Professional Documents

Culture Documents

Basics Safety Standards en

Uploaded by

Riadh2012Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basics Safety Standards en

Uploaded by

Riadh2012Copyright:

Available Formats

Siemens AG 2009. All Rights Reserved.

Safety of machinery /

European machinery

directive

Siemens AG 2009. All Rights Reserved.

Important note

(apply to all parts of the event):

The event shall give the participants overview over the topic area

safety of machines with the focus on "functional safety". The

represented lawful and normative requirements and implementation

strategies are represented simplified, i.e. for the practical

implementation a detailed analysis of the safety systems and

procedures is absolutely necessary!

The examples are non-committal and do not lay any claim to completeness with

regard to configuration and equipment as well as any eventualities. The

examples do not represent any custom-designed solutions but shall offer only

support at typical tasks. You are accountable for the proper mode of the

described products yourself.

These examples do not discharge you from the obligation to safe dealing for

application, installation, business and maintenance. By use of these examples

you appreciate that Siemens cannot be made liable for possible damages

beyond the provisions regarding described above. We reserve us the right to

carry out changes at these examples without announcement at any time. The

contents of the other documentation have priority at deviations between the

suggestions in these examples and other Siemens publications, such as

catalogues.

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 3/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Agenda

Part 1: The way to a safe machinery

Risk assessment / risk reduction / validation / placing on market

Part 2: Practical implementation IEC 62061 and ISO 13849-1

Norm overview "functional safety" / core requirements /

practical implementation at an application example

Shown is the principle procedure (simplified representation )

Part 3: SIL / PL-verification with the application example

Consideration according to ISO 13849-1 and IEC6201

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 4/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Safety of machinery / European machinery directive

Question:

What has to be considered, when a machinery is placed to market

in Europe?

Part 1: The way to a safe machinery

Risk assessment

Risk reduction

Validation

Placing on market

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 6/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Terms and definitions

Machinery

Machine + system (linked machines)

Machine manufacturer

Redesigns a machine or considerably modifies it

Implements safety functions

Machine owner

Purchases and uses a machine.

The machine owner becomes machine manufacturer when

machines are linked to form a system

the machine is considerably modified

Machine operator

Operator + maintenance personal

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 7/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Motivation for a safe machine

needless to say: Protection of people and the environment

but also: economic efficiency

Advantage of modern safety technologies and intelligent safety

concepts:

Protection measures do not turn into obstacles

Example:

Protection zones of laser scanners, depending on operating modes

Increase in productivity

Examples:

Safely reduced speed instead of complete stop or energy off

Selective emergency stop instead of global emergency stop

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 9/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

In Europe, machine manufacturers and machine owners are

required by law to ensure the safety of people and the

environment.

Machines placed on the market in Europe must be safe.

Placed on the market means:

The machine is manufactured or considerably modified in Europe

The machine is imported to and operating in Europe

European Directives for Machinery

describe essential requirements for the machine manufacturer

Situation in Europe

(and in many other countries)

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 10/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

Machine manufacturers and users are responsible

for the safety of machines and of the plant

* Until 2009/12/29

2006/95/EG

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 11/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

European Machinery Directive

Correlations

Machinery

Machinery

Directive

98/37/EC

Further directives:

Low Voltage

Electromagnetic

Compatibility

Harmonized standards:

Describe specific requirements

for the machine manufacturer.

European Directives for Machinery:

Essential requirements

A machine is considered to be

safe when the Machinery

Directive requirements are

meet

Presumption of conformity:

When applied correctly, the

corresponding directive is

considered to be complied

with

Certification by the

machine manufacturer:

The machine meets the

requirements of the Machinery

Directive and of all other

relevant directives

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 12/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

European Machinery Directive

Options for meeting the requirements

Applying harmonized standards

The machine manufacturer only has to prove that the requirements

of the harmonized standards have been met.

In this case, the presumption of conformity applies!

or

Without applying harmonized standards

The machine manufacturer must prove in detail that the Machinery

Directive requirements have been met.

Compared to the first option, this means increased overhead when

validating the machine.

