Professional Documents

Culture Documents

Mini Chopper Plans

Uploaded by

meblisboaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mini Chopper Plans

Uploaded by

meblisboaCopyright:

Available Formats

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

1

MINI CHOPPER PLANS BY

SOLUTION DESIGN (Revision2A Nov6, 05)

CLICK HERE TO REGISTER & UPDATE

Frame#1 The Little Stretch (Page 6)

Frame#2 The Little Tyke (Page 27)

Frame#4 The Easy Brute (Page 62)

Frame#3 The Rat Fink (Page 41)

Frame#6 The Hulk (Page 90)

Frame#8 The High Boy (Page 116)

Frame#7 The Low Boy (Page 104)

Frame#5 The Black Widow (Page 74)

Most

Popular

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

2

Need To Know How?

Need To Know NOW?

Then check out the worlds largest mini chopper resource

on the web!

HardCoreMiniChoppers.com

Heres a small sample of the topics you can learn from and

participate in:

Frame Building

Engines

Clutches/Torque Converters

Bodywork / Paint

Front ends

Electrical

Bar Stool Racers & Other Custom Rides

Some of the most knowledgeable builders in the industry

call the Hardcore Mini Chopper Forum home.shouldnt

you?

Welcome to Hardcore Mini Choppers

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

3

INTRODUCTION

Research the necessary cost & tools required to start this project. It

would be a disappointment to start but never finish. Keep in mind that

you could rent or have the more complex work done for you if you do

not have the experience or the tools. Get written quotes for material

and labor. This will help protect you from being overcharged.

Tools Required

Tube bender

Welder, (I use a small Lincoln 135t portable welder)

Drill

Wrenches, sockets, grinder, screwdrivers, hole saw, etc.

Where to Begin

I started by building the frame, bending the necessary tubes to create the main

frame and the handlebars. I used the details I have provided to make these parts. I

tack-welded the frame only until I had the complete mini bike built. I wanted to

be sure the position of the handlebars; foot pegs and seat fit my nephew.

Make sure the engine and clutch are aligned straight with the rear sprocket. This

is critical to smooth operation.

Make sure the rear tire is also aligned straight. I used a make-shift wooden jig to

hold the frame while I measured to ensure the axel bolt was in the right position. I

drilled the holes first, then using clamps, positioned them in the right position

before tack welding.

Do not allow any pre-test runs before the brakes have been added. I have seen a

few minor spills that could have been much worse because the bike was ridden

without brakes.

Have all worked checked by a professional. Good welds are vital to safety!

Measure twice - cut once. Be safe!!!!! I miscalculated a few times and had to go

back for more tube. I found out that it is a heck of a lot more expensive when you

only buy in small quantities. Quite often the cut charge is more than the piece you

may have needed.

Use only D.O.M tube.

All water pipe, conduit, fencing, etc., have different properties. They

also are not a true and perfect diameter. When you bend these using a

precision bender, the bends are weak because they do not fit the dies

correctly.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

4

Disclaimer and Limitation of Liability

THE ENTIRE RISK AS TO THE QUALITY AND

PERFORMANCE OF MATERIALS, INFORMATION,

ACCURACY, ADEQUACY, COMPLETENESS,

CURRENTNESS, VALIDITY AND QUALITY OF

INFORMATION IS WITH THE USER. IN NO EVENT

WILL SOLUTION DESIGN BE LIABLE TO ANY

PARTY FOR ANY DIRECT, INDIRECT, SPECIAL,

PUNITIVE OR CONSEQUENTIAL DAMAGES OR

ANY CLAIM ATTRIBUTABLE TO ACCIDENTS,

MISHAPS, FIRES, ROLLOVERS, EXPLOSIONS,

FAILURES, ERRORS, OMISSIONS, OR OTHER

INACCURACIES IN, OR DESTRUCTIVE PROPERTIES

OF ANY MATERIALS, MANUALS, INFORMATION

ECT

READ THE FOLLOWING

ENGINES, AND THE EQUIPTMENT THEY DRIVE

ARE AND CAN BE VERY DANGEROUS TO

OPERATE. THEY ARE ALSO DANGEROUS TO

WORK ON. IT IS ASSUMED THAT ALL PERSONS

WORKING ON OR WITH THE MATERIALS IN

QUESTION ARE CERTIFIED AND QUALIFIED TO

WORK ON OR WITH THE REQUIRED TOOLS.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

5

Helpful Hints

Plan, Plan, Plan - Building on the fly is fun but can be costly! Take

the time to understand the project, the materials and the total cost.

