the line in each of the corroded areas A, Band Care 1.5",

0.3" and 0.2" respectively. Comment on the acceptability of

the corroded condition.

"'8. Acceptable

b. Not acceptable

c. Conduct a patch plate repair

d. The pitting can be ignored as a case of widely scattered

pitting

f l DCI . - Subeaei 1 0':;1;: 1" 5. KIng Abd ul azt z COl . Prince Faisal Bin Falla Street s. Al- Khobar . Saud i .Arabia

'TE L ::)65'1 BS7 5533 0' f AX (9(,6) 3 BS7 6565 c mf o':"DgOtoi : c.com 0 www.qctcnc.com

l KTEGRATED

T ;: .v I e-, I C E. :-.: T 1: ;:

. .'_ , .. , -,_,.. j ,',.::,_ . ' ..... . ,'" I

-- - - -- --- ----- -------------------

t ra;n:ng and Cons ultat ion

API6S3 Preparat ory

2@h upto 31

1t

August 2006, AI-Khobar, KS'A.

Page20fS

DAILY EXAM 3 (OPEN)

2. A tank is constructed as per API 650. Its original thickness is 0.500

inch. Its diameter is 25 feet and height is 15 feet. After 10 years,

the tank is inspected ancithe following readings are recorded on the

shell. Figure 2 exh ibits a corroded portion of the developed shell of

the tank from the inside. The designed corrosion allowance is

0.125". Minimum thickness (t

2

) is among the following readings.

Plane A Plane B Plane C Plane 0

0.345 0.500 0.450 0.480

0.400 0.450 0.400 0.475

0.500 0.435 0.330 0.315

0.480 0.475 0.350 0.275

-

0.495 0.485 0.375 0 .300

0.480 0.450 0.400 0.350

0.485 0.470 0.425 0.400

t' ,'-I b

Fi gur e 2

a -n'

: It':)I. !" TO.... ... . k.1 :-:y cot . Prtr ce Ei n Fn. hC: ..Al - Khobar. Saudl Arabia

0: TEL f9EG'; 58, 5(33 0 f;\X !9GGj 3 BB: Gi GS c 0 wwrr ,cotouc.ccrn

---r- I N 'TE. C; l-l..t- '...'T E:L:'

........... ' -<: :"I T :i. H

....,. .. ,"" . -,..." . ,,..":',..

!:ai ni :1g and Consultat ion

-- --- ------- - - -:-=- --:---:-- - -

AP/653 Preparatory

26

th

upto 31S' August 2006, Al - Khobsr; KSA.

Page 3 of5

DAILY EXAM 3 (OPEN)

What is the minimum thickness recorded?

a. 0.315"

vb. 0.275"

c. 0.330"

d. all of the above

Calculate the critical L dimension for this condition 3.

.....-a.

b.

c.

d.

9 .7"

40"

12"

All of the above

" .2; 5-

L -; 3 '}

... q .1-'"

For the same conditions of Figure 2 if the location of the bottom of

the critical length is 2 feet from the tank floor and the designed

liqui d height is 12 f eet what is the value of H in the formula for

calculating t min? \) .

4.

,;V

.....

a. 3 feet

o

l I

b. 15 feet

vt. 10 feet

d. 13 feet

5. Find the value of S which may be assumed for the lower course of

old tank for calculat ing t

min

considering the fact that the material is

A516 gr 70.

04. 30,000 psi

b. 18 , 000 psi

c. 23,995 psi

d . 23,595 psi

;.: F -., r . ......1 :; 1,I:1g Abdul az-z COf. Prir:c ,>: Fa: sr.! Bir. Fahd Street s. Al -Kh ohar . Arabi a

. i:'L :'}G(,: 3 SS;' ::; C33 II> r .;";.\" :9GG; ::' 567 '35C15 . .v.wv,qctoit c.cor-i

o

------c-

: ;:: . _ 1 - , : (; c: ... -r i r;

....... ,... ....", ."..",.",".TIl" " .:.;.

. - _.. .-- - - - ------ _ ._---

?rcfessi oi":al T: zin i ng and Consult ati on

AP/653 Preparatory

2(jrh upto st August 2006

1

AI-Khobar, KSA.