Recommendation:

Application of harmonized standards

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 13/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

Directive

reference

Subject of directive

European Directives and applying standards

Web: http://www.newapproach.org/

Info

about

directive

Standards

activities

References

harmonised

standards

90/396/EEC Appliances burning gaseous fuels

00/9/EC Cableway installations designed to carry persons

89/106/EEC Construction products

89/336/EEC Electromagnetic compatibility

94/9/EC

Equipment and protective systems in potentially

explosive atmospheres

93/15/EEC Explosives for civil uses

95/16/EC Lifts

73/23/EEC Low voltage equipment

98/37/EC Machinery safety

90/385/EEC Medical devices: Active implantable

93/42/EEC

View

directive

Directives & Standards

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 14/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

TYPE

C standards

Specific safety features for individual machine families

Specialist

standards

TYPE

B standards

B1 standards

General safety aspects

B2 standards

Reference to special

protective devices

Group

safety standards

Basic design principles

and basic concepts

for machines

TYPE

A standards

Basic safety standards

IEC 62061

IEC 61811

IEC 61508

IEC 61800-5

EN 692

EN ISO 12100

Hierarchical organization of the EN standards

EN ISO 14121

EN 349

IEC 61496-1

EN 294

EN 418

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 15/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

Hierarchical organization of the EN standards

The B norms are also aimed primarily at the norm compositors for C

norms. They also can, however, be helpful to the manufacturers for

construction of a machine if there exist no C norms.

There is another subdivision at the B norms carried out:

B1: for primary safety aspects (ergonomic principles, safe distances

against reaching from sources of danger and to the avoidance of

squeezing parts of the body)

B2: intended for machines like: E- Stop, Two-hands-facilities,

contactless safeguards, safety-related parts of controls)

Minimum

distances to the

avoidance of

crushes from parts

of the body

EN 349

Safety

relevant

parts of

controls

EN 954-1

Electrical

equipment

of

machines

EN 60204-

1

Interlocking

devices

associated with

guards

EN 1088

Two hand control

EN 574

E- stop system,

design basic

principles ISO

13850

Light barriers,

light curtains

EN 61496-1

Electro-sensitive

protective equipment

EN 61496-1

Type B1 standards

General primary safety aspects

Type B2 standards

Specifications among others of safeguards

with a general character

EN 62061 & ISO 13849-1

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 16/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

USA:

UL, ANSI

Europe:

EN

Japan:

JIS

e.g. EN 954

World

e.g. IEC 61508,

IEC 62061, IEC 61511

Europe:

IEC 62061,

EN ISO 13849

New

The valid instructions and standards are significant at the place

of action of the machine and/or plant.

The European standards and instructions are accepted worldwide.

Norms

International safety norms

IEC, ISO

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 17/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

Export to Countries outside Europe

Overview

Situation in the different countries of the world

There are different concepts for machine safety:

Requirements and assessment of safety systems

Responsibilities

Legal consequences

The laws and regulations of the country in which the machine is

operated always apply.

Influence of Europe

The European procedure is accepted worldwide

The CE mark is accepted worldwide

Numerous European standards for machine safety

turned into internationally applicable standards

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 18/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

Machine

Risk evaluation/

-assessment

Acceptable

risk

Measurements

to reduce

the risk

Danger

Danger

The process is

prescribed by the

legislature and

defined in norms

The European Machinery Directive prescribes:

Manufacturer of machinery and plants have to perform a risk evaluation and

assessment before the construction. Only machinery with acceptable risk are allowed

to be placed on the market.

Safe Machine

Inducement

The European Machinery Directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 19/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

At the process, all

countries consider the

same basic principles, but

the exact instructions for

the implementation are

defined in country- or/and

region- specific

standards.

The valid guidelines and

standards at the place of

action of the machine

and/or plant are

significant.

The constructor of the

plant and/or the

machine is responsible

for the adherence of the

standards.

Changed machinery- or

process- design

Further Measurements to

reduce danger

Usage of

Safety Engineering

Determination of the

amount of damage,

probability, avoidableness

Classification

Proven by:

Certificate

Acceptance test

Norms

Process Implementation

Risk- evaluation/

-assessment

Acceptable

risk

Measurements

to reduce

the risk

!

Inducement

Process in overview

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 20/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

Implementation

Machinery Directive

Europe

The way to a safe

machinery

Safety of Machinery

European Machinery Directive

Basic implementation procedure

Steps to be performed by the machine manufacturer

1 Risk assessment

2 Risk reduction

Step 1: Safe design

Step 2: Technical protective measures

Step 3: User information on residual risks

3 Validation of the machine

4 Placing the machine on the market

Technical documentation

Each step must be comprehensibly documented:

Procedures and results

Test strategy and test results

Responsibilities,

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 22/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

The 3 step method

Start

Risk reduction by

selecting suitable

protective measures

YES

NO

Is the risk

adequately

reduced?