Measure twice - cut once!!!!!!!!!!!!!!! This is the golden rule!!!!!!!!

Good professional welds are important!! Do not compromise

safety!!!!!

When welding the frame, tack it first!!!! You may want to change

the frame to fit your needs and a tack can be easily removed!

Build the jig; it is well worth the extra time. It will ensure the

frame is straight and accurate

Ebay has some great deals!!!!!!!!!!!! Shop around for the best

prices!

Be sure you have brakes! Resist the temptation of that first ride

unless the bike is complete.

Take your time!! Do not cut corners!! You will end up with a

much better final project

Be sure you know how to operate the required tools. If you dont,

seek the assistance of somebody who does. This project can be a

great learning tool.

Wear all necessary protective clothing when working with

grinders, welders, and other power tools.

Always wear safety glasses when working with ANY tools.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

6

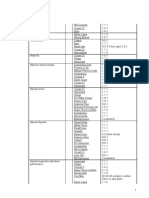

Frame Bill Of Material

Item Name Description Purchased Fabrication

Reqd

Quantity

1. Frame D.O.M See frame B.O.M Yes Online links

2. Steering Neck D.O.M See frame B.O.M Could be either Online links

3. Engine mount plate See detail Could be either Online links

4. Axel hangers See detail Could be either Online links

5. Front gusset See detail Yes Online links

6. Jack shaft hangers See page Yes Online links

7. Fender supports See page Yes Online links

8. Fender mount brackets See page Yes Online links

Front End Bill Of Material

9. Front tire mount brackets See detail Could be either Online links

10. Front fork tubes See front end B.O.M Yes Online links

11. Triple Trees See detail Could be either Online links

12. Steering Bolt 3\4- 10nc x 6 long Yes Online links

13. Handle bar risers See detail Could be either Online links

14. Handle bars See detail Could be either Online links

15. Front tire assembly 16" or 20" See page Yes Online links

16.

17.

Engine Drive Train Bill of Material

18. 3.5hp - 6h.p side shaft engine I used a 5hp Tecumseh Yes Online links

19. Option #1 standard clutch & jack

shaft set-up

See page Yes Online links

20. Option #2 belt driven torque-

converter set-up

See page Yes Online links

21. Chain length to suit option 1 or 2 See page Yes Online links

Online links

Rear Wheel Bill Of Material

22. Axel hangers See page Yes Online links

23. Bearing cages See page Yes Online links

24. 1" Diameter bearings See page Yes Online links

25. 1" Diameter live axel with retainers See page Yes Online links

26. Rear tire size 18.8-8.5-8 for wide tire

frame

Or

15-6.00-6.00 for medium tire frame

See page

Yes

27. Rear Rim 4 bolt See page Yes Online links

28. Rear disc See page Yes Online links

29. Rear disc hub See page Yes Online links

30. Rim Hub See page Yes Online links

31. Rear sprocket See page Yes Online links

32. Rear sprocket hub See page Yes Online links

33. Throttle assembly See page Yes Online links

34. Front brake lever and cable See page Yes Online links

Custom Parts to Suit Your Taste

35. Gas tank See page Yes Online links

36. Seat See page Could be either Online links

37. Rear fender See page Yes Online links

38. Kick stand See page Yes Online links

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

7

Mini Chopper #1 The Little Stretch

MEDIUM TIRE FRAME SERIES

REAR TIRE SIZE 15 X 6.00 6

FRONT TIRE 16 BICYCLE

ENGINE SIZE 2-6.5 HP

Suitable for riders who may want to convert their conventional mini bike into a mini bike

chopper .If you have never rode a stretched-out mini bike, you might be better off

moving on to the next frame - The Little Tyke

NOT SUITABLE FOR BEGINNERS

Riding mini bikes with stretched-out forks requires skill and balance. Learn the basics