Page 4 arS

DAILY EXAM 3 (OPEN)

6. Find the value of the allowable stress in the first shell course

of the conditions of the tank considered in above question if

material is not known.

a. 4680 psi

Vb. 23600 psi

c. 2550 psi

d. 30000 psi

7. From t he data of Figure 2, wh ich of the plane above will be

considered to calculate t

1?

a. Plane a

b. Plane b

c. Plane c

vet. Plane d

8. What will be the value of t

1

for above question?

\

a.

b.

c.

Jd.

0.380"

0.397"

0.468"

0.371"

9. A corroded roof plate is found to have an average thickness of

0.1" measured over an area of 100 sq. inches. This area shall

be:

a. Repaired or replaced

.AS. Found to be acceptable

c. Repair is prohibited

d. Replacement is mandated

:.:; -\.i Trr... [\mq Abdul azrz ( OT. Bin Fa hC: St re et s. At-Kh obar. Saud i Ara bi a

il!. ":l',l j SS ;" i t ,3:; F1; :" !950} 3 he,: C!

-

----..........--- ". ..... - '-'l- "'C ' ''' 7'") '\ ..-- - ,

.'-., "" .:.....,:......' ...-.... ... J. .t:.. .

I :' .' I I >- . ,; " i . T t it

. " , : .. >., .... , ...".. . ,,,:-:' 1. ' ' '

- - - -- - --

;,:) rc'i ::; ssional T:-aining and Consultati on

AP/ 6S3 Preparatory

2@h upto st August 2006, AI-Khobar, K:S"A.

page50f S

DAILY EXAM 3 (OPEN)

10. When determining average thickness in a corroded area of a

shell, a minimum of equally paced measurements shall be

taken ove r a lengt h of L. Spa'.)

a. 10

vb. 5

8

d. 6

11. Vertical welds must be ful ly radiographed if the shell

thickness exceeds inches:

a. 3/4

Ur. 1

c. 1 - 1/4

d. 1 - 112

12. Anticipated minimum t hi ckness of tank bottom where bottom

/ foundation design provides for leak detection and

containment is:

a. 0.10 inch

----6, 0.05 inch

c. 0.09 inch

d. same as wi t hout leak detection and containment

----------- ------------------ End ------- ----------------- - - ---

F LOI -\I TQ\o.... ll. !n g Ahdul aziz COL ::".i s<,.l Blr' Sn eers. Al -K hcbm. Saudi Ar abi a

j ' EL ' :)65: 3 537 [,633 :SGU! :5 &57 G565 e Cl

..,. "

'"'I '

I N'TEGR A TED

, .. \ I " \ l . v .. t..: T I I

, 0.,. ,'.,,' HO' :,..... c or TI . II. " . ,

Professi onal Tra ining and Consultation

AP/6S3 Preparatory

2@h upto st August 2006. AI-Khobar. KS4.

Page lof2

Q1.

DAILY EXAM 3 (OPEN)

Solution

The pits are acceptable if:

a. Thickness at bottom of pit (excluding tmin.; and

b. Sum of dimensions in 8" lenqth s 2"

In the example,

a. The minimum thickness at bottom of the pit = 0.54"

The thickness C.A. = 0.54 - 0.15 = 0.39"

This thickness V2 t ml

n

0.39" @:} V2 (0.75), i.e. , 0.39" 0.375" ---------- OK

,..-

b. Total sum = 1.5 +0.3+ 0.2 = 2" - - - - - - - - - OK

ANSWER: A

Q2. Minimum thickness (tz) = 0.275

ANSWER: B

Q3. L = =

ANSWER: A

x 0.275 = 9.7

Q4. liquid height = 12'

H = 12' - 2' = 10'

ANSWER:

S' ! tocr, "rowers. Ahdul aztz cor. t' nnce rc .se! Bin r an rt Streets. Al- Khobar . Saudi Arabia

1H 196G) ] 887 G633 FAX (U6(i J 3 SSi' G5GS mfo::,l 'gotol t c. com www.qorouc.com

U-: T EGRATED

I;; , I . , i- I .. I t - ,

.... .-"nt . :.... .. ... .

Professional Trai ni ng and Consultation

API6S3 Preparatory

26" uato 3 1" August 2006. AI-Khobar; II:S"A.

Page lof2

DAI LY EXAM 3 (OPEN)

Solution

Q5. Refer Table 4-1

S = 30,000 psi

ANSWER: A

Q6. Consider the value for:

Y = 30,000 psi and

T = 55,000 psi

Refer Table 4-1

ANSWER: B

Q7. The total of thicknesses taken on plane D works out to =

2.595" which is smallest of all planes A, B, C, and D.