End

For each hazard:

Estimation and assessment of the risk

Identifying the hazards on the machine

Defining the limits of the machine

The machine is safe

except for a reasonable

residual risk

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 23/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Relevant standards

EN ISO 12100

Safety of machinery

Basic concepts, general principles for design

Describes possible hazards on a machine

Describes strategies for risk reduction

Objective: Design of a safe machine

whose residual risk is reasonable

EN ISO 14121

Safety of machinery

Principles for risk assessment

Consideration of the risk

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 25/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

The 3-Step Method (according to EN ISO 12100)

YES

NO

Again: Risk assessment

For each hazard requiring risk reduction:

End

Start

YES

YES

NO

NO

Step 3: Risk reduction by user information on residual risks

Was the risk adequately reduced?

Was the risk adequately reduced?

Was the risk adequately reduced?

Step 1: Risk reduction by safe design

Step 2: Risk reduction by technical protective measures

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 26/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 1: Safe design

Safe design

Integration of safety into the design of the machine

Highest priority for risk assessment

Aspects for safe design (examples)

Avoidance of pinch points

Avoidance of electric shock

Concepts for stopping in the event of hazards

Concepts for operation and maintenance

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 27/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

Technical protective measures

A safety function must be defined for each hazard that

cannot be eliminated by design

Safety functions can be performed by

safety systems

Example: Safety function - without safety system

Access to the hazardous location is permanently prevented

(fixed mechanical cover, )

Example: Safety function - with safety system

When the protective cover is opened during normal

operation, the motor must be switched off.

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 28/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Safety system

Performs safety functions

Consists of subsystems

Subsystems of a safety system

Detecting (position switch, light curtain, )

Evaluating (fail-safe controller, safety switching device, )

Reacting (contactor, frequency converter, )

Safety system

motor

Protective

cover

Step 2: Technical protective measures

Subsystem 3:

Reacting

Subsystem 1:

Detecting

Subsystem 2:

Evaluating

or

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 29/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

Relevant standards for designing and realizing

safety systems for machinery

EN 954-1 (valid until the end of 2009)

EN ISO 13849-1 (valid since 2006)

EN 62061 (identical to IEC 62061) (valid since 2005)

Properties of the standards:

Harmonized norms (Europe )

EN 62061 and EN ISO 13849 are accepted internationally

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 30/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

The standards grown in the past in different countries will be harmonized and

reduced to a few European standards.

The often used standard EN954-1 will be replaced in October 2009.

The remaining relevant standards are:

IEC 61508: Basic-standard for functional safety (e.g. for PLC) (product liability)

IEC 61511: Application standard for process engineering

IEC 62061: Application standard for mechanical engineering and also for

electrical and electronic safety engineering.

ISO 13849-1: Application standard for mechanical engineering and also for

electronic and other technics (e.g. pneumatic, hydraulic).

Suppressor of EN 954-1.

IEC 61800-5-2: Product specific standard for electrical drives with integrated safety

functions.

IEC 62061 and ISO 13849-1 are often used for risk assessment of machines.

IEC 61508 and IEC 61800-5-2 are often used for risk assessment of safety devices

(e.g. PLC).

Step 2: Technical protective measures

The relevant standards

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 31/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

Basic procedure for each safety function

a) Specifying the safety function

b) Determining the required safety level

c) Designing the safety function

d) Determining the achieved safety level

e) Realizing and testing the safety function

The steps will be

explained in

the following

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 32/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

a) Specifying the safety function

Boundary conditions of the safety function

Hazard to be prevented on the machine

Affected persons on the machine

Affected operating modes of the machine

Mission time

...

Requirements for the functionality of the safety function

Functional description of the safety function

Required reaction time

Reaction to faults

Number of operations for electromechanical components

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 33/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

Required safety level

Significance of the required safety level

The required safety level is a measure for the reliability of the

safety function.

The required safety level depends on:

Severity of the injury

Frequency / exposure time

Possibility of avoiding

The more severe the injury and the more probable its occurrence,

the higher the required safety level.

EN 62061 and ISO 13849 show procedures for determining the

required safety level.

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 34/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

The risk dimension

results from:

The exact calculation is standard-specific different.