on a conventional mini bike before graduating to a chopper

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

8

Medium Tire Frame Bill Of Material

FRAME B.O.M

Detail # Material Wall Thickness Length Required

1 1.0Dia D.O.M .083 34.0

2 1.0Dia D.O.M .083 26 3/4

3 1.0Dia D.O.M .083 38.5

4 1.0Dia D.O.M .083 38.5

5 1.0Dia D.O.M .083 12 21/32

5a 1.0Dia D.O.M .083 12 21/32

6 1.0Dia D.O.M .083 20 7/16

7 1.0Dia D.O.M 083 18.5

8 (3 Required) 1.0Dia D.O.M .083 9.0

9 1.0Dia D.O.M .083 10 3/32

10 1.0Dia D.O.M Note***.120 6 1/4

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

9

FRAME DETAIL #1

Tube length 34.0, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

10

FRAME DETAIL #2

Tube length 26 3/4, Diameter 1.0, Wall thickness .083

Two 90 degree bends required

I like to add a few extra inches to the ends and trim them to length when I tack

weld the frame

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

11

FRAME DETAIL #3

Tube length 38.5, Diameter 1.0, Wall thickness .083

One 75 degree bend with a 15 degree tube notch

Bend radii is 3.5

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

12

FRAME DETAIL #4

Tube length 38.5, Diameter 1.0, Wall thickness .083

One 75 degree bend with a 15 degree tube notch

This notch is opposite to that of detail #3 (See 3D view for more info)

Bend radii is 3.5

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

13

FRAME DETAIL #5

Tube length 12 21/32, Diameter 1.0, Wall thickness .083

One notch and minor grinding to match to center frame tube

(See 3D View for more info)

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

14

FRAME DETAIL #5a

Tube length 12 21/32, Diameter 1.0, Wall thickness .083

One notch and minor grinding to match to center frame tube

(See 3D View for more info)

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

15

FRAME DETAIL #6

Tube length 20 7/16, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

16

FRAME DETAIL #7

Tube length 18.5, Diameter 1.0, Wall thickness .083

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

17

FRAME DETAIL #8

Tube length 9.0, Diameter 1.0, Wall thickness .083

Two notches required

3 of these required for seat & jack shaft mounting

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

18

FRAME DETAIL #9

Tube length 10 3\32, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

19

FRAME DETAIL #10

Tube length 6 1/4, Diameter 1.0, Wall thickness .120

ENGINE MOUNT PLATE

Use plate steel 3\16 thick

Center your engine and then transfer holes

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

20

AXEL & FRAME MOUNT PLATE

Use 1\4 thick plate steel if making these from scratch

The hanger below is a modified hanger that you can buy cheap, just weld a

triangle shape extension to the top of the hanger to match the frame angle

See the assembly views in the rear for axel and bearing mount info

Transfer bearing mount holes to ensure proper pattern

These can also be purchased on my website minichopperplans.com

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

21

FRAME GUSSET

Use 3\16 thick plate steel

When your frame is complete and you are happy with the angles and the position

of the forks, be sure to add frame gussets. You can use a cardboard template and

make a mock gusset and then trace it onto your plate steel.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

22

MEDIUM TIRE FRAME JIG

This is the most important step in building

your frame, this jig will ensure the frame is

assembled straight and accurate

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

23

Medium Tire Frame Jig Bill Of Material

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

24

Frame Assembly Information

Clamp or screw axel hangers in position, then tack weld

Weld detail 1, 2 & 10 together to make a sub-assembly

Finish the frame by measuring to be sure the frame details are in

their proper position

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

25

Main Starting Point for The Frame

1. Begin by tack welding the lower frame rails, foot rest and rear support. The

position of the rear support is dependant on the size of your rear tire. I also use it

to hold the rear fender. Only tack weld these pieces !!!!!!!!!!!!!!!!!!!!!!!!!!! You

may run into problems and find you would like to move some of the frame

parts !!!!!!!!!

This set up will be the most important!

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

26

Medium Tire Frame Side Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

27

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

28

Mini Chopper #2 The Little Tyke

REAR TIRE SIZE 15 X 6.00 6

FRONT TIRE 16 BICYCLE

ENGINE 2-6.5HP

Suitable for young riders and smaller engine sizes (2hp to 6.5hp).

One of the benefits of a frame this size is the availability of parts. Most of these parts can

be purchased from a go-kart or mini-bike parts supplier. This is a great frame for younger

riders because the forks are not as stretched-out as other models.

A GREAT

BEGINNER

BIKE

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

29

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

30

FRAME DETAIL #1

Tube length 34 1\4, Diameter 1.0, Wall thickness .083

One notch required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

31

FRAME DETAIL #2A & 2B

Tube length 14 3\4, Diameter 1.0, Wall thickness .083

One notch required per detail

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

32

FRAME DETAIL #3 & 4

Tube length 53 1\4, Diameter 1.0, Wall thickness .083

One notch required per detail

FRAME DETAIL #5

Tube length 9.0, Diameter 1.0, Wall thickness .083

Two notches per detail

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

33

FRAME DETAIL #6

Tube length 9 5\8, Diameter 1.0, Wall thickness .083

Notch 2 Places

FRAME DETAIL #7

Tube length 9 5\8, Diameter 1.0, Wall thickness .083

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

34

ENGINE MOUNT PLATE DETAIL

Use 1\8 mild steel plate

FORK DETAILS

Use 1 1\2 .085 wall tube

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

35

Little Tyke Rear Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

36

Little Tyke Frame Dimensions

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

37

The Little Tyke Jig Bill Of Material

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

38

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

39

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

40

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

41

Frame Assembly Information

Fasten details 3 & 4 into the wooden jig

Screw or clamp the axel hangers into position

Weld the steering neck, detail #1, detail #2A, detail #2B and detail #7, together