ANSWER: D

Q8. Value of tl = 2.73/7 = 0.371"

ANSWER: D

Q9. The thickness is more than 0.09" - - - - - - - OK

ANSWER: B

Q10. ANSWER: B

Q11. ANSWER: B

Q12. ANSWER: B

I rcor. -\ I - $l.lo:;., t:; o,-,er s, KIIl 9 cor. Pnnce Bill rcner At-Khobar , Saudi Arabia

1El J ee, UJ33 FAXiYflUI tiS; 1j56 5 tntoa-qotomrorn www.qcrouc.com

INTEGR ATE D

'1' I, I N IN O C L N f L I .

t ,\S . ... . ' '''In . . .. ..u r. "'"T'ULU u ...

- - ------- - - - - - - - -

Prof essional Trai ni ng and Consult at io n

API 653 Preparatory

26' upto 31" August 2006, AI-Khobar, KSA.

Page 1 of 1

DAILY EXAM 3 (OPEN)

Answer Key

Q. No. Answer Reference

.

.

1 A API 653 4 .3.2.2

2 B API 653

-

- "'";, .

3 A API 653. 4.3 .2 .1 (b)

4 C API 653. 4.3.3.1

'

- ,,,

,.......,

5 A API 653 Table 4-1

6 B API 653. 4.3.3.1

7 D API 653. 4.32.1 (c)

8 D API 653 4.32.1 (c)

.

9 B API 653, 4.2. 1. 2

10 B API 653 4.3.2.1(C)

. ""' "

11 B API 650. Ro.6-1

12 B API 653. Table 6-1 I 't. .,..,' ,.;; "" .,"

----- --

------------ ---------------------------------------------------------

...............__ - _ - --- _-..................................................-- _-_.

f- lJ(j 1 :.. In.; ' fO l :' . IWHJ Abdulaziz COL Pn nce Faisnl Itm fil hd St reet s. At- Khobar . Saudi Arabia

.. It!.. .::; SE; (&33 I-AX 3 ss; Ifl f o.:PgoI Oltc. com www.qor ou c.ccm

- -- -- - ---- - - - -

and Consultat ion

AP/653 Preparatory

26

th

upto s t August 2006, AI -Khobar, K5A.

Page l of 6

DAILY EXAM 2 (CLOSED)

Note: Encircle the letter of only one answer which you think is most appropriate.

1. Maximum design internal pressure in an AST referred to by API

650 and API 653 is:

vii. Not exceeding 2.5 psig

b. 15 psig approximately

c. Not exceeding 5.00 psig

d. None of the above

2. As per API 650, the design metal temperature of an AST is based

on the lowest one-day mean temperature in the locality where

the tank is installed, it is:

a. 15C above the lowest one day mean temperature of the

locality

vb. 8C above the lowest one day mean temperature of the

locality

c. Same as t he lowest one day mean temperature of the

locality

d. 5C below the lowest one day mean temperature of the

locality

3. In an AST built to API Standard 650, the minimum nominal

t hickness of bottom plates, exclusive of specified corrosion

allowance shall be:

a. 12.7 mm (1/2")

b. 8 mm (5/16")

.,c, 6.0 mm (1/4")

d. 5 mm (3/16")

4. The full course width for shell plate as per API 650 shall be

minimum:

vB. 72"

b. 96"

c. 60"

d. 90"

. --- - - - - - - - -- - - - - - - - - - - -

? r0fess i !12! Tr ai nin q and Consultation

AP/653 Preparatory

26" uoto3 ,,, August 2006. At-Khober, KSA.

Page 2 of6

DAILY EXAM 2 (CLOSED)

5. In accordance with API Standard 653, Repairs and Alteration

have been defined as distinct activities. State which of the

following activities does not constitute an Alteration?

a. The addition of man-ways and nozzles greater than NPS 12

b. Increase and decrease in tank shell height

0. Replacement of damaged flange on nozzle by flange of

same size and material

d. All of the above

6. In accordance with API Standard 653, Repairs and Alteration

have been defined as distinct activities. Activity which entails any

work necessary to maintain or restore a tank to a condition

suitable for safe operation. State which of the following activities

does not constitute repair?