Depending on the dimension of the risk, a certain safety level is postulated. The

notations of the safety levels are:

at EN 954-1: Category B, 1 - 4

at ISO 13849-1: Performance Level a - e (PL)

at IEC 62061: Safety Integrity Level 1 - 3 (SIL)

at IEC 61511: Safety Integrity Level 1 - 4 (SIL)

Heaviness of

injury

Wie

schwer

Frequency

and/ or

duration of stay

Possibilities of

avoidance

light

heavy

often

rare

Hardly

possible

possible

Step 2: Technical protective measures

Achievable safety level

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 35/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

b) Determining the required safety level

Specification according to EN ISO 13849: PLr a to PLr e

PL

r

b

PL

r

e

PL

r

a

PL

r

c

PL

r

d

Se1

Se2

Fr1

Fr1

Fr2

Fr2

P1

P2

P1

P2

P1

P2

P1

P2

Se1 Reversible injury

Se2 Irreversible injury

Se Severity of the injury

Fr1

Seldom up to quite

often / short

Fr2

Frequent up to

continuous / long

Fr

Frequency /

exposure time

P1 Possible

P2 Scarcely possible

P

Possibility of

avoiding

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 36/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

b) Determining the required safety level

Specification according to EN 62061: SIL 1 to SIL 3

2 More than 1 year

3 2 weeks to 1 year

4 1 day to 2 weeks

5 1 h to 1 day

5 Less than 1 hour

Fr

Frequency /

exposure time

1 Negligible

2 Rarely

3 Possible

4 Likely

5 Frequently

Pr

Probability of

occurrence

SIL 1 1

SIL 2 SIL 1 2

SIL 3 SIL 2 SIL 1 3

SIL 3 SIL 3 SIL 2 SIL 2 SIL 2 4

14 to 15 11 to 13 8 to 10 5 to 7 3 to 4

Class Cl = Fr + Pr + P Severity of the

injury Se

+

+

1 Likely

3 Possible

5 Impossible

P

Possibility of

avoiding

1 Reversible: E.g., requiring first aid

2 Reversible: E.g., requiring medical attention

3 Irreversible: E.g., broken limb(s)

4 Irreversible: E.g., losing limb(s)

Se Severity of the injury

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 37/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

b) Determining the required safety level

Requirements of the safety levels: Safety system

The requirements concern:

Engineering (depends strongly on the required safety level)

Procedure

Requirements for engineering: (low high safety level)

Hardware structure (one-channel two-channel)

Fault detection capability (none comprehensive

diagnostics)

Reliability of components (increasing)

Requirements for the procedure:

Project management

Test concept

Technical documentation,

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 38/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

c) Designing the safety function

Objective of the design

The safety system performing the safety function

must meet the requirements of the necessary safety level

(SIL, PL

r

).

Example

Safety function: When the protective cover is opened during

normal operation, the motor must be switched off.

Required safety level: SIL 3 or PL

r

e

Safety system

motor

Protective

cover

Subsystem 3:

Reacting

Subsystem 1:

Detecting

Subsystem 2:

Evaluating

or

Design

for SIL 3

or PLr e

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 39/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Safety system

motor

Protective

cover

Subsystem 1:

Detacting

Subsystem 2:

Evaluating

or

Subsystem 3:

Reacting

Design review

Can the required safety level (SIL, PL

r

) be achieved?

Basic procedure

Assessment of the individual subsystems

Achieved safety level (SIL, PL)

Probability of failure PFH

D

Assessment of the safety system

Achieved safety level (SIL, PL):

Normally, the lowest achieved safety level of a

subsystem determines the achieved safety level of the safety system.

Probability of failure PFH

D

: Total of PFH

D

of the subsystems

Achieved safety level of the safety system (SILCL, PL) =

required safety level of the safety function (SIL, PL

r

)?

Step 2: Technical protective measures

d) Determining the achieved safety level

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 40/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

d) Determining the achieved safety level

Assessment of the subsystems

Safety-relevant characteristics of a subsystem:

Achieved safety level (SILCL, PL)

Probability of failure PFH

D

Finished subsystem:

Characteristics and certificates from the

manufacturer

Designed subsystem:

Characteristics have to be calculated

EN 62061 and EN ISO 13849

show how

Subsystem 1:

Detecting

Subsystem 3:

Reacting

Subystem 2:

Evaluating

or

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 41/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

Step 3

Step 2

Step 1

3-Steps-Method

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 3: User information

User information warns of residual risks

User information does not replace

safe design

technical protective measures

Examples:

Warnings in the operating instructions

Special work instructions

Icons

Personal protective equipment

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 43/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Validation of the machine

Objective of the validation

Determination of the conformity (accordance) with the requirements

of

the European Machinery Directive

all other directives that apply to the machine

Implementation of the validation

For most machines:

Machine manufacturer

Machines listed in Annex IV of the Machinery Directive:

Machines with greater hazards (presses, )

The machine manufacturer has to call in an independent testing

agency and/or a certification body (examples: TV, BGIA).