then place into the jig

Check to make sure all components are straight then tack weld

Once complete, remove the frame, weld completely, and then move onto the drive

train

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

42

Mini Chopper #3 The Rat Fink

WIDE TIRE FRAME SERIES

REAR TIRE SIZE 18.5 X 8.5 8 OR 205-50-10

FRONT TIRE 20 BICYCLE

ENGINE SIZE 2-9HP

NOT SUITABLE FOR BEGINNERS

Riding mini bikes with stretched-out forks requires skill and balance. Learn the basics

on a conventional mini bike before graduating to a chopper

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

43

Wide Tire Tube Frame Bill Of Material

FRAME B.O.M

Detail # Material Wall Thickness Length Required

1W 1.0Dia D.O.M .083 38 11/32

2W 1.0Dia D.O.M .083 30 11/16

3W 1.0Dia D.O.M .083 43.5

4W 1.0Dia D.O.M .083 43.5

5W 1.0Dia D.O.M .083 17 5/32

5aW 1.0Dia D.O.M .083 17 5/32

6W 1.0Dia D.O.M .083 20 7/16

7W 1.0Dia D.O.M Note*** .120 23.0

8W (3 Required) 1.0Dia D.O.M .083 12.5

9W 1.0Dia D.O.M .083 11 1/8

10W 1.0Dia D.O.M Note***.120 6 1/4

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

44

FRAME DETAIL #1

Tube length 38 11/32, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

45

FRAME DETAIL #2

Tube length 30 11/16 , Diameter 1.0, Wall thickness .083

Two 90 Degree bends required. I like to add a few extra inches to the ends and

trim them to length when I tack weld the frame

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

46

FRAME DETAIL #3

Tube length 43.5, Diameter 1.0, Wall thickness .083

One 75 Degree bend with a 15 degree tube notch, Bend radii is 3.5

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

47

FRAME DETAIL #4

Tube length 43.5, Diameter 1.0, Wall thickness .083

One 75 Degree bend with a 15 degree tube notch, Bend radii is 3.5

Be sure to notch the tube opposite of detail #3

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

48

FRAME DETAIL #5

Tube length 17 5/32, Diameter 1.0, Wall thickness .083

One notch and minor grinding to match to center frame tube

(See 3D View for more info)

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

49

FRAME DETAIL #5a

Tube length 17 5/32, Diameter 1.0, Wall thickness .083

One notch and minor grinding to match to center frame tube

(See 3D View for more info)

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

50

FRAME DETAIL #6

Tube length 20 7/16, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

51

FRAME DETAIL #7

Tube length 23.0, Diameter 1.0, Wall thickness .083

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

52

FRAME DETAIL #8

Tube length 12.5, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

53

FRAME DETAIL #9

Tube length 11 1/8, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

54

FRAME DETAIL #10

Tube length 6 1/4, Diameter 1, Wall thickness .120

ENGINE MOUNT PLATE

Use 3\16 thick plate steel

Center your engine and then transfer holes

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

55

AXEL & FRAME MOUNT PLATE

Use 1\4 thick plate steel if making these from scratch

The hanger below is a modified hanger that you can buy cheap. Just weld a

triangle shape extension to the top of the hanger to match the frame angle

See the assembly views in the rear for axel and bearing mount info

Transfer bearing mount holes to ensure proper pattern

These can also be purchased on my website minichopperplans.com

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

56

FRAME GUSSET

Use plate steel 3\16 thick

When your frame is complete and you are happy with the angles and the position of the

forks, be sure to add frame gussets. You can use a cardboard template and make a mock

gusset and then trace it onto your plate steel.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

57

JIG WIDE TIRE FRAME

This is the most important step in building your

frame; this jig will ensure the frame is assembled

straight and accurate

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

58

Wide Tire Frame Jig Bill Of Material

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

59

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

60

Frame Assembly Information

Clamp or screw axel hangers in position, then tack weld

Weld detail 1, 2 & 10 together to make a sub-assembly

Finish the frame by measuring to be sure the frame details are in their

proper position

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

61

Main Starting Point for The Frame

Begin by tack welding the lower frame rails, foot rest and rear support. The position of

the rear support is dependant on the size of your rear tire. I also use it to hold the rear

fender. Only tack weld these pieces !!!!!!!!!!!!!!!!!!!!!!!!!!! You may run into

problems and find you would like to move some of the frame parts !!!!!!!!!