a. Re-Ieveling and/or jacking of a tank shell, bottom or roof

b. Addition of reinforcing plate/s to existing shell

penetratlon/s

<c. Changing the content with higher specific gravity

d. Repair of flaws, such as tears or gouges, by grinding

followed by welding

7. In accordance with API Standard 653, Critical Zone for repairs to

a tank bottom is that portion which is:

a. Measured vertically upwards along shell , within 6" of tank

bottom

./IS. Measured radially inward, within 3" of the inside edge of

shell

c. Measured radially outward within 1 '12" of outside edge of

shell

d. A circular area measurable radially within 12" from center

of tank bottom

8. Normally the corrosion rates of the tank bottom control the

inspection interval, which are based on the actual or anticipated

rates of corrosion. In the case of a tank, where corrosion rates

are not known, and where similar service experience is not

:. .s .. T'J....c;-s. \( P'i Q cor. Pnnce Faisal 5!,,; r and ;; I Khoba'-, Ara.xa

a ; b.. : ',E,G) 3 ,137 GG33 FAX (96G) :1 dS , 6 ) 6 5 c.'l It

: , ; ; I' L e-, ;" i I ;

. ,- , ' ' , ..... . t "'1" I ' I ' . -. ";

-

Trai ni ng and Cons ultat ion

AP/ 6S3 Preparatory

26

t h

upto 3/

Jt

August 2006, AI-Khobar, KSA.

Page 3 of6

DAILY EXAM 2 (CLOSED)

available, the actual thickness of the bottom is to be determined

by due inspections within:

a. 20 years

b. 5 years

---c. 10 years

d. 2 years

9. In case of the following conditions, the risk of failure by brittle

fracture in an AST built to API Standards is minimal:

a. Tank shell thickness 5/8" and shell metal temperatures at

20F and above

_b. Tank shell thickness 1jz" and shell metal temperatures at

60F and above

c. Tank shell thickness 3/ 4" and shell metal temperatures at

32F and above

d. Tank shell thickness 1" and shell metal temperatures at

OaF and above

10. As per API Standard 653, a routine, in service, close visual

external inspection of an aboveground storage tank CAST) shall

be done, at an interval not exceeding:

a.

dla.

d.

One year

Five years

One month

Ten years

11. As AST has a measured shell thickness of 0.75"; and it s

minimum required thickness is OS'. The known rate of corrosion

of shell is 5 mils per year. As per API Standard 653, when should

the external visual inspect ion by an Authori zed Inspector be

carried out at an interval not exceeding ?

a. One year

Five years

c. Twelve and half years

d. Ten years

;-;0

1

: Al- ':'w ::! c:: (' Towers. cor , PnriCC f a1sa! Ei"1 F" hd Streets. Al -Khoba!', Saudi Araofa

" !'] GG: OJ 83 ;' -5633 c Fft.x :966) 3 83 7 c ':I wvvvv ,qotcitc.com

- ------- - - - ---

Pr:::fe2s:C.nzl Traininq and Consultat ion

AP/6S3 Preparatory

26" upt o 3 1" August 2006, Al- Kbober, KSA.

Page 4 of5

DAILY EXAM 2 (CLOSED)

12. An AST has a measured shell thickness of 0.75; and its minimum

required thickness is 0.5". The rate of corrosion of shell is not

known. As per API Standard 653, the external ultrasonic

thickness measurement shall be carried out an interval not

exceedi ng:

a. One year

v-lr. Five years

c. Six &half years

d. Ten years

13. An AST has a measured shell thickness of 0.75"; and its'

minimum required thickness is 0.5 ". The known rate of corrosion

of shell is 5 mils per year. As per API Standard 653, t he external

ultrasonic th ickness measurement shall be carried out at an

interval not exceeding:

a.

b.

d.

One year

Twenty-five years

Fifteen years

Ten years

14. Corrosion on the bottom side of floor plates in aboveground

storage tanks is affect ed most by:

a. Composition of the contents stored in the tank <.

b. Welding procedures used during construction of t he ta nk

c. The metal used for construction of the t ank floor

'--'"t'l. Soil characteristics directly underneath t he tank

15. If arc strikes, gouges, or tears from temporary attachments are

ident ified, th ey:

Must be evaluated on a case-by-case basis

b. Must be repaired by welding with an appropriate repair

procedure

c. Must be repaired by removing the plate area containing the

scars and welding in a butt-welded patch

d. Are acceptable, provided they are more than 2 feet from

any wel d seam

',. A T::'::.t:J"s, 1( 11": 9 ..raz z co r. 5,:'"", FJhd ;-':-;l,r:ob::,"" Sauci

i lL \ ) ; .r: 1 6f.3 1 0 f AX[!.H:,G:O 3 SS;' I;: ':O'T: 0

;( .. ! .. : . : I' I :

' ".,," ,'<, ...... , : ...,.. ' . ' 1<."1 ' 11.0<... .