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 45/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Placing the Machine on the Market

Prerequisites

Determination of conformity, within the scope of the validation

Technical documentation

Placing on the market

Issuing the declaration of conformity:

The machine complies with all relevant directives.

Attaching the CE mark on the machine

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 46/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Safety of machinery / European machinery directive

Question:

What has to be considered, when designing safety related control

systems of a machinery?

Part 2: Practical implementation IEC 62061 and ISO 13849-1

Overview "functional safety

Core requirements

Practical implementation at an application example

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 48/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Functional safety

Safety require protection because of following hazards:

Danger by

malfunctions

Dangerous radiation

Heat and fire Electric shock

Functional safety means protection against dangers, which

caused by malfunctions.

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 49/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Worldwide:

Basic standard IEC 61508 (functional safety)

(Safety Integrity Level SIL)

Europe:

Harmonized standards

EN 954-1 (Categories) ( valid till 29.12.2009)

EN ISO 13849 (Performance Level PL)

EN 62061

(with identical SIL like IEC 61508)

IEC 61508 (SIL)

Nuclear

EN 61513

Machines

EN 62061

Functional Safety

Process

EN 61511

Sector standard

IEC

IEC

Basic standard

Previous regulations

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 50/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Influence of the IEC 61508 in the process and

manufacturing industry

IEC 61508

IEC 62061

ISO 13849

EN 954

(until 2009)

IEC 61511

process-

industry

Manufacturing industry

EEP systems

Factor also not-EEP

systems

(f.E. Hydr., Pneum)

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 51/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Environment

EN 954-1: 1996

EN ISO 13849-1: 2006

IEC 62061: 2005

identical to

EN 62061: 2005

Time

Irrespective of the application:

IEC 61508: 1998/2000

Functional safety of safety-related

electrical, electronic and programmable

electronic control systems

EN ISO 13849-1: 2006

Safety of machines

Safety-related parts of control systems

Part 1: General principles for design

EN 62061: 2005

Safety of machines

Functional safety of safety-related

electrical, electronic and programmable

electronic control systems

EN 954-1: 1996

Safety of machines

Safety-related parts of control systems

Part 1: General principles for design

Influences

IEC 61508: 1998/2000

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 52/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

EN 954-1:1996

harmonized under EU Mach. Dir.

only structure orientated

no programmable electronics

still valid up to the end of 2009

ISO 13849-1:2006

quantitative and structure

orientated

for control integrators and

manufactures

intended architectures for

electronics

also for hydraulics,

pneumatics

IEC 61508:1998/2000

recognized state-of-the-art

technology

for control and system

manufacturers

quantitative and structure oriented

IEC 62061:2005

harmonized under EU

Machine Directive

for controls integrators

quantitative and structure

orientated

uses PES acc. to IEC 61508

in extracts

Electromechanical devices

Further development of the basis standards

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 53/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Why new norms?

Points of criticism at the EN 954:

No direct connection between risk minimization and

category, the complexity is unconsidered,

No detailed requirements for programmable systems

and complex electronic,

No sufficient requirements for the consideration

of the values of the reliability

-> Does not represent the state of technology anymore

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 54/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

What is new about EN 62061 and EN ISO 13849?

Assessment of complete safety functions

(Overall view: Detecting evaluating reacting)

Requirements for the probability of failure (PFH

D

)

Requirements for the procedure

(project management, test concept, technical documentation, )

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 55/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Validity

Relevant standards for safety systems for machinery

2006 2007 2008 2009 2010

Machinery Directive 98/37/EC 2006/42/EC

EN ISO 13849-1

Transitional period: 3 years EN 954-1: 1996

EN 62061

Recommendation:

Immediate change from EN 954-1

to EN 62061 or EN ISO 13849

Predominantly electrical subsystems: EN 62061

Predominantly hydraulic, pneumatic devices: EN ISO 13849

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 56/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Concept

Functional safety

Control of dangers

failure during the operation

robust design

Avoiding of systematic

failure at the concept, production and

operation of the systems

robust process

Safety-lifecyle requirement

Technical design requirements of

safety-related functions

system architecture

failure probability

Requirements of planning processes

and methods

Functional safety management

From risk analysis until

deinstallation of safety-engineering

systems

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 57/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Summary