This set up will be the most important!

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

62

WIDE TIRE FRAME DIMENSIONS

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

63

Mini Chopper #4 The Easy Brute

WIDE TIRE FRAME SERIES

REAR TIRE SIZE 18 X 8.5 8 OR 205-50-10

FRONT TIRE 20 BICYCLE

ENGINE SIZE 2-9 HP

NOT SUITABLE FOR BEGINNERS

Riding mini bikes with stretched out forks requires skill and balance. Learn the basics

on a conventional mini bike before graduating to a chopper

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

64

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

65

FRAME DETAIL #1

Tube length 37 5/8, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

66

FRAME DETAIL #2

Tube length 30 3/4, Diameter 1.0, Wall thickness .083

Two notches required

FRAME DETAIL #3

Tube length 12 1\2, Diameter 1.0 Wall thickness .083

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

67

FRAME DETAIL #4

Tube length 53 1\4, Diameter 1.0, Wall thickness .083

One notch required

FRAME DETAIL #5

Tube length 53 1\4, Diameter 1.0, Wall thickness .083

One notch required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

68

FRAME DETAIL #6

Tube length 11 1/8, Diameter 1.0, Wall thickness .083

Two notches required

Engine Plate Detail

Use 3\16 thick mild steel plate

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

69

Frame Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

70

The Brute Jig

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

71

Screw together - Do not nail

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

72

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

73

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

74

Load details 3, 4, & 5 into the jig

Weld detail #1 to the steering neck outside of the jig

Screw or clamp the axel hangers into position

Tack weld detail #2 to the axel hangers

Tack weld in detail #1 with the steering neck

Check to make sure all components are straight, then tack weld

Once complete, remove the frame, weld completely and then move onto the drive

train

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

75

Mini Chopper #5

The Black Widow

WIDE TIRE FRAME SERIES

REAR TIRE SIZE 18.5 X 8.5 8 OR 205-50-10

FRONT TIRE 20 BICYCLE

ENGINE SIZE 2-9 HP

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

76

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

77

Detail #1

For this detail use a 1 Diameter, .083 Wall, D.O.M Tube 37 11/16 long

Make two notches as shown below

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

78

Detail #2

For this detail use a 1 Diameter, .083 Wall D.O.M Tube, 34 1/8 long

Make (2) 90 degree bends and (2) 50 degree bends as shown below

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

79

Detail #3

For this detail use a 1 Diameter, .083 Wall D.O.M Tube 36 1\8 long

Make (2) 90 degree bends and (2) 17 degree bends as shown below

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

80

Detail #4 & #6

For this detail use a 1 Diameter .083 Wall D.O.M Tube, 10 3/8 long

Make one bend & two notches

This detail does not have to be exact. It will hold the jack shaft mounting tabs

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

81

Detail #5

For this detail use a 1 Diameter .083 Wall D.O.M Tube, 12 1\2 long

Make two notches

Engine Mount Plate Detail

For the engine mount plate, use a 12 X 7 3\4 plate, 3\16 thick

Transfer the holes from the engine to mount in the proper location

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

82

Detail #7 & Detail #8

For this detail use a 1 Diameter .083 Wall D.O.M Tube, 50 1\8 long

Make one bend and add two notches to complete

A compound notch will be required to fit this tube to the neck

Make sure the notch at the steering neck matches the neck tube diameter

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

83

BLACK WIDOW JIG

This is the most important step in building your

frame; this jig will ensure the frame is assembled

straight and accurate

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

84

Black Widow Jig Bill Of Material

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

85

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

86

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

87

Frame Assembly Information

Clamp or screw axel hangers in position, then tack weld

Weld detail 1 & 9 together but measure to make sure it is centered

Use clamps to align the frame and make sure all the frame pieces are square

Only tack weld the frame first! You may want to make a change later

Measure and Measure! Make sure the frame pieces are in the proper location!