- ---- - - - --- - - - ---::-- -:-

AP/6S3 Preparatory

26" upto 3 I" August 2006, Al -Kbobsr, KSA.

Page Sof6

DAILY EXAM 2 (CLOSED)

16. Reinforcement pads shall be tested by applying pressure

between the tank shell and reinforcement plate using the telltale

hole. How much pressure is used to perform this inspection?

a.

b,

c.

15 psig hydrostatic pressure

5 psig pneumatic pressure

5 psig hydrostatic pressure

15 psig pneumatic pressure

17. According to API 653, authorized inspection agency is :

a. Inspection organization of jurisdiction

b. Inspection organization of insurance company which

underwrites insurance of storage tanks

c. Inspection organization of owner-operator

Any of the above

18. For all repairs and alterations under API 653 , the ultimate

responsibility rests with:

......a.- Owner-operator

b. API Committee

c. API 653 Inspector

d. Jurisdiction Authority

19. In API 653, the term "RBI" mea ns:

a. Repai ring Before Inspection

b. Report Based Inspection

c. Repair Based Inspection

Risk Based Inspection

20. Partial or complete jacking of a tank shell is considered :

a. Routine maintenance

b. An alteration

....c-- A repair

d. None of the above

:- :.CJ ,\ KmCj AOCl :.-l : : :z C'Jr. != aiSil l m:i r z. hC St ('2et s. Sauc l AraJI;

" T:". ,",jf,C) 3 j' GG33 e FAX i 9GGj :; 88 ;- 6565 Q l :"l fo.;oYO:Olt C. CO:n C ',v.'vvv ,g Oi.C:1C. C0r.1

11" T 1='r-' '!J , .... _ ... . _ _ ..i..." J... .

- : ; \ : I ;-. , 1 : : l. : It I.

1 _. " ''' ' ... ,, ' : " ".l . _.1"" 7 I I I I 1 " .: . ,

I rai ni ng and Consultation

AP/653 Preparatory

26" upco 3 T" August 2006, A/-Khobar, K5A.

Page 6of6

DAILY EXAM 2 (CLOSED)

21. A corroded area of a tank bottom plate is filled-up by welding

overlay. There is no change in the rating and no change is made

on the nameplate. Which of the following is the correct term to

describe this process?

Repair

b. Alteration

c. Can be repair or alteration

d. Neither repair or alteration

22. Under which of the conditions listed below is external inspection

of tank bottom plate permitted to be done in lieu of internal

inspection?

In cases where constructions size or other aspects allow

external access to the tank bottom to determine plate

thickness.

b. External inspect ion to determine bottom plate thickness is

never permitted in lieu of internal inspection

c. For tanks made of materials which have excellent chemical

resistance

d. All of t he above.

--- --- -- -- -------- ----- -- -- End -------- --------- ----------

lNTEGRATED

: I . . .. I 1": I ,.; .; , ' L N T I I

to. ' " , . .. . . . , .. . ... " ' ." l' TIJ " .1' , .

Professional Traini ng and Consul t ation

API 653 Preparatory

26

th

upto 31

st

August 2006, AI-Khobar, KSA

Page 1 of 1

DAILY EXAM 2 (CLOSED)

Answer Key

l

Q. No. Answer Reference

c

1 A API 653 3.3

2 B API 650 , 2.2.9.3

.'" ;,

..

3 C API 650 3.4.1

4 A API 650 3.4.1

5 C API 653 3.1

6 C API 653 3.15

7 B API 653 3.9

8 C API653, 6.4.2.2

9 B API 653, Flq. 5-2 & 5.3.4 & 5.3.5

10 C API 653 6.3.1.2

11 B API 653, 6,3.2 .1

12 B API 653, 6.3.3.2 (a)

.."

13 C API 653, 6.3.3.2 (b)

14 D API 653 4.4.7.1

15 A API 653, 4 .3.6