Functional safety

Control of dangers

failure during the operation

robust design

Avoiding of systematic

mistakes at the concept, production

and operation of the systems

robust process

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 58/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Robust design quantitative requirements

NEW: Quantitative measure for the safety-related

efficiency (Safety Performance)

- a - 10

-5

to < 10

-4

e

d

b

c

PL

3

2

1

SIL

>1000 years

>100 years

>10 years

one dangerous

failure every X years

10

-8

to < 10

-7

10

-7

to < 10

-6

10

-6

to < 10

-5

PFH

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 59/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Robust design quantitative requirements

Requirements of the safety levels: Probability of failure

EN 62061 and EN ISO 13849 describe requirements for the maximum

permissible probability of dangerous failure for a safety function:

Probability of dangerous failure per hour PFH

D

The higher the safety level, lower the required PFH

D

PFH

D

decreases

10

-8

10

-7

10

-6

10

-5

10

-4

3*10

-6

SIL 3 PL

r

e

SIL 1

SIL 2 PL

r

d

PL

r

c

PL

r

a

PL

r

b

Not more than 1 dangerous failure

of the safety function in 10 years

Not more than 1 dangerous failure

of the safety function in 100 years

Not more than 1 dangerous failure

of the safety function in 1000 years

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 60/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Robust design - qualitative requirements

IEC 62061:

The structure (architecture) of the subsystems must be suitable for

the demanded SIL (IEC 62061 / table 5.)

Example:

- to achieve SIL 2

with a single channel architecture (HFT = 0),

the rate of the safe failures must be (SFF) > 90%

ISO 13849-1:

The regulation of the PL bases on the categories from the

EN 954-1 (scheduled architectures )

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 61/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Successor of the EN 954-1 with quantitative

methods for evaluation

EN ISO 13849-1 (Successor of the EN 954-1 )

(Safety of machinery - safety parts of control systems

Part 1: General principles for design)

state: Version 2006

comment:

Treats electric and more

electronically systems also

hydraulics and pneumatics

PL

Performance Level

S

t

r

u

c

t

u

r

e

Cat

R

e

l

i

a

b

i

l

i

t

y

MTTF

D

D

i

a

g

n

o

s

i

s

DC

R

e

s

i

s

t

a

n

c

e

CCF

P

r

o

c

e

s

s

Verifying

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 62/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Sector norm under IEC 61508 with quantitative

methods for the evaluation of functional safety

IEC / EN 62061

Functional safety of safety related-electrical, electronic and

programmable electronic control systems

state: Version 01/2005,

harmonized under the EC

machine guideline 12/2005

comment:

Treats the integration of

safety relevant systems of

electrical and electronic

machines.

SIL

Safety Integrity Level

S

t

r

u

c

t

u

r

e

HFT

R

e

l

i

a

b

i

l

i

t

y

PFH

D

D

i

a

g

n

o

s

i

s

DC/SFF

R

e

s

i

s

t

a

n

c

e

CCF

P

r

o

c

e

s

s

Verifying

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 63/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Summary

Functional safety

Control of dangerous

failure during the operation

robust design

Avoiding of systematic

mistakes at the concept, production

and operation of the systems

robust process

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 64/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Systematic safety integrity

Besides the "safety integrity of the hardware" the IEC 62061 also

looks at the "systematic safety integrity" ,this consists:

Avoidance of systematic faults

Control of systematic faults

Examples of systematic faults:

Fault in the specification of the SRCF

Fault at design of the hardware or the applications software

Short-circuit, wire break

No regulation regarding responsibilities

Organizational and technical measures have to be taken to avoid

and master systematic faults.

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 65/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Avoiding of systematically faults (management)

Implementation of the demand "Avoiding of systematic failures at

concept, production and operation of the system"?

Through the FSM (Functional Safety Management)

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 66/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Plan of the functional safety

Process for safety relevant projects

should be created first (activities, rolls,

documents, milestones etc.) !

Topic of the "process and quality

management"

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 67/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Recommendation: Project independent implementation of

the management of the functional safety

Analysis of the installed QM-processes (Gap Analysis)

QM

(ISO 9001)

FSM (IEC 62061)

Quality securing processes

Functional Safety Management

Common

requirements

Identification of the

coincidences

e.g. personnel training,

internal audits, document

steering, maintenance, fault

analysis etc.

Identification of the

coincidences

e.g. personnel training,

internal audits, document

steering, maintenance, fault

analysis etc.