Detail #4 & #6 will mount as shown, these will hold the jack shaft

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

88

Black Widow Frame Side Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

89

Black Widow Rear Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

90

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

91

Mini Chopper #6 The Hulk

WIDE TIRE FRAME SERIES

REAR TIRE SIZE 18.5 X 8.5 8 OR 205-50-10

FRONT TIRE 20 BICYCLE

ENGINE SIZE 2-9 HP

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

92

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

93

Detail #1

For this detail use a 1 Diameter .083 Wall piece of D.O.M tube, 36 1\8 long

Notch both ends as shown

The 25 degree notch must match the steering neck tube diameter

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

94

Detail #2 & #3

For this detail use a 1 Diameter .083 Wall D.O.M Tube 36 1\8 long

Detail #2 and #3 are the same

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

95

Detail #4 & #5

For this detail use a 1 Diameter, .083 Wall D.O.M Tube 49 1\8 long

Make one bend and add two notches to complete

A compound notch will be required to fit this tube to the neck

Make sure the notch at the steering neck matches the neck tube diameter

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

96

Detail #6 & #7

For this detail use a 1 Diameter, .083 Wall D.O.M Tube 10 3/8 long

Make one bend & two notches

This detail does not have to be exact. It will hold the jack shaft mounting tabs

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

97

Detail #8

For this detail use a 1 Diameter, .083 Wall D.O.M Tube 11 1/16 long

Make two notches to match frame

Engine Mount Plate Detail

For the engine mount plate use a 12 X 7 3\4 plate 3\16 thick

Transfer the holes from the engine to mount in the proper location

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

98

The HULK JIG

This is the most important step in building your

frame; this jig will ensure the frame is assembled

straight and accurate

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

99

The Hulk Bill of Material

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

100

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

101

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

102

Frame Assembly Information

Clamp or screw axel hangers in position, then tack weld

Weld detail 1 & 9 together but measure to make sure it is centered

Use clamps to align the frame and make sure all the frame pieces are square

Only tack weld the frame first! You may want to make small changes later

Measure carefully! Make sure the frame pieces are in the proper location!

Detail #6 & #7 will mount as shown; these will hold the jack shaft

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

103

The Hulk Frame Side Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

104

The Hulk Rear Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

105

Mini Chopper #7 The Low Boy

WIDE TIRE FRAME SERIES

REAR TIRE SIZE 18.5 X 8.5 8 OR 205-50-10

FRONT TIRE 20 BICYCLE

ENGINE SIZE 2-9 HP

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

106

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

107

FRAME DETAIL #1

Tube length 33 1/4, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

108

The Low Boy Side Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

109

The Low Boy Jig

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

110

BE SURE TO SCREW THE JIG TOGETHER

DO NOT NAIL

PRE DRILL THE SCREW HOLES SO THAT YOU DO NOT

CRACK THE WOOD

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

111

FRAME DETAIL #2 & #3

Tube length 36.0, Diameter 1.0, Wall thickness .083

Two bends required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

112

Detail #4

For this detail use a 1 Diameter, .083 Wall D.O.M Tube, 11 1/16 long

Make two notches to match frame

Detail #5 & #6

For this detail use a 1 Diameter, .083 Wall D.O.M Tube, 10 3/8 long

Make one bend & two notches

This detail does not have to be exact. It will hold the jack shaft mounting tabs

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

113

Detail #7 & Detail #8

For this detail use a 1 Diameter, .083 Wall D.O.M Tube, 44 1\8 long

Make one bend and add two notches to complete

A compound notch will be required to fit this tube to the neck

Make sure the notch at the steering neck matches the neck tube diameter

Engine Mount Plate Detail

For the engine mount plate use a 12 X 7 3\4 plate, 3\16 thick

Transfer the holes from the engine to mount in the proper location

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

114

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

115

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

116

The Low Boy Side Profile

Load details 7, 8, & 3 into the jig

Weld detail #1 to the steering neck outside of the jig

Screw or clamp the axel hangers into position

Tack weld detail #2 to the axel hangers

Tack weld in detail #1 with the steering neck

Check to make sure all components are straight, then tack weld

Once complete remove the frame, weld completely, and then move onto the drive

train

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

117

Mini Chopper #8 The High Boy

WIDE TIRE FRAME SERIES

REAR TIRE SIZE 18.5 X 8.5 8 OR 205-50-10

FRONT TIRE 20 BICYCLE

ENGINE SIZE 2-9HP

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

118

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

119

FRAME DETAIL #1

Tube length 36 1/8, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

120

FRAME DETAIL #2 & #3

Tube length 36.0, Diameter 1.0, Wall thickness .083

Two bends required

FRAME DETAIL #4 & #5

Tube length 31 7/8, Diameter 1.0, Wall thickness .083

One bend & two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

121

FRAME DETAIL #6

Tube length 21 3/8, Diameter 1.0, Wall thickness .083

One notch required

Engine Mount Plate Detail

For the engine mount plate use a 12 X 7 3\4 plate 3\16 thick

Transfer the holes from the engine to mount in the proper location

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

122

FRAME DETAIL #7

Tube length 11 1/16, Diameter 1.0, Wall thickness .083

Two notches required

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

123

Detail #8 & #9

For this detail use a 1 Diameter, .083 Wall D.O.M Tube, 10 3/8 long

Make one bend & two notches

This detail does not have to be exact. It will hold the jack shaft mounting tabs

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

124

The High Boy Side Profile

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

125

The High Boy Jig Plans

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

126

BE SURE TO SCREW THE JIG TOGETHER

DO NOT NAIL

PRE DRILL THE SCREW HOLES SO THAT YOU DO NOT

CRACK THE WOOD

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

127

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

128

Load details 3, 4, & 5 into the jig

Weld detail #1 to the steering neck outside of the jig

Screw or clamp the axel hangers into position

Tack weld detail #2 to the axel hangers

Tack weld in detail #1 with the steering neck

Check to make sure all components are straight, then tack weld

Once complete, remove the frame, weld completely, and then move onto the drive

train

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

129

MINI CHOPPER FRONT END PLANS FOR BOTH

MEDIUM AND WIDE TIRE

FRAMES

Detail # Material Wall Thickness Length Required

1 D.O.M .083 20.0

2 D.O.M Note*** .120 7.0

3A D.O.M Note*** .120 6.25

3B D.O.M Note*** .120 6.25

4 PLATE STEEL SEE DETAIL N\A

5 D.O.M Note*** .120 40.0

6 BAR STOCK SEE DETAIL AS REQD

7 PLATE STEEL SEE DETAIL SEE DETAIL

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

130

DETAIL #1

Tube length 20 , Diameter 7/8, Wall thickness .083

Two bends required, bend radii is 3.5

BE SURE TO USE 7\8 DIAMETER TUBE FOR YOUR HANDLE BARS, THIS IS

THE INDUSTRY STANDARD. MOST HAND LEVERS AND CONTROLS ARE

DESIGNED TO FIT 7\8 HANDLE BARS. IF YOU USE 1 YOU WILL HAVE A

TOUGHER TIME FINDING LEVERS

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

131

Detail#2

Tube length approximately 8.0 , Diameter 1.0, Wall thickness .120

Notch for 7\8 handle bars

Make the riser to suit your body position. You may also wish to buy a bolt-on type riser. I

formed mine by cutting the arc on a 2x6. I heated the tube and bent it to the desired arc. I

then welded it to the triple trees.

FRAME DETAIL #3A & 3B STEERING NECKS

The most common steering neck is a 1 5\8, .120wall piece of D.O.M tube (this

will require two bearings to be pressed-in). This is the best way to go!

Some older frames use a 1, .120 wall tube. This requires no bearings.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

132

FRAME DETAIL #4

** Scale this on a photocopier to use as a tracing template, use the

dimensions to check scale accuracy.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

133

FRAME DETAIL #5 & #6

Tube length 40, Diameter 1.0, Wall thickness .120

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

134

FRAME DETAIL #6

1\4 PLATE 1.5 X 3.75

Weld this detail to the forks, it can be welded on center or to the inside as shown

below

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

135

Mounting the Forks to the Frame!

Option #1

Mount the forks to the frame using a 3\4-10nc x 8 or 1\2-16nc x 8 bolt

Option #2

You may also choose to replace detail 3 with a 1 5\8, .120 wall D.O.M tube; this

will allow you to use bearings in the neck. You will have to adjust the tube

notches on the other frame components.

Option #1

Option #2

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

136

Jack Shaft Drive

1 Clutch More Info

2 Locking collar More Info

3 Bearing More Info

4 Jack shaft More Info

5 Sprocket More Info

6 Locking collar, bearing, Flangettes More Info

7 1 Diameter axel shaft & locking key More Info

8 Wheel hub More Info

9 Sprocket hub More Info

10 Rear sprocket More Info

11 Chain to match your sprockets More Info

The above picture shows a jack shaft set-up, which has been used to

redirect power to the opposite side of the bike. To mount a jackshaft

you must weld two jackshaft mounting tabs to the frame. See the

following page.

6

7

8

9

10

4

1

2

3

5

11

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

137

Jack Shaft Mounting Info

Medium Tire Frame

Wide Tire Frame

For the chain to clear the frame you will need to mount the

jackshaft mount tabs above the base of the frame

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

138

Torque Converter Drive

A torque converter set up is not as complicated as it may sound. When

you buy the unit it comes complete with everything you will need to mount

it and use it. In most cases you can install one of these units in about 15

minutes. The unit will bolt to your engine using 4 bolts. The primary drive

pulley will mount to your engines shaft.