Integration of the "Add

Ons" into the QM-

system and description

in a "Safety plan"

Integration of the "Add

Ons" into the QM-

system and description

in a "Safety plan"

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 68/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Plan of the functional safety

In cooperation with the quality management should be cleared at

least on the project level following points and be documented in

the plan of the functional safety :

Who has which responsibility in the project?

Which minimum qualification of the employees is required for

which tasks?

Which documents have to be available to assign the delivering

release?

Which verification and validation activities have to be carried out

in front of delivering release?

How is the configuration management defined?

How are modifications converted and checked?

Who cares about the product care?

.

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 69/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Software safety life cycle (V-model)

Safety

SW specification

System design

Module design

Coding

Module test

Integration test

Validation

Verification

Validation

Result

Specification of

the safety

functions

software

validated

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 70/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Avoiding systematic faults (technology)

Technical measures for the avoidance of systematic faults:

The SRECS shall be designed and implemented in accordance

with the functional safety plan

Correct choice, combination, orders, assembly and installation of

components

Use of the components within manufacturer specification

Use of subsystems that have compatible operating characteristics

(business boundary conditions must be known)

Acceptance according to manufacturer regulation

Consider foreseeable misuse, environmental changes or

modification

Over-engineering of the components

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 71/198 Safety of machinery / European machinery directive

Support by Siemens

Application example

Functional safety

Overview

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Controlling of systematic faults

Technical measures for controlling of systematic faults :

Supervision during the operation (e.g. supervision of the

environmental temperature, voltage variation, electromagnetic

interference)

Tests by comparison at redundant hardware

At loss of the electrical supply no dangerous condition may

appear at the machine

Use of de-energization: the system shall be designed so that with

loss of its electrical supply a safe state of the machine is

achieved or maintained;

Siemens AG 2009. All Rights Reserved.

Support by Siemens

Application example

IEC 62061 and ISO 13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe machinery

Safety of Machinery

Safety of machinery / European machinery directive

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 73/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Example - cutting and stamping machine

Cutting -

machine

Stamping-

machine

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 74/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

The 3-Step-Method (EN ISO 12100)

YES

NO

Renewed: Risk evaluation

For any endangering which requires a risk reduction:

End

start

YES

YES

NO

NO

Step 3: Risk reduction by user information about remaining risks

Was the risk reduced adequately?

Was the risk reduced adequately?

Was the risk reduced adequately?

Step 1: Risk reduction by a safe construction

Step 2: Risk reduction by technical protective measures

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 75/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Example of endangering (extract) to ISO 14121-1

Root

cutting parts

possible consequences

-cut

-cutting off

Root

moving parts

possible consequences

-crushing

-hit

-cropping

Root

gravitation

stability

possible consequences

-crushing

-trapping

Root

droping parts

possible consequences

-crushing

-hit

Root

moving parts (3

examples)

possible consequences

-feeding

-abraison

-hit

Root

approach one of part

moving towards a rigid

part

possible consequences

-crushing

-hit

endangering endangering

Chart A.2

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 76/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Risk analysis and risk assessment

Endangering

place

Endangering

place

Examples of mechanically endangering

Endangering

place

Endangering

place

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 77/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Endangering

place

Endangering

place

Define suitable safety functions and additional

protection measures

Gate

monitoring

Door

monitoring

Additional:

Emergency stop

function

Examples of not

constructively avoidable

risks

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 78/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

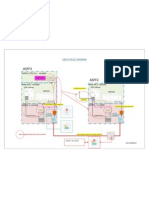

Principle procedure

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 79/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

b) Determination of the required safety level

Meaning of the required safety level:

The required safety level is a measure for the reliability of the

safety function.

The required safety level is dependent of:

Severity of the injury

Frequency / length of stay

Possibility for the avoidance

The heavier the possible injury, and the more probable the

occurrence, the higher is the required safety level.

EN 62061 and ISO 13849 show Methods, how the required safety

level can identified

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 80/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Step 2: Technical protective measures

b) Determining the required safety level

Requirements of the safety levels: Safety system

EN 62061 and EN ISO 13849 describe requirements

for the reliability of safety systems:

All phases of the lifetime of a machine are considered:

From planning

to shutdown

Increasing requirements

for the reliability

of safety systems

SIL 3 PL

r

e

SIL 1

SIL 2 PL

r

d

PL

r

c

PL

r

a

PL

r

b

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 81/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

SIL assignment IEC 62061, annex A

Endangering place - cutting machine

Mode cleaning/maintenance

Document Nr.:

Part of:

Pre risk assessment

Intermediate risk assessment

Follow up risk assessment

Severity

Se Fr Pr

Death, losing an eye or arm 4 <= 1 h Very high 5

Permanent, losing fingers 3 > 1 h to ? 1 day likely 4

Reversible, medical attention 2 > 1 day to ? 2 weeks possible 3 5

Reversible, first aid 1 > 2 weeks to ? 1 year rarely 2 3

> 1 year negligible 1 1

Ser. Hzd Hazard

Nr. Nr.

Comments

Avoidance

Product:

Issued by:

Date:

Effects

Class

Cl

Frequency and

duration

5-7 8-10 11-13

Probability of hazardous

event

Av

5

Safe Safety measure

SIL 2 SIL 2 SIL 2 SIL 3 SIL 3 5

3

2

OM SIL 1 SIL 2 SIL 3

OM SIL 1

OM SIL 1 SIL 2 impossible 4

possible

likely

Se Fr Pr Av Cl

Risk assessment and safety measures

14-15 3-4

Danger of cutting Sliding door supervision 1 3 5 4 3 12 SIL2 + + + =

Frequency: >1 hour to 1 day

Probability: likely

leads to

Fr 5 and Pr 4

Avoidance: possible,

leads to

Av 3

Severity: permanent

(loosing fingers)

leads to

Se 3

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 82/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

SIL assignment IEC 62061, annex A

Endangering place - cutting machine / stamping machine

Mode cleaning/maintenance

Document Nr.:

Part of:

Pre risk assessment

Intermediate risk assessment

Follow up risk assessment

Severity

Se Fr Pr

Death, losing an eye or arm 4 <= 1 h Very high 5

Permanent, losing fingers 3 > 1 h to ? 1 day likely 4

Reversible, medical attention 2 > 1 day to ? 2 weeks possible 3 5

Reversible, first aid 1 > 2 weeks to ? 1 year rarely 2 3

> 1 year negligible 1 1

Ser. Hzd Hazard

Nr. Nr.

Comments

Avoidance

Product:

Issued by:

Date:

Effects

Class

Cl

Frequency and

duration

5-7 8-10 11-13

Probability of hazardous

event

Av

5

Safe Safety measure

SIL 2 SIL 2 SIL 2 SIL 3 SIL 3 5

3

2

OM SIL 1 SIL 2 SIL 3

OM SIL 1

OM SIL 1 SIL 2 impossible 4

possible

likely

Se Fr Pr Av Cl

Risk assessment and safety measures

14-15 3-4

1 Danger of cutting 3 5 4 3 12 Sliding Door supervision SIL2

2 Danger of squeeze 3 4 4 3 11 Door supervision SIL2

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 83/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Risk Parameter

S = Severity of injury

S1 = Slight (normally reversible) injury.

S2 = Severe (normally irreversible) injury including death.

F = Frequency and/or exposure time to the hazard

F1 = Seldom up to often and/or the exposure time is short.

F2 = Frequent up to continuous and/or the exposure time is long.

P = Possibility of avoiding the hazard or limiting the harm

P1 = Possible under specific conditions.

P2 = Scarcely possible.

a,b,c,d,e = Estimates of safety-related Performance Level

a

b

c

d

e

Required

Performance

Level (PL)

Low Risk

High Risk

Starting point for

risk reduction

estimation

F1

F2

S2

S1

F1

F2

P1

P2

P1

P2

P1

P2

P1

P2

Risk = function of:

Measure of

damages (S)

Frequency

and duration (F)

Possibility of

avoidence (P)

Risk graph in the EN ISO 13849-1

Endangering place - cutting machine

Mode cleaning/maintenance

Siemens AG 2009. All Rights Reserved.

Industry Sector Page 84/198 Safety of machinery / European machinery directive

Support by Siemens

SIL verification

PL verification

Application example

IEC 62061 and ISO

13849-1

4 Placing to market

3 Validation

2 Risk reduction

1 Risk assessment

The way to a safe

machinery

Safety of Machinery

Risk graph in the EN ISO 13849-1

Endangering place - stamping machine

Mode cleaning/maintenance

Assessment according EN ISO 13849: PLr a bis PLr e

PL

r

b

PL

r

e

PL

r

a

PL

r

c

PL

r

d

S1

S2

F1

F1

F2

F2

P1

P2

P1

P2

P1

P2

P1

P2

S1 Reversible injury

S2 Irreversible injury

S