T

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

139

If you choose to use a torque converter set-up you will need to add a

roller. I used a roller from a two-stroke dirt bike and mounted a small

bracket to the frame. This will act as a support and guide to the chain

and keep it from rubbing on the frame.

Comet Torq-A-Verter TAV2-30

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

140

Live Axels Continued

Above you have a complete live axel set up

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

141

Rear Brakes

Below I show a mechanical type brake caliper. This unit will need to be

mounted to the frame. There are other options such as hydraulic disc brake

set-ups and friction bands.

If you are planning to use a mechanical brake system, I suggest the rotary

brand mechanical disc brake part# 04-9306.

The rotary brand mechanical brake as shown above is one of the best

mechanical brakes available.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

142

Hydraulic Disc Brakes

You can dress up your chopper with a tricked-out hydraulic brake system. The

rear disc brake can be easily mounted using two bolts as shown below. The pedal

assembly will mount the same way.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

143

Other Rear Brake Options

Clutch Band

Clutch Band: This style of brake is common on mini bikes.

Using an angle iron bracket, it rides on the clutch. As the brake

is activated, the band tightens around the clutch, stopping the

bike.

Rear Drum Brake

Rear Drum: There is also a drum style brake available. I have

never used one, but they do look slick.

Caliper Type Disc Brake

The caliper brake system shown below rides on the rear drive

sprocket. This unit can be mounted by making a custom

bracket.

Chain Guard

Dont forget safety! Be sure to protect

your little riders by adding a chain guard.

This unit is available at mfgsupply.com

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

144

Custom Front Pegs

Here are a few screen shots of my tricked-out foot pegs. I wanted a look that was a little

different and was quite pleased with the results.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

145

You can even make the seat

Make a seat frame with 2 pieces of plywood cut to fit your frame.

Glue high density foam to the plywood

Then cover with leather, vinyl or any material you choose

Staple the covering to the wood

Hot-glue a piece of felt to hide the wood and staples

Choose your look!!!!

If old school is the look you are after, try adding a solo seat and a set

of ape hanger handlebars

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

146

Helpful Info

If your seat rides on the fender. Be sure to add supports!!!!!!!!!!!!!!!!!!!!!!!!!!!!

This is when you will want to be sure your engine fits correctly.

Also be sure your rear tire has enough clearance.

If you are using a rear disc brake, be sure the width of the frame is adequate.

Also check for proper alignment from the rear sprocket to the front drive sprocket.

I use a long straight edge to be sure they are straight.

This is a good time to position the engine mount plate and holes.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

147

Tube Notch Templates

Cut the following templates and tape or scribe the profile onto your tube.

You can then grind the contour for an accurate tube notch

SOME PRINTERS MAY DISTORT THE SCALE OF THESE

TEMPLATES. IF YOU MEASURE THE DIMENSIONS AND

FIND THEY ARE NOT TO SCALE, USE A PHOTOCOPIER TO

RETURN THEM TO THE PROPER SIZE. THIS CAN BE

EASILY DONE BY EXPANDING OR SHRINKING THE

DRAWING USING THE PHOTOCOPIER CONTROLS.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

148

SOME PRINTERS MAY DISTORT THE SCALE OF THESE

TEMPLATES. IF YOU MEASURE THE DIMENSIONS AND

FIND THEY ARE NOT TO SCALE, USE A PHOTOCOPIER TO

RETURN THEM TO THE PROPER SIZE. THIS CAN BE

EASILY DONE BY EXPANDING OR SHRINKING THE

DRAWING USING THE PHOTOCOPIER CONTROLS.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

149

SOME PRINTERS MAY DISTORT THE SCALE OF THESE

TEMPLATES. IF YOU MEASURE THE DIMENSIONS AND

FIND THEY ARE NOT TO SCALE, USE A PHOTOCOPIER TO

RETURN THEM TO THE PROPER SIZE. THIS CAN BE

EASILY DONE BY EXPANDING OR SHRINKING THE

DRAWING USING THE PHOTOCOPIER CONTROLS.

Designed By Solution Design (Design Images not to be used without written permission)

P.O Box 10, Cottam On, N0R 1B0 (Not To Be Resold Or Circulated)

More info at www.minichopperplans.com

COPYWRIGHT 2002, SOLUTION DESIGN

NOT TO BE RESOLD OR CIRCULATED

150